How Do Environmental Conditions Affect Micro Energy Harvester Efficacy

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Background and Objectives

Micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. This technology focuses on capturing small amounts of energy from ambient environmental sources such as vibration, thermal gradients, light, and electromagnetic radiation, converting them into usable electrical power. The evolution of this field has been driven by advances in materials science, particularly piezoelectric materials, thermoelectric generators, and photovoltaic cells optimized for low-light conditions.

The trajectory of micro energy harvesting development shows a clear trend toward increased efficiency, miniaturization, and integration with other technologies. Early systems in the 2000s demonstrated proof-of-concept with limited power outputs in the microwatt range, while contemporary systems can achieve milliwatt outputs under optimal conditions, representing orders of magnitude improvement in energy density and conversion efficiency.

Environmental conditions play a crucial role in determining the efficacy of micro energy harvesters, creating both opportunities and challenges for implementation. Temperature fluctuations, humidity levels, light intensity, mechanical vibration frequencies, and electromagnetic field strengths all significantly impact harvester performance. Understanding these environmental dependencies is essential for designing robust energy harvesting systems that can operate reliably across diverse deployment scenarios.

The primary technical objective in this field is to develop micro energy harvesters that maintain consistent performance across varying environmental conditions while maximizing energy conversion efficiency. This includes creating adaptive systems that can automatically optimize their operation based on changing environmental parameters, as well as hybrid harvesters that can leverage multiple energy sources simultaneously to ensure continuous power generation regardless of environmental fluctuations.

Another key objective is to bridge the gap between laboratory performance and real-world application. Many micro energy harvesting technologies demonstrate promising results under controlled conditions but fail to deliver comparable performance when subjected to the unpredictable and often harsh conditions of actual deployment environments. Addressing this challenge requires comprehensive characterization of environmental effects on harvester performance and the development of mitigation strategies.

Long-term reliability represents another critical goal, as micro energy harvesters are often intended for deployment in remote or inaccessible locations where maintenance is impractical. Environmental factors such as temperature cycling, moisture exposure, and UV radiation can degrade harvester components over time, necessitating robust design approaches and protective measures to ensure sustained operation throughout the intended service life.

The ultimate aim of micro energy harvesting technology is to enable truly autonomous, maintenance-free operation of low-power electronic devices, particularly in Internet of Things (IoT) applications, remote sensing networks, and medical implants. Achieving this vision requires continued innovation in understanding and addressing the complex interplay between environmental conditions and harvester performance.

The trajectory of micro energy harvesting development shows a clear trend toward increased efficiency, miniaturization, and integration with other technologies. Early systems in the 2000s demonstrated proof-of-concept with limited power outputs in the microwatt range, while contemporary systems can achieve milliwatt outputs under optimal conditions, representing orders of magnitude improvement in energy density and conversion efficiency.

Environmental conditions play a crucial role in determining the efficacy of micro energy harvesters, creating both opportunities and challenges for implementation. Temperature fluctuations, humidity levels, light intensity, mechanical vibration frequencies, and electromagnetic field strengths all significantly impact harvester performance. Understanding these environmental dependencies is essential for designing robust energy harvesting systems that can operate reliably across diverse deployment scenarios.

The primary technical objective in this field is to develop micro energy harvesters that maintain consistent performance across varying environmental conditions while maximizing energy conversion efficiency. This includes creating adaptive systems that can automatically optimize their operation based on changing environmental parameters, as well as hybrid harvesters that can leverage multiple energy sources simultaneously to ensure continuous power generation regardless of environmental fluctuations.

Another key objective is to bridge the gap between laboratory performance and real-world application. Many micro energy harvesting technologies demonstrate promising results under controlled conditions but fail to deliver comparable performance when subjected to the unpredictable and often harsh conditions of actual deployment environments. Addressing this challenge requires comprehensive characterization of environmental effects on harvester performance and the development of mitigation strategies.

Long-term reliability represents another critical goal, as micro energy harvesters are often intended for deployment in remote or inaccessible locations where maintenance is impractical. Environmental factors such as temperature cycling, moisture exposure, and UV radiation can degrade harvester components over time, necessitating robust design approaches and protective measures to ensure sustained operation throughout the intended service life.

The ultimate aim of micro energy harvesting technology is to enable truly autonomous, maintenance-free operation of low-power electronic devices, particularly in Internet of Things (IoT) applications, remote sensing networks, and medical implants. Achieving this vision requires continued innovation in understanding and addressing the complex interplay between environmental conditions and harvester performance.

Market Analysis for Environmental Energy Harvesting Solutions

The global market for environmental energy harvesting solutions is experiencing robust growth, driven by increasing demand for sustainable power sources in IoT applications, wireless sensor networks, and remote monitoring systems. Current market valuations place this sector at approximately $600 million in 2023, with projections indicating a compound annual growth rate of 10-12% through 2030, potentially reaching $1.4 billion by the end of the decade.

Micro energy harvesters that convert ambient environmental energy into usable electricity are gaining significant traction across multiple industries. The industrial sector represents the largest market segment, accounting for roughly 35% of current demand, followed by consumer electronics (25%), building automation (20%), and healthcare applications (15%). This distribution reflects the diverse utility of these technologies across various operational contexts.

Regional analysis reveals that North America and Europe currently lead market adoption, collectively representing about 60% of global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at approximately 14% annually, driven by rapid industrialization, smart city initiatives, and increasing IoT deployment in countries like China, Japan, and South Korea.

Customer segmentation shows distinct market requirements based on application environments. Industrial applications prioritize durability and reliability under harsh conditions, while consumer electronics manufacturers emphasize miniaturization and aesthetic integration. The healthcare sector demands ultra-reliable performance and biocompatibility, creating specialized market niches with premium pricing potential.

Market dynamics are increasingly influenced by environmental variability concerns. End-users are showing strong preference for harvesting solutions that maintain consistent performance across fluctuating conditions, with 78% of procurement specialists citing environmental adaptability as a "critical" or "very important" selection criterion in recent industry surveys.

Pricing trends indicate a gradual decrease in cost-per-milliwatt metrics, with average prices declining by 8% annually as manufacturing scales and technologies mature. However, solutions offering superior environmental adaptability command premium pricing, typically 15-20% above market averages, highlighting the economic value of performance stability across varying conditions.

Market forecasts suggest particularly strong growth in hybrid harvesting systems that combine multiple energy sources (solar, thermal, vibration, etc.) to mitigate environmental variability. This segment is expected to grow at 18% annually, outpacing single-source harvesting technologies and potentially representing 40% of the total market by 2028.

Micro energy harvesters that convert ambient environmental energy into usable electricity are gaining significant traction across multiple industries. The industrial sector represents the largest market segment, accounting for roughly 35% of current demand, followed by consumer electronics (25%), building automation (20%), and healthcare applications (15%). This distribution reflects the diverse utility of these technologies across various operational contexts.

Regional analysis reveals that North America and Europe currently lead market adoption, collectively representing about 60% of global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at approximately 14% annually, driven by rapid industrialization, smart city initiatives, and increasing IoT deployment in countries like China, Japan, and South Korea.

Customer segmentation shows distinct market requirements based on application environments. Industrial applications prioritize durability and reliability under harsh conditions, while consumer electronics manufacturers emphasize miniaturization and aesthetic integration. The healthcare sector demands ultra-reliable performance and biocompatibility, creating specialized market niches with premium pricing potential.

Market dynamics are increasingly influenced by environmental variability concerns. End-users are showing strong preference for harvesting solutions that maintain consistent performance across fluctuating conditions, with 78% of procurement specialists citing environmental adaptability as a "critical" or "very important" selection criterion in recent industry surveys.

Pricing trends indicate a gradual decrease in cost-per-milliwatt metrics, with average prices declining by 8% annually as manufacturing scales and technologies mature. However, solutions offering superior environmental adaptability command premium pricing, typically 15-20% above market averages, highlighting the economic value of performance stability across varying conditions.

Market forecasts suggest particularly strong growth in hybrid harvesting systems that combine multiple energy sources (solar, thermal, vibration, etc.) to mitigate environmental variability. This segment is expected to grow at 18% annually, outpacing single-source harvesting technologies and potentially representing 40% of the total market by 2028.

Environmental Challenges in Micro Energy Harvesting

Micro energy harvesting systems face significant challenges when deployed in real-world environments, as their performance is highly susceptible to various environmental factors. Temperature fluctuations represent one of the most critical challenges, affecting both the mechanical properties of harvester materials and the efficiency of energy conversion processes. In extreme cold, materials may become brittle and less responsive to mechanical stimulation, while excessive heat can lead to thermal expansion, structural deformation, and accelerated degradation of sensitive components.

Humidity and moisture present another substantial obstacle, particularly for piezoelectric and electromagnetic harvesters. High humidity environments can cause corrosion of metallic components, short circuits in electrical pathways, and degradation of insulating materials. For systems deployed outdoors or in industrial settings, water ingress can completely compromise functionality, necessitating robust waterproofing solutions that often add bulk and complexity to micro-scale designs.

Mechanical stressors such as vibration, shock, and physical impact pose significant reliability challenges. While some harvesters are specifically designed to capture vibrational energy, unpredictable or excessive mechanical forces can lead to structural fatigue, misalignment of components, and premature failure. The miniature scale of these devices makes them particularly vulnerable to mechanical damage that might be inconsequential for larger systems.

Electromagnetic interference (EMI) and radiation exposure represent less visible but equally important environmental challenges. In urban or industrial settings, ambient electromagnetic fields can disrupt the operation of electromagnetic harvesters or interfere with the electronic components that process harvested energy. Similarly, UV radiation can degrade polymers and other materials commonly used in flexible harvesters, reducing their operational lifespan.

Particulate contamination, including dust, pollen, and industrial pollutants, can physically obstruct moving parts in kinetic harvesters or create insulating layers on thermal harvesters, dramatically reducing their efficiency. In agricultural or industrial applications, chemical exposure presents additional challenges, as corrosive substances can attack materials and compromise structural integrity.

The variability and unpredictability of environmental conditions further complicate the design of robust micro energy harvesters. Systems must be engineered to withstand not just steady-state environmental conditions but also rapid transitions and extreme events. This necessitates sophisticated environmental sensing, adaptive operation modes, and protective mechanisms that can respond to changing conditions while maintaining energy harvesting functionality.

Humidity and moisture present another substantial obstacle, particularly for piezoelectric and electromagnetic harvesters. High humidity environments can cause corrosion of metallic components, short circuits in electrical pathways, and degradation of insulating materials. For systems deployed outdoors or in industrial settings, water ingress can completely compromise functionality, necessitating robust waterproofing solutions that often add bulk and complexity to micro-scale designs.

Mechanical stressors such as vibration, shock, and physical impact pose significant reliability challenges. While some harvesters are specifically designed to capture vibrational energy, unpredictable or excessive mechanical forces can lead to structural fatigue, misalignment of components, and premature failure. The miniature scale of these devices makes them particularly vulnerable to mechanical damage that might be inconsequential for larger systems.

Electromagnetic interference (EMI) and radiation exposure represent less visible but equally important environmental challenges. In urban or industrial settings, ambient electromagnetic fields can disrupt the operation of electromagnetic harvesters or interfere with the electronic components that process harvested energy. Similarly, UV radiation can degrade polymers and other materials commonly used in flexible harvesters, reducing their operational lifespan.

Particulate contamination, including dust, pollen, and industrial pollutants, can physically obstruct moving parts in kinetic harvesters or create insulating layers on thermal harvesters, dramatically reducing their efficiency. In agricultural or industrial applications, chemical exposure presents additional challenges, as corrosive substances can attack materials and compromise structural integrity.

The variability and unpredictability of environmental conditions further complicate the design of robust micro energy harvesters. Systems must be engineered to withstand not just steady-state environmental conditions but also rapid transitions and extreme events. This necessitates sophisticated environmental sensing, adaptive operation modes, and protective mechanisms that can respond to changing conditions while maintaining energy harvesting functionality.

Current Environmental Adaptation Techniques

01 Piezoelectric energy harvesting technologies

Piezoelectric materials convert mechanical stress into electrical energy, making them effective for micro energy harvesting. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Advanced piezoelectric harvesters incorporate optimized geometries, composite materials, and resonance-matching techniques to maximize energy conversion efficiency. These technologies are particularly useful in wearable devices, infrastructure monitoring, and automotive applications.- Piezoelectric energy harvesting technologies: Piezoelectric materials convert mechanical stress into electrical energy, making them effective for micro energy harvesting applications. These systems can capture energy from vibrations, movements, and pressure changes in the environment. Advanced piezoelectric harvesters incorporate optimized geometries, composite materials, and resonance-matching techniques to maximize power output even from low-amplitude vibrations. These technologies are particularly useful in wearable devices, infrastructure monitoring, and autonomous sensor networks.

- Electromagnetic micro energy harvesting systems: Electromagnetic energy harvesters generate electricity through relative motion between magnets and coils based on Faraday's law of induction. These systems are designed to capture kinetic energy from various sources including human movement, machinery vibrations, and environmental oscillations. Recent advancements include miniaturized architectures, improved magnetic circuits, and low-friction mechanisms that enhance conversion efficiency. These harvesters can provide sustainable power for IoT devices, medical implants, and remote sensing applications.

- Thermal energy harvesting techniques: Thermal energy harvesters utilize temperature differentials to generate electrical power through thermoelectric effects. These systems can extract energy from waste heat, body heat, or environmental temperature gradients. Innovations in thermoelectric materials, thermal interface design, and heat flow management have significantly improved conversion efficiency. Micro-scale thermal harvesters are particularly valuable for powering wearable electronics, industrial sensors, and autonomous monitoring systems in environments with reliable temperature differences.

- Hybrid and multi-modal energy harvesting approaches: Hybrid energy harvesting systems combine multiple conversion mechanisms to maximize power generation across varying environmental conditions. These integrated approaches might combine piezoelectric, electromagnetic, thermoelectric, or photovoltaic technologies within a single device. Advanced power management circuits enable efficient energy capture from diverse and intermittent sources. This multi-modal approach improves reliability and overall energy yield, making these systems particularly effective for applications requiring continuous operation in changing environments.

- Energy harvesting efficiency enhancement methods: Various techniques can significantly improve the efficiency of micro energy harvesters. These include advanced circuit designs for impedance matching, sophisticated power conditioning systems, energy storage integration, and adaptive harvesting algorithms. Structural optimizations such as resonance tuning mechanisms and mechanical amplification designs can increase energy capture from low-intensity sources. Additionally, novel materials and nanoscale engineering approaches are being employed to overcome traditional efficiency limitations in micro-scale energy conversion systems.

02 Electromagnetic and inductive harvesting methods

Electromagnetic energy harvesters generate electricity through relative motion between magnets and coils based on Faraday's law of induction. These systems can be miniaturized for micro-scale applications while maintaining reasonable efficiency. Design innovations include multi-axis harvesters, frequency up-conversion mechanisms, and hybrid systems that combine electromagnetic principles with other harvesting methods. These technologies are effective for harvesting energy from low-frequency vibrations and movements in various environments.Expand Specific Solutions03 Thermal energy harvesting solutions

Thermal energy harvesters utilize temperature differentials to generate electricity through thermoelectric effects. Micro-scale thermal harvesters employ advanced materials with high Seebeck coefficients and optimized thermal management to improve conversion efficiency. These systems can harvest waste heat from industrial processes, body heat for wearable devices, or ambient temperature variations. Recent innovations include flexible thermoelectric generators and multi-stage systems that can operate with smaller temperature gradients.Expand Specific Solutions04 Solar and photovoltaic micro harvesting

Micro-scale solar energy harvesters utilize photovoltaic cells optimized for specific light conditions and form factors. These systems incorporate advanced materials like perovskites, organic semiconductors, or multi-junction cells to improve efficiency in low-light or indoor environments. Innovations include transparent solar cells, flexible photovoltaic films, and integrated energy storage solutions. These technologies are particularly valuable for self-powered sensors, IoT devices, and portable electronics that require sustainable power sources.Expand Specific Solutions05 Hybrid and multi-source energy harvesting systems

Hybrid energy harvesters combine multiple harvesting technologies to overcome the limitations of single-source systems and provide more consistent power output. These integrated systems may combine piezoelectric, solar, thermal, and electromagnetic harvesting methods with intelligent power management circuits. Advanced designs incorporate adaptive harvesting strategies that can switch between energy sources based on availability and demand. These hybrid approaches significantly improve overall system efficiency and reliability for powering autonomous sensors and IoT devices.Expand Specific Solutions

Leading Companies and Research Institutions in Energy Harvesting

The micro energy harvesting market is in a growth phase, with increasing demand driven by IoT applications and sustainable energy needs. Environmental conditions significantly impact harvester efficacy, creating a competitive landscape where technical differentiation is crucial. Major players like Robert Bosch GmbH, Qualcomm, and Intel are investing in adaptive harvesting technologies that can function across variable environments. Academic institutions including MIT, Yale, and Zhejiang University are advancing fundamental research on environmental resilience. The market is characterized by collaboration between commercial entities (TSMC, Lockheed Martin) and research organizations to develop harvesters that maintain efficiency despite temperature fluctuations, humidity variations, and mechanical stress. Technology maturity varies significantly across harvesting methods, with piezoelectric and thermal solutions being more environmentally robust than emerging photovoltaic micro-harvesters.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced micro energy harvesting systems that adapt to varying environmental conditions through multi-source integration. Their technology combines piezoelectric, thermoelectric, and photovoltaic harvesting methods within a single system architecture. This adaptive approach allows for continuous energy generation across fluctuating environments. Their proprietary MEMS-based harvesters feature self-tuning resonant frequencies that automatically adjust to ambient vibration patterns, maintaining optimal energy capture efficiency despite environmental variations. Bosch's systems incorporate environmental sensing and machine learning algorithms that predict condition changes and preemptively adjust harvester parameters. Their energy management circuits include dynamic impedance matching that continuously optimizes power transfer efficiency based on real-time environmental inputs.

Strengths: Industry-leading integration of multiple harvesting technologies provides resilience against environmental variability. Advanced adaptive algorithms enable superior performance in unpredictable conditions. Weaknesses: Higher system complexity increases manufacturing costs and potential failure points. Requires more sophisticated control systems that consume additional power.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed environmentally adaptive micro energy harvesting technology primarily focused on powering wireless communication devices in variable conditions. Their approach integrates RF energy harvesting with other modalities to create resilient power sources for IoT and mobile applications. Qualcomm's systems feature specialized antenna designs that maintain harvesting efficiency across varying signal strengths and environmental conditions. Their technology incorporates adaptive impedance matching circuits that continuously optimize energy transfer despite changing environmental parameters. Qualcomm has implemented machine learning algorithms that analyze environmental patterns and adjust harvester configurations to maximize energy capture. Their micro harvesters include multi-modal sensing capabilities that detect environmental changes and trigger appropriate system responses. Qualcomm's energy management systems dynamically allocate harvested power based on environmental conditions and application requirements.

Strengths: Exceptional expertise in wireless communications enables superior RF harvesting performance. Strong integration with communication systems provides optimized end-to-end solutions. Weaknesses: Primary focus on communication applications may limit optimization for other use cases. RF harvesting effectiveness highly dependent on ambient signal availability, which varies significantly across environments.

Key Patents and Research on Environmental Resilience

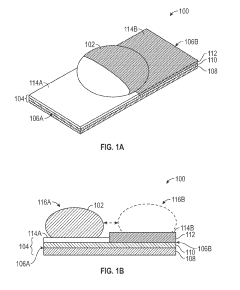

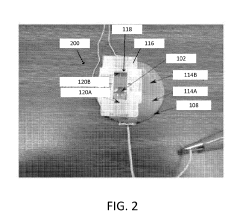

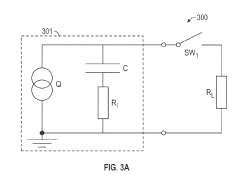

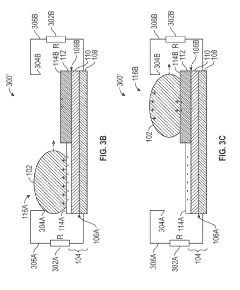

Ambient energy harvesting device with charge-carrying movable electrode

PatentActiveUS20190280621A1

Innovation

- The system employs an electrically conductive movable electrode that moves between dielectric interface regions with differing surface charge densities, creating varying capacitances and allowing for efficient energy accumulation and harvesting by closing conductive paths with a reference electrode, independent of frequency or kinetic energy.

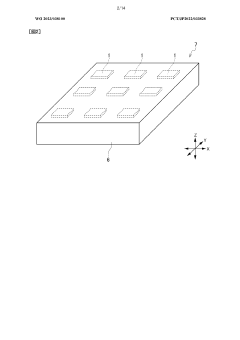

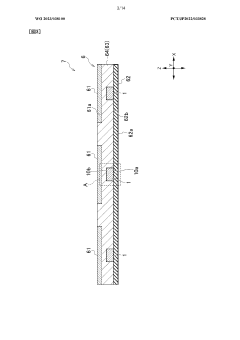

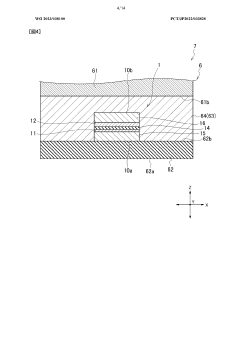

Environmental power generation device and environmental power generation system

PatentWO2023038100A1

Innovation

- An energy harvesting device that integrates a thermoelectric element without a temperature difference requirement, featuring a pair of electrodes with different work functions, an insulating part, and a heat conduction part, allowing direct heat transfer from the solar panel, and utilizing a sealant and heat storage sections to enhance power generation.

Environmental Impact Assessment

Environmental conditions play a crucial role in determining the efficacy and reliability of micro energy harvesting systems. These miniature power generation technologies operate at the intersection of multiple physical domains, making them particularly susceptible to environmental variations. Temperature fluctuations significantly impact the performance of thermoelectric generators, with efficiency typically decreasing at extreme temperatures due to material property changes and thermal stress effects. For piezoelectric harvesters, temperature variations alter crystal properties and mechanical characteristics, affecting their voltage output and conversion efficiency.

Humidity presents another critical environmental factor, as moisture can lead to electrical leakage paths, corrosion of sensitive components, and degradation of insulating materials. This is particularly problematic for electromagnetic and electrostatic harvesters where electrical isolation is paramount. High humidity environments may necessitate specialized encapsulation techniques to maintain long-term reliability.

Atmospheric pressure variations affect fluid-based energy harvesters and systems relying on pressure differentials. For instance, micro wind turbines and vibration-based harvesters demonstrate altered performance characteristics at different altitudes or in pressurized environments. These effects must be quantified and accounted for when designing systems for variable deployment scenarios.

Light conditions directly impact photovoltaic micro harvesters, with performance varying based on intensity, spectral composition, and incidence angle. Indoor light harvesting faces particular challenges due to lower intensity and different spectral characteristics compared to direct sunlight. Advanced materials and optical designs are being developed to optimize performance across diverse lighting conditions.

Mechanical vibration environments significantly influence vibration-based harvesters, with frequency matching between environmental vibrations and harvester resonant frequency being critical for optimal energy capture. Broadband harvesting techniques are emerging to address the challenge of unpredictable or variable vibration sources in real-world applications.

Chemical exposure represents an often overlooked environmental factor that can degrade harvester materials and components over time. Corrosive atmospheres, pollutants, and salt spray in coastal areas can accelerate aging processes and reduce operational lifespans of micro energy harvesting systems.

Electromagnetic interference from surrounding electronic systems may impact electromagnetic harvesters and sensitive electronic components within energy harvesting circuits. This necessitates appropriate shielding and circuit design considerations, particularly in densely populated electronic environments such as industrial settings or within complex electronic products.

Humidity presents another critical environmental factor, as moisture can lead to electrical leakage paths, corrosion of sensitive components, and degradation of insulating materials. This is particularly problematic for electromagnetic and electrostatic harvesters where electrical isolation is paramount. High humidity environments may necessitate specialized encapsulation techniques to maintain long-term reliability.

Atmospheric pressure variations affect fluid-based energy harvesters and systems relying on pressure differentials. For instance, micro wind turbines and vibration-based harvesters demonstrate altered performance characteristics at different altitudes or in pressurized environments. These effects must be quantified and accounted for when designing systems for variable deployment scenarios.

Light conditions directly impact photovoltaic micro harvesters, with performance varying based on intensity, spectral composition, and incidence angle. Indoor light harvesting faces particular challenges due to lower intensity and different spectral characteristics compared to direct sunlight. Advanced materials and optical designs are being developed to optimize performance across diverse lighting conditions.

Mechanical vibration environments significantly influence vibration-based harvesters, with frequency matching between environmental vibrations and harvester resonant frequency being critical for optimal energy capture. Broadband harvesting techniques are emerging to address the challenge of unpredictable or variable vibration sources in real-world applications.

Chemical exposure represents an often overlooked environmental factor that can degrade harvester materials and components over time. Corrosive atmospheres, pollutants, and salt spray in coastal areas can accelerate aging processes and reduce operational lifespans of micro energy harvesting systems.

Electromagnetic interference from surrounding electronic systems may impact electromagnetic harvesters and sensitive electronic components within energy harvesting circuits. This necessitates appropriate shielding and circuit design considerations, particularly in densely populated electronic environments such as industrial settings or within complex electronic products.

Standardization and Testing Protocols

The development of standardized testing protocols for micro energy harvesters represents a critical challenge in the field, as environmental conditions significantly impact device performance. Currently, the industry lacks universally accepted standards for evaluating harvester efficacy across varying environmental conditions, making it difficult to compare technologies and establish reliable performance benchmarks. Organizations such as IEEE, IEC, and ASTM have begun developing preliminary standards, but these efforts remain fragmented and incomplete.

A comprehensive standardization framework must address multiple environmental parameters simultaneously. Temperature testing protocols should evaluate performance across operational ranges (-40°C to 125°C for industrial applications), with particular attention to thermal cycling effects on material degradation and efficiency changes. Humidity testing requires controlled chambers capable of maintaining 0-100% relative humidity while monitoring performance degradation, especially for piezoelectric and triboelectric harvesters susceptible to moisture damage.

Vibration characterization demands precise acceleration measurement across frequency ranges (typically 1-200 Hz for ambient vibration harvesters), with standardized input profiles representing real-world conditions. For solar and thermal harvesters, light intensity and temperature gradient protocols must specify measurement conditions, including standardized artificial light sources that accurately simulate natural lighting spectra.

Testing duration represents another critical consideration, with short-term characterization insufficient for predicting long-term reliability. Accelerated aging protocols must be developed to simulate years of environmental exposure within reasonable testing timeframes, incorporating combined stressors that reflect real-world deployment conditions.

Data reporting formats require standardization to facilitate meaningful comparison between different harvester technologies. Minimum reporting requirements should include efficiency metrics under standardized conditions, operational range limits, degradation rates, and statistical reliability data. The development of standardized reference harvesters would provide calibration benchmarks against which new technologies could be evaluated.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish globally recognized testing protocols. Recent initiatives like the European Commission's "Harvest-All" program and the International Energy Harvesting Standardization Consortium represent promising steps toward unified standards, though significant work remains to achieve comprehensive testing frameworks applicable across diverse environmental conditions and harvester technologies.

A comprehensive standardization framework must address multiple environmental parameters simultaneously. Temperature testing protocols should evaluate performance across operational ranges (-40°C to 125°C for industrial applications), with particular attention to thermal cycling effects on material degradation and efficiency changes. Humidity testing requires controlled chambers capable of maintaining 0-100% relative humidity while monitoring performance degradation, especially for piezoelectric and triboelectric harvesters susceptible to moisture damage.

Vibration characterization demands precise acceleration measurement across frequency ranges (typically 1-200 Hz for ambient vibration harvesters), with standardized input profiles representing real-world conditions. For solar and thermal harvesters, light intensity and temperature gradient protocols must specify measurement conditions, including standardized artificial light sources that accurately simulate natural lighting spectra.

Testing duration represents another critical consideration, with short-term characterization insufficient for predicting long-term reliability. Accelerated aging protocols must be developed to simulate years of environmental exposure within reasonable testing timeframes, incorporating combined stressors that reflect real-world deployment conditions.

Data reporting formats require standardization to facilitate meaningful comparison between different harvester technologies. Minimum reporting requirements should include efficiency metrics under standardized conditions, operational range limits, degradation rates, and statistical reliability data. The development of standardized reference harvesters would provide calibration benchmarks against which new technologies could be evaluated.

International collaboration between academic institutions, industry stakeholders, and standards organizations is essential to establish globally recognized testing protocols. Recent initiatives like the European Commission's "Harvest-All" program and the International Energy Harvesting Standardization Consortium represent promising steps toward unified standards, though significant work remains to achieve comprehensive testing frameworks applicable across diverse environmental conditions and harvester technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!