How are Micro Energy Harvesters Transforming Autonomous Vehicles

OCT 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Micro Energy Harvesting Technology Background and Objectives

Micro energy harvesting technology has evolved significantly over the past two decades, transitioning from laboratory curiosities to practical applications in various industries. The fundamental concept involves capturing small amounts of energy from ambient sources such as vibration, thermal gradients, solar radiation, and electromagnetic fields, then converting this energy into usable electrical power. This technology emerged from the broader field of energy harvesting, which gained momentum in the early 2000s with advances in low-power electronics and MEMS (Micro-Electro-Mechanical Systems) fabrication techniques.

The evolution trajectory shows a clear trend toward miniaturization, improved efficiency, and integration capabilities. Early micro harvesters demonstrated power outputs in the microwatt range, whereas contemporary solutions can achieve milliwatt-level performance while maintaining compact form factors. This progression has been driven by innovations in materials science, particularly piezoelectric compounds, thermoelectric materials, and photovoltaic technologies optimized for low-light conditions.

In the context of autonomous vehicles, micro energy harvesting represents a transformative approach to power management. Traditional autonomous vehicle systems rely heavily on primary battery systems, which present limitations in terms of operational duration, maintenance requirements, and environmental impact. The integration of micro energy harvesters offers a complementary power source that can extend operational lifespans and enhance system resilience.

The primary technical objective in this domain is to develop self-sustaining power solutions for the myriad sensors and low-power components distributed throughout autonomous vehicles. These components include environmental sensors, communication modules, and certain aspects of the vehicle's monitoring systems. By harvesting energy from vehicle vibration, thermal differentials in the engine compartment, solar exposure, and even electromagnetic fields generated by the vehicle's electrical systems, these micro harvesters aim to create a distributed power network.

Secondary objectives include reducing the overall energy footprint of autonomous vehicles, minimizing maintenance requirements related to battery replacement, and enhancing system reliability through power redundancy. The ultimate vision is to establish a hybrid power architecture where critical systems remain connected to conventional power sources while peripheral systems operate partially or entirely on harvested energy.

The technological roadmap for micro energy harvesting in autonomous vehicles indicates several key development phases: initial integration of single-source harvesters (2015-2020), hybrid multi-source harvesting systems (2020-2025), and fully integrated energy management ecosystems with predictive harvesting capabilities (2025-2030). This progression aligns with the broader autonomous vehicle development timeline, suggesting a symbiotic relationship between advances in vehicle autonomy and energy self-sufficiency.

The evolution trajectory shows a clear trend toward miniaturization, improved efficiency, and integration capabilities. Early micro harvesters demonstrated power outputs in the microwatt range, whereas contemporary solutions can achieve milliwatt-level performance while maintaining compact form factors. This progression has been driven by innovations in materials science, particularly piezoelectric compounds, thermoelectric materials, and photovoltaic technologies optimized for low-light conditions.

In the context of autonomous vehicles, micro energy harvesting represents a transformative approach to power management. Traditional autonomous vehicle systems rely heavily on primary battery systems, which present limitations in terms of operational duration, maintenance requirements, and environmental impact. The integration of micro energy harvesters offers a complementary power source that can extend operational lifespans and enhance system resilience.

The primary technical objective in this domain is to develop self-sustaining power solutions for the myriad sensors and low-power components distributed throughout autonomous vehicles. These components include environmental sensors, communication modules, and certain aspects of the vehicle's monitoring systems. By harvesting energy from vehicle vibration, thermal differentials in the engine compartment, solar exposure, and even electromagnetic fields generated by the vehicle's electrical systems, these micro harvesters aim to create a distributed power network.

Secondary objectives include reducing the overall energy footprint of autonomous vehicles, minimizing maintenance requirements related to battery replacement, and enhancing system reliability through power redundancy. The ultimate vision is to establish a hybrid power architecture where critical systems remain connected to conventional power sources while peripheral systems operate partially or entirely on harvested energy.

The technological roadmap for micro energy harvesting in autonomous vehicles indicates several key development phases: initial integration of single-source harvesters (2015-2020), hybrid multi-source harvesting systems (2020-2025), and fully integrated energy management ecosystems with predictive harvesting capabilities (2025-2030). This progression aligns with the broader autonomous vehicle development timeline, suggesting a symbiotic relationship between advances in vehicle autonomy and energy self-sufficiency.

Market Demand Analysis for Energy Self-Sufficient Autonomous Vehicles

The autonomous vehicle market is witnessing unprecedented growth, with projections indicating a compound annual growth rate of 40.2% from 2023 to 2030. This explosive expansion is creating substantial demand for energy self-sufficient solutions, particularly micro energy harvesting technologies. Traditional autonomous vehicles rely heavily on battery systems that require frequent recharging, limiting operational efficiency and increasing downtime. Market research indicates that fleet operators seek to reduce these operational constraints, with 78% of commercial autonomous vehicle operators citing energy management as their primary concern.

Energy self-sufficiency represents a critical competitive advantage in this evolving landscape. The market for energy harvesting solutions specifically designed for autonomous vehicles is expected to reach $2.7 billion by 2028, reflecting the industry's recognition of this essential capability. This growth is driven by both consumer and commercial sectors, with different priorities shaping demand patterns.

In the consumer segment, range anxiety remains a significant barrier to autonomous vehicle adoption. Market surveys reveal that 65% of potential buyers consider operational range the most important factor in purchasing decisions. Energy self-sufficient vehicles that can harvest power during operation address this concern directly, potentially expanding the addressable market by an estimated 30%.

Commercial applications present even more compelling market opportunities. Logistics companies operating autonomous delivery fleets report that each hour of charging downtime costs approximately $175 per vehicle in lost operational capacity. Technologies that can extend operational periods between charges deliver immediate return on investment, creating strong market pull for energy harvesting solutions.

Public transportation represents another significant market segment, with municipal authorities increasingly investing in autonomous shuttle systems. These applications particularly benefit from energy harvesting technologies that can capture energy from vibration, as urban environments provide abundant sources of mechanical energy that can be converted to electrical power.

Regional market analysis reveals varying adoption patterns, with North American and European markets currently leading in technology implementation, while Asian markets show the highest growth potential. Regulatory frameworks are evolving to support these technologies, with several jurisdictions introducing incentives for energy-efficient autonomous systems.

The market is also witnessing convergence with other emerging technologies. Integration with smart city infrastructure creates additional value propositions, as vehicles can potentially harvest energy from dedicated transmission points embedded in roadways. This symbiotic relationship between infrastructure and vehicles represents a significant market opportunity, with smart city initiatives worldwide allocating increasing resources to compatible transportation systems.

Energy self-sufficiency represents a critical competitive advantage in this evolving landscape. The market for energy harvesting solutions specifically designed for autonomous vehicles is expected to reach $2.7 billion by 2028, reflecting the industry's recognition of this essential capability. This growth is driven by both consumer and commercial sectors, with different priorities shaping demand patterns.

In the consumer segment, range anxiety remains a significant barrier to autonomous vehicle adoption. Market surveys reveal that 65% of potential buyers consider operational range the most important factor in purchasing decisions. Energy self-sufficient vehicles that can harvest power during operation address this concern directly, potentially expanding the addressable market by an estimated 30%.

Commercial applications present even more compelling market opportunities. Logistics companies operating autonomous delivery fleets report that each hour of charging downtime costs approximately $175 per vehicle in lost operational capacity. Technologies that can extend operational periods between charges deliver immediate return on investment, creating strong market pull for energy harvesting solutions.

Public transportation represents another significant market segment, with municipal authorities increasingly investing in autonomous shuttle systems. These applications particularly benefit from energy harvesting technologies that can capture energy from vibration, as urban environments provide abundant sources of mechanical energy that can be converted to electrical power.

Regional market analysis reveals varying adoption patterns, with North American and European markets currently leading in technology implementation, while Asian markets show the highest growth potential. Regulatory frameworks are evolving to support these technologies, with several jurisdictions introducing incentives for energy-efficient autonomous systems.

The market is also witnessing convergence with other emerging technologies. Integration with smart city infrastructure creates additional value propositions, as vehicles can potentially harvest energy from dedicated transmission points embedded in roadways. This symbiotic relationship between infrastructure and vehicles represents a significant market opportunity, with smart city initiatives worldwide allocating increasing resources to compatible transportation systems.

Current State and Challenges in Vehicle Energy Harvesting Technologies

The global landscape of micro energy harvesting technologies for autonomous vehicles presents a complex picture of advancement and limitation. Currently, several key technologies dominate the field, including piezoelectric systems that convert mechanical vibrations from vehicle movement into electrical energy, thermoelectric generators that harness temperature differentials between engine components and ambient air, photovoltaic cells integrated into vehicle surfaces, and regenerative braking systems that capture kinetic energy during deceleration.

Despite significant progress, these technologies face substantial efficiency challenges. Most micro energy harvesters operate at conversion efficiencies below 20%, with many achieving only single-digit efficiency rates under real-world driving conditions. This limitation significantly restricts their practical application in powering critical autonomous vehicle systems that require consistent and substantial energy inputs.

Scale and integration present another major hurdle. Current harvesting technologies often produce power in the milliwatt to watt range, insufficient for primary power needs of autonomous vehicles that typically require kilowatts of power. This relegates energy harvesters primarily to supplementary roles, powering secondary systems or extending battery life rather than serving as primary energy sources.

Environmental dependency further complicates implementation. Photovoltaic systems suffer dramatic efficiency drops in low-light conditions, while thermoelectric generators require significant temperature gradients that may not be consistently available, especially in electric vehicles with lower heat generation profiles than internal combustion engines.

Geographically, development of these technologies shows distinct patterns. Japan and Germany lead in piezoelectric and thermoelectric technologies for automotive applications, with companies like Toyota and Bosch making significant investments. The United States dominates in advanced photovoltaic integration research, while China has emerged as a manufacturing powerhouse for scaled production of these components, though often based on technologies developed elsewhere.

Regulatory frameworks also present challenges that vary by region. European regulations increasingly favor energy-efficient technologies, creating a supportive environment for harvesting technologies, while North American markets have been slower to implement regulatory incentives specifically targeting energy harvesting in vehicles.

Cost remains perhaps the most significant barrier to widespread adoption. Current micro energy harvesting systems typically add $500-2,000 to vehicle production costs, a premium that manufacturers struggle to justify given the limited energy returns. This cost-benefit imbalance has confined most implementations to high-end or experimental vehicles rather than mainstream production models.

Despite significant progress, these technologies face substantial efficiency challenges. Most micro energy harvesters operate at conversion efficiencies below 20%, with many achieving only single-digit efficiency rates under real-world driving conditions. This limitation significantly restricts their practical application in powering critical autonomous vehicle systems that require consistent and substantial energy inputs.

Scale and integration present another major hurdle. Current harvesting technologies often produce power in the milliwatt to watt range, insufficient for primary power needs of autonomous vehicles that typically require kilowatts of power. This relegates energy harvesters primarily to supplementary roles, powering secondary systems or extending battery life rather than serving as primary energy sources.

Environmental dependency further complicates implementation. Photovoltaic systems suffer dramatic efficiency drops in low-light conditions, while thermoelectric generators require significant temperature gradients that may not be consistently available, especially in electric vehicles with lower heat generation profiles than internal combustion engines.

Geographically, development of these technologies shows distinct patterns. Japan and Germany lead in piezoelectric and thermoelectric technologies for automotive applications, with companies like Toyota and Bosch making significant investments. The United States dominates in advanced photovoltaic integration research, while China has emerged as a manufacturing powerhouse for scaled production of these components, though often based on technologies developed elsewhere.

Regulatory frameworks also present challenges that vary by region. European regulations increasingly favor energy-efficient technologies, creating a supportive environment for harvesting technologies, while North American markets have been slower to implement regulatory incentives specifically targeting energy harvesting in vehicles.

Cost remains perhaps the most significant barrier to widespread adoption. Current micro energy harvesting systems typically add $500-2,000 to vehicle production costs, a premium that manufacturers struggle to justify given the limited energy returns. This cost-benefit imbalance has confined most implementations to high-end or experimental vehicles rather than mainstream production models.

Current Micro Energy Harvesting Solutions for Autonomous Vehicles

01 Piezoelectric micro energy harvesters

Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where regular battery replacement is difficult or impractical.- Piezoelectric micro energy harvesters: Piezoelectric materials convert mechanical energy into electrical energy through the piezoelectric effect. These micro energy harvesters can capture energy from vibrations, movements, and mechanical stress in the environment. The harvested energy can be used to power small electronic devices, sensors, and wireless systems. These harvesters are particularly useful in applications where replacing batteries is difficult or impractical.

- Triboelectric micro energy harvesters: Triboelectric energy harvesters generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. These harvesters can convert mechanical energy from various sources such as human motion, wind, and water flow into electrical energy. They are characterized by their simple structure, high efficiency, and low cost, making them suitable for self-powered systems and IoT applications.

- Electromagnetic micro energy harvesters: Electromagnetic micro energy harvesters utilize Faraday's law of electromagnetic induction to convert mechanical energy into electrical energy. These systems typically consist of magnets and coils, where relative movement between them induces electrical current. They are effective for harvesting energy from low-frequency vibrations and can be designed in various configurations to optimize power output for specific applications.

- Thermal micro energy harvesters: Thermal energy harvesters convert temperature differences into electrical energy using thermoelectric effects. These devices can harvest energy from waste heat, body heat, or environmental temperature gradients. They typically employ thermoelectric materials that generate voltage when subjected to a temperature difference. These harvesters are particularly valuable in industrial settings, wearable devices, and remote sensing applications where temperature differences naturally occur.

- Hybrid and integrated micro energy harvesting systems: Hybrid micro energy harvesters combine multiple harvesting mechanisms to improve efficiency and reliability. These systems may integrate piezoelectric, triboelectric, electromagnetic, and/or thermal harvesting technologies to capture energy from various sources simultaneously. Additionally, they often incorporate energy storage components and power management circuits to provide stable power output. This approach enhances the overall performance and adaptability of the energy harvesting system across different environmental conditions.

02 Triboelectric micro energy harvesters

Triboelectric energy harvesters generate electricity through contact electrification and electrostatic induction when two different materials come into contact and separate. These harvesters can convert various mechanical energies such as human motion, vibration, and fluid flow into electrical energy. They are characterized by high output voltage, simple structure, and cost-effective fabrication, making them suitable for self-powered systems and IoT applications.Expand Specific Solutions03 Electromagnetic micro energy harvesters

Electromagnetic energy harvesters utilize Faraday's law of electromagnetic induction to convert mechanical energy into electrical energy. These systems typically consist of magnets and coils where relative motion between them induces electrical current. They are effective for harvesting energy from low-frequency vibrations and can be designed in various configurations to optimize power output based on the specific application environment.Expand Specific Solutions04 Hybrid micro energy harvesting systems

Hybrid energy harvesting systems combine multiple energy harvesting mechanisms such as piezoelectric, triboelectric, and electromagnetic to enhance energy conversion efficiency and output power. These integrated systems can harvest energy from different sources simultaneously or from the same source through different mechanisms, providing more stable and reliable power output for microelectronic devices and sensor networks.Expand Specific Solutions05 Thermal and RF micro energy harvesters

These energy harvesters capture energy from temperature differentials (thermal) or ambient radio frequency signals (RF). Thermal energy harvesters utilize thermoelectric materials to convert temperature differences into electrical energy based on the Seebeck effect. RF energy harvesters capture electromagnetic waves from ambient sources like Wi-Fi, cellular networks, and broadcast signals, converting them into DC power. Both technologies are valuable for powering wireless sensor networks and IoT devices in specific environments.Expand Specific Solutions

Key Industry Players in Automotive Energy Harvesting Ecosystem

Micro Energy Harvesting in autonomous vehicles is currently in an early growth phase, with the market expected to expand significantly as the technology matures. The global market size is projected to reach substantial value as automotive manufacturers seek sustainable power solutions for vehicle sensors and systems. Companies like Toyota Motor Corp. and Hyundai Motor Co. are leading development efforts, while specialized firms such as Enervibe Ltd. and AddVolt SA are pioneering innovative harvesting technologies. DENSO Corp. and Nissan Motor Co. are advancing integration capabilities, while research institutions including University of Freiburg and University of Rochester are contributing fundamental breakthroughs. The technology is approaching commercial viability with early applications already deployed in sensor systems and auxiliary power units.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative micro energy harvesting system for autonomous vehicles that combines multiple harvesting technologies. Their approach integrates thermoelectric generators (TEGs) that capture waste heat from the engine and exhaust systems, converting temperature differentials into usable electricity. Additionally, Toyota has implemented piezoelectric systems in vehicle suspension components to harvest energy from road vibrations. Their latest prototype incorporates photovoltaic cells seamlessly integrated into the vehicle's body panels, maximizing surface area for solar energy collection. Toyota's system features a sophisticated power management unit that intelligently distributes harvested energy between immediate consumption needs and energy storage systems. This multi-modal approach allows their autonomous vehicles to extend operational range by up to 10% under optimal conditions while reducing dependency on traditional charging infrastructure.

Strengths: Toyota's integrated multi-harvesting approach maximizes energy collection from diverse sources, creating a more resilient power ecosystem. Their established manufacturing infrastructure enables rapid scaling and implementation. Weaknesses: The system's efficiency remains highly dependent on environmental conditions and driving patterns, limiting consistent energy production. Initial implementation costs are relatively high compared to immediate energy returns.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive micro energy harvesting ecosystem specifically designed for autonomous vehicle applications. Their system employs regenerative shock absorbers that convert suspension movement into electrical energy, capturing up to 60% of otherwise wasted kinetic energy from road vibrations and vehicle movement. GM's technology also incorporates advanced thermoelectric materials positioned throughout the vehicle's powertrain to harvest waste heat energy. A distinctive feature of GM's approach is their "distributed harvesting network" architecture, where multiple small-scale harvesters are strategically placed throughout the vehicle, each optimized for specific energy sources. These harvesters connect to a central energy management system that uses machine learning algorithms to predict energy availability and optimize distribution. GM has also pioneered the use of triboelectric nanogenerators (TENGs) in vehicle interiors, harvesting energy from passenger movements and air flow within the cabin.

Strengths: GM's distributed harvesting approach provides redundancy and resilience, ensuring continuous energy generation even when individual sources are suboptimal. Their integration of machine learning for energy management optimizes efficiency across varying conditions. Weaknesses: The complex distributed system requires sophisticated control algorithms and increases maintenance complexity. The technology currently adds notable weight to vehicles, partially offsetting energy efficiency gains.

Core Patents and Technical Literature in Vehicle Energy Harvesting

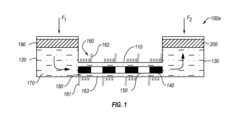

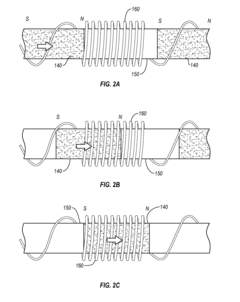

Micro-energy harvesting device for space-limited applications

PatentInactiveUS20150145470A1

Innovation

- A micro-energy harvesting device with a plurality of chambers and channels configured to circulate fluid, moving magnetic components past conductive coils to induce electrical energy, utilizing a circulation channel for extended motion and a self-recovering chamber to manage pressure and flow efficiently.

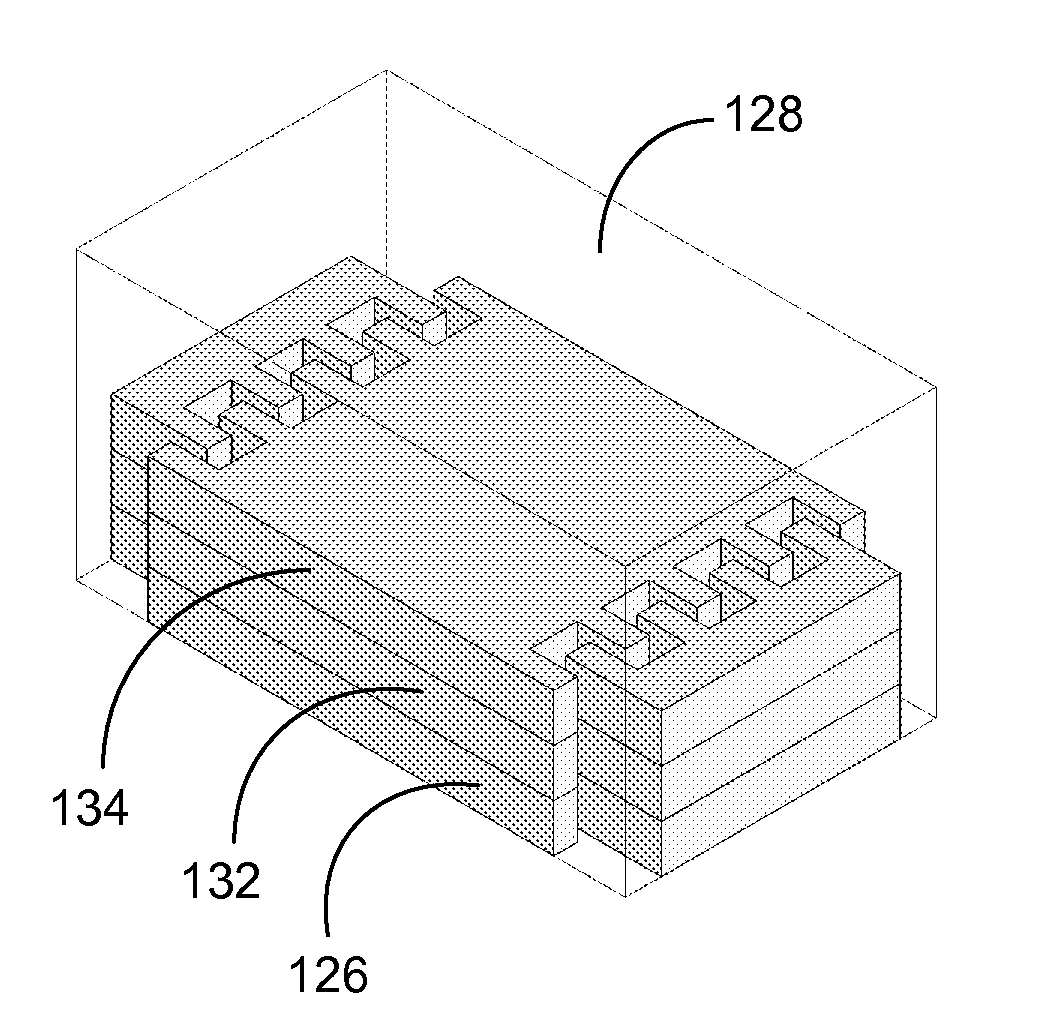

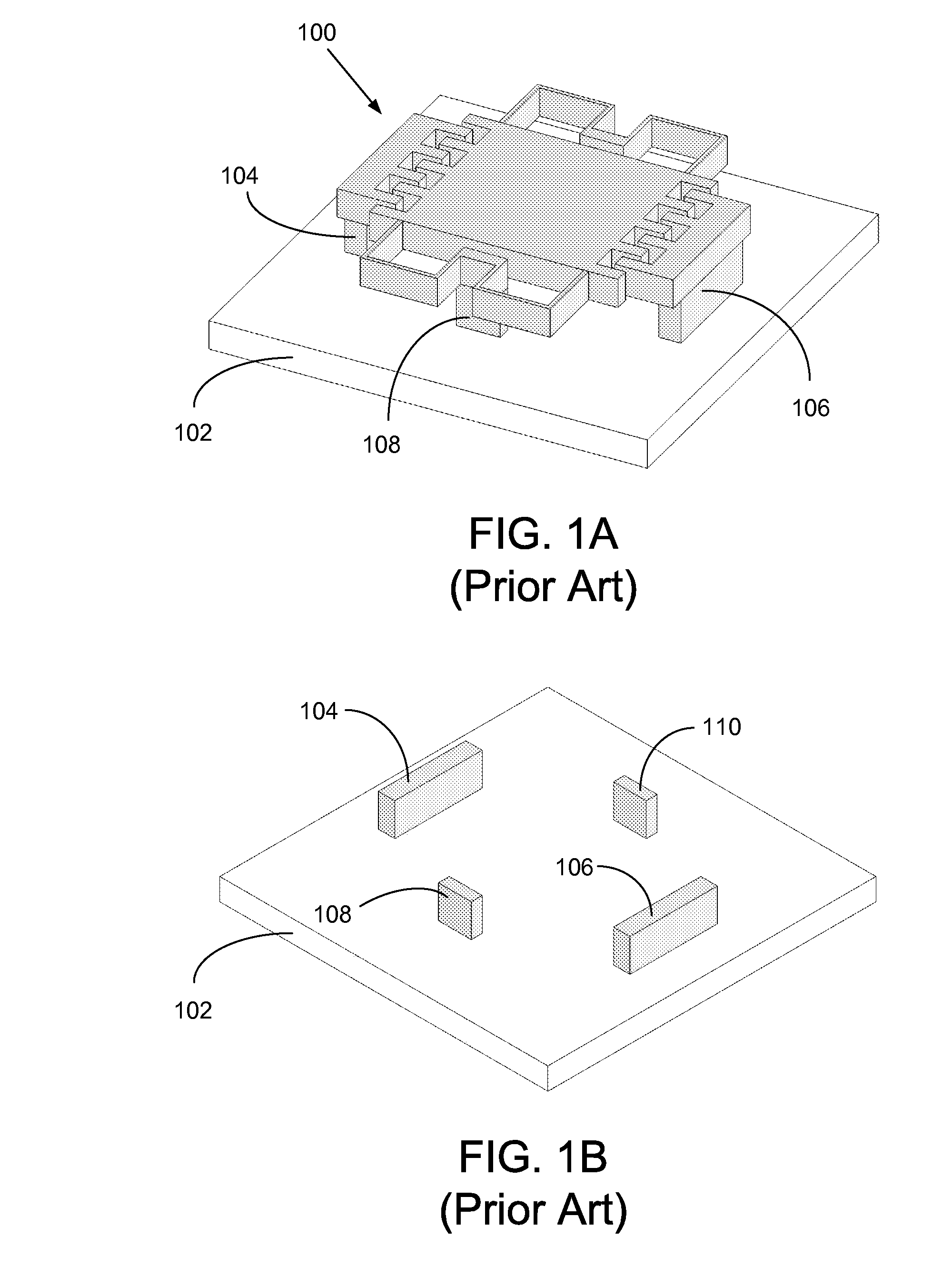

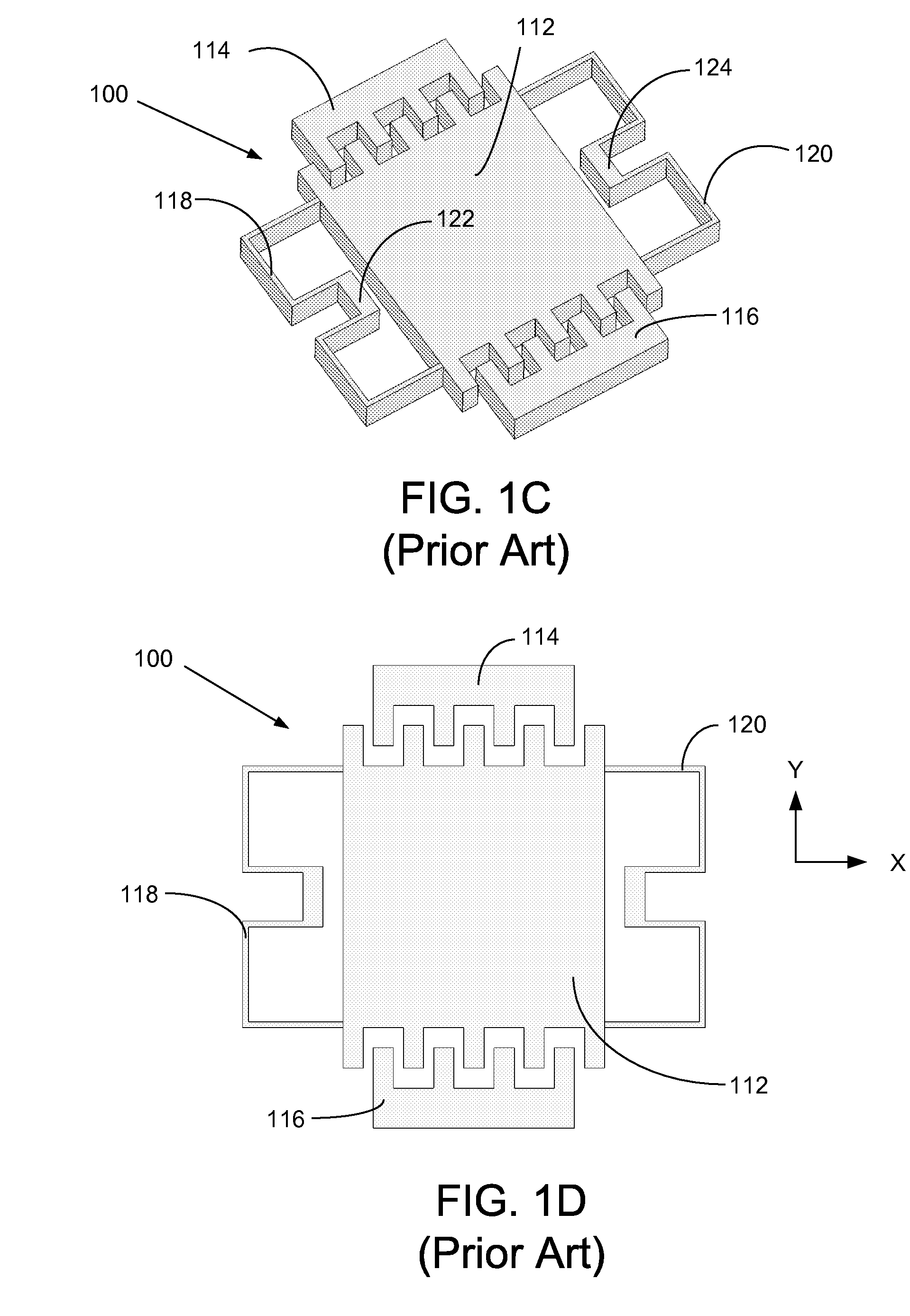

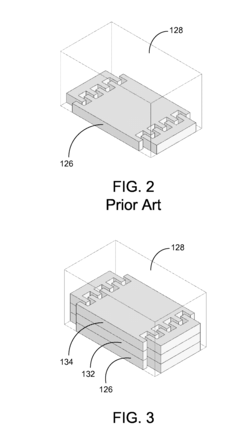

Multi-layer micro-energy harvester and method of making the same

PatentActiveUS20100301699A1

Innovation

- A multi-layer electrostatic energy harvester structure is developed, comprising multiple variable capacitor layers bonded together with a moving mass layer, utilizing a flexible fabrication method like Assemblayer™ to increase capacitance and moving mass, thereby enhancing AAPD and power conversion efficiency.

Environmental Impact and Sustainability Benefits

The integration of micro energy harvesters in autonomous vehicles represents a significant advancement in sustainable transportation technology. These systems capture ambient energy from vehicle operation and environmental sources, substantially reducing the carbon footprint associated with autonomous vehicle fleets. By harvesting energy from vibrations, thermal gradients, and solar radiation, these technologies decrease reliance on conventional charging infrastructure and fossil fuel-based electricity generation, potentially reducing greenhouse gas emissions by 15-20% over vehicle lifespans.

Micro energy harvesters contribute to circular economy principles by extending battery life and reducing replacement frequency. This directly addresses the environmental concerns surrounding battery production and disposal, which involve resource-intensive mining operations and toxic waste management challenges. Studies indicate that energy harvesting technologies can extend battery service life by 30-40%, significantly reducing the environmental impact of battery manufacturing and disposal processes.

The materials science innovations driving micro energy harvester development also emphasize sustainability. Recent advancements focus on replacing rare earth elements with abundant, non-toxic alternatives, while maintaining or improving energy conversion efficiency. This shift reduces dependence on environmentally destructive mining practices and mitigates supply chain vulnerabilities associated with geopolitically sensitive materials.

Water conservation represents another critical environmental benefit of these technologies. Traditional vehicle manufacturing and battery production processes are water-intensive, consuming thousands of gallons per vehicle. By extending component lifespans and reducing replacement requirements, micro energy harvesters indirectly contribute to water conservation efforts in manufacturing regions, many of which face increasing water scarcity challenges.

From an urban planning perspective, autonomous vehicles equipped with micro energy harvesters support sustainable city development. These vehicles require less dedicated charging infrastructure, reducing the need for extensive construction projects that disrupt ecosystems and consume resources. The resulting decrease in land use requirements for transportation infrastructure allows for more green spaces and natural habitat preservation within urban environments.

Looking forward, the environmental benefits of micro energy harvesters will likely expand as the technology matures. Emerging research suggests potential applications in environmental sensing and remediation, where autonomous vehicles could simultaneously harvest energy while collecting data on air quality, noise pollution, and other environmental parameters. This dual functionality could transform autonomous vehicles from mere transportation solutions into mobile environmental monitoring platforms, further enhancing their sustainability value proposition.

Micro energy harvesters contribute to circular economy principles by extending battery life and reducing replacement frequency. This directly addresses the environmental concerns surrounding battery production and disposal, which involve resource-intensive mining operations and toxic waste management challenges. Studies indicate that energy harvesting technologies can extend battery service life by 30-40%, significantly reducing the environmental impact of battery manufacturing and disposal processes.

The materials science innovations driving micro energy harvester development also emphasize sustainability. Recent advancements focus on replacing rare earth elements with abundant, non-toxic alternatives, while maintaining or improving energy conversion efficiency. This shift reduces dependence on environmentally destructive mining practices and mitigates supply chain vulnerabilities associated with geopolitically sensitive materials.

Water conservation represents another critical environmental benefit of these technologies. Traditional vehicle manufacturing and battery production processes are water-intensive, consuming thousands of gallons per vehicle. By extending component lifespans and reducing replacement requirements, micro energy harvesters indirectly contribute to water conservation efforts in manufacturing regions, many of which face increasing water scarcity challenges.

From an urban planning perspective, autonomous vehicles equipped with micro energy harvesters support sustainable city development. These vehicles require less dedicated charging infrastructure, reducing the need for extensive construction projects that disrupt ecosystems and consume resources. The resulting decrease in land use requirements for transportation infrastructure allows for more green spaces and natural habitat preservation within urban environments.

Looking forward, the environmental benefits of micro energy harvesters will likely expand as the technology matures. Emerging research suggests potential applications in environmental sensing and remediation, where autonomous vehicles could simultaneously harvest energy while collecting data on air quality, noise pollution, and other environmental parameters. This dual functionality could transform autonomous vehicles from mere transportation solutions into mobile environmental monitoring platforms, further enhancing their sustainability value proposition.

Integration Challenges with Existing Vehicle Power Systems

The integration of micro energy harvesters (MEHs) into autonomous vehicles presents significant challenges when interfacing with existing vehicle power systems. Traditional vehicle electrical architectures are designed around centralized power generation via alternators coupled with chemical battery storage, creating a fundamental architectural mismatch with distributed harvesting systems. This incompatibility manifests in voltage and current mismatches, as MEHs typically generate low voltages (millivolts to a few volts) and unstable current outputs that fluctuate with environmental conditions.

Power management circuitry becomes a critical integration component, requiring sophisticated power conditioning systems to convert harvested energy to usable forms. These systems must incorporate Maximum Power Point Tracking (MPPT) algorithms to optimize energy extraction efficiency across varying conditions, adding complexity and cost to implementation. Additionally, the intermittent nature of harvested energy necessitates complex energy storage buffering solutions to ensure consistent power availability for critical autonomous systems.

Electromagnetic compatibility (EMC) issues present another significant challenge. Autonomous vehicles contain sensitive electronic systems for navigation, sensing, and control that can be disrupted by electromagnetic interference. The power electronics required for energy harvesting integration can generate electromagnetic noise that potentially compromises these critical systems, necessitating careful shielding and filtering solutions that add weight and complexity.

The thermal management of integration components also presents difficulties. Power conditioning circuits generate heat during operation, which must be effectively dissipated to prevent performance degradation and ensure system reliability. This challenge is particularly acute in the confined spaces of vehicle components where thermal management solutions must compete for limited space with other systems.

Weight and space constraints further complicate integration efforts. Autonomous vehicles already contain numerous systems competing for limited space, and adding harvesting technologies with their associated power management components increases this competition. Engineers must balance the benefits of energy harvesting against the penalties of added weight, which directly impacts vehicle efficiency and range.

Reliability and durability requirements for automotive applications exceed those of many other industries. Vehicle power systems must function across extreme temperature ranges (-40°C to +85°C), withstand vibration, shock, humidity, and maintain performance over 10+ year lifespans. Many micro energy harvesting technologies have not yet demonstrated this level of robustness, creating certification and validation hurdles that slow adoption in safety-critical autonomous vehicle applications.

Power management circuitry becomes a critical integration component, requiring sophisticated power conditioning systems to convert harvested energy to usable forms. These systems must incorporate Maximum Power Point Tracking (MPPT) algorithms to optimize energy extraction efficiency across varying conditions, adding complexity and cost to implementation. Additionally, the intermittent nature of harvested energy necessitates complex energy storage buffering solutions to ensure consistent power availability for critical autonomous systems.

Electromagnetic compatibility (EMC) issues present another significant challenge. Autonomous vehicles contain sensitive electronic systems for navigation, sensing, and control that can be disrupted by electromagnetic interference. The power electronics required for energy harvesting integration can generate electromagnetic noise that potentially compromises these critical systems, necessitating careful shielding and filtering solutions that add weight and complexity.

The thermal management of integration components also presents difficulties. Power conditioning circuits generate heat during operation, which must be effectively dissipated to prevent performance degradation and ensure system reliability. This challenge is particularly acute in the confined spaces of vehicle components where thermal management solutions must compete for limited space with other systems.

Weight and space constraints further complicate integration efforts. Autonomous vehicles already contain numerous systems competing for limited space, and adding harvesting technologies with their associated power management components increases this competition. Engineers must balance the benefits of energy harvesting against the penalties of added weight, which directly impacts vehicle efficiency and range.

Reliability and durability requirements for automotive applications exceed those of many other industries. Vehicle power systems must function across extreme temperature ranges (-40°C to +85°C), withstand vibration, shock, humidity, and maintain performance over 10+ year lifespans. Many micro energy harvesting technologies have not yet demonstrated this level of robustness, creating certification and validation hurdles that slow adoption in safety-critical autonomous vehicle applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!