Analysis of Safety Standards for Metal Powders in Industry

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powder Safety Evolution and Objectives

Metal powder processing has evolved significantly since its industrial inception in the early 20th century. Initially, safety considerations were minimal, with limited understanding of combustion risks and explosion hazards associated with fine metal particulates. The 1940s marked a turning point as wartime manufacturing highlighted the dangers of aluminum and magnesium powder handling, leading to rudimentary containment protocols and segregation practices.

By the 1970s, following several catastrophic industrial incidents, formal safety standards began emerging. The National Fire Protection Association (NFPA) in the United States introduced specific guidelines for combustible metals, while European authorities developed parallel frameworks. These early standards primarily focused on fire prevention rather than comprehensive risk management.

The technological revolution of the 1990s brought automated processing systems and more sophisticated metal powder applications, necessitating more nuanced safety approaches. During this period, standards evolved from prescriptive rules to performance-based requirements, acknowledging the diverse characteristics of different metal powders and their specific hazard profiles.

Recent developments in additive manufacturing and nanotechnology have introduced novel safety challenges. Ultra-fine metal powders used in 3D printing exhibit heightened reactivity and unique dispersion characteristics that traditional safety frameworks struggle to address adequately. This has prompted a new wave of research and standardization efforts specifically targeting these emerging technologies.

Current safety objectives center on developing harmonized global standards that can accommodate both traditional and emerging metal powder applications. Key goals include establishing scientifically validated testing methodologies for determining combustibility parameters, implementing risk-based classification systems, and creating scalable safety protocols applicable across different industrial settings.

The industry aims to transition from reactive safety measures to proactive risk management frameworks. This includes developing predictive models for dust explosion behaviors, implementing real-time monitoring technologies, and establishing comprehensive training protocols for personnel working with metal powders.

Looking forward, the technical objective is to create an integrated safety ecosystem that combines material science insights with practical engineering controls. This involves standardizing test methods for determining minimum ignition energy, maximum explosion pressure, and dust cloud characteristics across different metal powder types and particle distributions. Additionally, there is growing recognition of the need for lifecycle safety considerations, from powder production through processing to disposal or recycling.

By the 1970s, following several catastrophic industrial incidents, formal safety standards began emerging. The National Fire Protection Association (NFPA) in the United States introduced specific guidelines for combustible metals, while European authorities developed parallel frameworks. These early standards primarily focused on fire prevention rather than comprehensive risk management.

The technological revolution of the 1990s brought automated processing systems and more sophisticated metal powder applications, necessitating more nuanced safety approaches. During this period, standards evolved from prescriptive rules to performance-based requirements, acknowledging the diverse characteristics of different metal powders and their specific hazard profiles.

Recent developments in additive manufacturing and nanotechnology have introduced novel safety challenges. Ultra-fine metal powders used in 3D printing exhibit heightened reactivity and unique dispersion characteristics that traditional safety frameworks struggle to address adequately. This has prompted a new wave of research and standardization efforts specifically targeting these emerging technologies.

Current safety objectives center on developing harmonized global standards that can accommodate both traditional and emerging metal powder applications. Key goals include establishing scientifically validated testing methodologies for determining combustibility parameters, implementing risk-based classification systems, and creating scalable safety protocols applicable across different industrial settings.

The industry aims to transition from reactive safety measures to proactive risk management frameworks. This includes developing predictive models for dust explosion behaviors, implementing real-time monitoring technologies, and establishing comprehensive training protocols for personnel working with metal powders.

Looking forward, the technical objective is to create an integrated safety ecosystem that combines material science insights with practical engineering controls. This involves standardizing test methods for determining minimum ignition energy, maximum explosion pressure, and dust cloud characteristics across different metal powder types and particle distributions. Additionally, there is growing recognition of the need for lifecycle safety considerations, from powder production through processing to disposal or recycling.

Industry Demand for Metal Powder Safety Standards

The metal powder industry has witnessed significant growth in recent years, driven primarily by advancements in additive manufacturing, powder metallurgy, and various industrial applications. This expansion has correspondingly increased the demand for comprehensive safety standards that address the unique hazards associated with metal powders. Market research indicates that the global metal powder market is projected to reach $10.2 billion by 2025, with a compound annual growth rate of 6.7% from 2020, highlighting the urgent need for standardized safety protocols.

Manufacturing sectors, particularly aerospace, automotive, and medical device industries, are increasingly adopting metal powder-based processes for their production needs. These industries require stringent safety standards to mitigate risks associated with metal powder handling, storage, and processing. A survey conducted among 150 manufacturing companies revealed that 78% consider safety standards as "extremely important" for their operations involving metal powders, while 65% reported challenges in navigating the current fragmented regulatory landscape.

The combustibility and explosivity of metal powders represent primary safety concerns across industries. Aluminum, titanium, and magnesium powders, widely used in lightweight applications, pose significant fire and explosion hazards when improperly handled. Industry stakeholders have expressed a growing demand for standardized testing methodologies to accurately assess these risks and implement appropriate preventive measures.

Environmental and health considerations are also driving the demand for enhanced safety standards. Fine metal particles can cause respiratory issues and environmental contamination if not properly contained. Approximately 42% of companies in the metal powder industry have reported increasing pressure from regulatory bodies regarding worker exposure limits and environmental impact assessments, necessitating clearer guidelines and standards.

The globalization of supply chains has further amplified the need for harmonized international safety standards. Companies operating across multiple jurisdictions face challenges in complying with varying regional requirements. A unified approach to metal powder safety would facilitate international trade and ensure consistent safety practices worldwide.

Emerging technologies, particularly in nanomaterials and reactive metal powders, are creating new safety challenges that existing standards may not adequately address. Industry associations report that 57% of their members are seeking updated guidelines specifically tailored to novel metal powder formulations and processing techniques.

Insurance providers and risk management professionals have also become key stakeholders driving demand for comprehensive safety standards. The financial implications of incidents involving metal powders can be substantial, with insurance premiums increasingly tied to compliance with recognized safety protocols and standards.

Manufacturing sectors, particularly aerospace, automotive, and medical device industries, are increasingly adopting metal powder-based processes for their production needs. These industries require stringent safety standards to mitigate risks associated with metal powder handling, storage, and processing. A survey conducted among 150 manufacturing companies revealed that 78% consider safety standards as "extremely important" for their operations involving metal powders, while 65% reported challenges in navigating the current fragmented regulatory landscape.

The combustibility and explosivity of metal powders represent primary safety concerns across industries. Aluminum, titanium, and magnesium powders, widely used in lightweight applications, pose significant fire and explosion hazards when improperly handled. Industry stakeholders have expressed a growing demand for standardized testing methodologies to accurately assess these risks and implement appropriate preventive measures.

Environmental and health considerations are also driving the demand for enhanced safety standards. Fine metal particles can cause respiratory issues and environmental contamination if not properly contained. Approximately 42% of companies in the metal powder industry have reported increasing pressure from regulatory bodies regarding worker exposure limits and environmental impact assessments, necessitating clearer guidelines and standards.

The globalization of supply chains has further amplified the need for harmonized international safety standards. Companies operating across multiple jurisdictions face challenges in complying with varying regional requirements. A unified approach to metal powder safety would facilitate international trade and ensure consistent safety practices worldwide.

Emerging technologies, particularly in nanomaterials and reactive metal powders, are creating new safety challenges that existing standards may not adequately address. Industry associations report that 57% of their members are seeking updated guidelines specifically tailored to novel metal powder formulations and processing techniques.

Insurance providers and risk management professionals have also become key stakeholders driving demand for comprehensive safety standards. The financial implications of incidents involving metal powders can be substantial, with insurance premiums increasingly tied to compliance with recognized safety protocols and standards.

Current Safety Challenges in Metal Powder Handling

Metal powder handling in industrial settings presents significant safety challenges due to the inherently hazardous properties of these materials. The primary concern is the high flammability and explosivity of metal powders, which can ignite when dispersed in air, creating dust clouds that may lead to devastating explosions. This risk is particularly pronounced with fine powders of aluminum, magnesium, titanium, and zirconium, which have extremely low minimum ignition energies.

Static electricity generation during powder handling operations represents another critical challenge. The movement of metal powders through processing equipment creates triboelectric charging, potentially generating sparks that can serve as ignition sources. Despite implementation of grounding and bonding procedures, maintaining consistent electrical continuity remains problematic in complex processing environments.

Exposure risks constitute a significant health concern for workers. Metal powders can be inhaled, causing respiratory issues ranging from irritation to serious conditions like metal fume fever or pneumoconiosis. Certain metal powders, such as those containing nickel, chromium, or beryllium, present carcinogenic risks, necessitating stringent exposure controls that are often difficult to implement effectively.

Cross-contamination between different metal powders presents both safety and quality challenges. When incompatible metals mix, they may create unexpected reaction hazards or compromise product integrity. This is particularly problematic in facilities handling multiple powder types, where segregation protocols may be inadequate.

The additive manufacturing industry faces unique challenges as it rapidly adopts metal powder technologies. The relatively new nature of these processes means safety standards are still evolving, creating regulatory gaps. Many operators lack comprehensive understanding of the specific hazards associated with fine metal powders used in these applications.

Emergency response capabilities for metal powder incidents remain underdeveloped in many facilities. Traditional firefighting methods can exacerbate metal fires, as water may react violently with certain metals. Special Class D fire extinguishers and specific training are required, but are not universally available or understood by emergency responders.

Regulatory compliance presents ongoing challenges due to fragmented standards across different jurisdictions and industries. Companies operating globally must navigate complex and sometimes contradictory requirements, while smaller operations may lack resources to fully implement comprehensive safety programs aligned with best practices.

Static electricity generation during powder handling operations represents another critical challenge. The movement of metal powders through processing equipment creates triboelectric charging, potentially generating sparks that can serve as ignition sources. Despite implementation of grounding and bonding procedures, maintaining consistent electrical continuity remains problematic in complex processing environments.

Exposure risks constitute a significant health concern for workers. Metal powders can be inhaled, causing respiratory issues ranging from irritation to serious conditions like metal fume fever or pneumoconiosis. Certain metal powders, such as those containing nickel, chromium, or beryllium, present carcinogenic risks, necessitating stringent exposure controls that are often difficult to implement effectively.

Cross-contamination between different metal powders presents both safety and quality challenges. When incompatible metals mix, they may create unexpected reaction hazards or compromise product integrity. This is particularly problematic in facilities handling multiple powder types, where segregation protocols may be inadequate.

The additive manufacturing industry faces unique challenges as it rapidly adopts metal powder technologies. The relatively new nature of these processes means safety standards are still evolving, creating regulatory gaps. Many operators lack comprehensive understanding of the specific hazards associated with fine metal powders used in these applications.

Emergency response capabilities for metal powder incidents remain underdeveloped in many facilities. Traditional firefighting methods can exacerbate metal fires, as water may react violently with certain metals. Special Class D fire extinguishers and specific training are required, but are not universally available or understood by emergency responders.

Regulatory compliance presents ongoing challenges due to fragmented standards across different jurisdictions and industries. Companies operating globally must navigate complex and sometimes contradictory requirements, while smaller operations may lack resources to fully implement comprehensive safety programs aligned with best practices.

Existing Metal Powder Risk Mitigation Approaches

01 Safety standards for handling and storage of metal powders

Metal powders require specific handling and storage protocols to prevent hazards. These standards include proper containment systems, controlled environments to prevent dust explosions, and specialized storage facilities that maintain appropriate temperature and humidity levels. Safety measures also include proper labeling, segregation from incompatible materials, and regular inspection of storage areas to ensure compliance with safety regulations.- Safety standards for handling and storage of metal powders: Metal powders require specific safety standards for handling and storage due to their potential flammability and reactivity. These standards include proper containment systems, controlled environments to prevent dust explosions, and specialized storage facilities that maintain appropriate temperature and humidity levels. Safety protocols also address the prevention of oxidation, contamination, and accidental ignition sources.

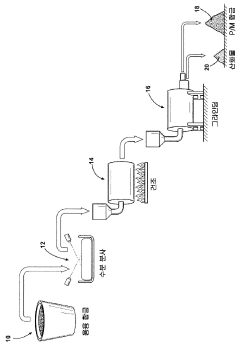

- Metal powder processing safety requirements: Processing metal powders involves specific safety requirements to mitigate risks during manufacturing operations. These include specialized equipment designs with explosion-proof features, proper ventilation systems to remove airborne particles, grounding mechanisms to prevent static electricity buildup, and monitoring systems for detecting potential hazards. Safety standards also cover process parameters like temperature control and pressure management during metal powder processing.

- Protective measures for workers handling metal powders: Worker safety when handling metal powders requires comprehensive protective measures including personal protective equipment (PPE), respiratory protection systems, specialized training protocols, and emergency response procedures. Safety standards mandate regular health monitoring for workers exposed to metal powders, proper decontamination facilities, and implementation of engineering controls to minimize exposure to hazardous metal dust.

- Fire and explosion prevention standards for metal powders: Metal powders present significant fire and explosion hazards requiring specialized prevention standards. These include classification systems for combustibility and reactivity, isolation techniques to prevent propagation of explosions, suppression systems designed specifically for metal fires, and detection systems for early warning. Standards also address proper electrical equipment ratings, spark-resistant tools, and specialized firefighting agents suitable for metal powder fires.

- Environmental and disposal regulations for metal powders: Environmental safety standards for metal powders address proper disposal methods, containment of waste materials, prevention of environmental contamination, and recycling protocols. These regulations include requirements for filtration systems to prevent airborne release, wastewater treatment to remove metal particulates, proper labeling and documentation for hazardous waste transport, and specialized disposal facilities designed to handle reactive metal waste safely.

02 Fire and explosion prevention measures for metal powders

Metal powders present significant fire and explosion risks due to their high surface area and reactivity. Safety standards address these risks through requirements for explosion-proof equipment, grounding systems to prevent static electricity buildup, inert gas environments for highly reactive metals, and specialized fire suppression systems designed specifically for metal powder fires. These measures are critical as conventional water-based fire suppression can exacerbate metal powder fires.Expand Specific Solutions03 Manufacturing and processing safety requirements

Safety standards for manufacturing and processing metal powders focus on equipment design, process controls, and operational procedures. These include enclosed processing systems to prevent dust release, monitoring equipment for detecting unsafe conditions, emergency shutdown protocols, and specialized ventilation systems. Standards also cover maintenance procedures, worker training requirements, and process validation to ensure consistent safety compliance during production operations.Expand Specific Solutions04 Personal protective equipment and worker safety protocols

Worker safety around metal powders requires comprehensive protective measures including specialized respiratory protection, anti-static clothing, and protective eyewear. Safety standards specify appropriate PPE based on powder characteristics and exposure risks. Protocols include decontamination procedures, exposure monitoring, medical surveillance programs, and emergency response training for workers. These standards also address workplace design elements such as safety showers, eyewash stations, and proper ventilation systems.Expand Specific Solutions05 Testing and classification standards for metal powder hazards

Metal powders are subject to standardized testing protocols to determine their hazard classification, which informs handling requirements. These tests evaluate properties such as explosibility, combustibility, reactivity with water or air, particle size distribution, and toxicity. Classification systems categorize powders based on risk levels and provide corresponding safety requirements. Regular testing and certification ensure ongoing compliance with safety standards as material properties may change during processing or storage.Expand Specific Solutions

Leading Organizations in Metal Powder Safety Standardization

The metal powder safety standards industry is currently in a mature growth phase, with increasing emphasis on standardization due to expanding applications in additive manufacturing and advanced materials. The global market for metal powders is estimated at $6-7 billion, growing at 4-5% annually, driven by automotive, aerospace, and healthcare sectors. Leading companies demonstrate varying levels of technical maturity: ArcelorMittal, thyssenkrupp, and Höganäs AB represent established manufacturers with comprehensive safety protocols; EOS GmbH and Nanoscale Powders LLC focus on specialized applications with advanced handling procedures; while research institutions like Battelle Memorial Institute and Central Iron & Steel Research Institute contribute to evolving safety frameworks through scientific innovation and regulatory development.

Deutsche Edelstahlwerke Specialty Steel GmbH & Co. KG

Technical Solution: Deutsche Edelstahlwerke has implemented a comprehensive safety management system for metal powder handling in specialty steel production. Their approach centers on a hierarchical risk control framework that addresses both chronic and acute hazards associated with metal powders. The company has developed specialized containment systems that minimize dust generation during powder transfer operations, incorporating negative pressure environments and specialized ventilation designs that exceed German technical standards for hazardous materials. Their safety protocols include advanced fire suppression systems specifically designed for metal powder fires, which utilize specialized extinguishing agents effective against Class D fires. The company has pioneered the implementation of continuous monitoring technologies that track particulate concentrations, oxygen levels, and electrostatic conditions in real-time[4]. Their safety management system includes detailed emergency response protocols specific to different metal powder compositions, with specialized training for response teams. Deutsche Edelstahlwerke has also developed comprehensive documentation systems that track powder handling procedures, exposure monitoring, and equipment maintenance to ensure ongoing compliance with evolving safety standards.

Strengths: Rigorous engineering controls that exceed regulatory requirements; specialized expertise in high-alloy and reactive metal powders; comprehensive documentation and compliance systems. Weaknesses: Systems primarily designed for large-scale industrial environments; significant capital investment required for implementation; complex protocols may create operational inefficiencies in smaller facilities.

Central Iron & Steel Research Institute

Technical Solution: The Central Iron & Steel Research Institute has developed a systematic approach to metal powder safety that integrates material science principles with practical industrial applications. Their framework begins with comprehensive characterization of powder properties that influence safety risks, including particle size distribution, surface area, chemical reactivity, and moisture sensitivity. Based on these characteristics, they've established a classification system that categorizes metal powders according to their hazard profiles, enabling targeted safety measures for specific risk factors. Their technical solutions include specialized storage systems with controlled atmospheres for reactive powders, monitoring technologies that detect early signs of oxidation or decomposition, and modified handling equipment designed to minimize friction and impact forces that could trigger reactions. The Institute has conducted extensive research on explosion parameters for various metal powder compositions, establishing safety thresholds that have been incorporated into national standards[6][8]. Their approach also includes specialized waste management protocols for contaminated or oxidized powders, addressing environmental and safety concerns throughout the material lifecycle.

Strengths: Strong scientific foundation based on material properties and reaction mechanisms; comprehensive testing capabilities for establishing safety parameters; significant influence on national standards development. Weaknesses: Implementation guidance sometimes lacks practical details for industrial settings; solutions may require significant adaptation for different manufacturing environments; limited focus on economic feasibility of safety measures.

Critical Safety Technologies for Metal Powder Management

Powder metal compositions for wear and temperature resistance applications and method of producing same

PatentInactiveKR1020150132856A

Innovation

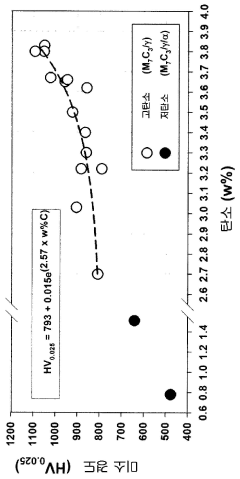

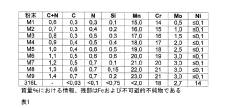

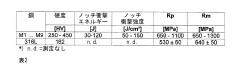

- A method involving a high-carbon, low-oxygen iron-based alloy is atomized using gas injection, followed by mechanical grinding to remove oxide skins, eliminating the need for additional annealing and allowing direct formation of carbides during sintering.

Metal powders for additive manufacturing processes, uses thereof, methods of making parts, and parts thereof

PatentInactiveJP2023511877A

Innovation

- Development of metal powders with controlled carbon and nitrogen content, combined with manganese and other elements, optimized for additive manufacturing, ensuring a predominantly austenitic structure and high mechanical properties through precise atomization and heat treatment, avoiding chromium carbide formation.

Regulatory Compliance Framework for Metal Powder Industries

The regulatory landscape for metal powder industries is characterized by a complex web of international, national, and industry-specific standards designed to mitigate risks associated with these potentially hazardous materials. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have established foundational frameworks that govern the classification, handling, and processing of metal powders across borders.

Within the United States, the Occupational Safety and Health Administration (OSHA) has implemented comprehensive regulations under 29 CFR 1910 that specifically address combustible dust hazards, including metal powders. These regulations mandate risk assessments, proper ventilation systems, and regular equipment maintenance to prevent dust explosions and fires. Complementing OSHA's efforts, the National Fire Protection Association (NFPA) has developed standards such as NFPA 484 (Standard for Combustible Metals) and NFPA 652 (Standard on the Fundamentals of Combustible Dust), which provide detailed guidelines for safe handling practices.

The European Union has established its regulatory framework through directives like ATEX 137 (workplace safety) and ATEX 95 (equipment standards), which require manufacturers and operators to implement explosion prevention and protection measures. These directives are further supported by harmonized standards developed by the European Committee for Standardization (CEN).

In Asia, countries like Japan and China have developed their own regulatory frameworks. Japan's Industrial Safety and Health Law includes specific provisions for metal powder handling, while China's Work Safety Law and associated standards address combustible dust hazards in manufacturing environments.

Industry-specific standards have emerged to address unique challenges in sectors such as additive manufacturing, where organizations like ASTM International have developed standards for metal powder characterization (ASTM F3049) and quality assurance (ASTM F3303). These standards focus on particle size distribution, chemical composition, and flow properties that are critical for ensuring consistent product quality and safety.

Compliance with these regulations typically requires a multi-faceted approach including hazard identification, risk assessment, implementation of engineering controls, development of administrative procedures, and regular employee training. Companies must maintain detailed documentation of their compliance efforts, including dust hazard analyses, equipment inspection records, and incident reports.

The regulatory landscape continues to evolve as new technologies emerge and our understanding of metal powder hazards improves. Recent trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing companies more flexibility in how they achieve safety objectives while maintaining rigorous protection standards.

Within the United States, the Occupational Safety and Health Administration (OSHA) has implemented comprehensive regulations under 29 CFR 1910 that specifically address combustible dust hazards, including metal powders. These regulations mandate risk assessments, proper ventilation systems, and regular equipment maintenance to prevent dust explosions and fires. Complementing OSHA's efforts, the National Fire Protection Association (NFPA) has developed standards such as NFPA 484 (Standard for Combustible Metals) and NFPA 652 (Standard on the Fundamentals of Combustible Dust), which provide detailed guidelines for safe handling practices.

The European Union has established its regulatory framework through directives like ATEX 137 (workplace safety) and ATEX 95 (equipment standards), which require manufacturers and operators to implement explosion prevention and protection measures. These directives are further supported by harmonized standards developed by the European Committee for Standardization (CEN).

In Asia, countries like Japan and China have developed their own regulatory frameworks. Japan's Industrial Safety and Health Law includes specific provisions for metal powder handling, while China's Work Safety Law and associated standards address combustible dust hazards in manufacturing environments.

Industry-specific standards have emerged to address unique challenges in sectors such as additive manufacturing, where organizations like ASTM International have developed standards for metal powder characterization (ASTM F3049) and quality assurance (ASTM F3303). These standards focus on particle size distribution, chemical composition, and flow properties that are critical for ensuring consistent product quality and safety.

Compliance with these regulations typically requires a multi-faceted approach including hazard identification, risk assessment, implementation of engineering controls, development of administrative procedures, and regular employee training. Companies must maintain detailed documentation of their compliance efforts, including dust hazard analyses, equipment inspection records, and incident reports.

The regulatory landscape continues to evolve as new technologies emerge and our understanding of metal powder hazards improves. Recent trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing companies more flexibility in how they achieve safety objectives while maintaining rigorous protection standards.

Environmental Impact of Metal Powder Safety Measures

The implementation of metal powder safety measures carries significant environmental implications that extend beyond immediate workplace safety concerns. Traditional safety systems often involve extensive ventilation, filtration, and containment mechanisms that consume substantial energy resources. High-powered industrial ventilation systems required for metal powder dust control can increase a facility's carbon footprint by 15-20% compared to operations without such intensive safety requirements.

Water-based suppression systems, while effective for certain metal powder hazards, generate contaminated wastewater that requires specialized treatment before environmental release. Studies indicate that untreated wastewater from metal powder processing facilities may contain heavy metals at concentrations 5-10 times higher than permissible environmental discharge limits, posing risks to aquatic ecosystems.

The production of specialized safety equipment itself creates an environmental burden. Flame-resistant materials, explosion-proof electrical systems, and specialized containment structures require energy-intensive manufacturing processes and often incorporate materials with significant ecological footprints. Life cycle assessments reveal that the environmental impact of manufacturing specialized metal powder safety equipment can be substantial, with carbon emissions equivalent to approximately 3-5 metric tons of CO2 per facility annually.

Waste management presents another environmental challenge. Spent filters, contaminated PPE, and residual metal powder waste must be handled as hazardous materials in many jurisdictions. The disposal pathways for these materials often involve specialized treatment facilities with their own environmental impacts. Recent industry data suggests that a medium-sized metal powder processing facility generates approximately 2-3 tons of hazardous waste annually from safety-related consumables alone.

However, advancements in green safety technologies are emerging. Innovative approaches include closed-loop ventilation systems that reduce energy consumption by 30-40%, biodegradable suppression agents that minimize wastewater contamination, and recyclable filter media that reduce waste generation. These developments represent a promising trend toward reconciling robust safety standards with environmental sustainability goals.

The regulatory landscape increasingly recognizes this environmental dimension, with integrated permitting frameworks in regions like the EU requiring facilities to address both safety and environmental impacts holistically. This trend is driving innovation in safety technologies that minimize ecological footprints while maintaining or enhancing protection levels for workers and surrounding communities.

Water-based suppression systems, while effective for certain metal powder hazards, generate contaminated wastewater that requires specialized treatment before environmental release. Studies indicate that untreated wastewater from metal powder processing facilities may contain heavy metals at concentrations 5-10 times higher than permissible environmental discharge limits, posing risks to aquatic ecosystems.

The production of specialized safety equipment itself creates an environmental burden. Flame-resistant materials, explosion-proof electrical systems, and specialized containment structures require energy-intensive manufacturing processes and often incorporate materials with significant ecological footprints. Life cycle assessments reveal that the environmental impact of manufacturing specialized metal powder safety equipment can be substantial, with carbon emissions equivalent to approximately 3-5 metric tons of CO2 per facility annually.

Waste management presents another environmental challenge. Spent filters, contaminated PPE, and residual metal powder waste must be handled as hazardous materials in many jurisdictions. The disposal pathways for these materials often involve specialized treatment facilities with their own environmental impacts. Recent industry data suggests that a medium-sized metal powder processing facility generates approximately 2-3 tons of hazardous waste annually from safety-related consumables alone.

However, advancements in green safety technologies are emerging. Innovative approaches include closed-loop ventilation systems that reduce energy consumption by 30-40%, biodegradable suppression agents that minimize wastewater contamination, and recyclable filter media that reduce waste generation. These developments represent a promising trend toward reconciling robust safety standards with environmental sustainability goals.

The regulatory landscape increasingly recognizes this environmental dimension, with integrated permitting frameworks in regions like the EU requiring facilities to address both safety and environmental impacts holistically. This trend is driving innovation in safety technologies that minimize ecological footprints while maintaining or enhancing protection levels for workers and surrounding communities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!