What Are Key Performance Indicators for Micro Energy Harvester Success

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Background and Objectives

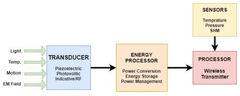

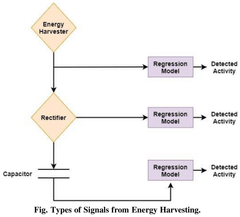

Micro energy harvesting technology has evolved significantly over the past two decades, transforming from theoretical concepts into practical applications across multiple industries. The fundamental principle behind this technology involves capturing small amounts of energy from ambient sources such as vibration, heat, light, and electromagnetic radiation, then converting this energy into usable electrical power. This approach represents a paradigm shift from traditional battery-dependent systems toward self-sustaining energy solutions.

The historical trajectory of micro energy harvesting began in the early 2000s with rudimentary piezoelectric and thermoelectric generators. By 2010, significant advancements in materials science and miniaturization techniques enabled the development of more efficient harvesting mechanisms with improved power density. The period between 2015 and 2020 witnessed the integration of these technologies with wireless sensor networks and Internet of Things (IoT) devices, expanding their practical applications.

Current technological trends indicate a move toward hybrid energy harvesting systems that combine multiple energy sources to enhance reliability and output. Additionally, there is growing interest in developing flexible and stretchable harvesters that can conform to various surfaces and withstand mechanical stress, making them suitable for wearable applications and structural health monitoring.

The primary objective of micro energy harvester development is to achieve sufficient power output for target applications while maintaining minimal size and weight. Specifically, modern harvesters aim to generate power in the microwatt to milliwatt range, which is adequate for low-power electronics and sensors. Another critical goal is to enhance conversion efficiency, currently ranging from 1-20% depending on the harvesting mechanism, to maximize energy capture from limited ambient sources.

Long-term reliability represents another significant objective, as these devices are often deployed in remote or inaccessible locations where maintenance is challenging. Researchers are working toward harvesters with operational lifespans exceeding 10 years without degradation in performance. Cost-effectiveness is equally important, with efforts focused on reducing manufacturing complexity and utilizing abundant, environmentally friendly materials.

The ultimate technological vision is to develop autonomous, maintenance-free micro-scale power sources that can indefinitely sustain the operation of small electronic devices, particularly in remote monitoring applications, medical implants, and distributed sensor networks. This would eliminate the need for battery replacement and reduce electronic waste, aligning with global sustainability goals while enabling new applications previously constrained by power limitations.

The historical trajectory of micro energy harvesting began in the early 2000s with rudimentary piezoelectric and thermoelectric generators. By 2010, significant advancements in materials science and miniaturization techniques enabled the development of more efficient harvesting mechanisms with improved power density. The period between 2015 and 2020 witnessed the integration of these technologies with wireless sensor networks and Internet of Things (IoT) devices, expanding their practical applications.

Current technological trends indicate a move toward hybrid energy harvesting systems that combine multiple energy sources to enhance reliability and output. Additionally, there is growing interest in developing flexible and stretchable harvesters that can conform to various surfaces and withstand mechanical stress, making them suitable for wearable applications and structural health monitoring.

The primary objective of micro energy harvester development is to achieve sufficient power output for target applications while maintaining minimal size and weight. Specifically, modern harvesters aim to generate power in the microwatt to milliwatt range, which is adequate for low-power electronics and sensors. Another critical goal is to enhance conversion efficiency, currently ranging from 1-20% depending on the harvesting mechanism, to maximize energy capture from limited ambient sources.

Long-term reliability represents another significant objective, as these devices are often deployed in remote or inaccessible locations where maintenance is challenging. Researchers are working toward harvesters with operational lifespans exceeding 10 years without degradation in performance. Cost-effectiveness is equally important, with efforts focused on reducing manufacturing complexity and utilizing abundant, environmentally friendly materials.

The ultimate technological vision is to develop autonomous, maintenance-free micro-scale power sources that can indefinitely sustain the operation of small electronic devices, particularly in remote monitoring applications, medical implants, and distributed sensor networks. This would eliminate the need for battery replacement and reduce electronic waste, aligning with global sustainability goals while enabling new applications previously constrained by power limitations.

Market Analysis for Micro Energy Harvesting Solutions

The micro energy harvesting market is experiencing significant growth, driven by the proliferation of IoT devices and the increasing need for sustainable power solutions. Currently valued at approximately $450 million in 2023, the market is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 21.7%. This growth trajectory is supported by the expanding application scope across various industries including consumer electronics, healthcare, industrial automation, and smart infrastructure.

Consumer electronics represents the largest market segment, accounting for roughly 35% of the total market share. The integration of micro energy harvesters in wearable devices, wireless sensors, and smart home products has been particularly successful, with vibration and thermal energy harvesting technologies leading adoption rates. Healthcare applications follow closely at 28% market share, where micro energy harvesters power implantable medical devices and remote patient monitoring systems.

Regional analysis indicates North America currently dominates the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.3% CAGR through 2028, primarily driven by rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, and South Korea.

Customer demand patterns reveal a strong preference for solutions offering higher power density, with 65% of surveyed end-users ranking this as their top priority. Reliability under variable environmental conditions and cost-effectiveness follow as the second and third most important factors influencing purchasing decisions, cited by 58% and 47% of respondents respectively.

The competitive landscape features both established players and innovative startups. Major semiconductor companies have expanded their portfolios to include micro energy harvesting solutions, while specialized firms focus on developing proprietary technologies for specific energy sources. Price sensitivity varies significantly by application, with industrial and infrastructure applications demonstrating greater willingness to invest in premium solutions offering higher reliability and longer operational lifespans.

Market barriers include the relatively high initial cost compared to conventional batteries, with current price points averaging $5-15 per unit depending on harvesting technology and power output. Technical limitations in energy conversion efficiency, currently averaging 15-30% depending on the harvesting method, also present challenges to wider adoption. However, these barriers are gradually diminishing as manufacturing scales increase and technological advancements continue to improve performance metrics.

Consumer electronics represents the largest market segment, accounting for roughly 35% of the total market share. The integration of micro energy harvesters in wearable devices, wireless sensors, and smart home products has been particularly successful, with vibration and thermal energy harvesting technologies leading adoption rates. Healthcare applications follow closely at 28% market share, where micro energy harvesters power implantable medical devices and remote patient monitoring systems.

Regional analysis indicates North America currently dominates the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.3% CAGR through 2028, primarily driven by rapid industrialization, smart city initiatives, and increasing IoT adoption in countries like China, Japan, and South Korea.

Customer demand patterns reveal a strong preference for solutions offering higher power density, with 65% of surveyed end-users ranking this as their top priority. Reliability under variable environmental conditions and cost-effectiveness follow as the second and third most important factors influencing purchasing decisions, cited by 58% and 47% of respondents respectively.

The competitive landscape features both established players and innovative startups. Major semiconductor companies have expanded their portfolios to include micro energy harvesting solutions, while specialized firms focus on developing proprietary technologies for specific energy sources. Price sensitivity varies significantly by application, with industrial and infrastructure applications demonstrating greater willingness to invest in premium solutions offering higher reliability and longer operational lifespans.

Market barriers include the relatively high initial cost compared to conventional batteries, with current price points averaging $5-15 per unit depending on harvesting technology and power output. Technical limitations in energy conversion efficiency, currently averaging 15-30% depending on the harvesting method, also present challenges to wider adoption. However, these barriers are gradually diminishing as manufacturing scales increase and technological advancements continue to improve performance metrics.

Current Technical Challenges in Micro Energy Harvester Development

Despite significant advancements in micro energy harvesting technologies, several critical technical challenges continue to impede widespread implementation and commercial success. The miniaturization of energy harvesting devices presents fundamental physical limitations that affect power output capabilities. As dimensions decrease to micro and nano scales, the power generation capacity diminishes exponentially, creating a significant barrier to achieving practical energy outputs for real-world applications.

Material limitations represent another substantial challenge. Current piezoelectric, thermoelectric, and photovoltaic materials used in micro harvesters often demonstrate reduced efficiency at smaller scales. The conversion efficiency of these materials typically ranges from 1-15%, with significant performance degradation when fabricated in micro dimensions due to increased surface effects and material property changes at small scales.

Integration complexity poses significant engineering hurdles. Micro energy harvesters must be seamlessly incorporated with power management circuits, energy storage components, and the target application systems. This integration requires sophisticated microfabrication techniques and often results in reliability issues at connection points between dissimilar materials and components.

Environmental sensitivity remains a persistent challenge, as micro harvesters are particularly vulnerable to operating condition variations. Temperature fluctuations, mechanical stress, humidity, and contamination can dramatically affect performance stability and device longevity. For instance, piezoelectric micro harvesters may experience up to 40% efficiency reduction when operating outside their optimal frequency range.

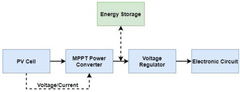

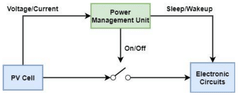

Energy storage and power management present additional complications. The intermittent nature of harvested energy necessitates efficient storage solutions and sophisticated power management circuits. However, existing micro-scale batteries and supercapacitors often suffer from limited capacity, high self-discharge rates, and degradation over time, compromising the overall system reliability.

Manufacturing scalability continues to be problematic. Current fabrication processes for high-performance micro harvesters typically involve complex, multi-step procedures that are difficult to scale for mass production. This results in high unit costs and inconsistent device performance, limiting commercial viability.

Standardization gaps further complicate development efforts. Unlike established energy technologies, micro energy harvesting lacks comprehensive standards for performance evaluation, testing protocols, and reliability assessment. This absence of standardization makes it difficult to compare different solutions objectively and establish clear performance benchmarks for industry adoption.

Material limitations represent another substantial challenge. Current piezoelectric, thermoelectric, and photovoltaic materials used in micro harvesters often demonstrate reduced efficiency at smaller scales. The conversion efficiency of these materials typically ranges from 1-15%, with significant performance degradation when fabricated in micro dimensions due to increased surface effects and material property changes at small scales.

Integration complexity poses significant engineering hurdles. Micro energy harvesters must be seamlessly incorporated with power management circuits, energy storage components, and the target application systems. This integration requires sophisticated microfabrication techniques and often results in reliability issues at connection points between dissimilar materials and components.

Environmental sensitivity remains a persistent challenge, as micro harvesters are particularly vulnerable to operating condition variations. Temperature fluctuations, mechanical stress, humidity, and contamination can dramatically affect performance stability and device longevity. For instance, piezoelectric micro harvesters may experience up to 40% efficiency reduction when operating outside their optimal frequency range.

Energy storage and power management present additional complications. The intermittent nature of harvested energy necessitates efficient storage solutions and sophisticated power management circuits. However, existing micro-scale batteries and supercapacitors often suffer from limited capacity, high self-discharge rates, and degradation over time, compromising the overall system reliability.

Manufacturing scalability continues to be problematic. Current fabrication processes for high-performance micro harvesters typically involve complex, multi-step procedures that are difficult to scale for mass production. This results in high unit costs and inconsistent device performance, limiting commercial viability.

Standardization gaps further complicate development efforts. Unlike established energy technologies, micro energy harvesting lacks comprehensive standards for performance evaluation, testing protocols, and reliability assessment. This absence of standardization makes it difficult to compare different solutions objectively and establish clear performance benchmarks for industry adoption.

Current KPI Measurement Methodologies for Micro Harvesters

01 Efficiency and Power Output Metrics

Performance indicators for micro energy harvesters often focus on efficiency and power output metrics. These include conversion efficiency (how effectively the harvester converts ambient energy to electrical energy), power density (output power per unit area or volume), and maximum power output under various operating conditions. These metrics are crucial for evaluating the practical utility of harvesters in real-world applications and comparing different harvesting technologies.- Efficiency and Power Output Metrics: Performance indicators for micro energy harvesters often focus on efficiency and power output metrics. These include conversion efficiency (how effectively the harvester converts ambient energy to electrical energy), power density (output power per unit area or volume), and maximum power output under various operating conditions. These metrics are crucial for evaluating the practical utility of micro energy harvesters in real-world applications and comparing different harvesting technologies.

- Environmental Adaptability and Operating Range: The performance of micro energy harvesters is significantly affected by their ability to operate across varying environmental conditions. Key indicators include operational frequency range, temperature tolerance, humidity resistance, and adaptability to fluctuating energy sources. Harvesters that can maintain stable performance across a wide range of environmental conditions are particularly valuable for outdoor or harsh environment applications.

- Durability and Reliability Measurements: Long-term performance stability is a critical indicator for micro energy harvesters. This includes metrics such as operational lifespan, degradation rate, failure modes, and mean time between failures. Testing protocols often involve accelerated aging tests, cyclic loading, and performance monitoring over extended periods to ensure that harvesters can provide consistent power output throughout their intended service life.

- Integration Capabilities and Form Factor: The physical characteristics and integration capabilities of micro energy harvesters are important performance indicators. These include size, weight, flexibility, and compatibility with existing systems or manufacturing processes. Harvesters that can be seamlessly integrated into devices without significantly increasing their size or weight are preferred, especially for wearable technology, IoT devices, and medical implants.

- Energy Storage and Management Efficiency: The effectiveness of energy storage and power management systems associated with micro energy harvesters significantly impacts overall performance. Key indicators include energy storage efficiency, power conditioning effectiveness, start-up time, and response to intermittent energy sources. Advanced harvesters often incorporate sophisticated power management circuits that optimize energy capture, storage, and delivery to maximize the utility of harvested energy.

02 Environmental Adaptability and Operating Range

The performance of micro energy harvesters is significantly affected by their ability to operate across varying environmental conditions. Key indicators include operational frequency range, temperature tolerance, humidity resistance, and performance stability under fluctuating ambient conditions. Harvesters that maintain consistent output across a wide range of environmental parameters are considered more robust and reliable for deployment in diverse settings.Expand Specific Solutions03 Durability and Lifespan Indicators

Longevity-related performance indicators are essential for evaluating micro energy harvesters. These include cycle life (number of operational cycles before significant degradation), mechanical durability (resistance to physical stress and vibration), fatigue resistance, and long-term output stability. These metrics help determine the total energy harvested over the device lifetime and maintenance requirements, which directly impact the economic viability of harvesting solutions.Expand Specific Solutions04 Integration and Form Factor Considerations

The physical characteristics of micro energy harvesters significantly influence their performance in integrated systems. Important indicators include size and weight efficiency (power output relative to physical dimensions), integration compatibility with existing electronic systems, scalability for different applications, and flexibility or conformability for wearable or embedded applications. These factors determine how effectively harvesters can be deployed in space-constrained applications.Expand Specific Solutions05 Energy Storage and Management Efficiency

The overall performance of micro energy harvesting systems depends on how effectively harvested energy is stored and managed. Key indicators include energy storage efficiency, power management circuit losses, standby power consumption, energy retention over time, and load matching capabilities. Advanced systems incorporate adaptive power management that optimizes energy capture and utilization based on available ambient energy and application power requirements.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Harvesting

The micro energy harvester market is currently in a growth phase, characterized by increasing demand for sustainable power solutions in IoT and wearable devices. The global market size is projected to expand significantly, driven by applications in healthcare, industrial monitoring, and consumer electronics. Technologically, the field shows varying maturity levels across different harvesting mechanisms. Leading academic institutions like MIT, Southeast University, and Nanyang Technological University are advancing fundamental research, while commercial players including Robert Bosch, Infineon Technologies, and Intel are developing practical applications. Research organizations such as IMEC Nederland and Korea Institute of Ceramic Engineering & Technology are bridging the gap between theoretical concepts and commercial viability. Success indicators increasingly focus on power density, conversion efficiency, reliability, and integration capabilities rather than just output power.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a comprehensive framework for evaluating micro energy harvesters based on multiple KPIs including power density, conversion efficiency, and operational bandwidth. Their approach integrates MEMS-based piezoelectric harvesters with advanced power management circuits that can achieve conversion efficiencies exceeding 70% across varying environmental conditions. MIT's research has established benchmark metrics for comparing different harvesting technologies, including a normalized power density metric (μW/cm³/g²) for vibration harvesters and standardized testing protocols under realistic operating conditions. Their recent innovations include self-tuning resonant frequency harvesters that can automatically adjust to environmental vibration changes, maintaining optimal power output across a wider frequency range (5-200 Hz) than conventional fixed-frequency designs.

Strengths: Industry-leading conversion efficiency metrics and standardized evaluation frameworks that enable objective comparison across harvesting technologies. Weaknesses: Solutions often require complex implementation and may have higher initial costs compared to simpler harvesting approaches.

Robert Bosch GmbH

Technical Solution: Bosch has developed an industrial-focused micro energy harvester evaluation system centered on reliability and longevity KPIs. Their approach emphasizes long-term performance stability under harsh industrial conditions, with harvesters designed to maintain at least 80% of initial power output after 10+ years of operation. Bosch's technical solution incorporates thermoelectric and vibration-based harvesting technologies optimized for industrial machinery applications, with specialized power conditioning circuits that can operate efficiently across temperature ranges from -40°C to +125°C. Their proprietary performance evaluation framework includes accelerated life testing protocols that correlate harvester degradation with operational parameters, enabling accurate lifetime prediction models. Bosch has also pioneered hybrid harvesting systems that combine multiple energy sources (vibration, thermal, RF) with intelligent switching to maximize energy capture across varying industrial environments.

Strengths: Exceptional reliability metrics and robust performance in harsh industrial environments with comprehensive lifetime prediction models. Weaknesses: Solutions typically optimized for specific industrial applications with limited flexibility for adaptation to consumer electronics or medical applications.

Critical Patents and Research in Micro Energy Harvesting

Efficient energy harvesting system for IoT devices

PatentPendingIN202441066639A

Innovation

- Energy harvesting technologies that convert ambient energy from sources like solar, mechanical, wind, thermal, and radiofrequency into electrical energy, combined with advanced Power Management Integrated Circuits (PMICs) for efficient power optimization and storage, reducing reliance on conventional power sources.

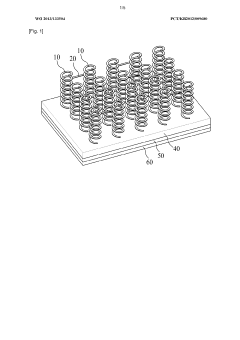

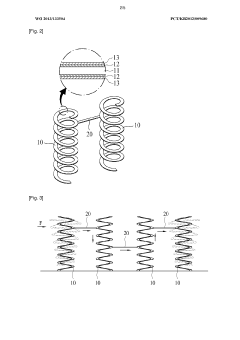

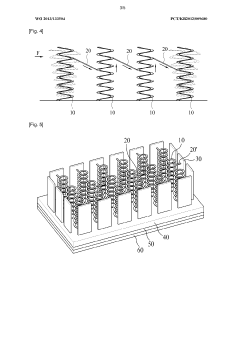

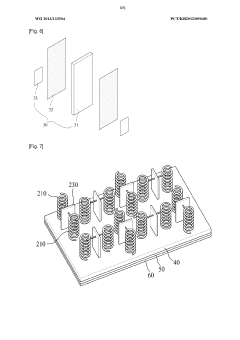

Energy-harvesting apparatus comprising coil spring-type microscale piezoelectric resonator

PatentWO2013133504A1

Innovation

- The energy harvesting device employs a plurality of micro-piezoelectric vibrators in the form of coil springs and plate-type piezoelectric vibrators connected through various connection units on a printed circuit board, allowing for efficient power generation from external forces and heat, with the ability to transmit and collect energy through diverse paths.

Standardization Efforts for Micro Energy Harvester Metrics

The standardization of micro energy harvester metrics represents a critical advancement in the field, enabling meaningful comparisons between different harvesting technologies and establishing industry-wide benchmarks for performance evaluation. Currently, several international organizations are actively working to develop comprehensive standards that address the unique challenges of micro-scale energy harvesting systems.

The International Electrotechnical Commission (IEC) has established the Technical Committee 120 specifically focused on Electrical Energy Storage Systems, which includes working groups addressing energy harvesting technologies. Their efforts aim to create unified testing protocols and performance metrics that account for the diverse operating conditions and energy sources utilized in micro harvesters.

IEEE has also contributed significantly through its P1789 working group, which focuses on standardizing measurement methodologies for piezoelectric, electromagnetic, and thermoelectric micro-generators. These standards define specific testing environments, load conditions, and reporting formats to ensure reproducibility and comparability of performance data across different research institutions and manufacturers.

ASTM International has developed the E3006 standard, which provides guidelines for characterizing the performance of energy harvesting devices under various environmental conditions. This standard emphasizes the importance of reporting power density (μW/cm³), conversion efficiency, and operational lifetime as key performance indicators.

The European Committee for Standardization (CEN) has implemented the EN 62830 series, specifically addressing standardized measurement methods for semiconductor-based energy harvesting devices. These standards define specific procedures for evaluating energy conversion efficiency under controlled conditions, ensuring consistent reporting across the industry.

Industry consortia like the Energy Harvesting Network and the Wireless Power Consortium have also contributed to standardization efforts by developing application-specific benchmarks that reflect real-world deployment scenarios. These include metrics for startup time, cold-start capability, and performance degradation over time.

A significant challenge in standardization remains the development of metrics that can fairly compare fundamentally different harvesting technologies. For instance, comparing a vibration-based harvester with a thermal gradient harvester requires carefully defined reference conditions and normalization factors to ensure meaningful comparisons.

Recent progress includes the development of standardized test benches and reference environments that simulate typical application scenarios, allowing for more realistic performance evaluation beyond laboratory conditions. These standardized testing platforms enable manufacturers to validate their technologies against industry-accepted benchmarks, accelerating market adoption and technological maturity.

The International Electrotechnical Commission (IEC) has established the Technical Committee 120 specifically focused on Electrical Energy Storage Systems, which includes working groups addressing energy harvesting technologies. Their efforts aim to create unified testing protocols and performance metrics that account for the diverse operating conditions and energy sources utilized in micro harvesters.

IEEE has also contributed significantly through its P1789 working group, which focuses on standardizing measurement methodologies for piezoelectric, electromagnetic, and thermoelectric micro-generators. These standards define specific testing environments, load conditions, and reporting formats to ensure reproducibility and comparability of performance data across different research institutions and manufacturers.

ASTM International has developed the E3006 standard, which provides guidelines for characterizing the performance of energy harvesting devices under various environmental conditions. This standard emphasizes the importance of reporting power density (μW/cm³), conversion efficiency, and operational lifetime as key performance indicators.

The European Committee for Standardization (CEN) has implemented the EN 62830 series, specifically addressing standardized measurement methods for semiconductor-based energy harvesting devices. These standards define specific procedures for evaluating energy conversion efficiency under controlled conditions, ensuring consistent reporting across the industry.

Industry consortia like the Energy Harvesting Network and the Wireless Power Consortium have also contributed to standardization efforts by developing application-specific benchmarks that reflect real-world deployment scenarios. These include metrics for startup time, cold-start capability, and performance degradation over time.

A significant challenge in standardization remains the development of metrics that can fairly compare fundamentally different harvesting technologies. For instance, comparing a vibration-based harvester with a thermal gradient harvester requires carefully defined reference conditions and normalization factors to ensure meaningful comparisons.

Recent progress includes the development of standardized test benches and reference environments that simulate typical application scenarios, allowing for more realistic performance evaluation beyond laboratory conditions. These standardized testing platforms enable manufacturers to validate their technologies against industry-accepted benchmarks, accelerating market adoption and technological maturity.

Environmental Impact and Sustainability Considerations

Micro energy harvesting technologies represent a significant opportunity for sustainable energy generation at small scales, with profound implications for environmental conservation and resource efficiency. The environmental footprint of these systems must be evaluated across their entire lifecycle, from raw material extraction to end-of-life disposal or recycling. Most micro harvesters utilize materials with minimal environmental impact compared to conventional power sources, particularly when considering their extended operational lifespans without replacement requirements.

The sustainability advantages of micro energy harvesters are substantial when compared to traditional battery technologies. By eliminating or significantly reducing battery replacement needs, these systems directly decrease hazardous waste generation associated with battery disposal. This aspect is particularly critical in remote sensing applications where battery replacement logistics create additional environmental burdens through transportation emissions and physical disturbance of sensitive ecosystems.

Carbon footprint analysis reveals that while initial manufacturing processes for specialized harvesting materials may have moderate environmental impacts, the lifetime emissions savings typically offset these initial costs within months of deployment. The net environmental benefit increases exponentially in long-term installations, especially when harvesters enable the operation of environmental monitoring systems that contribute to conservation efforts or resource optimization.

Material selection represents a crucial environmental consideration in harvester design. Recent innovations have focused on bio-compatible and biodegradable components for transient applications, particularly in medical and environmental sensing contexts. Additionally, research into recycling pathways for specialized harvesting materials shows promising developments for creating closed-loop material systems that further enhance sustainability credentials.

Energy payback periods—the time required for a harvester to generate the energy consumed during its production—have decreased significantly with manufacturing improvements. Current generation harvesters typically achieve energy payback within 1-3 years depending on deployment conditions, representing substantial improvements over earlier iterations. This metric serves as a critical performance indicator when evaluating environmental sustainability.

The integration of micro energy harvesters into circular economy frameworks presents additional opportunities for sustainability enhancement. Design approaches that facilitate easy disassembly, component reuse, and material recovery are increasingly recognized as essential performance indicators beyond pure energy metrics. These considerations must be incorporated into comprehensive evaluation frameworks for harvester technologies to ensure their contribution to broader sustainability goals.

The sustainability advantages of micro energy harvesters are substantial when compared to traditional battery technologies. By eliminating or significantly reducing battery replacement needs, these systems directly decrease hazardous waste generation associated with battery disposal. This aspect is particularly critical in remote sensing applications where battery replacement logistics create additional environmental burdens through transportation emissions and physical disturbance of sensitive ecosystems.

Carbon footprint analysis reveals that while initial manufacturing processes for specialized harvesting materials may have moderate environmental impacts, the lifetime emissions savings typically offset these initial costs within months of deployment. The net environmental benefit increases exponentially in long-term installations, especially when harvesters enable the operation of environmental monitoring systems that contribute to conservation efforts or resource optimization.

Material selection represents a crucial environmental consideration in harvester design. Recent innovations have focused on bio-compatible and biodegradable components for transient applications, particularly in medical and environmental sensing contexts. Additionally, research into recycling pathways for specialized harvesting materials shows promising developments for creating closed-loop material systems that further enhance sustainability credentials.

Energy payback periods—the time required for a harvester to generate the energy consumed during its production—have decreased significantly with manufacturing improvements. Current generation harvesters typically achieve energy payback within 1-3 years depending on deployment conditions, representing substantial improvements over earlier iterations. This metric serves as a critical performance indicator when evaluating environmental sustainability.

The integration of micro energy harvesters into circular economy frameworks presents additional opportunities for sustainability enhancement. Design approaches that facilitate easy disassembly, component reuse, and material recovery are increasingly recognized as essential performance indicators beyond pure energy metrics. These considerations must be incorporated into comprehensive evaluation frameworks for harvester technologies to ensure their contribution to broader sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!