Understanding Metal Powders in Context of Additive Layer Manufacturing

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powder Evolution and ALM Objectives

Metal powder technology has evolved significantly over the past decades, transforming from conventional powder metallurgy applications to becoming the cornerstone of modern Additive Layer Manufacturing (ALM). The journey began in the 1970s with early experiments in laser sintering, but it wasn't until the 1990s that metal powders specifically designed for additive manufacturing emerged. This evolution has been characterized by increasingly stringent requirements for powder morphology, size distribution, flowability, and chemical composition to meet the demanding specifications of ALM processes.

The technological trajectory has seen remarkable advancements in powder production methods, transitioning from conventional atomization techniques to more sophisticated approaches such as plasma rotating electrode processes (PREP) and gas atomization. These innovations have enabled the production of highly spherical particles with minimal satellite formations and controlled oxygen content, critical factors for successful ALM operations.

Current trends indicate a growing focus on tailoring powder characteristics to specific ALM technologies, whether it be powder bed fusion, directed energy deposition, or binder jetting. The industry is witnessing increased emphasis on recycling capabilities and sustainability considerations, with research directed toward understanding powder degradation mechanisms during multiple reuse cycles.

The primary objective in metal powder development for ALM is achieving optimal processability while maintaining consistent mechanical properties in the final components. This includes enhancing powder flowability to ensure uniform layer deposition, improving packing density to minimize porosity, and controlling particle size distribution to optimize laser-powder interaction during fusion processes.

Another crucial goal is expanding the material portfolio available for ALM applications. While traditional alloys like Ti-6Al-4V, Inconel 718, and 316L stainless steel dominate the market, significant research efforts are directed toward adapting high-performance alloys, refractory metals, and novel compositions specifically designed for additive manufacturing.

Looking forward, the field aims to establish standardized testing methodologies and quality control protocols for metal powders in ALM contexts. This standardization is essential for industry-wide adoption and certification of critical components, particularly in aerospace, medical, and automotive applications where performance reliability is paramount.

The convergence of computational modeling with experimental approaches represents another key objective, enabling the prediction of powder behavior during processing and its impact on final part properties. This integration of simulation tools with powder development accelerates innovation cycles and reduces the empirical nature of current development approaches.

The technological trajectory has seen remarkable advancements in powder production methods, transitioning from conventional atomization techniques to more sophisticated approaches such as plasma rotating electrode processes (PREP) and gas atomization. These innovations have enabled the production of highly spherical particles with minimal satellite formations and controlled oxygen content, critical factors for successful ALM operations.

Current trends indicate a growing focus on tailoring powder characteristics to specific ALM technologies, whether it be powder bed fusion, directed energy deposition, or binder jetting. The industry is witnessing increased emphasis on recycling capabilities and sustainability considerations, with research directed toward understanding powder degradation mechanisms during multiple reuse cycles.

The primary objective in metal powder development for ALM is achieving optimal processability while maintaining consistent mechanical properties in the final components. This includes enhancing powder flowability to ensure uniform layer deposition, improving packing density to minimize porosity, and controlling particle size distribution to optimize laser-powder interaction during fusion processes.

Another crucial goal is expanding the material portfolio available for ALM applications. While traditional alloys like Ti-6Al-4V, Inconel 718, and 316L stainless steel dominate the market, significant research efforts are directed toward adapting high-performance alloys, refractory metals, and novel compositions specifically designed for additive manufacturing.

Looking forward, the field aims to establish standardized testing methodologies and quality control protocols for metal powders in ALM contexts. This standardization is essential for industry-wide adoption and certification of critical components, particularly in aerospace, medical, and automotive applications where performance reliability is paramount.

The convergence of computational modeling with experimental approaches represents another key objective, enabling the prediction of powder behavior during processing and its impact on final part properties. This integration of simulation tools with powder development accelerates innovation cycles and reduces the empirical nature of current development approaches.

Market Analysis for Metal Powder-Based ALM

The global market for metal powder-based Additive Layer Manufacturing (ALM) has experienced significant growth in recent years, driven by increasing adoption across various industrial sectors. The market size was valued at approximately $2.6 billion in 2022 and is projected to reach $9.4 billion by 2030, representing a compound annual growth rate (CAGR) of 17.5% during the forecast period.

Aerospace and defense sectors currently dominate the metal powder ALM market, accounting for roughly 31% of the total market share. These industries leverage the technology primarily for producing complex components with reduced weight and enhanced performance characteristics. The medical and dental sectors follow closely, constituting about 24% of the market, with applications in customized implants and prosthetics.

Automotive and industrial manufacturing sectors represent emerging growth areas, collectively accounting for 28% of the market. These sectors are increasingly adopting metal powder ALM for prototyping, tooling, and small-batch production of specialized components. Energy sector applications, including oil and gas equipment and renewable energy components, comprise approximately 12% of the market.

Geographically, North America leads the market with a 38% share, followed by Europe at 35% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. China, in particular, has demonstrated the fastest growth rate, with government initiatives strongly supporting advanced manufacturing technologies.

The metal powder supply chain represents a critical component of the ALM ecosystem. Currently, titanium alloys dominate the market with a 29% share, followed by nickel-based superalloys (24%), stainless steel (21%), aluminum alloys (15%), and other specialty metals (11%). Powder suppliers are increasingly focusing on developing specialized alloys optimized specifically for ALM processes.

Key market drivers include the growing demand for lightweight components in transportation industries, increasing need for customized medical implants, and the push for more efficient supply chains with reduced lead times. Additionally, the ability to produce complex geometries impossible with traditional manufacturing methods continues to expand the application scope.

Market challenges include the high cost of metal powders, which can represent 30-50% of the total part production cost, quality consistency issues, and limited material options compared to conventional manufacturing. Regulatory hurdles in critical industries like aerospace and medical devices also impact market growth rates.

Aerospace and defense sectors currently dominate the metal powder ALM market, accounting for roughly 31% of the total market share. These industries leverage the technology primarily for producing complex components with reduced weight and enhanced performance characteristics. The medical and dental sectors follow closely, constituting about 24% of the market, with applications in customized implants and prosthetics.

Automotive and industrial manufacturing sectors represent emerging growth areas, collectively accounting for 28% of the market. These sectors are increasingly adopting metal powder ALM for prototyping, tooling, and small-batch production of specialized components. Energy sector applications, including oil and gas equipment and renewable energy components, comprise approximately 12% of the market.

Geographically, North America leads the market with a 38% share, followed by Europe at 35% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. China, in particular, has demonstrated the fastest growth rate, with government initiatives strongly supporting advanced manufacturing technologies.

The metal powder supply chain represents a critical component of the ALM ecosystem. Currently, titanium alloys dominate the market with a 29% share, followed by nickel-based superalloys (24%), stainless steel (21%), aluminum alloys (15%), and other specialty metals (11%). Powder suppliers are increasingly focusing on developing specialized alloys optimized specifically for ALM processes.

Key market drivers include the growing demand for lightweight components in transportation industries, increasing need for customized medical implants, and the push for more efficient supply chains with reduced lead times. Additionally, the ability to produce complex geometries impossible with traditional manufacturing methods continues to expand the application scope.

Market challenges include the high cost of metal powders, which can represent 30-50% of the total part production cost, quality consistency issues, and limited material options compared to conventional manufacturing. Regulatory hurdles in critical industries like aerospace and medical devices also impact market growth rates.

Current Metal Powder Technologies and Barriers

Metal powder technologies for Additive Layer Manufacturing (ALM) have evolved significantly over the past decade, yet several barriers remain. Current powder production methods include gas atomization, water atomization, plasma atomization, and mechanical alloying. Gas atomization dominates the market due to its ability to produce spherical particles with good flowability and packing density, essential characteristics for powder bed fusion processes. Plasma atomization, though more expensive, yields higher purity powders with excellent sphericity, making it preferred for critical aerospace and medical applications.

The quality of metal powders significantly impacts the final part properties. Key powder characteristics include particle size distribution, morphology, flowability, and chemical composition. Most commercial ALM systems operate optimally with powders in the 15-45μm or 45-105μm ranges, depending on the specific technology employed. Spherical particles are highly desirable as they enhance flowability and packing density, resulting in more uniform layers and fewer defects in the final parts.

Despite technological advancements, several barriers impede wider adoption of metal ALM. Cost remains a primary concern, with high-quality metal powders typically priced between $200-500 per kilogram, significantly higher than conventional manufacturing materials. Limited material availability presents another challenge, as only about 30 metal alloys are commercially available for ALM compared to thousands in traditional manufacturing. This restricts application possibilities and slows industry growth.

Powder recyclability presents both technical and economic challenges. During the ALM process, unused powder is exposed to heat and oxygen, potentially altering its properties. Current recycling protocols often involve blending used powder with virgin material, but this approach lacks standardization across the industry. Studies indicate that powder properties can degrade after multiple reuse cycles, affecting final part quality and consistency.

Quality control and standardization remain significant barriers. Variations in powder batches, even from the same supplier, can lead to inconsistent part properties. The industry lacks comprehensive standards for powder characterization specific to ALM applications, though organizations like ASTM and ISO are working to address this gap.

Health and safety concerns also limit adoption, particularly in smaller enterprises. Metal powders present explosion and inhalation hazards, requiring specialized handling equipment and protocols that increase operational costs and complexity. Regulatory frameworks for metal powder handling vary globally, creating compliance challenges for international operations.

The quality of metal powders significantly impacts the final part properties. Key powder characteristics include particle size distribution, morphology, flowability, and chemical composition. Most commercial ALM systems operate optimally with powders in the 15-45μm or 45-105μm ranges, depending on the specific technology employed. Spherical particles are highly desirable as they enhance flowability and packing density, resulting in more uniform layers and fewer defects in the final parts.

Despite technological advancements, several barriers impede wider adoption of metal ALM. Cost remains a primary concern, with high-quality metal powders typically priced between $200-500 per kilogram, significantly higher than conventional manufacturing materials. Limited material availability presents another challenge, as only about 30 metal alloys are commercially available for ALM compared to thousands in traditional manufacturing. This restricts application possibilities and slows industry growth.

Powder recyclability presents both technical and economic challenges. During the ALM process, unused powder is exposed to heat and oxygen, potentially altering its properties. Current recycling protocols often involve blending used powder with virgin material, but this approach lacks standardization across the industry. Studies indicate that powder properties can degrade after multiple reuse cycles, affecting final part quality and consistency.

Quality control and standardization remain significant barriers. Variations in powder batches, even from the same supplier, can lead to inconsistent part properties. The industry lacks comprehensive standards for powder characterization specific to ALM applications, though organizations like ASTM and ISO are working to address this gap.

Health and safety concerns also limit adoption, particularly in smaller enterprises. Metal powders present explosion and inhalation hazards, requiring specialized handling equipment and protocols that increase operational costs and complexity. Regulatory frameworks for metal powder handling vary globally, creating compliance challenges for international operations.

Existing Metal Powder Solutions for ALM

01 Production methods for metal powders

Various methods are employed for producing metal powders, including atomization, chemical reduction, and electrolytic processes. These techniques allow for control over particle size, shape, and purity, which are critical factors affecting the performance of metal powders in different applications. The production methods can be optimized to yield powders with specific characteristics suitable for particular industrial uses.- Production methods for metal powders: Various methods are employed to produce metal powders with specific characteristics. These include atomization techniques, reduction processes, electrolytic deposition, and mechanical milling. Each method yields powders with different particle sizes, shapes, and surface properties, which are crucial for their subsequent applications. The production method significantly influences the powder's behavior in further processing steps such as sintering or additive manufacturing.

- Metal powder compositions and alloys: Metal powders can be formulated as pure metals or as alloys combining multiple elements to achieve enhanced properties. These compositions may include precious metals, transition metals, refractory metals, or specialized alloys designed for specific applications. The elemental composition and microstructure of these powders determine their physical and chemical properties, including melting point, strength, corrosion resistance, and magnetic characteristics.

- Applications in additive manufacturing and 3D printing: Metal powders are extensively used in additive manufacturing technologies such as selective laser melting, electron beam melting, and direct metal laser sintering. These processes require powders with specific flow characteristics, particle size distributions, and packing densities to achieve optimal part quality. The powder properties directly influence the final printed component's mechanical properties, surface finish, and dimensional accuracy.

- Surface treatments and coatings for metal powders: Metal powders can be surface-treated or coated to enhance their properties and performance in various applications. Surface modifications may include oxidation prevention coatings, functionalization for improved dispersion, or treatments to enhance sintering behavior. These treatments can improve powder flowability, reduce agglomeration, increase shelf life, and enhance compatibility with binder systems in metal injection molding or other forming processes.

- Processing and handling of metal powders: Specialized techniques are required for the processing and handling of metal powders to ensure safety and quality. These include methods for powder classification, mixing, compaction, and sintering. Considerations must be made for the reactive nature of fine metal particles, potential for dust explosions, and oxidation sensitivity. Advanced processing techniques can improve powder packing density, flowability, and ultimately the properties of the final manufactured components.

02 Metal powder compositions and alloys

Metal powders can be formulated as pure metals or as alloys combining multiple metallic elements to achieve enhanced properties. These compositions may include additives or surface treatments to improve characteristics such as oxidation resistance, flowability, or compressibility. The specific composition of metal powders significantly influences their behavior during processing and the properties of the final products.Expand Specific Solutions03 Applications in additive manufacturing and 3D printing

Metal powders are extensively used in additive manufacturing technologies, including selective laser melting, electron beam melting, and binder jetting. These powders must possess specific characteristics such as spherical morphology, appropriate particle size distribution, and good flowability to ensure successful printing processes. The quality of the metal powder directly impacts the mechanical properties, surface finish, and dimensional accuracy of the printed components.Expand Specific Solutions04 Powder metallurgy processing techniques

Powder metallurgy involves the processing of metal powders through compaction and sintering to create solid metal parts. This includes techniques such as hot isostatic pressing, metal injection molding, and spark plasma sintering. The processing parameters, including pressure, temperature, and time, must be carefully controlled to achieve desired material properties and minimize defects in the final components.Expand Specific Solutions05 Surface treatments and coatings for metal powders

Metal powders can be subjected to various surface treatments and coatings to enhance their properties and performance. These treatments may include oxidation prevention coatings, functionalization for improved bonding, or encapsulation with polymers or ceramics. Surface-modified metal powders offer advantages such as improved stability, better dispersion in matrices, and enhanced compatibility with specific applications.Expand Specific Solutions

Leading Companies in Metal Powder ALM Ecosystem

The additive layer manufacturing (ALM) metal powder market is currently in a growth phase, with an expanding ecosystem of players across the value chain. The market is experiencing significant technological advancement, driven by key industrial players like EOS GmbH, Renishaw Plc, and Stratasys Ltd., who are pioneering 3D printing systems development. Traditional metal manufacturers such as ArcelorMittal SA, Howmet Aerospace, and Daido Steel are adapting their capabilities to serve this emerging sector. The technology maturity varies across applications, with aerospace leaders (Boeing, Safran Aircraft Engines) and automotive companies (Volkswagen, GM) actively implementing metal ALM for production parts. Research institutions like Universität Stuttgart and Trinity College Dublin are collaborating with industry to overcome technical challenges in powder characterization and process optimization, indicating the technology's ongoing evolution toward full industrial maturity.

EOS GmbH

Technical Solution: EOS GmbH has developed comprehensive metal powder solutions specifically designed for additive layer manufacturing (ALM). Their EOS Metal Materials portfolio includes a wide range of metal powders optimized for different applications, from titanium alloys to tool steels. Their proprietary powder production process ensures spherical particles with controlled size distribution (typically 15-45μm), resulting in high flowability and packing density. EOS implements strict quality control measures, including chemical composition analysis, particle size distribution testing, and flow rate measurements to ensure batch-to-batch consistency. Their Direct Metal Laser Sintering (DMLS) technology is specifically calibrated to work with these powders, with parameter sets developed for each material to optimize mechanical properties and surface finish. EOS also offers specialized powder handling systems that minimize contamination risks and improve operator safety.

Strengths: Highly optimized powder-machine combinations with proven parameter sets; comprehensive material portfolio covering aerospace, medical, and industrial applications; advanced quality control systems. Weaknesses: Premium pricing compared to generic powders; proprietary nature limits use with other manufacturers' systems; requires specific handling equipment.

Renishaw Plc

Technical Solution: Renishaw has developed a sophisticated approach to metal powder management for additive manufacturing, focusing on their laser powder bed fusion (LPBF) systems. Their technology centers around carefully characterized metal powders with tight specifications for particle size distribution (typically 15-53μm) and morphology. Renishaw's powder handling system features automated sieving and recirculation capabilities that maintain powder quality through multiple build cycles, significantly reducing waste. Their QuantAM software incorporates material-specific parameters that optimize laser-powder interaction for different metal alloys. Renishaw has pioneered in-process monitoring systems that analyze melt pool dynamics in real-time, allowing for adjustments based on how specific powder batches respond to laser energy. Their metal powder portfolio includes specialized alloys for medical implants, aerospace components, and high-temperature applications, with each powder validated through extensive mechanical testing and microstructural analysis.

Strengths: Advanced in-process monitoring capabilities that adapt to powder variations; efficient powder recycling systems that maintain material properties; comprehensive material qualification processes. Weaknesses: Limited range of proprietary powders compared to some competitors; higher initial investment costs; system optimization primarily focused on their own machine ecosystem.

Critical Patents in Metal Powder ALM Technology

metal powder for a powder bed additive manufacturing process

PatentActiveFR3129857A1

Innovation

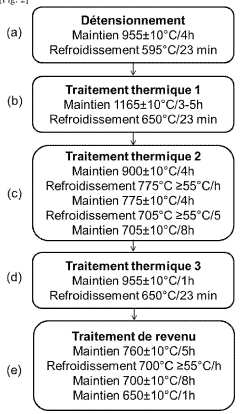

- A nickel-based alloy powder with specific elemental composition and particle size distribution, combined with a laser-based additive manufacturing process and structured heat treatments, to produce a material with enhanced mechanical properties up to 850°C.

Metal powder for additive manufacturing and additive manufacturing object formed using the same

PatentInactiveJP2024023541A

Innovation

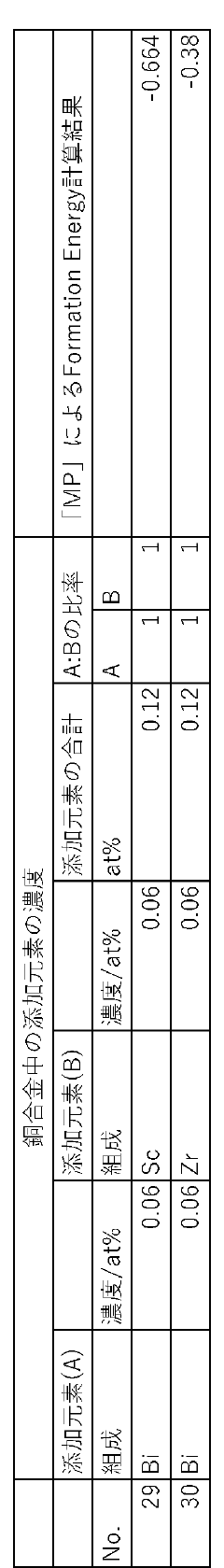

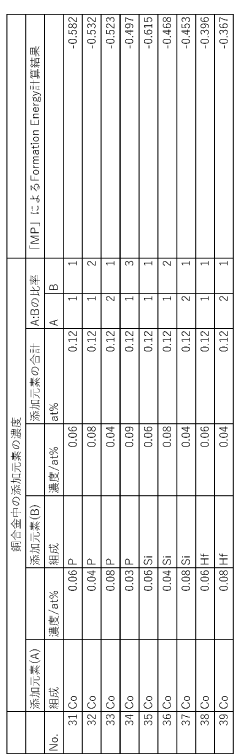

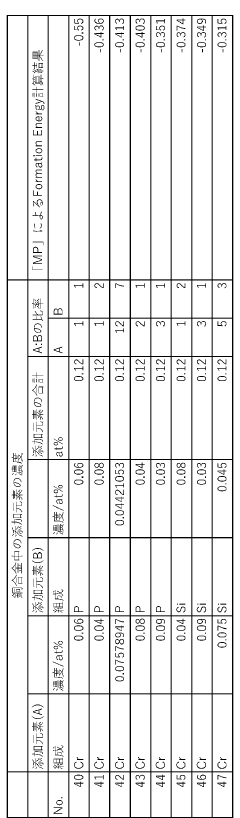

- A metal powder for additive manufacturing is formulated by combining copper with specific alloying elements such as Al, Bi, Co, Cr, Fe, Ga, Ni, P, Sc, Si, Ti, or Zr, with total compositions of these elements ranging from 0.01 to 0.3 at%, balanced with copper, to form stable compounds that enhance mechanical strength while maintaining high conductivity.

Sustainability Aspects of Metal Powder Production

The sustainability of metal powder production for Additive Layer Manufacturing (ALM) has become a critical consideration as the industry expands. Traditional metal powder production methods, including gas atomization, water atomization, and plasma atomization, consume significant energy and resources. Gas atomization, the most common technique, requires temperatures exceeding 1600°C to melt metals, resulting in substantial energy consumption and associated carbon emissions.

Environmental impacts extend beyond energy usage to include raw material extraction. Mining operations for metals like titanium, aluminum, and nickel create substantial ecological disruption through habitat destruction, soil erosion, and potential water contamination. The refining processes further compound these environmental concerns through additional energy consumption and chemical processing.

Water usage represents another significant sustainability challenge in metal powder production. Cooling systems and water atomization processes consume large volumes of water, while wastewater containing metal particles and processing chemicals requires extensive treatment before release, adding to the environmental footprint.

Recycling and circular economy principles offer promising pathways toward improved sustainability. Post-processing waste powder recovery systems can recapture up to 95% of unused powder in some ALM operations. Advanced filtration and classification technologies enable multiple reuse cycles without compromising material integrity, significantly reducing the demand for virgin material production.

Emerging technologies are transforming sustainability prospects in metal powder production. Renewable energy integration in production facilities is reducing carbon footprints, while process optimization through AI and machine learning is minimizing material waste and energy consumption. Novel atomization techniques utilizing induction heating and controlled solidification are demonstrating 30-40% energy efficiency improvements over conventional methods.

Regulatory frameworks increasingly influence sustainability practices in this sector. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for reduced-carbon production methods. Industry standards like ISO 14001 and specialized ALM sustainability certifications are driving transparency and environmental accountability throughout the supply chain.

The economic dimension of sustainability cannot be overlooked. While sustainable production methods often require higher initial investment, lifecycle analyses demonstrate long-term cost advantages through reduced energy consumption, material efficiency, and compliance with evolving regulations. Companies pioneering sustainable powder production are gaining competitive advantages through premium positioning and preferential treatment in environmentally conscious markets.

Environmental impacts extend beyond energy usage to include raw material extraction. Mining operations for metals like titanium, aluminum, and nickel create substantial ecological disruption through habitat destruction, soil erosion, and potential water contamination. The refining processes further compound these environmental concerns through additional energy consumption and chemical processing.

Water usage represents another significant sustainability challenge in metal powder production. Cooling systems and water atomization processes consume large volumes of water, while wastewater containing metal particles and processing chemicals requires extensive treatment before release, adding to the environmental footprint.

Recycling and circular economy principles offer promising pathways toward improved sustainability. Post-processing waste powder recovery systems can recapture up to 95% of unused powder in some ALM operations. Advanced filtration and classification technologies enable multiple reuse cycles without compromising material integrity, significantly reducing the demand for virgin material production.

Emerging technologies are transforming sustainability prospects in metal powder production. Renewable energy integration in production facilities is reducing carbon footprints, while process optimization through AI and machine learning is minimizing material waste and energy consumption. Novel atomization techniques utilizing induction heating and controlled solidification are demonstrating 30-40% energy efficiency improvements over conventional methods.

Regulatory frameworks increasingly influence sustainability practices in this sector. The EU's Carbon Border Adjustment Mechanism and similar policies worldwide are creating economic incentives for reduced-carbon production methods. Industry standards like ISO 14001 and specialized ALM sustainability certifications are driving transparency and environmental accountability throughout the supply chain.

The economic dimension of sustainability cannot be overlooked. While sustainable production methods often require higher initial investment, lifecycle analyses demonstrate long-term cost advantages through reduced energy consumption, material efficiency, and compliance with evolving regulations. Companies pioneering sustainable powder production are gaining competitive advantages through premium positioning and preferential treatment in environmentally conscious markets.

Quality Control Standards for ALM Metal Powders

Quality control standards for metal powders used in Additive Layer Manufacturing (ALM) have evolved significantly to address the unique challenges of this manufacturing process. These standards are critical as powder characteristics directly impact the final part quality, mechanical properties, and process reliability. Currently, several international organizations including ASTM International, ISO, and NIST have developed comprehensive frameworks for powder qualification and testing.

The primary quality parameters monitored in ALM metal powders include particle size distribution, morphology, chemical composition, flowability, and apparent density. Particle size distribution is typically measured using laser diffraction techniques, with most ALM applications requiring powders in the 15-45 μm or 45-105 μm ranges depending on the specific process. Morphological requirements generally favor spherical particles with minimal satellites, which is assessed through scanning electron microscopy (SEM) analysis.

Chemical composition standards are particularly stringent for aerospace and medical applications, with tight controls on oxygen, nitrogen, and hydrogen content that can lead to embrittlement or porosity in final parts. ASTM F3049 specifically addresses the requirements for powder feedstock testing in ALM processes, while ASTM F3303 provides guidelines for process control and qualification.

Flowability standards, measured through Hall flowmeter tests or dynamic angle of repose measurements, ensure consistent powder deposition during the build process. The Hausner ratio and Carr index are commonly used metrics to quantify powder flowability, with ideal ALM powders having a Hausner ratio below 1.25.

Recyclability assessment has emerged as a critical component of quality standards, with protocols now established to evaluate powder degradation after multiple reuse cycles. These protocols typically monitor changes in oxygen content, particle size distribution shifts, and the presence of agglomerates that may form during processing.

Recent developments in quality control standards include real-time monitoring systems that can detect powder bed anomalies during the build process, allowing for immediate corrective actions. Additionally, standards now increasingly address powder storage and handling requirements, as environmental exposure can significantly alter powder properties through moisture absorption or oxidation.

The trend toward industry-specific standards is notable, with aerospace (AS9100), medical (ISO 13485), and automotive sectors developing specialized requirements for ALM metal powders that address their unique performance and reliability needs. These standards continue to evolve as the understanding of powder-process-property relationships in ALM deepens through ongoing research and industrial experience.

The primary quality parameters monitored in ALM metal powders include particle size distribution, morphology, chemical composition, flowability, and apparent density. Particle size distribution is typically measured using laser diffraction techniques, with most ALM applications requiring powders in the 15-45 μm or 45-105 μm ranges depending on the specific process. Morphological requirements generally favor spherical particles with minimal satellites, which is assessed through scanning electron microscopy (SEM) analysis.

Chemical composition standards are particularly stringent for aerospace and medical applications, with tight controls on oxygen, nitrogen, and hydrogen content that can lead to embrittlement or porosity in final parts. ASTM F3049 specifically addresses the requirements for powder feedstock testing in ALM processes, while ASTM F3303 provides guidelines for process control and qualification.

Flowability standards, measured through Hall flowmeter tests or dynamic angle of repose measurements, ensure consistent powder deposition during the build process. The Hausner ratio and Carr index are commonly used metrics to quantify powder flowability, with ideal ALM powders having a Hausner ratio below 1.25.

Recyclability assessment has emerged as a critical component of quality standards, with protocols now established to evaluate powder degradation after multiple reuse cycles. These protocols typically monitor changes in oxygen content, particle size distribution shifts, and the presence of agglomerates that may form during processing.

Recent developments in quality control standards include real-time monitoring systems that can detect powder bed anomalies during the build process, allowing for immediate corrective actions. Additionally, standards now increasingly address powder storage and handling requirements, as environmental exposure can significantly alter powder properties through moisture absorption or oxidation.

The trend toward industry-specific standards is notable, with aerospace (AS9100), medical (ISO 13485), and automotive sectors developing specialized requirements for ALM metal powders that address their unique performance and reliability needs. These standards continue to evolve as the understanding of powder-process-property relationships in ALM deepens through ongoing research and industrial experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!