Micro Energy Harvesters: Proposing New Standards for Evaluation

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. The fundamental principle involves capturing small amounts of ambient energy from environmental sources such as vibration, thermal gradients, light, and RF signals, then converting this energy into usable electrical power. This technology has roots in the broader field of energy harvesting that began gaining significant research attention in the early 2000s, with micro-scale applications becoming increasingly prominent since 2010.

The evolution of micro energy harvesting has been driven by parallel advancements in low-power electronics, MEMS (Micro-Electro-Mechanical Systems) technology, and nanomaterials. Early harvesters demonstrated efficiencies below 1%, whereas current state-of-the-art devices can achieve conversion efficiencies exceeding 20% in optimal conditions. This progression has enabled the practical implementation of self-powered sensors and IoT devices in previously inaccessible environments.

Current technological trends indicate a shift toward hybrid harvesting systems that combine multiple energy sources to improve reliability and output. Additionally, there is growing interest in developing harvesters specifically optimized for particular application environments rather than pursuing general-purpose solutions. The miniaturization trend continues, with recent research focusing on nano-scale energy harvesting mechanisms that can be integrated directly into semiconductor manufacturing processes.

The primary objective of establishing new evaluation standards for micro energy harvesters addresses a critical gap in the field. Current evaluation methods vary significantly across research institutions and manufacturers, making direct performance comparisons challenging and hindering technology adoption. Standardized metrics would enable objective assessment of harvester performance across different technologies and applications, accelerating commercialization and implementation.

These standards aim to establish uniform testing protocols that account for real-world operating conditions rather than idealized laboratory environments. They should define consistent measurement methodologies for key parameters including power density, conversion efficiency, operational lifetime, and performance stability under variable conditions. Additionally, the standards must address the unique challenges of different harvesting mechanisms while maintaining cross-technology comparability.

The ultimate goal is to create a framework that enables technology developers, system integrators, and end-users to make informed decisions about harvester selection and implementation. This standardization effort represents a crucial step toward mainstream adoption of micro energy harvesting technology across industrial, medical, consumer, and IoT applications, potentially revolutionizing how we power the next generation of electronic devices.

The evolution of micro energy harvesting has been driven by parallel advancements in low-power electronics, MEMS (Micro-Electro-Mechanical Systems) technology, and nanomaterials. Early harvesters demonstrated efficiencies below 1%, whereas current state-of-the-art devices can achieve conversion efficiencies exceeding 20% in optimal conditions. This progression has enabled the practical implementation of self-powered sensors and IoT devices in previously inaccessible environments.

Current technological trends indicate a shift toward hybrid harvesting systems that combine multiple energy sources to improve reliability and output. Additionally, there is growing interest in developing harvesters specifically optimized for particular application environments rather than pursuing general-purpose solutions. The miniaturization trend continues, with recent research focusing on nano-scale energy harvesting mechanisms that can be integrated directly into semiconductor manufacturing processes.

The primary objective of establishing new evaluation standards for micro energy harvesters addresses a critical gap in the field. Current evaluation methods vary significantly across research institutions and manufacturers, making direct performance comparisons challenging and hindering technology adoption. Standardized metrics would enable objective assessment of harvester performance across different technologies and applications, accelerating commercialization and implementation.

These standards aim to establish uniform testing protocols that account for real-world operating conditions rather than idealized laboratory environments. They should define consistent measurement methodologies for key parameters including power density, conversion efficiency, operational lifetime, and performance stability under variable conditions. Additionally, the standards must address the unique challenges of different harvesting mechanisms while maintaining cross-technology comparability.

The ultimate goal is to create a framework that enables technology developers, system integrators, and end-users to make informed decisions about harvester selection and implementation. This standardization effort represents a crucial step toward mainstream adoption of micro energy harvesting technology across industrial, medical, consumer, and IoT applications, potentially revolutionizing how we power the next generation of electronic devices.

Market Demand Analysis for Micro Energy Harvesting Solutions

The micro energy harvesting market is experiencing significant growth driven by the proliferation of Internet of Things (IoT) devices and the increasing demand for autonomous, self-powered systems. Current market projections indicate that the global micro energy harvesting market will reach approximately $2.6 billion by 2028, with a compound annual growth rate of 11.4% from 2023. This growth trajectory is primarily fueled by the expanding applications across various sectors including consumer electronics, healthcare, industrial automation, and smart infrastructure.

In the consumer electronics segment, there is a growing demand for energy harvesting solutions to power wearable devices, wireless sensors, and smart home applications. The need for extended battery life and reduced maintenance requirements has become a critical market driver, with consumers increasingly valuing devices that can operate autonomously for extended periods.

The healthcare sector represents another significant market opportunity, with applications ranging from implantable medical devices to remote patient monitoring systems. The ability to harvest energy from body heat, motion, or ambient sources eliminates the need for battery replacement surgeries and enables continuous health monitoring without user intervention.

Industrial IoT applications constitute a rapidly expanding market segment, with energy harvesting technologies being deployed in remote sensing, predictive maintenance, and asset tracking systems. The industrial sector values solutions that can operate reliably in harsh environments and reduce the total cost of ownership by eliminating battery replacements and associated maintenance.

Smart infrastructure and building automation systems are increasingly incorporating micro energy harvesters to power wireless sensor networks for environmental monitoring, occupancy detection, and energy management. The market demand in this sector is driven by the push for energy-efficient buildings and the need for distributed sensing capabilities.

Regional analysis reveals that North America and Europe currently lead the market adoption, with Asia-Pacific showing the fastest growth rate due to rapid industrialization and smart city initiatives. The market is also witnessing increased demand from emerging economies as they invest in modernizing their infrastructure and industrial capabilities.

Customer requirements analysis indicates several key market demands: higher energy conversion efficiency, smaller form factors, multi-source harvesting capabilities, and improved energy storage solutions. There is also a growing emphasis on cost-effectiveness and scalability to enable mass deployment in IoT applications.

The market landscape is further shaped by regulatory trends promoting energy efficiency and sustainability, creating favorable conditions for micro energy harvesting technologies as alternatives to traditional batteries. This regulatory push, combined with technological advancements and decreasing component costs, is expected to accelerate market adoption across multiple industries in the coming years.

In the consumer electronics segment, there is a growing demand for energy harvesting solutions to power wearable devices, wireless sensors, and smart home applications. The need for extended battery life and reduced maintenance requirements has become a critical market driver, with consumers increasingly valuing devices that can operate autonomously for extended periods.

The healthcare sector represents another significant market opportunity, with applications ranging from implantable medical devices to remote patient monitoring systems. The ability to harvest energy from body heat, motion, or ambient sources eliminates the need for battery replacement surgeries and enables continuous health monitoring without user intervention.

Industrial IoT applications constitute a rapidly expanding market segment, with energy harvesting technologies being deployed in remote sensing, predictive maintenance, and asset tracking systems. The industrial sector values solutions that can operate reliably in harsh environments and reduce the total cost of ownership by eliminating battery replacements and associated maintenance.

Smart infrastructure and building automation systems are increasingly incorporating micro energy harvesters to power wireless sensor networks for environmental monitoring, occupancy detection, and energy management. The market demand in this sector is driven by the push for energy-efficient buildings and the need for distributed sensing capabilities.

Regional analysis reveals that North America and Europe currently lead the market adoption, with Asia-Pacific showing the fastest growth rate due to rapid industrialization and smart city initiatives. The market is also witnessing increased demand from emerging economies as they invest in modernizing their infrastructure and industrial capabilities.

Customer requirements analysis indicates several key market demands: higher energy conversion efficiency, smaller form factors, multi-source harvesting capabilities, and improved energy storage solutions. There is also a growing emphasis on cost-effectiveness and scalability to enable mass deployment in IoT applications.

The market landscape is further shaped by regulatory trends promoting energy efficiency and sustainability, creating favorable conditions for micro energy harvesting technologies as alternatives to traditional batteries. This regulatory push, combined with technological advancements and decreasing component costs, is expected to accelerate market adoption across multiple industries in the coming years.

Current State and Technical Challenges in Micro Energy Harvesting

Micro energy harvesting technology has evolved significantly over the past decade, with various approaches being developed to capture ambient energy from environmental sources such as vibration, thermal gradients, light, and RF signals. Currently, the global market for micro energy harvesters is experiencing rapid growth, with a projected CAGR of approximately 13% through 2026, driven primarily by IoT applications and wireless sensor networks. Despite this promising trajectory, the field faces substantial technical challenges that impede widespread commercial adoption.

The current state of micro energy harvesting is characterized by fragmentation across multiple technological approaches. Piezoelectric harvesters dominate vibration energy capture, with PZT-based devices achieving power densities of 10-100 μW/cm³. Thermoelectric generators typically operate at efficiencies below 5% for small temperature differentials, while photovoltaic micro-harvesters can reach 20% efficiency under optimal conditions. Electromagnetic and triboelectric harvesters have shown promising results in laboratory settings but face significant miniaturization challenges.

A fundamental limitation across all harvesting technologies is low power density, typically ranging from nanowatts to microwatts per cubic centimeter, which restricts application scenarios. This limitation is exacerbated by the unpredictable and intermittent nature of ambient energy sources, necessitating complex power management systems that often consume a significant portion of the harvested energy.

Material constraints present another major challenge. Current piezoelectric materials suffer from brittleness and limited operational temperature ranges, while thermoelectric materials struggle with thermal conductivity issues that reduce efficiency. Additionally, many high-performance materials contain rare or toxic elements, raising sustainability and environmental concerns.

The lack of standardized evaluation metrics represents a critical barrier to progress in the field. Unlike established energy technologies, micro energy harvesting lacks universally accepted testing protocols and performance benchmarks, making direct comparisons between different technologies and devices nearly impossible. This absence of standardization hampers investment decisions and slows technological advancement.

Integration challenges further complicate implementation, as micro harvesters must coexist with other system components in extremely confined spaces while maintaining electromagnetic compatibility. The miniaturization of associated power management circuits presents additional difficulties, particularly in designing ultra-low-power converters and regulators that can operate efficiently at sub-microwatt input levels.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with the United States and China leading in patent applications. European institutions excel in fundamental research, while Asian manufacturers dominate production capabilities. This global distribution creates both collaborative opportunities and competitive challenges in establishing universal standards for evaluation and performance metrics.

The current state of micro energy harvesting is characterized by fragmentation across multiple technological approaches. Piezoelectric harvesters dominate vibration energy capture, with PZT-based devices achieving power densities of 10-100 μW/cm³. Thermoelectric generators typically operate at efficiencies below 5% for small temperature differentials, while photovoltaic micro-harvesters can reach 20% efficiency under optimal conditions. Electromagnetic and triboelectric harvesters have shown promising results in laboratory settings but face significant miniaturization challenges.

A fundamental limitation across all harvesting technologies is low power density, typically ranging from nanowatts to microwatts per cubic centimeter, which restricts application scenarios. This limitation is exacerbated by the unpredictable and intermittent nature of ambient energy sources, necessitating complex power management systems that often consume a significant portion of the harvested energy.

Material constraints present another major challenge. Current piezoelectric materials suffer from brittleness and limited operational temperature ranges, while thermoelectric materials struggle with thermal conductivity issues that reduce efficiency. Additionally, many high-performance materials contain rare or toxic elements, raising sustainability and environmental concerns.

The lack of standardized evaluation metrics represents a critical barrier to progress in the field. Unlike established energy technologies, micro energy harvesting lacks universally accepted testing protocols and performance benchmarks, making direct comparisons between different technologies and devices nearly impossible. This absence of standardization hampers investment decisions and slows technological advancement.

Integration challenges further complicate implementation, as micro harvesters must coexist with other system components in extremely confined spaces while maintaining electromagnetic compatibility. The miniaturization of associated power management circuits presents additional difficulties, particularly in designing ultra-low-power converters and regulators that can operate efficiently at sub-microwatt input levels.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with the United States and China leading in patent applications. European institutions excel in fundamental research, while Asian manufacturers dominate production capabilities. This global distribution creates both collaborative opportunities and competitive challenges in establishing universal standards for evaluation and performance metrics.

Existing Evaluation Methods for Micro Energy Harvesters

01 Performance evaluation standards for micro energy harvesters

Standards and methodologies for evaluating the performance of micro energy harvesters, including efficiency metrics, power output measurements, and conversion rates. These standards help in comparing different harvesting technologies and ensuring consistent evaluation across various applications. The evaluation frameworks consider factors such as energy density, operational frequency range, and output stability under varying environmental conditions.- Performance evaluation metrics for micro energy harvesters: Standardized metrics are essential for evaluating the performance of micro energy harvesters. These metrics include power density, energy conversion efficiency, operational frequency range, and output stability under various environmental conditions. Establishing these evaluation standards helps in comparing different harvesting technologies and determining their suitability for specific applications. The metrics also consider the harvester's response to different energy input levels and its long-term reliability.

- Testing protocols for piezoelectric micro energy harvesters: Specific testing protocols have been developed for piezoelectric micro energy harvesters to standardize their evaluation. These protocols include vibration testing at various frequencies and amplitudes, temperature cycling tests, and durability assessments. The standardized testing methods ensure consistent measurement of key parameters such as resonant frequency, bandwidth, and output voltage under defined conditions. These protocols help in validating the performance claims and ensuring the reliability of piezoelectric energy harvesting devices.

- Efficiency standards for thermal energy harvesting systems: Thermal energy harvesting systems require specific efficiency standards for proper evaluation. These standards focus on the temperature gradient utilization, thermal-to-electrical conversion efficiency, and heat flow management. The evaluation criteria include the Seebeck coefficient measurement, thermal resistance optimization, and cold-side temperature maintenance. Standardized testing under various thermal conditions ensures consistent performance assessment and facilitates the development of more efficient thermal energy harvesting technologies.

- Reliability and durability assessment frameworks: Frameworks for assessing the reliability and durability of micro energy harvesters are crucial for their practical implementation. These frameworks include accelerated aging tests, environmental stress screening, and failure mode analysis. Standard evaluation methods measure the degradation of performance over time, resistance to environmental factors such as humidity and temperature fluctuations, and mechanical robustness. These assessment protocols help in predicting the operational lifetime and maintenance requirements of energy harvesting systems in real-world applications.

- Integration standards for micro energy harvesters in IoT devices: Standards for evaluating the integration capabilities of micro energy harvesters in IoT devices focus on form factor compatibility, power management efficiency, and system-level performance. These standards assess how well the harvester interfaces with power conditioning circuits, energy storage elements, and the IoT device's power requirements. Evaluation metrics include start-up time, power output stability during intermittent energy availability, and overall system efficiency. These integration standards ensure that the energy harvesting solution can reliably power IoT devices in their intended application environments.

02 Testing protocols for vibration-based energy harvesters

Specific testing protocols designed for vibration-based micro energy harvesters, which convert mechanical vibrations into electrical energy. These protocols define standard vibration profiles, frequency ranges, and acceleration levels for consistent performance evaluation. They include methods for measuring resonant frequency, bandwidth, and damping characteristics, as well as procedures for determining the harvester's response to random vibrations and shock inputs.Expand Specific Solutions03 Reliability and durability assessment methods

Methods and standards for evaluating the long-term reliability and durability of micro energy harvesters under various environmental conditions. These assessment techniques include accelerated aging tests, thermal cycling, humidity exposure, and mechanical fatigue testing. The standards define acceptable degradation rates, failure modes analysis, and lifetime prediction models to ensure that harvesters can maintain performance over their intended operational lifespan.Expand Specific Solutions04 Integration and system-level evaluation frameworks

Frameworks for evaluating micro energy harvesters at the system level, focusing on their integration with power management circuits, energy storage elements, and end applications. These standards assess the overall system efficiency, including power conditioning losses, storage efficiency, and load matching characteristics. They provide guidelines for optimizing the interface between harvesters and electronic systems to maximize usable energy output in real-world applications.Expand Specific Solutions05 Standardized comparison metrics for different harvesting technologies

Standardized metrics and benchmarks that enable fair comparison between different micro energy harvesting technologies, such as piezoelectric, electromagnetic, triboelectric, and thermoelectric harvesters. These metrics include normalized power density, energy return on investment, and application-specific performance indicators. The standards provide a common language for researchers and manufacturers to communicate harvester capabilities and facilitate technology selection for specific use cases.Expand Specific Solutions

Key Industry Players in Micro Energy Harvesting Field

Micro Energy Harvesting technology is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is estimated to reach $1.5 billion by 2025, growing at a CAGR of approximately 12%. Regarding technical maturity, the field shows varying levels of development across companies. State Grid Corp. of China and Robert Bosch GmbH lead with established research programs, while IMEC Nederland and Qualcomm are advancing miniaturization techniques. Academic institutions like Peking University and Xi'an Jiaotong University contribute fundamental research. The lack of standardized evaluation metrics remains a significant challenge, hindering comparison of harvester performance across different operational environments and energy sources.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered micro energy harvesting technologies specifically designed for industrial IoT and automotive applications. Their approach focuses on vibration-based harvesters utilizing electromagnetic and piezoelectric principles optimized for the frequency ranges common in machinery (20-200Hz). Bosch's micro harvesters incorporate adaptive resonance tuning mechanisms that can automatically adjust to varying vibration frequencies, significantly improving energy capture in dynamic environments. Their evaluation standards emphasize operational reliability metrics including mean time between failures (MTBF) exceeding 10 years, temperature stability from -40°C to +125°C, and resistance to mechanical shocks up to 50g. Bosch has implemented a comprehensive characterization protocol that measures performance across multiple environmental parameters simultaneously, providing more realistic efficiency metrics than single-parameter testing.

Strengths: Exceptional durability and reliability in harsh industrial environments; adaptive frequency tuning capabilities; comprehensive testing under combined stressors (temperature, humidity, vibration). Weaknesses: Larger form factor than some competitors; higher cost structure; optimization primarily for industrial rather than consumer applications.

Stichting IMEC Nederland

Technical Solution: IMEC Nederland has developed advanced micro energy harvesting solutions based on their proprietary thin-film technology platform. Their approach integrates multiple harvesting mechanisms (piezoelectric, thermoelectric, and photovoltaic) on a single chip to maximize energy capture from ambient sources. IMEC's micro energy harvesters feature ultra-low power management circuits that can operate with input voltages as low as 10mV and deliver power conversion efficiencies exceeding 85% for sub-microwatt inputs. Their standardized evaluation framework includes metrics for energy density (μW/cm²), conversion efficiency across varying input conditions, and long-term reliability testing under environmental stressors. IMEC has successfully demonstrated self-powered wireless sensor nodes that can operate perpetually in industrial environments using their harvesting technology.

Strengths: Industry-leading integration density allowing for miniaturization below 1cm³; exceptional low-voltage startup capability; comprehensive testing methodology that accounts for real-world variability. Weaknesses: Higher manufacturing costs compared to single-mode harvesters; complex power management requirements; performance highly dependent on specific deployment environment.

Core Technical Innovations in Micro Energy Harvesting

Multi-layer micro-energy harvester and method of making the same

PatentActiveUS20100301699A1

Innovation

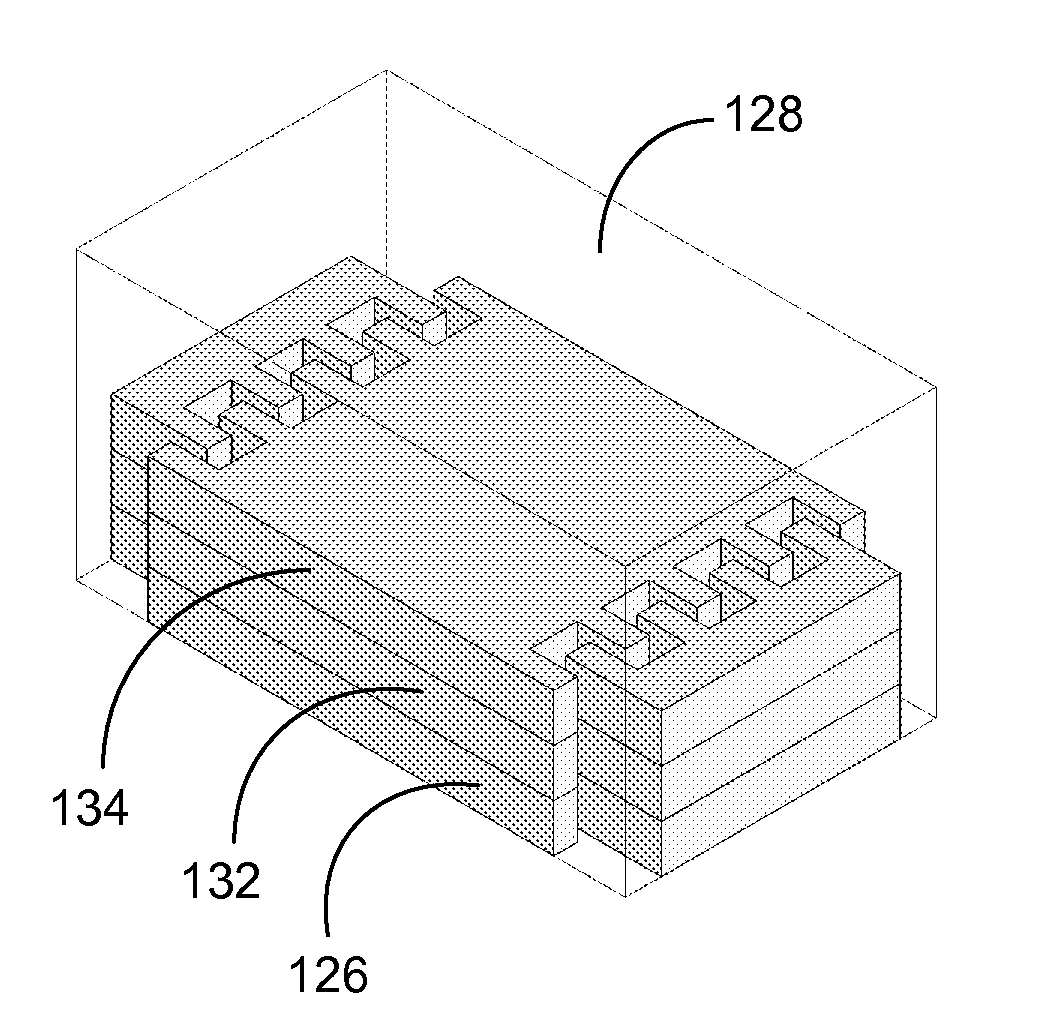

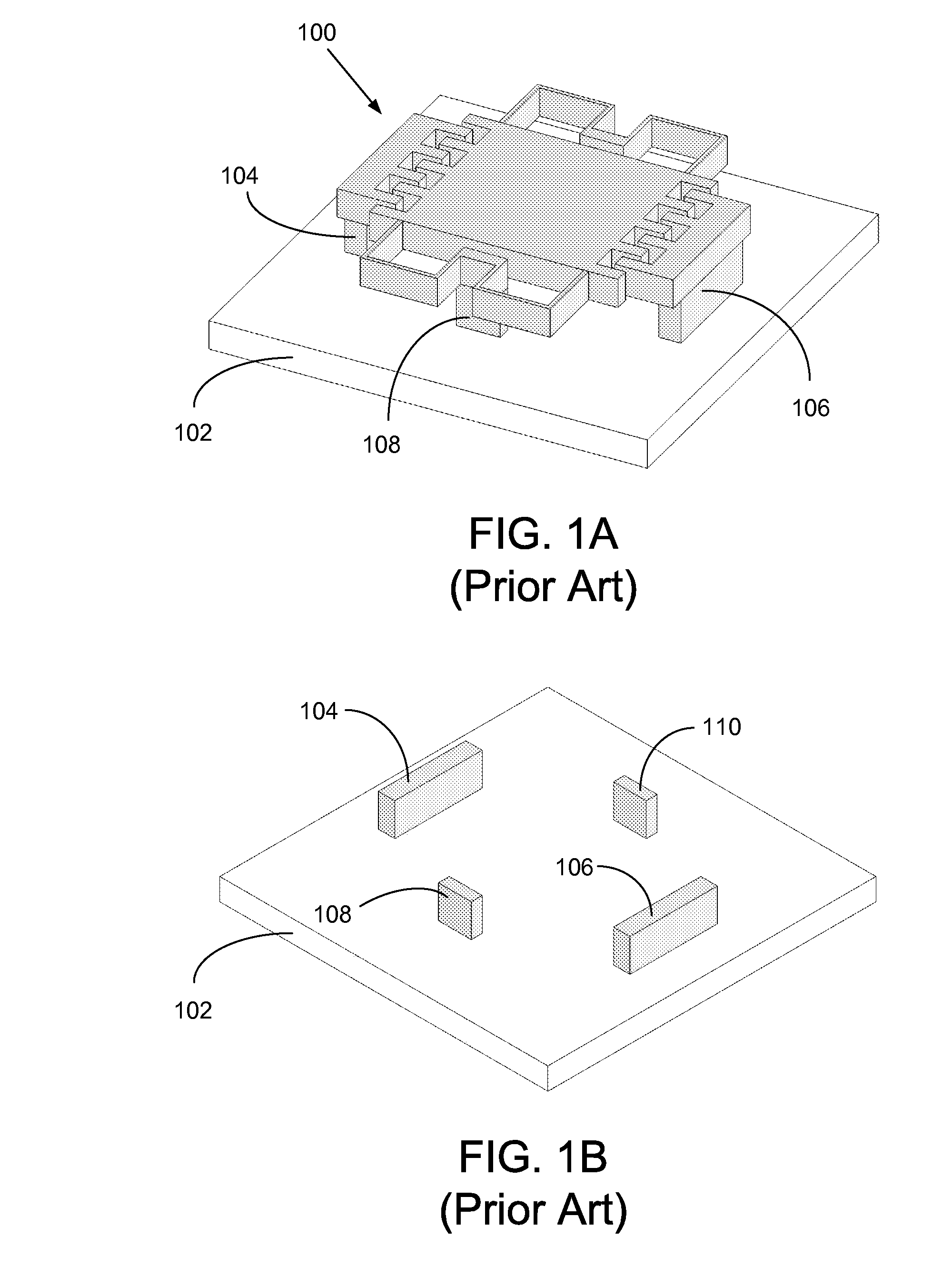

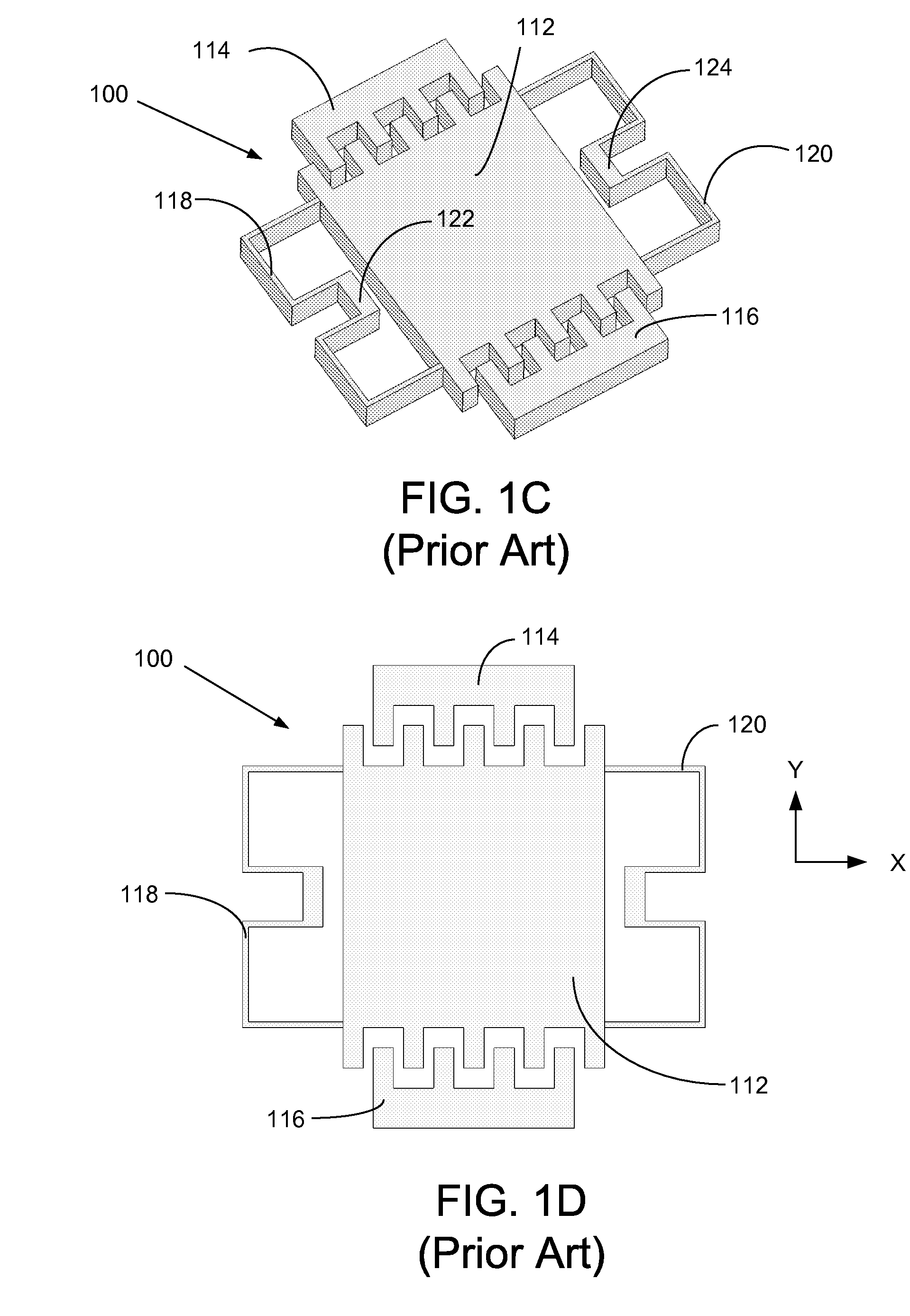

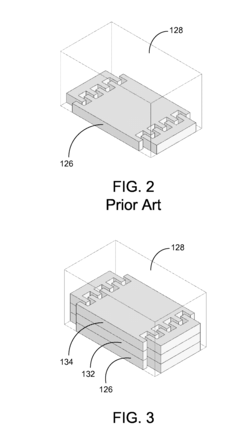

- A multi-layer electrostatic energy harvester structure is developed, comprising multiple variable capacitor layers bonded together with a moving mass layer, utilizing a flexible fabrication method like Assemblayer™ to increase capacitance and moving mass, thereby enhancing AAPD and power conversion efficiency.

Piezoelectric micromechanical energy harvesters

PatentActiveUS8680752B2

Innovation

- The development of micromechanical energy harvesters that incorporate a proof mass and a transducer with piezoelectric material, where the proof mass is accelerated to transfer kinetic energy to the transducer, causing it to vibrate at a resonance frequency, thereby upconverting the energy to a higher frequency, and these systems can operate in multiple planes to capture energy from various directions.

Regulatory Framework for Energy Harvesting Technologies

The regulatory landscape for micro energy harvesting technologies is currently fragmented, with no unified global standards specifically addressing these emerging technologies. Different regions have established varying approaches to regulate energy harvesting devices, creating challenges for manufacturers seeking international market access. In the United States, the Federal Communications Commission (FCC) regulates wireless energy harvesting devices under Part 15 rules for unlicensed radio frequency devices, while the Food and Drug Administration (FDA) provides additional oversight for medical applications.

The European Union has implemented the Radio Equipment Directive (RED) 2014/53/EU and Electromagnetic Compatibility Directive 2014/30/EU, which indirectly affect energy harvesting technologies. Additionally, the EU's Ecodesign Directive 2009/125/EC establishes a framework for setting ecological requirements for energy-related products, though specific implementing measures for micro energy harvesters are still developing.

In Asia, Japan's Ministry of Internal Affairs and Communications (MIC) and China's Ministry of Industry and Information Technology (MIIT) have established their own regulatory frameworks for wireless power transmission technologies, which overlap with certain energy harvesting applications. These regional differences highlight the need for international harmonization of standards.

Safety considerations form a critical component of the regulatory framework, particularly for implantable or wearable energy harvesters. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment, while ISO 14708 addresses implantable medical devices specifically. These standards must be adapted to address the unique characteristics of micro energy harvesters.

Environmental regulations also impact energy harvesting technologies. The EU's Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation affect material selection for energy harvesters. Similarly, end-of-life considerations are governed by the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU.

Certification processes for micro energy harvesters vary significantly across jurisdictions, creating market entry barriers. The International Electrotechnical Commission (IEC) has begun developing standards through its Technical Committee 120 on Electrical Energy Storage Systems, but specific standards for micro-scale energy harvesting remain limited. The IEEE Standards Association has also initiated work on standards for energy harvesting, wireless power, and management for low energy devices through its P1882 working group.

Moving forward, a coordinated international approach to standardization is essential to facilitate innovation while ensuring safety and interoperability. Industry stakeholders, regulatory bodies, and standards organizations must collaborate to develop a comprehensive regulatory framework that addresses the unique characteristics of micro energy harvesting technologies while promoting global market access.

The European Union has implemented the Radio Equipment Directive (RED) 2014/53/EU and Electromagnetic Compatibility Directive 2014/30/EU, which indirectly affect energy harvesting technologies. Additionally, the EU's Ecodesign Directive 2009/125/EC establishes a framework for setting ecological requirements for energy-related products, though specific implementing measures for micro energy harvesters are still developing.

In Asia, Japan's Ministry of Internal Affairs and Communications (MIC) and China's Ministry of Industry and Information Technology (MIIT) have established their own regulatory frameworks for wireless power transmission technologies, which overlap with certain energy harvesting applications. These regional differences highlight the need for international harmonization of standards.

Safety considerations form a critical component of the regulatory framework, particularly for implantable or wearable energy harvesters. IEC 60601-1 provides general requirements for basic safety and essential performance of medical electrical equipment, while ISO 14708 addresses implantable medical devices specifically. These standards must be adapted to address the unique characteristics of micro energy harvesters.

Environmental regulations also impact energy harvesting technologies. The EU's Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation affect material selection for energy harvesters. Similarly, end-of-life considerations are governed by the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU.

Certification processes for micro energy harvesters vary significantly across jurisdictions, creating market entry barriers. The International Electrotechnical Commission (IEC) has begun developing standards through its Technical Committee 120 on Electrical Energy Storage Systems, but specific standards for micro-scale energy harvesting remain limited. The IEEE Standards Association has also initiated work on standards for energy harvesting, wireless power, and management for low energy devices through its P1882 working group.

Moving forward, a coordinated international approach to standardization is essential to facilitate innovation while ensuring safety and interoperability. Industry stakeholders, regulatory bodies, and standards organizations must collaborate to develop a comprehensive regulatory framework that addresses the unique characteristics of micro energy harvesting technologies while promoting global market access.

Sustainability Impact of Micro Energy Harvesting Solutions

Micro energy harvesting technologies represent a significant advancement in sustainable energy solutions, offering the potential to power small electronic devices through ambient energy sources. The sustainability impact of these solutions extends far beyond their immediate technical applications, encompassing environmental, economic, and social dimensions that warrant comprehensive evaluation.

From an environmental perspective, micro energy harvesters contribute to sustainability by reducing reliance on traditional batteries, which contain toxic materials and present disposal challenges. By harvesting energy from ambient sources such as vibration, thermal gradients, and light, these technologies can significantly decrease electronic waste generation. Research indicates that widespread adoption of energy harvesting solutions could potentially reduce battery waste by up to 30% in certain application sectors, particularly in wireless sensor networks and IoT devices.

The carbon footprint reduction potential of micro energy harvesters is substantial when considering lifecycle assessments. While manufacturing processes for specialized materials used in these harvesters may initially have environmental impacts, the extended operational lifetime and elimination of battery replacement cycles typically result in net positive environmental outcomes. Studies suggest that energy autonomous systems powered by harvesters can achieve carbon neutrality within 1-3 years of deployment, depending on application scenarios.

Economic sustainability benefits emerge through reduced maintenance requirements and operational costs. In remote sensing applications, the cost of battery replacement often exceeds the initial device investment by several factors. Energy harvesting solutions eliminate these recurring costs while extending system lifespans. This economic advantage becomes particularly pronounced in large-scale deployments where maintenance logistics present significant challenges.

The social sustainability dimension manifests in expanded access to technology in underserved regions. Self-powered medical monitoring devices, environmental sensors, and communication tools can function in areas lacking reliable grid infrastructure, supporting critical services without dependence on external energy sources. This democratization of technology access represents a meaningful contribution to sustainable development goals.

Resource efficiency constitutes another critical sustainability metric. Current evaluation standards often focus narrowly on power output rather than holistic resource utilization. A comprehensive sustainability assessment framework should incorporate material sourcing considerations, manufacturing energy requirements, and end-of-life recoverability alongside traditional performance metrics.

Future standardization efforts should establish sustainability impact as a core evaluation criterion for micro energy harvesting technologies, with quantifiable metrics that enable meaningful comparison across different harvesting approaches and application contexts. This would drive innovation toward solutions that optimize not only technical performance but also broader environmental and social benefits.

From an environmental perspective, micro energy harvesters contribute to sustainability by reducing reliance on traditional batteries, which contain toxic materials and present disposal challenges. By harvesting energy from ambient sources such as vibration, thermal gradients, and light, these technologies can significantly decrease electronic waste generation. Research indicates that widespread adoption of energy harvesting solutions could potentially reduce battery waste by up to 30% in certain application sectors, particularly in wireless sensor networks and IoT devices.

The carbon footprint reduction potential of micro energy harvesters is substantial when considering lifecycle assessments. While manufacturing processes for specialized materials used in these harvesters may initially have environmental impacts, the extended operational lifetime and elimination of battery replacement cycles typically result in net positive environmental outcomes. Studies suggest that energy autonomous systems powered by harvesters can achieve carbon neutrality within 1-3 years of deployment, depending on application scenarios.

Economic sustainability benefits emerge through reduced maintenance requirements and operational costs. In remote sensing applications, the cost of battery replacement often exceeds the initial device investment by several factors. Energy harvesting solutions eliminate these recurring costs while extending system lifespans. This economic advantage becomes particularly pronounced in large-scale deployments where maintenance logistics present significant challenges.

The social sustainability dimension manifests in expanded access to technology in underserved regions. Self-powered medical monitoring devices, environmental sensors, and communication tools can function in areas lacking reliable grid infrastructure, supporting critical services without dependence on external energy sources. This democratization of technology access represents a meaningful contribution to sustainable development goals.

Resource efficiency constitutes another critical sustainability metric. Current evaluation standards often focus narrowly on power output rather than holistic resource utilization. A comprehensive sustainability assessment framework should incorporate material sourcing considerations, manufacturing energy requirements, and end-of-life recoverability alongside traditional performance metrics.

Future standardization efforts should establish sustainability impact as a core evaluation criterion for micro energy harvesting technologies, with quantifiable metrics that enable meaningful comparison across different harvesting approaches and application contexts. This would drive innovation toward solutions that optimize not only technical performance but also broader environmental and social benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!