The Role of Standards in Micro Energy Harvester Technology Adoption

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Standards Evolution and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to commercially viable solutions for powering small electronic devices. The evolution began in the early 2000s with rudimentary piezoelectric and thermoelectric harvesters that demonstrated the concept but lacked standardization and practical efficiency. By 2010, research institutions and early commercial players had developed improved materials and designs, yet the absence of unified standards hindered widespread adoption and interoperability.

The watershed moment came in 2013 when the International Electrotechnical Commission (IEC) established the Technical Committee 120 specifically dedicated to Electrical Energy Storage Systems, which later expanded to include energy harvesting technologies. This initiative marked the first coordinated international effort to standardize terminology, testing methods, and performance metrics for micro energy harvesters.

Between 2015 and 2020, several key standards emerged, including IEEE 1801-2015 for low-power system design, IEC 62830 series for piezoelectric, electromagnetic, and thermoelectric energy harvesting devices, and ISO/IEC 14543-3-10 for wireless applications powered by energy harvesters. These standards provided crucial frameworks for manufacturers and integrators, enabling more consistent product development and evaluation.

The primary objectives of standardization in micro energy harvesting technology are multifaceted. First, establishing common terminology and classification systems facilitates clear communication among researchers, manufacturers, and end-users. Second, standardized testing protocols ensure fair comparison of performance metrics across different harvesting technologies and products, reducing market confusion and building consumer confidence.

Third, interoperability standards enable seamless integration of harvesting technologies with various electronic systems and power management circuits, expanding potential applications. Fourth, safety and reliability standards address concerns regarding long-term operation, environmental impact, and potential failure modes, which are critical for industrial and medical applications.

Looking forward, standardization efforts aim to address emerging challenges such as the integration of multiple harvesting technologies in hybrid systems, miniaturization requirements for IoT applications, and the development of more efficient power management circuits. The roadmap for future standards development includes provisions for new materials like organic semiconductors and metamaterials, as well as novel architectures that can harvest energy from previously untapped ambient sources.

The ultimate goal of these standardization efforts is to accelerate market adoption by reducing technical barriers, lowering manufacturing costs through economies of scale, and building consumer confidence in the reliability and performance of micro energy harvesting technologies across diverse application domains.

The watershed moment came in 2013 when the International Electrotechnical Commission (IEC) established the Technical Committee 120 specifically dedicated to Electrical Energy Storage Systems, which later expanded to include energy harvesting technologies. This initiative marked the first coordinated international effort to standardize terminology, testing methods, and performance metrics for micro energy harvesters.

Between 2015 and 2020, several key standards emerged, including IEEE 1801-2015 for low-power system design, IEC 62830 series for piezoelectric, electromagnetic, and thermoelectric energy harvesting devices, and ISO/IEC 14543-3-10 for wireless applications powered by energy harvesters. These standards provided crucial frameworks for manufacturers and integrators, enabling more consistent product development and evaluation.

The primary objectives of standardization in micro energy harvesting technology are multifaceted. First, establishing common terminology and classification systems facilitates clear communication among researchers, manufacturers, and end-users. Second, standardized testing protocols ensure fair comparison of performance metrics across different harvesting technologies and products, reducing market confusion and building consumer confidence.

Third, interoperability standards enable seamless integration of harvesting technologies with various electronic systems and power management circuits, expanding potential applications. Fourth, safety and reliability standards address concerns regarding long-term operation, environmental impact, and potential failure modes, which are critical for industrial and medical applications.

Looking forward, standardization efforts aim to address emerging challenges such as the integration of multiple harvesting technologies in hybrid systems, miniaturization requirements for IoT applications, and the development of more efficient power management circuits. The roadmap for future standards development includes provisions for new materials like organic semiconductors and metamaterials, as well as novel architectures that can harvest energy from previously untapped ambient sources.

The ultimate goal of these standardization efforts is to accelerate market adoption by reducing technical barriers, lowering manufacturing costs through economies of scale, and building consumer confidence in the reliability and performance of micro energy harvesting technologies across diverse application domains.

Market Demand Analysis for Standardized Energy Harvesters

The global market for micro energy harvesting technologies is experiencing significant growth, driven by the proliferation of Internet of Things (IoT) devices and wireless sensor networks. Current market analysis indicates that the energy harvesting market is projected to reach $1.5 billion by 2027, with micro-scale harvesters representing approximately 35% of this value. The demand for standardized energy harvesters is particularly strong in industrial automation, smart buildings, wearable technology, and environmental monitoring sectors.

Industry surveys reveal that 78% of IoT solution providers cite power management as a critical challenge in deployment scenarios. Standardized energy harvesters address this pain point by providing predictable power outputs and simplified integration processes. The market demand is further segmented by harvesting technology type, with photovoltaic, thermoelectric, piezoelectric, and electromagnetic solutions each serving distinct application niches.

Consumer electronics manufacturers have expressed growing interest in standardized micro energy harvesters, with 63% of surveyed companies indicating plans to incorporate energy harvesting in future product designs. This trend is particularly evident in wearable technology, where battery replacement presents significant user experience challenges.

In the industrial sector, the demand for standardized energy harvesters is primarily driven by the need for maintenance-free power solutions in remote monitoring applications. Factory automation systems utilizing wireless sensor networks represent a high-growth segment, with an estimated annual growth rate of 22% through 2026.

Geographic market distribution shows strongest demand in North America and Europe, where IoT adoption rates are highest. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, particularly in manufacturing applications where energy harvesters can significantly reduce operational costs associated with battery replacement.

Market research indicates that standardization would address several key customer requirements. First, interoperability between harvesting technologies and power management systems ranks as the top concern among 82% of system integrators. Second, predictable performance metrics across varying environmental conditions is essential for 76% of end-users. Third, simplified design-in processes would reduce time-to-market for 68% of device manufacturers.

The demand for standardized testing protocols is particularly strong, as current performance claims by manufacturers often utilize proprietary testing methodologies that prevent direct comparison between solutions. This market gap represents a significant opportunity for standards development organizations to create unified testing frameworks that would accelerate adoption across multiple industries.

Industry surveys reveal that 78% of IoT solution providers cite power management as a critical challenge in deployment scenarios. Standardized energy harvesters address this pain point by providing predictable power outputs and simplified integration processes. The market demand is further segmented by harvesting technology type, with photovoltaic, thermoelectric, piezoelectric, and electromagnetic solutions each serving distinct application niches.

Consumer electronics manufacturers have expressed growing interest in standardized micro energy harvesters, with 63% of surveyed companies indicating plans to incorporate energy harvesting in future product designs. This trend is particularly evident in wearable technology, where battery replacement presents significant user experience challenges.

In the industrial sector, the demand for standardized energy harvesters is primarily driven by the need for maintenance-free power solutions in remote monitoring applications. Factory automation systems utilizing wireless sensor networks represent a high-growth segment, with an estimated annual growth rate of 22% through 2026.

Geographic market distribution shows strongest demand in North America and Europe, where IoT adoption rates are highest. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, particularly in manufacturing applications where energy harvesters can significantly reduce operational costs associated with battery replacement.

Market research indicates that standardization would address several key customer requirements. First, interoperability between harvesting technologies and power management systems ranks as the top concern among 82% of system integrators. Second, predictable performance metrics across varying environmental conditions is essential for 76% of end-users. Third, simplified design-in processes would reduce time-to-market for 68% of device manufacturers.

The demand for standardized testing protocols is particularly strong, as current performance claims by manufacturers often utilize proprietary testing methodologies that prevent direct comparison between solutions. This market gap represents a significant opportunity for standards development organizations to create unified testing frameworks that would accelerate adoption across multiple industries.

Current Standards Landscape and Technical Barriers

The micro energy harvesting technology landscape currently lacks a comprehensive standardization framework, which presents a significant barrier to widespread adoption. Existing standards primarily focus on specific energy harvesting methods rather than providing an integrated approach. For instance, IEEE 1547 addresses grid interconnection of distributed resources, while IEC 62830 series covers piezoelectric energy harvesting devices. However, these standards operate in isolation without sufficient cross-compatibility considerations.

The fragmentation of standards across different regions creates additional challenges. In North America, ASTM and IEEE lead standardization efforts, while Europe follows IEC and CENELEC frameworks. Asian markets, particularly Japan and South Korea, have developed their own national standards. This regional disparity complicates global market access for manufacturers and creates uncertainty for end-users regarding device performance and reliability.

Technical barriers to standardization include the diverse nature of energy harvesting technologies themselves. Vibration, thermal, RF, and photovoltaic harvesters each operate on fundamentally different principles, making unified performance metrics difficult to establish. The miniaturization requirements for micro-scale devices further complicate standardization efforts, as conventional testing methodologies may not adequately capture performance characteristics at such small scales.

Measurement and characterization present another significant challenge. Current standards lack consensus on testing protocols for micro-energy harvesters, particularly regarding environmental conditions that affect performance. The absence of standardized testing conditions makes it difficult to compare efficiency claims across different manufacturers and technologies, creating market confusion and slowing adoption rates.

Interoperability issues represent a critical barrier, as micro energy harvesters must often integrate with existing systems and power management circuits. The lack of standardized interfaces and communication protocols limits plug-and-play capabilities, forcing custom integration solutions that increase implementation costs and complexity. This particularly affects IoT applications where seamless integration is essential.

Safety and reliability standards for micro energy harvesters remain underdeveloped compared to conventional power sources. Without established safety protocols, concerns regarding long-term stability, material degradation, and potential failure modes persist among potential adopters. This uncertainty increases perceived risk, particularly in critical applications like medical devices or industrial monitoring systems.

Regulatory compliance frameworks have not kept pace with technological advancements in micro energy harvesting. Many existing regulations were designed for conventional power sources and do not adequately address the unique characteristics of energy harvesters. This regulatory gap creates uncertainty for manufacturers regarding certification requirements and market access pathways.

The fragmentation of standards across different regions creates additional challenges. In North America, ASTM and IEEE lead standardization efforts, while Europe follows IEC and CENELEC frameworks. Asian markets, particularly Japan and South Korea, have developed their own national standards. This regional disparity complicates global market access for manufacturers and creates uncertainty for end-users regarding device performance and reliability.

Technical barriers to standardization include the diverse nature of energy harvesting technologies themselves. Vibration, thermal, RF, and photovoltaic harvesters each operate on fundamentally different principles, making unified performance metrics difficult to establish. The miniaturization requirements for micro-scale devices further complicate standardization efforts, as conventional testing methodologies may not adequately capture performance characteristics at such small scales.

Measurement and characterization present another significant challenge. Current standards lack consensus on testing protocols for micro-energy harvesters, particularly regarding environmental conditions that affect performance. The absence of standardized testing conditions makes it difficult to compare efficiency claims across different manufacturers and technologies, creating market confusion and slowing adoption rates.

Interoperability issues represent a critical barrier, as micro energy harvesters must often integrate with existing systems and power management circuits. The lack of standardized interfaces and communication protocols limits plug-and-play capabilities, forcing custom integration solutions that increase implementation costs and complexity. This particularly affects IoT applications where seamless integration is essential.

Safety and reliability standards for micro energy harvesters remain underdeveloped compared to conventional power sources. Without established safety protocols, concerns regarding long-term stability, material degradation, and potential failure modes persist among potential adopters. This uncertainty increases perceived risk, particularly in critical applications like medical devices or industrial monitoring systems.

Regulatory compliance frameworks have not kept pace with technological advancements in micro energy harvesting. Many existing regulations were designed for conventional power sources and do not adequately address the unique characteristics of energy harvesters. This regulatory gap creates uncertainty for manufacturers regarding certification requirements and market access pathways.

Existing Standardization Approaches and Frameworks

01 Piezoelectric Energy Harvesting Standards

Piezoelectric materials are widely used in micro energy harvesters to convert mechanical vibrations into electrical energy. These standards define the specifications for piezoelectric transducers, including material properties, performance metrics, and testing methodologies. The standards ensure consistent performance and reliability of piezoelectric energy harvesters across different applications, from wearable devices to industrial sensors.- Piezoelectric Energy Harvesting Standards: Piezoelectric materials are widely used in micro energy harvesters to convert mechanical vibrations into electrical energy. These standards define the specifications for piezoelectric transducers, including material properties, performance metrics, and testing methodologies. The standards ensure consistent performance and reliability of piezoelectric energy harvesters across different applications, from wearable devices to industrial sensors.

- Electromagnetic Micro Energy Harvesting Protocols: Electromagnetic energy harvesting technologies convert ambient electromagnetic fields into usable electrical power. These standards establish protocols for the design, testing, and implementation of electromagnetic micro energy harvesters. They specify requirements for coil configurations, magnetic materials, and conversion efficiency metrics to ensure optimal performance in various electromagnetic environments.

- Thermal Energy Harvesting Certification Standards: Standards for thermal energy harvesting technologies focus on the conversion of temperature differentials into electrical energy at the micro scale. These certification standards define the testing procedures, efficiency metrics, and material requirements for thermoelectric generators. They ensure consistent performance across different operating temperatures and environmental conditions, facilitating integration into various applications.

- Integration Standards for Multi-source Energy Harvesters: These standards address the integration of multiple energy harvesting technologies into a single system. They define protocols for combining different harvesting mechanisms such as piezoelectric, electromagnetic, and photovoltaic to maximize energy capture from various ambient sources. The standards specify interface requirements, power management architectures, and testing methodologies for hybrid energy harvesting systems.

- Micro Energy Storage and Management Standards: These standards focus on the storage and management of harvested energy at the micro scale. They define specifications for energy storage components, power conditioning circuits, and energy management algorithms. The standards ensure efficient capture, storage, and utilization of harvested energy, addressing challenges such as intermittent energy availability and varying load requirements in micro-scale applications.

02 Electromagnetic Micro Energy Harvesting Protocols

Standards for electromagnetic micro energy harvesters focus on the conversion of kinetic energy into electrical energy through electromagnetic induction. These protocols specify coil designs, magnetic material requirements, and output characteristics. They also address the integration of electromagnetic harvesters with power management circuits to ensure efficient energy capture and storage from ambient vibrations and movements.Expand Specific Solutions03 Thermoelectric Energy Harvesting Specifications

Thermoelectric energy harvesting standards define the requirements for devices that convert temperature differentials into electrical energy. These specifications cover thermoelectric materials, module construction, thermal interface requirements, and performance metrics. The standards ensure consistent performance across varying temperature conditions and provide guidelines for integrating thermoelectric harvesters into microelectronic systems.Expand Specific Solutions04 Solar Micro Energy Harvester Certification

Standards for micro-scale photovoltaic energy harvesters define the specifications for materials, construction, and performance of miniaturized solar cells. These certification protocols include testing methodologies for efficiency, durability, and output characteristics under various lighting conditions. They also address the integration of solar micro harvesters with energy storage and power management systems for indoor and outdoor applications.Expand Specific Solutions05 RF and Wireless Energy Harvesting Guidelines

Standards for radio frequency and wireless energy harvesting define the specifications for devices that capture electromagnetic radiation and convert it into usable electrical energy. These guidelines cover antenna designs, rectifier circuits, frequency ranges, and power conversion efficiencies. They also address safety considerations, electromagnetic compatibility, and integration with wireless communication systems for IoT and sensor network applications.Expand Specific Solutions

Key Industry Players and Standards Organizations

The micro energy harvester technology market is currently in a growth phase, characterized by increasing standardization efforts to accelerate adoption across industries. The market is projected to expand significantly as IoT applications proliferate, with key players driving innovation through different approaches. Leading technology companies like Bosch, Intel, Huawei, and ABB are focusing on commercial applications, while academic institutions such as MIT, Xi'an Jiaotong University, and Drexel University contribute fundamental research. The technology is approaching maturity in specific applications but remains in development for broader implementation. Collaboration between industry leaders (Tesla, LG Electronics, Sony) and research organizations (IMEC, A*STAR) is accelerating standardization efforts, which will be crucial for overcoming fragmentation and enabling widespread integration into smart devices and industrial systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive micro energy harvesting solutions that comply with multiple international standards including ISO/IEC 14543-3-10 for energy harvesting wireless sensors and IEEE 1801-2015 for power modeling. Their technology portfolio includes piezoelectric, thermoelectric, and electromagnetic harvesters designed for industrial IoT applications. Bosch's standardized micro energy harvesting modules can generate 10-100mW from industrial vibrations, with their latest MEMS-based harvesters achieving conversion efficiencies of up to 35% under optimal conditions. The company actively participates in the EnOcean Alliance to promote interoperability standards for energy harvesting wireless technology and has contributed to the development of the Wireless Power Consortium's standards for micro-scale power transfer.

Strengths: Strong integration capabilities with existing industrial systems; comprehensive standards compliance across multiple harvesting technologies; established manufacturing infrastructure. Weaknesses: Solutions tend to be optimized for industrial applications rather than consumer electronics; relatively higher cost compared to non-standardized alternatives.

Stichting IMEC Nederland

Technical Solution: IMEC has pioneered ultra-low-power micro energy harvesting technologies that adhere to emerging standards in the field. Their approach focuses on nanoscale thin-film thermoelectric generators (TEGs) that comply with ASTM E2546 standards for thermoelectric materials testing. IMEC's micro energy harvesters achieve power densities of 0.5-5mW/cm² from temperature gradients as low as 5°C, making them suitable for wearable and implantable medical devices. The organization has developed standardized testing protocols for micro energy harvesters that have been adopted by the International Electrotechnical Commission (IEC) Technical Committee 47. IMEC also leads the European Standardization Initiative for Energy Harvesting (ESIEH), which aims to establish unified testing methodologies and performance metrics for micro-scale energy harvesting technologies across the EU.

Strengths: Cutting-edge research in nanoscale materials; leadership in standards development; strong focus on medical and wearable applications. Weaknesses: Technologies often require specialized manufacturing processes; some solutions remain in pre-commercial research phases.

Critical Patents and Technical Documentation Analysis

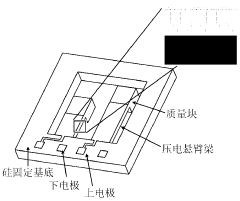

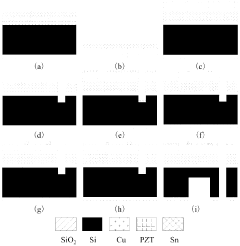

Micro energy collector based on piezoelectric thick film MEMS process and preparation method thereof

PatentWO2019090601A1

Innovation

- Using piezoelectric thick film MEMS technology, through eutectic bonding of piezoelectric ceramic wafers and silicon dioxide wafers, combined with electroplating and laser cutting processes, a multi-layered piezoelectric cantilever beam and fixed base are prepared to achieve piezoelectric thick film High performance and diverse structural design.

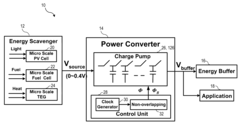

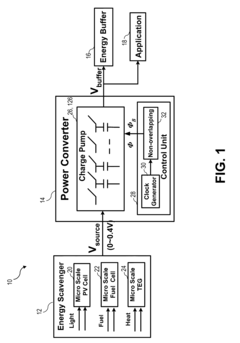

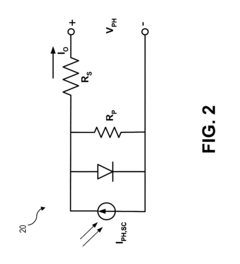

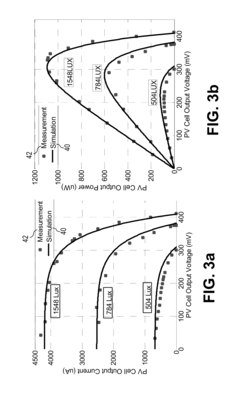

Efficient Power Conversion for Ultra Low Voltage Micro Scale Energy Transducers

PatentInactiveUS20110260536A1

Innovation

- A three-stage charge pump with a tree topology is employed, featuring capacitors and MOS switches, where the output of each stage is coupled to the input of the next, with a control unit generating non-overlapping clocking signals to enhance voltage boosting efficiency.

Interoperability and Cross-Industry Implementation Challenges

Interoperability remains one of the most significant barriers to widespread adoption of micro energy harvesting technologies across different industries. The lack of standardized interfaces, protocols, and communication methods creates substantial implementation challenges when attempting to integrate these technologies into existing systems or across multiple sectors.

The fragmentation of standards across different industry verticals presents a primary obstacle. For instance, medical device manufacturers follow ISO 13485 standards, while automotive applications adhere to ISO 26262, creating compatibility issues when the same energy harvesting technology needs to serve both sectors. This divergence in regulatory frameworks forces technology providers to develop multiple versions of similar solutions, increasing development costs and time-to-market.

Communication protocol incompatibility further exacerbates these challenges. Energy harvesters designed for industrial IoT applications may utilize protocols like MQTT or CoAP, while consumer electronics might employ Bluetooth Low Energy or Zigbee. This protocol diversity creates significant integration hurdles when attempting to implement a single harvesting solution across multiple product categories or when enabling cross-industry applications.

Data format standardization represents another critical interoperability concern. The absence of uniform data structures for reporting energy generation metrics, system health, and operational parameters complicates system integration and performance monitoring across platforms. Organizations must develop custom middleware solutions to translate between proprietary formats, adding complexity and potential points of failure.

Power management interfaces also lack standardization, with different industries employing varied approaches to energy storage, power conditioning, and load management. This inconsistency forces developers to create custom interface circuits for each application domain, limiting economies of scale and increasing implementation costs.

Cross-industry implementation is further complicated by varying environmental requirements. Energy harvesters designed for consumer electronics may not withstand the temperature extremes, vibration profiles, or electromagnetic interference present in industrial or automotive environments. Without standardized testing methodologies and performance metrics, comparing solutions across these domains becomes problematic.

The absence of unified certification processes across industries creates additional market fragmentation. Technology providers must navigate multiple certification pathways, each with unique requirements and testing procedures, significantly increasing compliance costs and extending time-to-market for cross-industry solutions.

The fragmentation of standards across different industry verticals presents a primary obstacle. For instance, medical device manufacturers follow ISO 13485 standards, while automotive applications adhere to ISO 26262, creating compatibility issues when the same energy harvesting technology needs to serve both sectors. This divergence in regulatory frameworks forces technology providers to develop multiple versions of similar solutions, increasing development costs and time-to-market.

Communication protocol incompatibility further exacerbates these challenges. Energy harvesters designed for industrial IoT applications may utilize protocols like MQTT or CoAP, while consumer electronics might employ Bluetooth Low Energy or Zigbee. This protocol diversity creates significant integration hurdles when attempting to implement a single harvesting solution across multiple product categories or when enabling cross-industry applications.

Data format standardization represents another critical interoperability concern. The absence of uniform data structures for reporting energy generation metrics, system health, and operational parameters complicates system integration and performance monitoring across platforms. Organizations must develop custom middleware solutions to translate between proprietary formats, adding complexity and potential points of failure.

Power management interfaces also lack standardization, with different industries employing varied approaches to energy storage, power conditioning, and load management. This inconsistency forces developers to create custom interface circuits for each application domain, limiting economies of scale and increasing implementation costs.

Cross-industry implementation is further complicated by varying environmental requirements. Energy harvesters designed for consumer electronics may not withstand the temperature extremes, vibration profiles, or electromagnetic interference present in industrial or automotive environments. Without standardized testing methodologies and performance metrics, comparing solutions across these domains becomes problematic.

The absence of unified certification processes across industries creates additional market fragmentation. Technology providers must navigate multiple certification pathways, each with unique requirements and testing procedures, significantly increasing compliance costs and extending time-to-market for cross-industry solutions.

Regulatory Compliance and Certification Requirements

Regulatory compliance and certification requirements play a pivotal role in the widespread adoption of micro energy harvester technologies across global markets. These requirements establish the necessary framework for ensuring that energy harvesting devices meet safety standards, performance benchmarks, and interoperability guidelines essential for commercial deployment.

The regulatory landscape for micro energy harvesters varies significantly across regions, with major markets such as the European Union, North America, and Asia-Pacific each maintaining distinct certification processes. In the EU, compliance with the Radio Equipment Directive (RED), Electromagnetic Compatibility (EMC) Directive, and RoHS (Restriction of Hazardous Substances) is mandatory for market access. North American markets require FCC certification for wireless energy harvesting devices and UL safety certifications, while Asian markets have their own regional standards bodies.

Industry-specific regulations further complicate the compliance landscape. Medical applications of energy harvesting technology must adhere to stringent FDA requirements in the US and equivalent medical device regulations elsewhere. Aerospace and automotive implementations face additional certification hurdles through standards like DO-160 for airborne equipment or ISO 26262 for automotive functional safety.

Testing protocols for micro energy harvesters present unique challenges due to their small form factors and variable energy outputs. Standard testing methodologies must account for performance under diverse environmental conditions, including temperature fluctuations, humidity variations, and mechanical stress. The development of specialized testing equipment and procedures specifically designed for micro-scale energy harvesting devices remains an ongoing challenge for certification bodies.

Harmonization efforts between international standards organizations such as IEEE, IEC, and ISO have begun addressing the fragmentation in certification requirements. The IEEE P1789 working group has been developing standards specifically for energy harvesting devices, while IEC Technical Committee 120 focuses on standardizing electrical energy storage systems that often interface with harvesting technologies.

Certification costs represent a significant barrier to market entry, particularly for startups and small manufacturers. The complex web of regional and application-specific requirements can extend time-to-market and increase development expenses. Industry consortia like the Energy Harvesting Network and the EnOcean Alliance are working to streamline certification processes and develop unified testing protocols to reduce these barriers.

Looking forward, the evolution of regulatory frameworks will need to keep pace with rapid technological advancements in the field. Emerging technologies such as nanogenerators and hybrid energy harvesting systems will require updated standards that address their unique characteristics and applications, ensuring both innovation and safety in this rapidly evolving technological landscape.

The regulatory landscape for micro energy harvesters varies significantly across regions, with major markets such as the European Union, North America, and Asia-Pacific each maintaining distinct certification processes. In the EU, compliance with the Radio Equipment Directive (RED), Electromagnetic Compatibility (EMC) Directive, and RoHS (Restriction of Hazardous Substances) is mandatory for market access. North American markets require FCC certification for wireless energy harvesting devices and UL safety certifications, while Asian markets have their own regional standards bodies.

Industry-specific regulations further complicate the compliance landscape. Medical applications of energy harvesting technology must adhere to stringent FDA requirements in the US and equivalent medical device regulations elsewhere. Aerospace and automotive implementations face additional certification hurdles through standards like DO-160 for airborne equipment or ISO 26262 for automotive functional safety.

Testing protocols for micro energy harvesters present unique challenges due to their small form factors and variable energy outputs. Standard testing methodologies must account for performance under diverse environmental conditions, including temperature fluctuations, humidity variations, and mechanical stress. The development of specialized testing equipment and procedures specifically designed for micro-scale energy harvesting devices remains an ongoing challenge for certification bodies.

Harmonization efforts between international standards organizations such as IEEE, IEC, and ISO have begun addressing the fragmentation in certification requirements. The IEEE P1789 working group has been developing standards specifically for energy harvesting devices, while IEC Technical Committee 120 focuses on standardizing electrical energy storage systems that often interface with harvesting technologies.

Certification costs represent a significant barrier to market entry, particularly for startups and small manufacturers. The complex web of regional and application-specific requirements can extend time-to-market and increase development expenses. Industry consortia like the Energy Harvesting Network and the EnOcean Alliance are working to streamline certification processes and develop unified testing protocols to reduce these barriers.

Looking forward, the evolution of regulatory frameworks will need to keep pace with rapid technological advancements in the field. Emerging technologies such as nanogenerators and hybrid energy harvesting systems will require updated standards that address their unique characteristics and applications, ensuring both innovation and safety in this rapidly evolving technological landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!