Exploring the Role of Polymers in Modern Micro Energy Harvesters

OCT 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer-Based Micro Energy Harvesting: Background & Objectives

Polymer-based micro energy harvesting has emerged as a transformative technology over the past two decades, evolving from theoretical concepts to practical applications across multiple industries. The integration of polymeric materials in energy harvesting systems represents a significant shift from traditional rigid, inorganic materials toward more flexible, lightweight, and cost-effective alternatives. This technological evolution has been driven by the growing demand for autonomous, self-powered microsystems in applications ranging from wearable electronics to remote sensing networks.

The historical trajectory of polymer-based energy harvesters can be traced back to the early 2000s, when researchers began exploring piezoelectric polymers such as polyvinylidene fluoride (PVDF) for mechanical energy conversion. Subsequent advancements in material science, particularly in electroactive polymers (EAPs), conductive polymers, and polymer nanocomposites, have substantially expanded the capabilities and efficiency of these systems.

Current technological trends indicate a convergence of multiple energy harvesting mechanisms within polymer-based systems, including piezoelectric, triboelectric, thermoelectric, and photovoltaic effects. This multi-modal approach aims to maximize energy capture from diverse ambient sources, addressing the inherent limitations of single-mechanism harvesters. Additionally, the integration of polymer-based energy harvesters with flexible electronics and energy storage systems represents a significant trend toward creating fully autonomous, self-sustaining microsystems.

The primary objective of this technical research is to comprehensively evaluate the current state and future potential of polymer-based micro energy harvesting technologies. Specifically, we aim to identify the most promising polymer materials and composite structures for enhancing energy conversion efficiency, durability, and scalability. Furthermore, we seek to assess the technical feasibility of integrating these harvesting systems with existing microelectronic platforms and to identify potential barriers to widespread commercial adoption.

Secondary objectives include mapping the intellectual property landscape surrounding polymer-based energy harvesters, identifying key technological gaps that present opportunities for innovation, and evaluating the environmental sustainability of various polymer materials throughout their lifecycle. Additionally, we aim to establish performance benchmarks for different polymer-based harvesting mechanisms across various operating conditions and application scenarios.

The ultimate goal is to develop a strategic roadmap for advancing polymer-based micro energy harvesting technologies from their current capabilities toward commercially viable solutions that can power the next generation of autonomous microsystems, thereby enabling new applications in healthcare monitoring, environmental sensing, and the Internet of Things (IoT) infrastructure.

The historical trajectory of polymer-based energy harvesters can be traced back to the early 2000s, when researchers began exploring piezoelectric polymers such as polyvinylidene fluoride (PVDF) for mechanical energy conversion. Subsequent advancements in material science, particularly in electroactive polymers (EAPs), conductive polymers, and polymer nanocomposites, have substantially expanded the capabilities and efficiency of these systems.

Current technological trends indicate a convergence of multiple energy harvesting mechanisms within polymer-based systems, including piezoelectric, triboelectric, thermoelectric, and photovoltaic effects. This multi-modal approach aims to maximize energy capture from diverse ambient sources, addressing the inherent limitations of single-mechanism harvesters. Additionally, the integration of polymer-based energy harvesters with flexible electronics and energy storage systems represents a significant trend toward creating fully autonomous, self-sustaining microsystems.

The primary objective of this technical research is to comprehensively evaluate the current state and future potential of polymer-based micro energy harvesting technologies. Specifically, we aim to identify the most promising polymer materials and composite structures for enhancing energy conversion efficiency, durability, and scalability. Furthermore, we seek to assess the technical feasibility of integrating these harvesting systems with existing microelectronic platforms and to identify potential barriers to widespread commercial adoption.

Secondary objectives include mapping the intellectual property landscape surrounding polymer-based energy harvesters, identifying key technological gaps that present opportunities for innovation, and evaluating the environmental sustainability of various polymer materials throughout their lifecycle. Additionally, we aim to establish performance benchmarks for different polymer-based harvesting mechanisms across various operating conditions and application scenarios.

The ultimate goal is to develop a strategic roadmap for advancing polymer-based micro energy harvesting technologies from their current capabilities toward commercially viable solutions that can power the next generation of autonomous microsystems, thereby enabling new applications in healthcare monitoring, environmental sensing, and the Internet of Things (IoT) infrastructure.

Market Analysis for Polymer Energy Harvesting Solutions

The global market for polymer-based energy harvesting solutions has experienced significant growth in recent years, driven by increasing demand for sustainable power sources in IoT devices, wearable technology, and remote sensing applications. Current market valuations indicate that the polymer energy harvesting sector reached approximately 520 million USD in 2022, with projections suggesting a compound annual growth rate of 14.7% through 2028.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the total market share. This dominance stems from the integration of flexible polymer-based harvesters in smartphones, wearable fitness trackers, and smart watches. The medical device sector follows closely at 24% market share, where polymer energy harvesters are increasingly utilized in implantable devices and health monitoring systems.

Regional analysis reveals that North America currently leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, increasing electronic device manufacturing, and supportive government policies promoting green energy technologies.

Key market drivers include the growing adoption of IoT devices, which is expected to reach 30.9 billion connected units by 2025, creating substantial demand for autonomous power solutions. Additionally, the push toward miniaturization in electronics has accelerated the need for compact, flexible energy harvesting technologies where polymers offer significant advantages over traditional rigid materials.

Consumer preference for maintenance-free devices and the global emphasis on reducing battery waste are further propelling market growth. The environmental benefits of polymer-based energy harvesters align with increasingly stringent sustainability regulations across major markets.

Market challenges include price sensitivity, particularly in consumer applications, and competition from alternative energy harvesting technologies such as silicon-based photovoltaics. Performance limitations in extreme environmental conditions also present barriers to adoption in certain industrial applications.

Emerging opportunities exist in smart textiles, where the global market is projected to reach 9.3 billion USD by 2025, with energy harvesting components representing a crucial enabling technology. The automotive sector also presents significant growth potential, particularly for polymer piezoelectric materials that can harvest vibration energy from vehicle operations.

Consumer electronics represents the largest application segment, accounting for nearly 38% of the total market share. This dominance stems from the integration of flexible polymer-based harvesters in smartphones, wearable fitness trackers, and smart watches. The medical device sector follows closely at 24% market share, where polymer energy harvesters are increasingly utilized in implantable devices and health monitoring systems.

Regional analysis reveals that North America currently leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to rapid industrialization, increasing electronic device manufacturing, and supportive government policies promoting green energy technologies.

Key market drivers include the growing adoption of IoT devices, which is expected to reach 30.9 billion connected units by 2025, creating substantial demand for autonomous power solutions. Additionally, the push toward miniaturization in electronics has accelerated the need for compact, flexible energy harvesting technologies where polymers offer significant advantages over traditional rigid materials.

Consumer preference for maintenance-free devices and the global emphasis on reducing battery waste are further propelling market growth. The environmental benefits of polymer-based energy harvesters align with increasingly stringent sustainability regulations across major markets.

Market challenges include price sensitivity, particularly in consumer applications, and competition from alternative energy harvesting technologies such as silicon-based photovoltaics. Performance limitations in extreme environmental conditions also present barriers to adoption in certain industrial applications.

Emerging opportunities exist in smart textiles, where the global market is projected to reach 9.3 billion USD by 2025, with energy harvesting components representing a crucial enabling technology. The automotive sector also presents significant growth potential, particularly for polymer piezoelectric materials that can harvest vibration energy from vehicle operations.

Current Polymer Technologies and Technical Barriers

Polymer materials have emerged as critical components in modern micro energy harvesting systems, offering unique properties that enable efficient energy conversion and storage. Currently, several polymer technologies dominate this landscape. Piezoelectric polymers, particularly polyvinylidene fluoride (PVDF) and its copolymers like P(VDF-TrFE), demonstrate excellent electromechanical coupling capabilities, converting mechanical strain directly into electrical energy. These materials exhibit flexibility, lightweight characteristics, and relatively simple processing requirements, making them ideal for wearable and implantable energy harvesting applications.

Triboelectric polymers represent another significant category, with materials such as polytetrafluoroethylene (PTFE), polydimethylsiloxane (PDMS), and polyimide being extensively utilized in triboelectric nanogenerators (TENGs). These polymers generate electrical charges through contact-separation or sliding friction mechanisms, effectively harvesting energy from ambient mechanical movements and vibrations.

Conducting polymers, including polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene) (PEDOT), serve crucial roles in thermoelectric energy harvesting systems. Their unique combination of electrical conductivity and low thermal conductivity enables efficient conversion of temperature gradients into electrical energy.

Despite these advancements, significant technical barriers persist in polymer-based micro energy harvesters. The primary challenge involves efficiency limitations, as current polymer-based systems typically achieve energy conversion efficiencies below 10%, substantially lower than their inorganic counterparts. This efficiency gap restricts their practical application in scenarios requiring higher power outputs.

Durability and reliability issues present another major obstacle. Polymers often suffer from mechanical fatigue, chemical degradation, and performance deterioration under prolonged operation or extreme environmental conditions. This vulnerability compromises the long-term stability essential for commercial viability.

Manufacturing scalability remains problematic, with many high-performance polymer composites requiring complex fabrication processes that are difficult to scale for mass production. The integration of polymers with other system components, particularly electronic interfaces and energy storage elements, presents additional challenges in creating fully functional, compact energy harvesting systems.

Furthermore, the fundamental understanding of structure-property relationships in polymer-based energy materials remains incomplete. This knowledge gap hampers the rational design of next-generation materials with optimized properties for specific energy harvesting mechanisms.

Triboelectric polymers represent another significant category, with materials such as polytetrafluoroethylene (PTFE), polydimethylsiloxane (PDMS), and polyimide being extensively utilized in triboelectric nanogenerators (TENGs). These polymers generate electrical charges through contact-separation or sliding friction mechanisms, effectively harvesting energy from ambient mechanical movements and vibrations.

Conducting polymers, including polyaniline (PANI), polypyrrole (PPy), and poly(3,4-ethylenedioxythiophene) (PEDOT), serve crucial roles in thermoelectric energy harvesting systems. Their unique combination of electrical conductivity and low thermal conductivity enables efficient conversion of temperature gradients into electrical energy.

Despite these advancements, significant technical barriers persist in polymer-based micro energy harvesters. The primary challenge involves efficiency limitations, as current polymer-based systems typically achieve energy conversion efficiencies below 10%, substantially lower than their inorganic counterparts. This efficiency gap restricts their practical application in scenarios requiring higher power outputs.

Durability and reliability issues present another major obstacle. Polymers often suffer from mechanical fatigue, chemical degradation, and performance deterioration under prolonged operation or extreme environmental conditions. This vulnerability compromises the long-term stability essential for commercial viability.

Manufacturing scalability remains problematic, with many high-performance polymer composites requiring complex fabrication processes that are difficult to scale for mass production. The integration of polymers with other system components, particularly electronic interfaces and energy storage elements, presents additional challenges in creating fully functional, compact energy harvesting systems.

Furthermore, the fundamental understanding of structure-property relationships in polymer-based energy materials remains incomplete. This knowledge gap hampers the rational design of next-generation materials with optimized properties for specific energy harvesting mechanisms.

Current Polymer Solutions for Micro Energy Harvesting

01 Piezoelectric polymers for energy harvesting

Piezoelectric polymers such as PVDF (polyvinylidene fluoride) and its copolymers are used in micro energy harvesters to convert mechanical energy into electrical energy. These polymers generate electrical charges when subjected to mechanical stress or vibration, making them ideal for wearable and flexible energy harvesting devices. The piezoelectric properties can be enhanced through various processing techniques such as stretching, poling, and the addition of nanofillers.- Piezoelectric polymers for energy harvesting: Piezoelectric polymers, such as PVDF (polyvinylidene fluoride) and its copolymers, are used in micro energy harvesters to convert mechanical energy into electrical energy. These polymers generate electrical charges when subjected to mechanical stress or vibration, making them ideal for harvesting energy from ambient movements. The flexibility and lightweight nature of these polymers allow for integration into various applications including wearable devices and structural monitoring systems.

- Electroactive polymers in micro generators: Electroactive polymers (EAPs) are utilized in micro energy harvesting systems to convert mechanical deformation into electrical energy. These polymers change shape in response to electrical stimulation and, conversely, generate electrical signals when mechanically deformed. This bidirectional energy conversion capability makes them suitable for applications in self-powered sensors, actuators, and small-scale power generation devices. EAPs offer advantages such as high energy density, flexibility, and the ability to operate across a wide frequency range.

- Polymer composites for enhanced energy harvesting: Polymer composites, consisting of polymers embedded with functional materials such as carbon nanotubes, graphene, or ceramic particles, are developed to enhance the performance of micro energy harvesters. These composites combine the flexibility and processability of polymers with the superior electrical or mechanical properties of the embedded materials. The resulting materials exhibit improved energy conversion efficiency, durability, and can be tailored for specific operating conditions or energy sources, such as vibration, temperature gradients, or fluid flow.

- Triboelectric polymers for contact-based energy harvesting: Triboelectric polymers are employed in micro energy harvesters that generate electricity through contact electrification and electrostatic induction. When two different polymer materials come into contact and then separate, they generate opposite electrical charges, creating a potential difference that can be harvested. These systems can effectively convert mechanical energy from human motion, wind, or water into electrical energy. The selection of polymer pairs with significant differences in their electron affinity is crucial for maximizing the triboelectric effect and energy output.

- Polymer-based flexible and stretchable energy harvesters: Flexible and stretchable polymers are used to create conformable micro energy harvesters that can adapt to irregular surfaces or withstand deformation while maintaining functionality. These systems typically incorporate elastomeric substrates or intrinsically stretchable conductive polymers to achieve mechanical compliance while harvesting energy. Applications include wearable electronics, biomedical implants, and soft robotics, where the energy harvester needs to accommodate body movements or environmental deformations without performance degradation.

02 Triboelectric polymer-based energy harvesters

Triboelectric nanogenerators (TENGs) utilize polymers with different electron affinities to generate electricity through contact and separation. These devices employ polymers such as PTFE, PDMS, and nylon that can create charge separation when brought into contact with other materials. The triboelectric effect in these polymers enables the conversion of mechanical energy from everyday movements into usable electrical power for small electronic devices and sensors.Expand Specific Solutions03 Electroactive polymers for mechanical energy conversion

Electroactive polymers (EAPs) can change shape or size when stimulated by an electric field and conversely generate electrical energy when deformed. These smart materials are incorporated into micro energy harvesters to capture energy from various mechanical sources such as human motion, vibrations, or fluid flow. Dielectric elastomers and ionic polymer-metal composites are common types used in flexible and stretchable energy harvesting applications.Expand Specific Solutions04 Polymer composites with enhanced energy harvesting properties

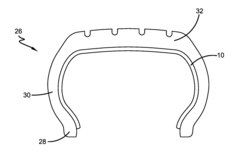

Polymer composites incorporating conductive fillers, nanoparticles, or carbon-based materials are designed to enhance the energy harvesting capabilities of micro devices. These composites combine the flexibility and processability of polymers with the electrical properties of the fillers. Materials such as graphene, carbon nanotubes, or metallic nanoparticles dispersed in polymer matrices create synergistic effects that improve energy conversion efficiency and mechanical durability.Expand Specific Solutions05 Polymer encapsulation and substrate materials for micro energy harvesters

Polymers serve as protective encapsulation and substrate materials for micro energy harvesting devices, providing mechanical support, electrical insulation, and environmental protection. Flexible polymers like polyimide, PET, and PDMS are used as substrates to enable conformable and stretchable device architectures. These materials help maintain device performance under various operating conditions while allowing integration into complex systems such as wearable electronics or implantable devices.Expand Specific Solutions

Industry Leaders in Polymer Energy Harvesting

The polymer-based micro energy harvesting market is in a growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding due to rising demand for sustainable power sources in IoT devices and wearable technology. Technologically, the field remains in development with varying maturity levels across different harvesting mechanisms. Leading academic institutions like Southeast University, Xi'an Jiaotong University, and The University of Chicago are driving fundamental research, while companies such as Toray Industries, DSM IP Assets, and SRI International are advancing commercial applications. Research collaborations between industry players like Renault SA and academic institutions are accelerating technological maturity, particularly in piezoelectric and triboelectric polymer-based harvesters, though challenges in efficiency and scalability remain.

The Regents of the University of California

Technical Solution: UC researchers have developed groundbreaking polymer-based micro energy harvesters utilizing electroactive polymers (EAPs) with enhanced electromechanical coupling. Their technology employs specially synthesized block copolymers that self-assemble into ordered nanostructures, creating highly efficient piezoelectric domains. UC's approach incorporates controlled chain alignment techniques that significantly enhance the piezoelectric response of polymers like P(VDF-TrFE) through precise processing conditions. Their micro energy harvesters feature multilayer architectures with gradient polymer compositions that can effectively capture mechanical energy across a broad frequency spectrum[6]. UC researchers have pioneered the integration of graphene-polymer nanocomposites that enhance charge transport while maintaining the flexibility of the harvesting device. Their technology utilizes innovative electrode designs with fractal patterns that maximize the effective area for charge collection while accommodating mechanical deformation. UC has also developed biodegradable piezoelectric polymers based on modified polylactic acid (PLA) for environmentally friendly energy harvesting applications in transient electronics[8]. Their systems demonstrate remarkable energy conversion efficiency, approaching 5-7% under optimal conditions.

Strengths: Cutting-edge materials science approach yielding higher energy conversion efficiencies; excellent biocompatibility for medical applications; innovative device architectures that maximize energy capture from ambient sources; potential for biodegradable and sustainable energy harvesting solutions. Weaknesses: Complex synthesis procedures limiting immediate commercial scalability; challenges in maintaining performance consistency across large production batches; higher initial development costs compared to conventional approaches.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed innovative polymer-based triboelectric nanogenerators (TENGs) for micro energy harvesting applications. Their approach utilizes specially engineered fluoropolymers with modified surface structures to enhance charge separation and retention. The technology employs a multilayer architecture with alternating polymer films of different electron affinities, creating effective charge generation during mechanical contact-separation cycles. CEA's micro harvesters incorporate nanopatterned polymer surfaces with controlled roughness to maximize the effective contact area and enhance power output[2]. Their systems feature self-powered energy management circuits that can effectively rectify and store the harvested energy. CEA has also pioneered hybrid harvesters that combine triboelectric and piezoelectric mechanisms within a single polymer-based device, allowing energy capture from multiple mechanical energy sources simultaneously[4]. Their technology demonstrates excellent durability with minimal performance degradation after millions of operation cycles.

Strengths: Exceptional output voltage generation; ability to harvest energy from irregular, low-frequency movements; compatibility with large-area, flexible applications; relatively simple fabrication process. Weaknesses: Lower current output compared to other harvesting technologies; susceptibility to environmental factors like humidity affecting performance; challenges in standardizing output due to material surface condition variations.

Key Patents and Research in Polymer Energy Materials

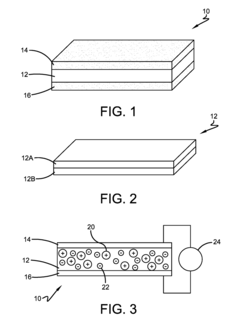

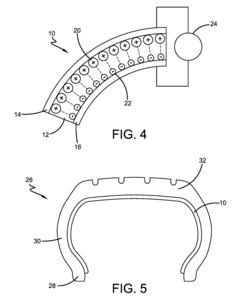

Polymer electrolyte membrane assembly

PatentActiveUS20180337417A1

Innovation

- A polymer electrolyte membrane assembly composed of a polymer matrix, plasticizer, and ionic material, with flexible electrodes, that converts mechanical deformation into electrical signals and vice versa, utilizing a composition that includes thiosiloxanes, polysiloxanes, and ionic materials like lithium and potassium ions, allowing for flexible and efficient energy harvesting and actuation.

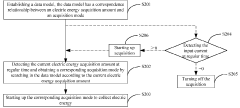

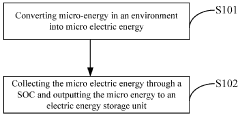

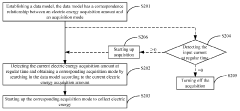

Micro-energy collection method and device, and micro-energy supply device

PatentInactiveAU2019100308A4

Innovation

- A micro-energy collection method and device that converts micro-energy into micro-electric energy using a conversion unit and collects it through a System on Chip (SOC), reducing power consumption and enabling the collection of micro-ampere level currents, with segmented collection techniques and adaptive detection modes to optimize energy collection across varying environments.

Sustainability Impact of Polymer Energy Harvesters

Polymer-based micro energy harvesters represent a significant advancement in sustainable energy technology, offering environmental benefits that extend far beyond their primary function of energy generation. The sustainability impact of these devices is multifaceted, encompassing their entire lifecycle from production to disposal.

The manufacturing process of polymer energy harvesters generally requires less energy compared to traditional silicon-based alternatives. Polymers such as PVDF (polyvinylidene fluoride) and its copolymers can be processed at lower temperatures, reducing the carbon footprint associated with production. Additionally, many polymers used in these applications can be synthesized from renewable resources, further enhancing their sustainability credentials.

During their operational lifetime, polymer energy harvesters contribute to sustainability by enabling self-powered devices that reduce dependency on conventional batteries. This is particularly significant in IoT applications, where billions of sensors could potentially operate without requiring battery replacements or grid connections. The elimination of battery waste represents a substantial environmental benefit, as conventional batteries contain toxic materials that pose disposal challenges.

The flexibility and durability of polymers also extend device lifespans, reducing electronic waste generation. Many polymer-based harvesters can withstand mechanical stress and environmental exposure better than rigid alternatives, making them suitable for long-term deployment in harsh environments without frequent replacement.

End-of-life considerations further highlight the sustainability advantages of polymer energy harvesters. Many polymers used in these applications can be recycled or biodegraded under appropriate conditions. Research into biodegradable piezoelectric polymers, such as modified cellulose and chitosan derivatives, shows promise for creating truly cradle-to-cradle sustainable energy harvesting solutions.

The scalability of polymer manufacturing processes also contributes to their sustainability impact. Roll-to-roll processing techniques enable mass production with minimal material waste, optimizing resource utilization. This efficiency in production translates to lower embodied energy in the final devices.

Looking forward, the integration of polymer energy harvesters into circular economy frameworks presents opportunities for further sustainability improvements. Designs that facilitate easy disassembly and material recovery could enhance end-of-life management, while continued research into bio-based polymers may reduce dependency on petroleum-derived materials, aligning these technologies with broader sustainability goals and carbon neutrality targets.

The manufacturing process of polymer energy harvesters generally requires less energy compared to traditional silicon-based alternatives. Polymers such as PVDF (polyvinylidene fluoride) and its copolymers can be processed at lower temperatures, reducing the carbon footprint associated with production. Additionally, many polymers used in these applications can be synthesized from renewable resources, further enhancing their sustainability credentials.

During their operational lifetime, polymer energy harvesters contribute to sustainability by enabling self-powered devices that reduce dependency on conventional batteries. This is particularly significant in IoT applications, where billions of sensors could potentially operate without requiring battery replacements or grid connections. The elimination of battery waste represents a substantial environmental benefit, as conventional batteries contain toxic materials that pose disposal challenges.

The flexibility and durability of polymers also extend device lifespans, reducing electronic waste generation. Many polymer-based harvesters can withstand mechanical stress and environmental exposure better than rigid alternatives, making them suitable for long-term deployment in harsh environments without frequent replacement.

End-of-life considerations further highlight the sustainability advantages of polymer energy harvesters. Many polymers used in these applications can be recycled or biodegraded under appropriate conditions. Research into biodegradable piezoelectric polymers, such as modified cellulose and chitosan derivatives, shows promise for creating truly cradle-to-cradle sustainable energy harvesting solutions.

The scalability of polymer manufacturing processes also contributes to their sustainability impact. Roll-to-roll processing techniques enable mass production with minimal material waste, optimizing resource utilization. This efficiency in production translates to lower embodied energy in the final devices.

Looking forward, the integration of polymer energy harvesters into circular economy frameworks presents opportunities for further sustainability improvements. Designs that facilitate easy disassembly and material recovery could enhance end-of-life management, while continued research into bio-based polymers may reduce dependency on petroleum-derived materials, aligning these technologies with broader sustainability goals and carbon neutrality targets.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of polymer-based micro energy harvesters represents a critical factor in their commercial viability and widespread adoption. Current production methods vary significantly across different polymer systems, with injection molding and roll-to-roll processing emerging as the most promising approaches for high-volume manufacturing. These techniques offer substantial advantages in terms of throughput capacity and unit cost reduction when scaled appropriately.

Analysis of production costs reveals that material expenses typically constitute 30-45% of total manufacturing costs for polymer-based harvesters, significantly lower than their ceramic or silicon counterparts. Labor costs remain relatively modest at 15-20%, while equipment depreciation and energy consumption account for approximately 25-30% of overall expenses. This cost structure presents a favorable scenario for economies of scale, with studies indicating potential cost reductions of 60-70% when production volumes increase from prototype quantities to millions of units annually.

Key manufacturing challenges include maintaining precise dimensional control during polymer processing, ensuring consistent electrical properties across large production batches, and developing effective quality control methodologies suitable for high-speed production lines. The integration of functional elements such as electrodes and encapsulation layers presents additional complexity that must be addressed through specialized manufacturing protocols.

Recent advancements in additive manufacturing technologies offer promising alternatives for small to medium production volumes, enabling rapid design iterations and customization options without significant tooling investments. However, these approaches currently face limitations in terms of throughput capacity and material property consistency compared to traditional manufacturing methods.

Supply chain considerations also significantly impact manufacturing scalability, with the availability of specialized polymers and conductive materials potentially creating bottlenecks in production scaling. Diversification of material suppliers and development of alternative formulations represent important strategies for mitigating these risks and ensuring production resilience.

Cost projections based on learning curve models suggest that polymer-based micro energy harvesters could achieve price points below $0.10 per cm² of active area at high production volumes, making them economically viable for numerous IoT and wearable applications. This represents a substantial advantage over competing technologies, which typically maintain higher cost structures even at scale due to inherent material and processing limitations.

Analysis of production costs reveals that material expenses typically constitute 30-45% of total manufacturing costs for polymer-based harvesters, significantly lower than their ceramic or silicon counterparts. Labor costs remain relatively modest at 15-20%, while equipment depreciation and energy consumption account for approximately 25-30% of overall expenses. This cost structure presents a favorable scenario for economies of scale, with studies indicating potential cost reductions of 60-70% when production volumes increase from prototype quantities to millions of units annually.

Key manufacturing challenges include maintaining precise dimensional control during polymer processing, ensuring consistent electrical properties across large production batches, and developing effective quality control methodologies suitable for high-speed production lines. The integration of functional elements such as electrodes and encapsulation layers presents additional complexity that must be addressed through specialized manufacturing protocols.

Recent advancements in additive manufacturing technologies offer promising alternatives for small to medium production volumes, enabling rapid design iterations and customization options without significant tooling investments. However, these approaches currently face limitations in terms of throughput capacity and material property consistency compared to traditional manufacturing methods.

Supply chain considerations also significantly impact manufacturing scalability, with the availability of specialized polymers and conductive materials potentially creating bottlenecks in production scaling. Diversification of material suppliers and development of alternative formulations represent important strategies for mitigating these risks and ensuring production resilience.

Cost projections based on learning curve models suggest that polymer-based micro energy harvesters could achieve price points below $0.10 per cm² of active area at high production volumes, making them economically viable for numerous IoT and wearable applications. This represents a substantial advantage over competing technologies, which typically maintain higher cost structures even at scale due to inherent material and processing limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!