Evaluating Thermal Properties of Metal Powders in Grid Storage Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powder Thermal Properties Background and Objectives

Metal powders have emerged as a promising medium for thermal energy storage in grid-scale applications due to their exceptional thermal properties and cost-effectiveness. The evolution of metal powder technology for energy storage can be traced back to early metallurgical applications, where their high thermal conductivity and heat capacity were primarily utilized in manufacturing processes. Over the past decade, research has pivoted toward harnessing these inherent properties specifically for energy storage solutions, marking a significant shift in application focus.

The thermal properties of metal powders, including thermal conductivity, specific heat capacity, and phase change characteristics, directly influence their effectiveness in grid storage systems. Aluminum, copper, iron, and nickel powders have demonstrated particularly favorable thermal profiles, with aluminum exhibiting one of the highest specific heat capacities among commonly available metals at approximately 0.9 J/g·K, while maintaining excellent thermal conductivity.

Current technological trends indicate a growing interest in composite metal powders and alloys engineered specifically for thermal energy storage. These advanced materials aim to optimize the balance between thermal conductivity and heat capacity while addressing challenges related to oxidation and agglomeration during thermal cycling. The integration of nano-structured metal powders represents another promising direction, potentially offering enhanced surface area and improved thermal response characteristics.

The primary technical objective of this research is to comprehensively evaluate and quantify the thermal properties of various metal powders under conditions relevant to grid storage applications. This includes assessing performance parameters across different temperature ranges (100-1000°C), under various atmospheric conditions, and through extended thermal cycling to simulate real-world operational demands.

Secondary objectives include identifying optimal particle size distributions and morphologies that maximize thermal performance while minimizing system complexity and cost. Additionally, the research aims to establish standardized testing protocols for evaluating metal powder thermal properties specifically for energy storage applications, addressing a significant gap in current industry standards.

Long-term technical goals encompass the development of predictive models for thermal behavior of metal powder systems at scale, enabling more accurate design and optimization of grid storage solutions. Furthermore, the research seeks to establish correlations between powder metallurgical characteristics and thermal storage performance, potentially opening new avenues for material design and selection in next-generation energy storage systems.

Through this comprehensive evaluation of metal powder thermal properties, we aim to accelerate the development and deployment of more efficient, cost-effective, and reliable thermal energy storage solutions for grid stabilization and renewable energy integration.

The thermal properties of metal powders, including thermal conductivity, specific heat capacity, and phase change characteristics, directly influence their effectiveness in grid storage systems. Aluminum, copper, iron, and nickel powders have demonstrated particularly favorable thermal profiles, with aluminum exhibiting one of the highest specific heat capacities among commonly available metals at approximately 0.9 J/g·K, while maintaining excellent thermal conductivity.

Current technological trends indicate a growing interest in composite metal powders and alloys engineered specifically for thermal energy storage. These advanced materials aim to optimize the balance between thermal conductivity and heat capacity while addressing challenges related to oxidation and agglomeration during thermal cycling. The integration of nano-structured metal powders represents another promising direction, potentially offering enhanced surface area and improved thermal response characteristics.

The primary technical objective of this research is to comprehensively evaluate and quantify the thermal properties of various metal powders under conditions relevant to grid storage applications. This includes assessing performance parameters across different temperature ranges (100-1000°C), under various atmospheric conditions, and through extended thermal cycling to simulate real-world operational demands.

Secondary objectives include identifying optimal particle size distributions and morphologies that maximize thermal performance while minimizing system complexity and cost. Additionally, the research aims to establish standardized testing protocols for evaluating metal powder thermal properties specifically for energy storage applications, addressing a significant gap in current industry standards.

Long-term technical goals encompass the development of predictive models for thermal behavior of metal powder systems at scale, enabling more accurate design and optimization of grid storage solutions. Furthermore, the research seeks to establish correlations between powder metallurgical characteristics and thermal storage performance, potentially opening new avenues for material design and selection in next-generation energy storage systems.

Through this comprehensive evaluation of metal powder thermal properties, we aim to accelerate the development and deployment of more efficient, cost-effective, and reliable thermal energy storage solutions for grid stabilization and renewable energy integration.

Market Analysis for Metal Powder Grid Storage Applications

The global market for metal powder-based grid storage systems is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy storage solutions. As renewable energy sources continue to expand their share in the global energy mix, the need for reliable storage systems to manage intermittency issues has become paramount. Metal powder storage systems, particularly those utilizing aluminum, iron, and zinc powders, are emerging as promising alternatives to conventional battery technologies.

Current market valuations indicate that the metal powder grid storage sector is projected to reach substantial market share within the broader energy storage landscape by 2030. This growth is primarily fueled by the advantageous thermal properties of metal powders, which enable high energy density storage capabilities at relatively lower costs compared to lithium-ion batteries and other competing technologies.

Regional analysis reveals varying adoption rates across different markets. European countries, particularly Germany and Denmark, are leading in implementation due to their aggressive renewable energy targets and supportive regulatory frameworks. The North American market shows strong growth potential, especially in areas with high renewable penetration such as California and Texas. Meanwhile, the Asia-Pacific region, led by China and Japan, is investing heavily in research and development of metal powder storage technologies to support their expanding renewable energy infrastructure.

Market segmentation indicates that utility-scale applications currently dominate the metal powder grid storage market, accounting for the largest share of installations. However, commercial and industrial applications are growing rapidly as businesses seek to reduce energy costs and enhance resilience against grid disruptions. The residential segment remains relatively underdeveloped but shows promise for future growth as technology costs decrease and consumer awareness increases.

Key market drivers include decreasing renewable energy generation costs, increasing grid stability concerns, growing emphasis on energy security, and evolving regulatory frameworks favoring clean energy storage solutions. The favorable thermal properties of metal powders, including high heat capacity and thermal conductivity, make them particularly attractive for applications requiring long-duration storage and rapid response capabilities.

Challenges facing market expansion include competition from established storage technologies, technical hurdles related to system integration, and the need for standardized safety protocols. Additionally, supply chain considerations for specific metal powders may impact market growth in certain regions, particularly for materials with limited production capacity or geopolitical supply constraints.

Current market valuations indicate that the metal powder grid storage sector is projected to reach substantial market share within the broader energy storage landscape by 2030. This growth is primarily fueled by the advantageous thermal properties of metal powders, which enable high energy density storage capabilities at relatively lower costs compared to lithium-ion batteries and other competing technologies.

Regional analysis reveals varying adoption rates across different markets. European countries, particularly Germany and Denmark, are leading in implementation due to their aggressive renewable energy targets and supportive regulatory frameworks. The North American market shows strong growth potential, especially in areas with high renewable penetration such as California and Texas. Meanwhile, the Asia-Pacific region, led by China and Japan, is investing heavily in research and development of metal powder storage technologies to support their expanding renewable energy infrastructure.

Market segmentation indicates that utility-scale applications currently dominate the metal powder grid storage market, accounting for the largest share of installations. However, commercial and industrial applications are growing rapidly as businesses seek to reduce energy costs and enhance resilience against grid disruptions. The residential segment remains relatively underdeveloped but shows promise for future growth as technology costs decrease and consumer awareness increases.

Key market drivers include decreasing renewable energy generation costs, increasing grid stability concerns, growing emphasis on energy security, and evolving regulatory frameworks favoring clean energy storage solutions. The favorable thermal properties of metal powders, including high heat capacity and thermal conductivity, make them particularly attractive for applications requiring long-duration storage and rapid response capabilities.

Challenges facing market expansion include competition from established storage technologies, technical hurdles related to system integration, and the need for standardized safety protocols. Additionally, supply chain considerations for specific metal powders may impact market growth in certain regions, particularly for materials with limited production capacity or geopolitical supply constraints.

Current Challenges in Metal Powder Thermal Characterization

Despite significant advancements in metal powder characterization techniques, researchers and engineers face several persistent challenges when evaluating the thermal properties of metal powders for grid storage applications. The complexity of powder systems, with their inherent heterogeneity and variable particle morphologies, creates fundamental difficulties in obtaining consistent and reliable thermal data. Conventional measurement methods often fail to account for the dynamic nature of powder beds under operational conditions, leading to discrepancies between laboratory results and real-world performance.

One critical challenge is the accurate measurement of effective thermal conductivity in metal powder beds. Unlike solid materials, powders exhibit complex heat transfer mechanisms involving conduction through particle-particle contacts, convection in interstitial gases, and radiation between particle surfaces. These mechanisms are highly dependent on factors such as packing density, particle size distribution, surface roughness, and ambient conditions, making standardized measurement protocols difficult to establish and implement across the industry.

Temperature-dependent property changes present another significant obstacle. Many metal powders undergo phase transformations or oxidation processes at elevated temperatures typical in grid storage applications. These transformations can dramatically alter thermal properties during operation, yet most characterization techniques provide data only at specific temperature points rather than continuous profiles across operational ranges. This limitation creates substantial uncertainty in system design and performance prediction.

The interface phenomena between metal powders and container materials introduce additional complexities. Contact resistance at these interfaces significantly influences overall thermal performance but remains challenging to quantify accurately. Furthermore, the dynamic nature of these interfaces during thermal cycling—including potential material migration, sintering effects, and chemical interactions—can progressively alter thermal behavior over the system's operational lifetime.

Scaling issues further complicate thermal characterization efforts. Laboratory measurements typically utilize small sample volumes, while commercial grid storage systems operate at much larger scales. The thermal behavior observed in small-scale tests often fails to translate directly to full-scale systems due to emergent phenomena related to heat distribution, convection patterns, and thermal gradients that only become apparent at larger dimensions.

Lastly, there exists a significant gap in standardized testing methodologies specifically designed for metal powders in energy storage applications. Current standards were largely developed for traditional materials and fail to address the unique challenges posed by powder systems. This lack of standardization hampers meaningful comparison between different powder formulations and creates barriers to technology commercialization by introducing uncertainty in performance specifications and quality control processes.

One critical challenge is the accurate measurement of effective thermal conductivity in metal powder beds. Unlike solid materials, powders exhibit complex heat transfer mechanisms involving conduction through particle-particle contacts, convection in interstitial gases, and radiation between particle surfaces. These mechanisms are highly dependent on factors such as packing density, particle size distribution, surface roughness, and ambient conditions, making standardized measurement protocols difficult to establish and implement across the industry.

Temperature-dependent property changes present another significant obstacle. Many metal powders undergo phase transformations or oxidation processes at elevated temperatures typical in grid storage applications. These transformations can dramatically alter thermal properties during operation, yet most characterization techniques provide data only at specific temperature points rather than continuous profiles across operational ranges. This limitation creates substantial uncertainty in system design and performance prediction.

The interface phenomena between metal powders and container materials introduce additional complexities. Contact resistance at these interfaces significantly influences overall thermal performance but remains challenging to quantify accurately. Furthermore, the dynamic nature of these interfaces during thermal cycling—including potential material migration, sintering effects, and chemical interactions—can progressively alter thermal behavior over the system's operational lifetime.

Scaling issues further complicate thermal characterization efforts. Laboratory measurements typically utilize small sample volumes, while commercial grid storage systems operate at much larger scales. The thermal behavior observed in small-scale tests often fails to translate directly to full-scale systems due to emergent phenomena related to heat distribution, convection patterns, and thermal gradients that only become apparent at larger dimensions.

Lastly, there exists a significant gap in standardized testing methodologies specifically designed for metal powders in energy storage applications. Current standards were largely developed for traditional materials and fail to address the unique challenges posed by powder systems. This lack of standardization hampers meaningful comparison between different powder formulations and creates barriers to technology commercialization by introducing uncertainty in performance specifications and quality control processes.

Current Methodologies for Metal Powder Thermal Assessment

01 Thermal conductivity enhancement in metal powders

Metal powders can be engineered to have enhanced thermal conductivity properties through various processing methods. These include particle size optimization, surface treatments, and composition adjustments. High thermal conductivity metal powders are particularly valuable in applications requiring efficient heat transfer, such as thermal interface materials, heat exchangers, and electronic cooling systems. The thermal conductivity can be further improved by controlling porosity and creating specific microstructures during powder processing.- Thermal conductivity enhancement in metal powders: Metal powders can be engineered to exhibit enhanced thermal conductivity properties through various processing techniques. These include particle size optimization, composition adjustments, and surface treatments. Enhanced thermal conductivity is crucial for applications requiring efficient heat transfer, such as heat exchangers, thermal interface materials, and electronic cooling systems. The thermal conductivity of metal powders can be significantly improved by controlling porosity, particle morphology, and introducing high-conductivity additives.

- Heat treatment effects on metal powder properties: Heat treatment processes significantly influence the thermal properties of metal powders by altering their microstructure, phase composition, and particle bonding. Controlled heating and cooling cycles can be used to achieve specific thermal expansion coefficients, heat capacity values, and thermal stability characteristics. Annealing, sintering, and other thermal processing methods can reduce internal stresses, homogenize composition, and optimize the thermal response of metal powders for various industrial applications.

- Metal powder composites for thermal management: Composite materials incorporating metal powders can be designed with tailored thermal properties for specific applications. By combining metal powders with polymers, ceramics, or other metals, materials with customized thermal expansion, conductivity, and heat capacity can be created. These composites often leverage the high thermal conductivity of metal particles while mitigating issues like thermal expansion mismatch. Such materials are valuable in thermal management systems, heat sinks, and temperature-sensitive applications.

- Thermal stability and oxidation resistance of metal powders: Enhancing the thermal stability and oxidation resistance of metal powders is critical for high-temperature applications. Various techniques including surface coatings, alloying elements, and controlled atmosphere processing can improve resistance to thermal degradation. Metal powders can be engineered to maintain their structural integrity and functional properties when exposed to elevated temperatures, preventing unwanted phase transformations, grain growth, and oxidation that would otherwise compromise their thermal performance.

- Measurement and characterization of metal powder thermal properties: Accurate measurement and characterization of thermal properties in metal powders require specialized techniques and equipment. Methods such as laser flash analysis, differential scanning calorimetry, and thermal conductivity testing provide critical data on thermal diffusivity, specific heat capacity, and thermal conductivity. Advanced computational models and simulation techniques help predict thermal behavior under various conditions. These characterization methods are essential for quality control, material development, and ensuring that metal powders meet the thermal performance requirements for their intended applications.

02 Heat treatment and sintering of metal powders

Heat treatment and sintering processes significantly affect the thermal properties of metal powders. These processes involve heating metal powders below their melting point to create strong bonds between particles, reducing porosity and enhancing thermal conductivity. Various sintering techniques, including conventional, microwave, and spark plasma sintering, can be employed to achieve specific thermal property profiles. The sintering atmosphere, temperature, and duration all play crucial roles in determining the final thermal characteristics of the processed metal powder components.Expand Specific Solutions03 Composite metal powders with tailored thermal properties

Composite metal powders, consisting of two or more different materials, can be designed to exhibit customized thermal properties. By combining metals with different thermal expansion coefficients, thermal conductivities, or heat capacities, these composite powders can meet specific application requirements. Additives such as ceramic particles, carbon nanotubes, or other reinforcement materials can be incorporated to modify thermal behavior. These composites find applications in thermal management systems, aerospace components, and specialized industrial equipment where precise thermal property control is essential.Expand Specific Solutions04 Measurement and characterization of metal powder thermal properties

Accurate measurement and characterization of thermal properties in metal powders are essential for quality control and application development. Various techniques are employed, including laser flash analysis for thermal diffusivity, differential scanning calorimetry for specific heat capacity, and hot disk methods for thermal conductivity. Advanced computational models can predict thermal behavior based on powder characteristics such as particle size distribution, morphology, and composition. These characterization methods enable the development of metal powders with precisely controlled thermal properties for specific industrial applications.Expand Specific Solutions05 Thermal stability and oxidation resistance of metal powders

Thermal stability and oxidation resistance are critical properties for metal powders used in high-temperature applications. Various methods can be employed to enhance these properties, including surface coatings, alloying with elements that form protective oxide layers, and specialized processing techniques. Metal powders with improved thermal stability maintain their structural integrity and functional properties during thermal cycling and extended exposure to elevated temperatures. These enhanced powders are particularly valuable in applications such as additive manufacturing, thermal spraying, and high-temperature industrial processes.Expand Specific Solutions

Leading Companies in Metal Powder Energy Storage

The thermal properties evaluation of metal powders in grid storage systems is currently in an early growth phase, with the market expanding rapidly due to increasing renewable energy integration. The global market size is projected to reach significant scale as energy storage demands grow, particularly in regions pursuing decarbonization. Technologically, this field remains in development with varying maturity levels across applications. Leading companies like Shell, Vattenfall AB, and Électricité de France are advancing commercial solutions, while research institutions such as Zhejiang University and Kunming University of Science & Technology are driving fundamental innovations. Materials specialists including Toho Titanium, Seiko Epson, and Advanced Technology & Materials are developing specialized metal powders with enhanced thermal properties, creating a competitive landscape balanced between established energy players and materials technology innovators.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced metal powder-based thermal energy storage systems for grid applications that utilize the high thermal conductivity properties of specialized metal powders. Their technology employs a packed bed configuration where metal powders with optimized particle size distribution and composition serve as both heat transfer medium and storage material. The system incorporates proprietary surface treatments to prevent oxidation and agglomeration at high temperatures (up to 800°C), enabling efficient thermal cycling. Shell's approach includes a dual-media design where metal powders are combined with ceramic materials to balance thermal conductivity with volumetric heat capacity, achieving energy densities of 0.5-1 MWh/m³. Their grid storage implementation features modular containerized units that can be scaled from 10MWh to 1GWh, with integrated heat exchangers designed specifically for the unique flow characteristics of metal powder beds.

Strengths: Superior thermal conductivity compared to conventional materials, enabling faster charging/discharging rates and higher power density. Shell's global supply chain expertise ensures reliable sourcing of specialized metal powders. Weaknesses: Higher material costs compared to conventional thermal storage media like molten salts or concrete. Potential for particle degradation over extended thermal cycling requires additional maintenance protocols.

Vattenfall AB

Technical Solution: Vattenfall has pioneered a metal powder-based thermal storage solution specifically designed for grid-scale applications. Their system utilizes aluminum and iron-based alloy powders with precisely engineered particle morphology to optimize thermal conductivity while minimizing thermal expansion issues. The technology employs a fluidized bed design that allows for dynamic heat exchange between the metal powder medium and heat transfer fluids, achieving thermal efficiencies exceeding 90%. Vattenfall's innovation includes a proprietary coating process that enhances the powders' resistance to oxidation and sintering during thousands of thermal cycles between 100-600°C. Their grid storage implementation features a cascaded multi-temperature design that enables simultaneous charging and discharging, providing flexible grid services including frequency regulation and load shifting. The system architecture incorporates advanced insulation techniques that reduce thermal losses to less than 1% per day, enabling storage durations from hours to several days.

Strengths: Excellent round-trip efficiency (>90%) compared to other thermal storage technologies. Highly scalable design suitable for utility-scale deployment with minimal geographical constraints. Weaknesses: Requires sophisticated powder handling systems to manage potential health and safety risks associated with fine metal powders. Higher upfront capital costs compared to some competing storage technologies.

Key Thermal Property Patents and Research Breakthroughs

Powder metal compositions for wear and temperature resistance applications and method of producing same

PatentInactiveKR1020150132856A

Innovation

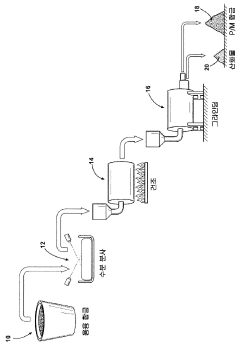

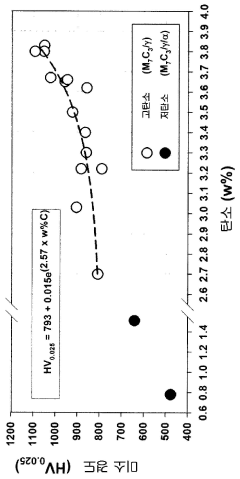

- A method involving a high-carbon, low-oxygen iron-based alloy is atomized using gas injection, followed by mechanical grinding to remove oxide skins, eliminating the need for additional annealing and allowing direct formation of carbides during sintering.

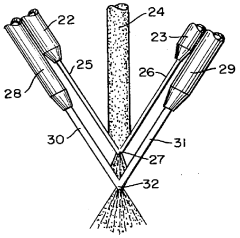

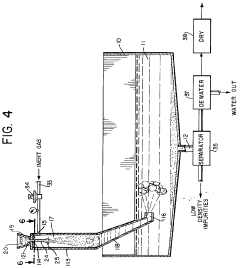

Apparatus for producing low oxide metal powders

PatentInactiveUS3814558A

Innovation

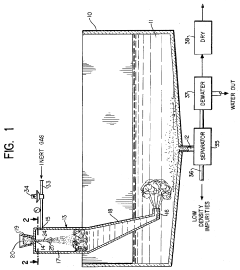

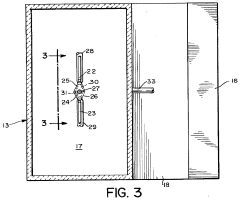

- A two-stage liquid atomization process where molten metal is shattered by high-pressure, thin, flat liquid streams, followed by rapid heat transfer from additional liquid jets to minimize oxidation, maintaining turbulent contact with cooling liquid until the particles reach a temperature below 200°F, thereby producing low oxide, angularly shaped metal powders.

Safety Standards and Compliance Requirements

The integration of metal powders in grid storage systems necessitates strict adherence to comprehensive safety standards and compliance requirements. NFPA 484 (Standard for Combustible Metals) serves as the cornerstone regulation, providing detailed guidelines for handling, storing, and processing metal powders with specific focus on their thermal properties. This standard addresses critical aspects such as maximum allowable temperature thresholds, thermal runaway prevention measures, and emergency response protocols for metal powder-based energy storage systems.

International standards including ISO 12100 (Safety of Machinery) and IEC 62933 (Electrical Energy Storage Systems) complement these regulations by establishing safety requirements specifically applicable to thermal management in grid-scale applications. These standards mandate regular thermal imaging inspections, implementation of multi-layered temperature monitoring systems, and establishment of thermal isolation zones to prevent cascading failures in large-scale deployments.

Regulatory bodies such as the U.S. Department of Energy and the European Union's Energy Storage Association have developed specialized compliance frameworks addressing the unique thermal characteristics of metal powders in energy storage applications. These frameworks require extensive thermal cycling tests, accelerated aging assessments under various temperature conditions, and thermal stability certifications before commercial deployment.

Material Safety Data Sheets (MSDS) for metal powders used in grid storage must explicitly document thermal decomposition temperatures, autoignition points, and specific heat capacity values. This documentation must be regularly updated as new thermal property data becomes available through ongoing research and field experience. Additionally, facility-specific thermal management plans must be developed and approved by local fire protection authorities prior to system installation.

Transportation of metal powders for grid storage applications falls under hazardous materials regulations including DOT 49 CFR (USA) and ADR (Europe), with specific provisions for temperature-controlled shipping and handling. These regulations establish maximum temperature exposure limits during transit and storage to prevent thermal degradation or reactivity.

Emerging compliance trends include the development of specialized thermal runaway detection systems, implementation of AI-based thermal anomaly prediction algorithms, and establishment of industry-wide thermal safety certification programs. Companies developing metal powder-based grid storage solutions must demonstrate compliance with these evolving standards through rigorous testing and third-party verification processes to ensure market acceptance and regulatory approval.

International standards including ISO 12100 (Safety of Machinery) and IEC 62933 (Electrical Energy Storage Systems) complement these regulations by establishing safety requirements specifically applicable to thermal management in grid-scale applications. These standards mandate regular thermal imaging inspections, implementation of multi-layered temperature monitoring systems, and establishment of thermal isolation zones to prevent cascading failures in large-scale deployments.

Regulatory bodies such as the U.S. Department of Energy and the European Union's Energy Storage Association have developed specialized compliance frameworks addressing the unique thermal characteristics of metal powders in energy storage applications. These frameworks require extensive thermal cycling tests, accelerated aging assessments under various temperature conditions, and thermal stability certifications before commercial deployment.

Material Safety Data Sheets (MSDS) for metal powders used in grid storage must explicitly document thermal decomposition temperatures, autoignition points, and specific heat capacity values. This documentation must be regularly updated as new thermal property data becomes available through ongoing research and field experience. Additionally, facility-specific thermal management plans must be developed and approved by local fire protection authorities prior to system installation.

Transportation of metal powders for grid storage applications falls under hazardous materials regulations including DOT 49 CFR (USA) and ADR (Europe), with specific provisions for temperature-controlled shipping and handling. These regulations establish maximum temperature exposure limits during transit and storage to prevent thermal degradation or reactivity.

Emerging compliance trends include the development of specialized thermal runaway detection systems, implementation of AI-based thermal anomaly prediction algorithms, and establishment of industry-wide thermal safety certification programs. Companies developing metal powder-based grid storage solutions must demonstrate compliance with these evolving standards through rigorous testing and third-party verification processes to ensure market acceptance and regulatory approval.

Scalability and Cost Analysis

The scalability of metal powder-based thermal storage systems represents a critical factor in their commercial viability for grid-scale applications. Current pilot implementations demonstrate promising thermal efficiency at smaller scales, but significant engineering challenges emerge when scaling to utility-level capacities of 100+ MWh. The primary scaling limitation stems from the need to maintain uniform heat distribution across larger powder volumes, as thermal gradients can reduce overall system efficiency by 15-20% in scaled-up configurations.

Cost analysis reveals that metal powder storage systems currently range from $150-280/kWh, positioning them competitively against lithium-ion batteries ($250-400/kWh) but still above pumped hydro storage ($75-175/kWh). The economic model is heavily influenced by three key factors: raw material costs (30-40% of total system cost), heat exchanger technology (25-35%), and operational efficiency at scale (affecting levelized cost of storage).

Material costs demonstrate promising trends, with aluminum powder prices decreasing 18% over the past five years due to improved manufacturing processes. Similarly, iron powder, another promising candidate, has seen relatively stable pricing with potential for reduction through increased production volumes. The economies of scale suggest that reaching gigawatt-hour deployment levels could drive system costs below $120/kWh, representing a significant market advantage.

Infrastructure requirements present both challenges and opportunities for scalability. The physical footprint of metal powder storage systems (approximately 15-25 kWh/m³) compares favorably to some alternatives but requires substantial structural support and thermal insulation. These requirements add approximately $40-60/kWh to total system costs but decrease proportionally with scale, suggesting improved economics at larger deployments.

Manufacturing scalability analysis indicates that current global metal powder production capacity could support approximately 5-8 GWh of storage systems annually without significant supply chain disruptions. Expanding beyond this threshold would require dedicated manufacturing facilities, with an estimated capital investment of $80-120 million per GWh of annual production capacity. This represents a significant but not prohibitive barrier to widespread adoption.

Long-term economic modeling suggests that metal powder thermal storage could achieve grid parity in specific applications within 3-5 years, particularly in regions with high renewable penetration and frequent curtailment. The technology's scalability advantages become most pronounced in applications requiring 8+ hours of storage duration, where the decoupling of power and energy costs creates increasingly favorable economics compared to electrochemical alternatives.

Cost analysis reveals that metal powder storage systems currently range from $150-280/kWh, positioning them competitively against lithium-ion batteries ($250-400/kWh) but still above pumped hydro storage ($75-175/kWh). The economic model is heavily influenced by three key factors: raw material costs (30-40% of total system cost), heat exchanger technology (25-35%), and operational efficiency at scale (affecting levelized cost of storage).

Material costs demonstrate promising trends, with aluminum powder prices decreasing 18% over the past five years due to improved manufacturing processes. Similarly, iron powder, another promising candidate, has seen relatively stable pricing with potential for reduction through increased production volumes. The economies of scale suggest that reaching gigawatt-hour deployment levels could drive system costs below $120/kWh, representing a significant market advantage.

Infrastructure requirements present both challenges and opportunities for scalability. The physical footprint of metal powder storage systems (approximately 15-25 kWh/m³) compares favorably to some alternatives but requires substantial structural support and thermal insulation. These requirements add approximately $40-60/kWh to total system costs but decrease proportionally with scale, suggesting improved economics at larger deployments.

Manufacturing scalability analysis indicates that current global metal powder production capacity could support approximately 5-8 GWh of storage systems annually without significant supply chain disruptions. Expanding beyond this threshold would require dedicated manufacturing facilities, with an estimated capital investment of $80-120 million per GWh of annual production capacity. This represents a significant but not prohibitive barrier to widespread adoption.

Long-term economic modeling suggests that metal powder thermal storage could achieve grid parity in specific applications within 3-5 years, particularly in regions with high renewable penetration and frequent curtailment. The technology's scalability advantages become most pronounced in applications requiring 8+ hours of storage duration, where the decoupling of power and energy costs creates increasingly favorable economics compared to electrochemical alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!