New Frontiers of Metal Powders in Hydrogen Storage Solutions

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powder Hydrogen Storage Background and Objectives

Hydrogen storage has emerged as a critical challenge in the global transition towards sustainable energy systems. The history of metal powder-based hydrogen storage dates back to the 1970s when researchers first discovered certain metals' ability to absorb hydrogen. Over subsequent decades, this technology has evolved from simple metal hydrides to complex alloys and nanostructured materials, demonstrating the field's continuous innovation trajectory.

Metal powders offer unique advantages for hydrogen storage due to their high surface area-to-volume ratio and tunable properties. Traditional approaches have focused primarily on intermetallic compounds and alloys, while recent advancements have expanded to include complex hydrides, nanostructured materials, and metal-organic frameworks. These developments reflect the technology's evolution from theoretical concepts to practical applications in various sectors.

The primary objective of metal powder hydrogen storage research is to develop materials capable of storing hydrogen safely at high densities under moderate temperature and pressure conditions. Current targets established by the U.S. Department of Energy include achieving 6.5 wt% hydrogen content and 50 g/L volumetric capacity by 2025, with ultimate goals of 7.5 wt% and 70 g/L for practical vehicular applications.

Technical challenges driving innovation in this field include improving hydrogen absorption/desorption kinetics, enhancing cycling stability, reducing operating temperatures, and minimizing material costs. These challenges have spurred research into novel material compositions, catalyst integration, and advanced manufacturing techniques for optimized powder morphologies.

The global hydrogen economy is projected to reach $2.5 trillion by 2050, with storage solutions representing a significant market segment. Metal powder storage systems are positioned to capture substantial market share in stationary applications, transportation, and grid-scale energy storage, particularly as renewable energy integration accelerates worldwide.

Recent technological breakthroughs, including the development of high-entropy alloys and mechanochemical synthesis methods, have demonstrated potential for overcoming traditional limitations. These innovations suggest promising pathways toward meeting performance targets while addressing cost and scalability concerns.

Looking forward, the technology roadmap for metal powder hydrogen storage includes near-term goals of improving gravimetric capacity and cycling stability, mid-term objectives of cost reduction and manufacturing scalability, and long-term visions of fully integrated systems with advanced thermal management and safety features. This progressive development approach aligns with broader hydrogen infrastructure deployment timelines across major economies.

Metal powders offer unique advantages for hydrogen storage due to their high surface area-to-volume ratio and tunable properties. Traditional approaches have focused primarily on intermetallic compounds and alloys, while recent advancements have expanded to include complex hydrides, nanostructured materials, and metal-organic frameworks. These developments reflect the technology's evolution from theoretical concepts to practical applications in various sectors.

The primary objective of metal powder hydrogen storage research is to develop materials capable of storing hydrogen safely at high densities under moderate temperature and pressure conditions. Current targets established by the U.S. Department of Energy include achieving 6.5 wt% hydrogen content and 50 g/L volumetric capacity by 2025, with ultimate goals of 7.5 wt% and 70 g/L for practical vehicular applications.

Technical challenges driving innovation in this field include improving hydrogen absorption/desorption kinetics, enhancing cycling stability, reducing operating temperatures, and minimizing material costs. These challenges have spurred research into novel material compositions, catalyst integration, and advanced manufacturing techniques for optimized powder morphologies.

The global hydrogen economy is projected to reach $2.5 trillion by 2050, with storage solutions representing a significant market segment. Metal powder storage systems are positioned to capture substantial market share in stationary applications, transportation, and grid-scale energy storage, particularly as renewable energy integration accelerates worldwide.

Recent technological breakthroughs, including the development of high-entropy alloys and mechanochemical synthesis methods, have demonstrated potential for overcoming traditional limitations. These innovations suggest promising pathways toward meeting performance targets while addressing cost and scalability concerns.

Looking forward, the technology roadmap for metal powder hydrogen storage includes near-term goals of improving gravimetric capacity and cycling stability, mid-term objectives of cost reduction and manufacturing scalability, and long-term visions of fully integrated systems with advanced thermal management and safety features. This progressive development approach aligns with broader hydrogen infrastructure deployment timelines across major economies.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing adoption of hydrogen as a clean energy carrier. As of 2023, the market was valued at approximately $15.4 billion, with projections indicating a compound annual growth rate (CAGR) of 9.7% through 2030, potentially reaching $28.1 billion by the end of the decade. This growth trajectory is underpinned by substantial investments in hydrogen infrastructure worldwide, with governments committing over $70 billion in public funding.

Metal powder-based hydrogen storage solutions are gaining particular traction within this expanding market. These materials offer advantages in volumetric efficiency compared to compressed gas and cryogenic liquid storage methods. The metal hydride segment currently accounts for about 18% of the hydrogen storage market, with expectations to grow at a faster rate than the overall market due to technological advancements in metal powder formulations.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, led by Japan, South Korea, and China's aggressive hydrogen strategy implementations. Europe follows with 31% market share, driven by the European Union's hydrogen roadmap targeting 40GW of electrolyzer capacity by 2030. North America represents about 22% of the market, with significant growth potential as the United States implements its Hydrogen Earthshot initiative.

By application sector, transportation represents the largest market segment (38%), followed by industrial applications (29%), power generation (18%), and others (15%). The transportation sector's dominance is attributed to the increasing deployment of fuel cell vehicles, particularly in commercial fleet applications where metal powder storage systems offer weight and safety advantages over high-pressure tanks.

Customer demand patterns indicate a growing preference for storage solutions that balance energy density, safety, and cost-effectiveness. End-users are increasingly willing to pay premium prices for storage technologies that demonstrate superior cycle stability and fast kinetics, areas where advanced metal powder formulations excel.

Market barriers include high initial costs, with metal hydride systems typically commanding a 30-40% price premium over conventional storage methods. However, this gap is narrowing as manufacturing scales up and material science advances. Technical challenges related to thermal management during hydrogen absorption/desorption cycles remain a concern for widespread commercial adoption.

Emerging market opportunities include the integration of metal powder storage systems with renewable energy installations for grid balancing and the development of modular, scalable storage solutions for distributed energy applications in remote and off-grid locations.

Metal powder-based hydrogen storage solutions are gaining particular traction within this expanding market. These materials offer advantages in volumetric efficiency compared to compressed gas and cryogenic liquid storage methods. The metal hydride segment currently accounts for about 18% of the hydrogen storage market, with expectations to grow at a faster rate than the overall market due to technological advancements in metal powder formulations.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 42% share, led by Japan, South Korea, and China's aggressive hydrogen strategy implementations. Europe follows with 31% market share, driven by the European Union's hydrogen roadmap targeting 40GW of electrolyzer capacity by 2030. North America represents about 22% of the market, with significant growth potential as the United States implements its Hydrogen Earthshot initiative.

By application sector, transportation represents the largest market segment (38%), followed by industrial applications (29%), power generation (18%), and others (15%). The transportation sector's dominance is attributed to the increasing deployment of fuel cell vehicles, particularly in commercial fleet applications where metal powder storage systems offer weight and safety advantages over high-pressure tanks.

Customer demand patterns indicate a growing preference for storage solutions that balance energy density, safety, and cost-effectiveness. End-users are increasingly willing to pay premium prices for storage technologies that demonstrate superior cycle stability and fast kinetics, areas where advanced metal powder formulations excel.

Market barriers include high initial costs, with metal hydride systems typically commanding a 30-40% price premium over conventional storage methods. However, this gap is narrowing as manufacturing scales up and material science advances. Technical challenges related to thermal management during hydrogen absorption/desorption cycles remain a concern for widespread commercial adoption.

Emerging market opportunities include the integration of metal powder storage systems with renewable energy installations for grid balancing and the development of modular, scalable storage solutions for distributed energy applications in remote and off-grid locations.

Current Metal Hydride Technology Landscape and Challenges

Metal hydride technology represents a significant advancement in hydrogen storage solutions, offering higher volumetric density compared to compressed gas or liquid hydrogen systems. Currently, the landscape is dominated by conventional metal hydrides such as LaNi5, TiFe, and Mg-based compounds, each with specific operating characteristics and applications. These materials typically achieve hydrogen storage capacities ranging from 1.5 to 7.5 weight percent, with most commercial systems operating below 3 weight percent.

The global research community has made substantial progress in enhancing the kinetics of hydrogen absorption and desorption through various techniques including catalytic doping, nanostructuring, and compositional optimization. Notable improvements include reducing absorption temperatures from above 300°C to below 200°C for magnesium-based systems and enhancing cycling stability from hundreds to thousands of cycles for intermetallic compounds.

Despite these advancements, significant challenges persist in the widespread adoption of metal hydride technology. The primary technical barriers include insufficient gravimetric capacity for mobile applications, slow kinetics at ambient temperatures, thermal management issues during hydrogen charging/discharging, and material degradation over multiple cycles. Most current systems require either high temperatures (>300°C) for adequate hydrogen release or operate at suboptimal capacities under practical conditions.

Cost factors also present substantial obstacles, with rare earth and transition metal-based hydrides remaining prohibitively expensive for large-scale applications. Manufacturing complexities further compound these economic challenges, particularly in producing high-purity, homogeneous metal powders at industrial scales.

Environmental and safety concerns constitute another dimension of challenges. Some metal hydride systems are pyrophoric when exposed to air, creating handling risks during manufacturing and maintenance. Additionally, the environmental footprint of mining and processing rare earth elements for certain hydride compositions raises sustainability questions.

The geographical distribution of metal hydride technology development shows concentration in research hubs across North America, Europe, Japan, South Korea, and increasingly China. This distribution largely correlates with advanced materials science capabilities and hydrogen economy initiatives rather than with natural resource availability, creating potential supply chain vulnerabilities.

Recent technological trends indicate growing interest in complex hydrides, high-entropy alloys, and two-dimensional materials as potential breakthrough candidates. These emerging approaches aim to overcome the fundamental limitations of conventional metal hydrides while maintaining their inherent safety advantages over high-pressure storage systems.

The global research community has made substantial progress in enhancing the kinetics of hydrogen absorption and desorption through various techniques including catalytic doping, nanostructuring, and compositional optimization. Notable improvements include reducing absorption temperatures from above 300°C to below 200°C for magnesium-based systems and enhancing cycling stability from hundreds to thousands of cycles for intermetallic compounds.

Despite these advancements, significant challenges persist in the widespread adoption of metal hydride technology. The primary technical barriers include insufficient gravimetric capacity for mobile applications, slow kinetics at ambient temperatures, thermal management issues during hydrogen charging/discharging, and material degradation over multiple cycles. Most current systems require either high temperatures (>300°C) for adequate hydrogen release or operate at suboptimal capacities under practical conditions.

Cost factors also present substantial obstacles, with rare earth and transition metal-based hydrides remaining prohibitively expensive for large-scale applications. Manufacturing complexities further compound these economic challenges, particularly in producing high-purity, homogeneous metal powders at industrial scales.

Environmental and safety concerns constitute another dimension of challenges. Some metal hydride systems are pyrophoric when exposed to air, creating handling risks during manufacturing and maintenance. Additionally, the environmental footprint of mining and processing rare earth elements for certain hydride compositions raises sustainability questions.

The geographical distribution of metal hydride technology development shows concentration in research hubs across North America, Europe, Japan, South Korea, and increasingly China. This distribution largely correlates with advanced materials science capabilities and hydrogen economy initiatives rather than with natural resource availability, creating potential supply chain vulnerabilities.

Recent technological trends indicate growing interest in complex hydrides, high-entropy alloys, and two-dimensional materials as potential breakthrough candidates. These emerging approaches aim to overcome the fundamental limitations of conventional metal hydrides while maintaining their inherent safety advantages over high-pressure storage systems.

Current Metal Alloy Solutions for Hydrogen Storage

01 Metal alloy compositions for hydrogen storage

Various metal alloy compositions have been developed specifically for hydrogen storage applications. These alloys typically include combinations of transition metals, rare earth metals, and other elements that form intermetallic compounds with favorable hydrogen absorption and desorption properties. The specific composition of these alloys can be tailored to optimize hydrogen storage capacity, kinetics, and cycling stability under different operating conditions.- Metal alloy compositions for hydrogen storage: Various metal alloy compositions can be used for hydrogen storage applications. These include magnesium-based alloys, titanium-based alloys, and rare earth metal alloys that offer improved hydrogen absorption and desorption properties. The specific composition of these alloys can be tailored to optimize hydrogen storage capacity, kinetics, and cycling stability. These materials typically form metal hydrides when exposed to hydrogen gas under specific temperature and pressure conditions.

- Nanostructured metal powders for enhanced hydrogen storage: Nanostructured metal powders provide enhanced hydrogen storage capabilities due to their increased surface area and shortened diffusion paths. These materials can be synthesized through various methods including ball milling, chemical vapor deposition, and solution-based approaches. The nanoscale structure facilitates faster hydrogen absorption/desorption kinetics and can improve the overall storage capacity. Additionally, nanostructuring can help reduce the operating temperature required for hydrogen release.

- Metal powder processing techniques for hydrogen storage applications: Specific processing techniques can significantly improve the hydrogen storage properties of metal powders. These include mechanical alloying, high-energy ball milling, and various heat treatment processes. Such techniques can create defects, amorphous structures, or specific crystalline phases that enhance hydrogen absorption. Additionally, catalytic additives can be incorporated during processing to improve kinetics and reduce activation energy for hydrogen uptake and release.

- Metal-organic frameworks and composite materials for hydrogen storage: Metal-organic frameworks (MOFs) and metal-based composite materials offer promising hydrogen storage solutions. These materials combine metal centers with organic linkers or other components to create structures with high porosity and surface area. The incorporation of metal nanoparticles into porous substrates can create synergistic effects that enhance hydrogen uptake. These composite systems often operate at more moderate conditions than traditional metal hydrides while maintaining good storage capacities.

- Practical applications and systems for metal powder hydrogen storage: Metal powder hydrogen storage systems have been developed for various practical applications including fuel cells, transportation, and stationary energy storage. These systems incorporate metal powders or hydrides within engineered containers with heat management capabilities, pressure regulation, and safety features. The design considerations include thermal management during hydrogen absorption/desorption, powder compaction issues, and integration with hydrogen delivery systems. These practical implementations address challenges related to volumetric expansion, heat transfer, and system durability.

02 Metal powder processing techniques for hydrogen storage

Specialized processing techniques for metal powders can significantly enhance hydrogen storage capabilities. These techniques include mechanical alloying, ball milling, rapid solidification, and various heat treatments that create specific microstructures favorable for hydrogen absorption. The processing methods can introduce defects, increase surface area, and create nanoscale features that improve hydrogen diffusion pathways and storage capacity in the metal matrix.Expand Specific Solutions03 Nanostructured metal powders for enhanced hydrogen storage

Nanostructured metal powders offer superior hydrogen storage properties compared to conventional materials. By reducing particle size to the nanoscale, these materials provide increased surface area, shorter diffusion paths, and modified thermodynamics that enhance hydrogen absorption and desorption kinetics. Various synthesis methods including chemical reduction, sol-gel processing, and controlled decomposition can be used to create these nanostructured materials with optimized morphology for hydrogen storage.Expand Specific Solutions04 Catalyst-enhanced metal powder systems

The addition of catalysts to metal powder systems can dramatically improve hydrogen storage performance. These catalysts, often transition metals or their compounds, facilitate the dissociation of hydrogen molecules at the material surface and accelerate the absorption and desorption processes. Catalyst distribution, loading amount, and interaction with the base metal powder are critical factors that determine the overall efficiency of the hydrogen storage system.Expand Specific Solutions05 Metal hydride composites and hybrid systems

Advanced metal hydride composites combine different types of metal powders or integrate metal powders with other materials like carbon structures to create hybrid hydrogen storage systems. These composites can overcome limitations of single-component systems by combining the advantages of different materials. The synergistic effects between components can lead to improved hydrogen capacity, better thermal management, enhanced kinetics, and greater cycling stability compared to conventional metal hydride systems.Expand Specific Solutions

Leading Companies and Research Institutions in Metal Hydride Storage

The hydrogen storage market using metal powders is in a growth phase, characterized by increasing R&D investments and expanding applications. The global market is projected to reach significant scale as hydrogen economy initiatives accelerate worldwide. Technologically, the field shows varying maturity levels, with academic institutions (Zhejiang University, University of Michigan) focusing on fundamental research while companies demonstrate different commercialization stages. Leading players like BASF, Johnson Matthey, and Intelligent Energy are advancing commercial solutions, while specialized firms like GRZ Technologies and Jiaxing Zheda Parken are developing proprietary metal hydride technologies. Government research organizations (CNRS, AIST) are bridging fundamental science with industrial applications, creating a competitive landscape that balances innovation with practical implementation challenges.

BASF SE

Technical Solution: BASF has developed an innovative hydrogen storage solution based on their proprietary Metal-Organic Framework (MOF) technology combined with specialized metal powder catalysts. Their system utilizes highly porous MOF structures with exceptionally high surface areas (>3000 m²/g) that are impregnated with precisely engineered metal nanoparticles (primarily palladium, platinum, and nickel alloys) to facilitate hydrogen adsorption and release[5]. The company's approach involves a dual-mechanism storage system where hydrogen is both physically adsorbed on the MOF surface and chemically bound to the metal catalyst sites, achieving storage densities of approximately 5.5 wt% at moderate pressures (100 bar) and temperatures (-20°C to 50°C)[6]. BASF has further enhanced this technology by developing specialized surface functionalization techniques that optimize the binding energy between hydrogen molecules and the storage material, striking an optimal balance between storage capacity and release kinetics. Their manufacturing process employs proprietary techniques to ensure uniform distribution of metal catalysts throughout the MOF structure, maintaining performance consistency across production batches.

Strengths: Operates across a wide temperature range without requiring extreme conditions; reversible storage with minimal capacity loss over hundreds of cycles; tunable binding energies allow customization for specific applications. Weaknesses: Production of high-purity MOFs with consistent properties remains costly at scale; sensitivity to certain contaminants can degrade performance over time; requires moderate pressure (100 bar) for optimal storage density.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed an advanced hydrogen storage solution utilizing precisely engineered palladium-based alloy powders. Their proprietary technology employs a core-shell nanostructure where palladium-rich shells surround more economical metal cores (typically nickel or copper alloys), optimizing the use of precious metals while maintaining exceptional hydrogen absorption properties[9]. The company has refined a specialized manufacturing process that creates highly porous metal structures with controlled particle sizes (typically 50-200 nm) and specific surface areas exceeding 40 m²/g, maximizing hydrogen interaction sites. Their system achieves reversible hydrogen storage capacities of approximately 2.5 wt% at near-ambient conditions (1-10 bar, 0-50°C), with exceptionally fast kinetics allowing complete charging in under 5 minutes[10]. Johnson Matthey has further enhanced their technology by incorporating proprietary surface modifiers that prevent agglomeration and sintering during repeated hydrogen cycling, maintaining performance over thousands of cycles. The company has also developed specialized activation protocols that optimize the metal powder's performance without requiring extreme conditions, simplifying system integration and operation.

Strengths: Operates at near-ambient conditions without requiring high temperatures or pressures; extremely fast absorption/desorption kinetics; exceptional cycling stability (>5000 cycles with minimal capacity loss); high hydrogen purity delivery suitable for fuel cells. Weaknesses: Lower gravimetric capacity (2.5 wt%) compared to some competing technologies; higher material costs due to precious metal content; sensitivity to certain contaminants requiring protective measures.

Key Patents and Innovations in Metal Powder Storage Technology

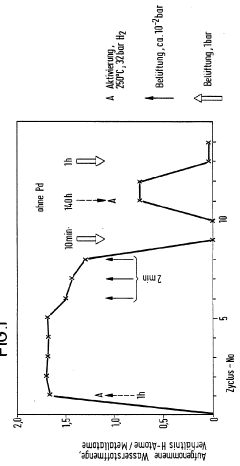

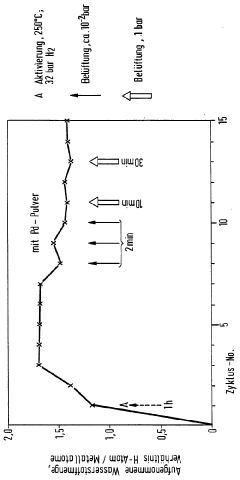

Powder-type hydrogen storage material and production thereof

PatentWO1987002022A1

Innovation

- Incorporating hydrogenation/dehydrogenation catalysts, such as subgroup I and VIII metals like Pd, into the storage material powder, allowing for reactivation and maintaining storage capacity even under oxidizing conditions, enabling air-stable operation without expensive surface coatings.

Hydrogen storage material, and production method therefor

PatentInactiveJP2004204309A

Innovation

- A hydrogen storage material is produced by adding metal powders with hydrogen molecule dissociation catalytic ability and anti-adhesion agents to magnesium or magnesium-based alloy powders, and ball milling them in an inert atmosphere under reduced pressure, using metal chlorides and hydrides as anti-adhesion agents to prevent oxidation and adhesion.

Environmental Impact and Sustainability Considerations

The environmental implications of metal powder-based hydrogen storage systems represent a critical dimension in evaluating their viability as sustainable energy solutions. Life cycle assessments reveal that while these systems offer significant advantages in operational phases, the extraction and processing of metal powders—particularly rare earth elements and transition metals—generate substantial environmental footprints. Mining operations for these materials often result in habitat disruption, soil degradation, and water contamination, necessitating comprehensive remediation strategies.

Energy consumption during metal powder production presents another environmental challenge. The high-temperature processes required for refining and alloying consume considerable energy, potentially offsetting some of the carbon reduction benefits achieved through hydrogen utilization. However, recent innovations in manufacturing techniques, including plasma processing and mechanochemical synthesis, have demonstrated energy requirement reductions of up to 30% compared to conventional methods.

Water usage constitutes a significant environmental concern, with traditional metal powder production requiring 70-120 liters of water per kilogram of processed material. Advanced closed-loop water recycling systems have emerged as promising solutions, achieving recovery rates exceeding 85% while minimizing discharge of contaminated effluents. These systems represent essential advancements for implementing metal-based hydrogen storage in water-stressed regions.

The recyclability of metal hydride materials presents a notable sustainability advantage. Unlike many conventional energy storage technologies, metal powders used in hydrogen storage can be reclaimed and reprocessed with minimal performance degradation. Research indicates that certain aluminum and magnesium-based alloys maintain over 90% of their hydrogen capacity after five recycling cycles, significantly extending their effective lifecycle and reducing waste generation.

Carbon footprint analyses demonstrate that metal powder hydrogen storage systems can achieve carbon neutrality within 2-5 years of operation when powered by renewable energy sources. This favorable carbon payback period compares advantageously against lithium-ion batteries (3-8 years) and compressed hydrogen tanks (4-7 years), positioning metal powder solutions as environmentally competitive options for long-term energy storage applications.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics for hydrogen technologies. The European Union's Hydrogen Strategy explicitly prioritizes solutions with minimal environmental impacts, while similar policies in Japan and South Korea offer incentives for technologies demonstrating superior lifecycle performance. These evolving regulatory landscapes will significantly influence the commercial trajectory of metal powder hydrogen storage systems in coming decades.

Energy consumption during metal powder production presents another environmental challenge. The high-temperature processes required for refining and alloying consume considerable energy, potentially offsetting some of the carbon reduction benefits achieved through hydrogen utilization. However, recent innovations in manufacturing techniques, including plasma processing and mechanochemical synthesis, have demonstrated energy requirement reductions of up to 30% compared to conventional methods.

Water usage constitutes a significant environmental concern, with traditional metal powder production requiring 70-120 liters of water per kilogram of processed material. Advanced closed-loop water recycling systems have emerged as promising solutions, achieving recovery rates exceeding 85% while minimizing discharge of contaminated effluents. These systems represent essential advancements for implementing metal-based hydrogen storage in water-stressed regions.

The recyclability of metal hydride materials presents a notable sustainability advantage. Unlike many conventional energy storage technologies, metal powders used in hydrogen storage can be reclaimed and reprocessed with minimal performance degradation. Research indicates that certain aluminum and magnesium-based alloys maintain over 90% of their hydrogen capacity after five recycling cycles, significantly extending their effective lifecycle and reducing waste generation.

Carbon footprint analyses demonstrate that metal powder hydrogen storage systems can achieve carbon neutrality within 2-5 years of operation when powered by renewable energy sources. This favorable carbon payback period compares advantageously against lithium-ion batteries (3-8 years) and compressed hydrogen tanks (4-7 years), positioning metal powder solutions as environmentally competitive options for long-term energy storage applications.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics for hydrogen technologies. The European Union's Hydrogen Strategy explicitly prioritizes solutions with minimal environmental impacts, while similar policies in Japan and South Korea offer incentives for technologies demonstrating superior lifecycle performance. These evolving regulatory landscapes will significantly influence the commercial trajectory of metal powder hydrogen storage systems in coming decades.

Safety Standards and Regulatory Framework for Hydrogen Storage Systems

The regulatory landscape for hydrogen storage systems utilizing metal powders is evolving rapidly as this technology gains prominence in the clean energy transition. Currently, the International Organization for Standardization (ISO) has established ISO 16111 as the primary standard governing metal hydride hydrogen storage systems, specifying requirements for material compatibility, pressure vessel design, and performance testing. This standard works in conjunction with ISO 14687, which defines hydrogen fuel quality specifications critical for ensuring safe operation of storage systems.

In the United States, the Department of Energy's Hydrogen Program has developed comprehensive safety guidelines specifically addressing metal powder-based storage solutions, with particular emphasis on thermal management during hydrogenation and dehydrogenation cycles. The National Fire Protection Association (NFPA) has incorporated hydrogen storage considerations into NFPA 2: Hydrogen Technologies Code, which now includes specific provisions for metal hydride storage systems in both stationary and mobile applications.

European regulations have progressed significantly through the Alternative Fuels Infrastructure Directive (AFID) and the Renewable Energy Directive II (RED II), both of which establish frameworks for hydrogen infrastructure including storage solutions. The European Industrial Gases Association (EIGA) has published Document 100, providing detailed safety recommendations for metal hydride storage systems with specific attention to potential pyrophoric reactions of fine metal powders when exposed to air.

Risk assessment methodologies for metal powder hydrogen storage systems have been standardized through IEC 61508 (Functional Safety) and ISO 31000 (Risk Management), requiring manufacturers to implement rigorous failure mode and effects analysis (FMEA) during product development. These standards mandate quantitative risk assessment approaches that consider the unique properties of different metal alloys and their behavior under various environmental conditions.

Transportation regulations for metal hydride storage systems have been harmonized through the UN Recommendations on the Transport of Dangerous Goods, with specific provisions in the Model Regulations addressing classification, packaging, and handling requirements. These regulations recognize the distinct safety profile of metal powder-based systems compared to compressed or liquid hydrogen storage alternatives.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing for greater innovation in metal powder formulations while maintaining safety. International harmonization efforts are underway through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which is developing a global regulatory framework to facilitate cross-border deployment of hydrogen storage technologies including advanced metal hydride systems.

In the United States, the Department of Energy's Hydrogen Program has developed comprehensive safety guidelines specifically addressing metal powder-based storage solutions, with particular emphasis on thermal management during hydrogenation and dehydrogenation cycles. The National Fire Protection Association (NFPA) has incorporated hydrogen storage considerations into NFPA 2: Hydrogen Technologies Code, which now includes specific provisions for metal hydride storage systems in both stationary and mobile applications.

European regulations have progressed significantly through the Alternative Fuels Infrastructure Directive (AFID) and the Renewable Energy Directive II (RED II), both of which establish frameworks for hydrogen infrastructure including storage solutions. The European Industrial Gases Association (EIGA) has published Document 100, providing detailed safety recommendations for metal hydride storage systems with specific attention to potential pyrophoric reactions of fine metal powders when exposed to air.

Risk assessment methodologies for metal powder hydrogen storage systems have been standardized through IEC 61508 (Functional Safety) and ISO 31000 (Risk Management), requiring manufacturers to implement rigorous failure mode and effects analysis (FMEA) during product development. These standards mandate quantitative risk assessment approaches that consider the unique properties of different metal alloys and their behavior under various environmental conditions.

Transportation regulations for metal hydride storage systems have been harmonized through the UN Recommendations on the Transport of Dangerous Goods, with specific provisions in the Model Regulations addressing classification, packaging, and handling requirements. These regulations recognize the distinct safety profile of metal powder-based systems compared to compressed or liquid hydrogen storage alternatives.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, allowing for greater innovation in metal powder formulations while maintaining safety. International harmonization efforts are underway through the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE), which is developing a global regulatory framework to facilitate cross-border deployment of hydrogen storage technologies including advanced metal hydride systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!