Metal Powders as Pivotal Components in Modern Aerospace

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Metal Powder Technology Evolution and Objectives

Metal powders have evolved significantly in aerospace applications since the mid-20th century, transforming from simple structural components to sophisticated engineered materials with tailored properties. Initially limited to basic aluminum alloys, the field has expanded to encompass superalloys, titanium-based compounds, and advanced metal matrix composites specifically designed for extreme aerospace environments. This evolution has been driven by increasing demands for materials that can withstand higher temperatures, greater mechanical stresses, and more aggressive operating conditions while simultaneously reducing weight and improving fuel efficiency.

The technological trajectory of aerospace metal powders has been marked by several pivotal developments. The 1960s saw the introduction of vacuum induction melting and gas atomization techniques, significantly improving powder purity and consistency. By the 1980s, rapid solidification processing enabled the creation of powders with metastable phases and unique microstructures. The 1990s brought plasma rotating electrode processes (PREP) that further enhanced sphericity and flow characteristics critical for advanced manufacturing methods.

Today's aerospace metal powder technology focuses on achieving unprecedented material performance through precise control of particle size distribution, morphology, and chemical homogeneity. Modern powders incorporate nanoscale features and carefully engineered surface characteristics that directly influence final component properties. The integration of computational materials science has accelerated development cycles, allowing for virtual testing of novel compositions before physical production.

The primary objectives driving current research include developing powders compatible with additive manufacturing processes that maintain consistent properties throughout complex geometries. Engineers seek to create materials with superior high-temperature strength, exceptional fatigue resistance, and enhanced oxidation protection for next-generation aircraft engines and hypersonic vehicles. Additionally, there is significant emphasis on powders that enable weight reduction while maintaining or improving mechanical performance, directly contributing to fuel efficiency and emissions reduction goals.

Environmental considerations have also become central to powder development objectives, with increasing focus on reducing rare earth element dependencies and improving recyclability. Researchers are exploring methods to decrease energy consumption during powder production while maintaining the exacting standards required for aerospace certification. The industry aims to establish closed-loop material systems where end-of-life components can be effectively recycled into new powder feedstock with minimal property degradation.

The technological trajectory of aerospace metal powders has been marked by several pivotal developments. The 1960s saw the introduction of vacuum induction melting and gas atomization techniques, significantly improving powder purity and consistency. By the 1980s, rapid solidification processing enabled the creation of powders with metastable phases and unique microstructures. The 1990s brought plasma rotating electrode processes (PREP) that further enhanced sphericity and flow characteristics critical for advanced manufacturing methods.

Today's aerospace metal powder technology focuses on achieving unprecedented material performance through precise control of particle size distribution, morphology, and chemical homogeneity. Modern powders incorporate nanoscale features and carefully engineered surface characteristics that directly influence final component properties. The integration of computational materials science has accelerated development cycles, allowing for virtual testing of novel compositions before physical production.

The primary objectives driving current research include developing powders compatible with additive manufacturing processes that maintain consistent properties throughout complex geometries. Engineers seek to create materials with superior high-temperature strength, exceptional fatigue resistance, and enhanced oxidation protection for next-generation aircraft engines and hypersonic vehicles. Additionally, there is significant emphasis on powders that enable weight reduction while maintaining or improving mechanical performance, directly contributing to fuel efficiency and emissions reduction goals.

Environmental considerations have also become central to powder development objectives, with increasing focus on reducing rare earth element dependencies and improving recyclability. Researchers are exploring methods to decrease energy consumption during powder production while maintaining the exacting standards required for aerospace certification. The industry aims to establish closed-loop material systems where end-of-life components can be effectively recycled into new powder feedstock with minimal property degradation.

Market Analysis of Metal Powder Applications in Aerospace

The global market for metal powders in aerospace applications has experienced significant growth over the past decade, driven primarily by the increasing adoption of additive manufacturing technologies and the aerospace industry's continuous pursuit of lightweight, high-performance components. Currently valued at approximately $2.3 billion, this market segment is projected to grow at a compound annual growth rate (CAGR) of 8.7% through 2028, outpacing the broader metal powders market.

Titanium alloy powders dominate the aerospace metal powder market with a 37% share, followed by nickel-based superalloys at 28%, aluminum alloys at 21%, and specialty steels and other alloys comprising the remaining 14%. This distribution reflects the aerospace industry's prioritization of high strength-to-weight ratios and excellent corrosion resistance properties in critical components.

Geographically, North America leads the market with 42% share, benefiting from the presence of major aerospace manufacturers and substantial defense spending. Europe follows at 31%, with significant contributions from countries like Germany, France, and the UK. The Asia-Pacific region, currently at 19% market share, represents the fastest-growing market segment with a 12.3% CAGR, driven by China's and India's expanding aerospace industries and increasing defense budgets.

By application segment, engine components represent the largest market share at 41%, where metal powders are used in manufacturing turbine blades, combustion chambers, and other critical high-temperature components. Structural components account for 35% of the market, while landing gear systems and auxiliary systems represent 14% and 10% respectively.

The demand patterns show strong correlation with commercial aircraft production cycles, with notable peaks coinciding with new aircraft program launches. Military aerospace applications provide more stable demand, though at lower volumes compared to commercial applications. Space applications, while currently representing only 7% of the total market, are growing at 15.2% annually, driven by increased satellite deployments and private space ventures.

Supply chain dynamics reveal moderate concentration, with the top five powder suppliers controlling approximately 58% of the market. Recent supply chain disruptions have highlighted vulnerabilities, prompting aerospace manufacturers to pursue supplier diversification strategies and invest in regional production capabilities to ensure continuity of critical material supplies.

Titanium alloy powders dominate the aerospace metal powder market with a 37% share, followed by nickel-based superalloys at 28%, aluminum alloys at 21%, and specialty steels and other alloys comprising the remaining 14%. This distribution reflects the aerospace industry's prioritization of high strength-to-weight ratios and excellent corrosion resistance properties in critical components.

Geographically, North America leads the market with 42% share, benefiting from the presence of major aerospace manufacturers and substantial defense spending. Europe follows at 31%, with significant contributions from countries like Germany, France, and the UK. The Asia-Pacific region, currently at 19% market share, represents the fastest-growing market segment with a 12.3% CAGR, driven by China's and India's expanding aerospace industries and increasing defense budgets.

By application segment, engine components represent the largest market share at 41%, where metal powders are used in manufacturing turbine blades, combustion chambers, and other critical high-temperature components. Structural components account for 35% of the market, while landing gear systems and auxiliary systems represent 14% and 10% respectively.

The demand patterns show strong correlation with commercial aircraft production cycles, with notable peaks coinciding with new aircraft program launches. Military aerospace applications provide more stable demand, though at lower volumes compared to commercial applications. Space applications, while currently representing only 7% of the total market, are growing at 15.2% annually, driven by increased satellite deployments and private space ventures.

Supply chain dynamics reveal moderate concentration, with the top five powder suppliers controlling approximately 58% of the market. Recent supply chain disruptions have highlighted vulnerabilities, prompting aerospace manufacturers to pursue supplier diversification strategies and invest in regional production capabilities to ensure continuity of critical material supplies.

Current Capabilities and Barriers in Aerospace Metal Powder Technology

The aerospace industry currently leverages several advanced metal powder technologies that enable the production of high-performance components. Powder metallurgy techniques, particularly Additive Manufacturing (AM) and Hot Isostatic Pressing (HIP), have revolutionized aerospace manufacturing by allowing the creation of complex geometries with reduced material waste. These processes utilize specialized metal powders including titanium alloys, nickel-based superalloys, and aluminum alloys, each offering specific advantages in terms of strength-to-weight ratio, temperature resistance, and durability.

Despite these capabilities, significant barriers persist in aerospace metal powder technology. Powder quality inconsistency remains a critical challenge, with variations in particle size distribution, morphology, and chemical composition affecting the final product's mechanical properties. The industry struggles to establish standardized quality control protocols that can reliably detect impurities and defects at the microscopic level, which is essential for aerospace-grade components.

Cost factors present another substantial barrier, as high-quality metal powders for aerospace applications can cost 5-10 times more than conventional manufacturing materials. The specialized equipment required for powder production and handling further increases the overall manufacturing expense, limiting widespread adoption across the industry.

Technical limitations in powder production also constrain advancement. Current atomization techniques struggle to consistently produce powders with the ideal spherical morphology and narrow size distribution required for optimal flowability and packing density in AM processes. Additionally, reactive metals like titanium and aluminum present oxidation risks during production and handling, necessitating costly inert atmosphere systems.

Scalability remains problematic, with many powder production methods unable to meet increasing demand while maintaining quality. This creates bottlenecks in the aerospace manufacturing supply chain, particularly for specialized alloy compositions developed specifically for extreme aerospace environments.

Regulatory hurdles compound these challenges, as certification of powder-based components for flight-critical applications requires extensive testing and validation. The aerospace industry's stringent safety requirements necessitate comprehensive material traceability and process documentation, which adds complexity to the implementation of new powder metallurgy technologies.

Environmental and safety concerns also impact development, with fine metal powders presenting explosion and inhalation hazards that require sophisticated containment systems and handling protocols. These safety requirements add another layer of complexity and cost to powder metallurgy operations in aerospace manufacturing facilities.

Despite these capabilities, significant barriers persist in aerospace metal powder technology. Powder quality inconsistency remains a critical challenge, with variations in particle size distribution, morphology, and chemical composition affecting the final product's mechanical properties. The industry struggles to establish standardized quality control protocols that can reliably detect impurities and defects at the microscopic level, which is essential for aerospace-grade components.

Cost factors present another substantial barrier, as high-quality metal powders for aerospace applications can cost 5-10 times more than conventional manufacturing materials. The specialized equipment required for powder production and handling further increases the overall manufacturing expense, limiting widespread adoption across the industry.

Technical limitations in powder production also constrain advancement. Current atomization techniques struggle to consistently produce powders with the ideal spherical morphology and narrow size distribution required for optimal flowability and packing density in AM processes. Additionally, reactive metals like titanium and aluminum present oxidation risks during production and handling, necessitating costly inert atmosphere systems.

Scalability remains problematic, with many powder production methods unable to meet increasing demand while maintaining quality. This creates bottlenecks in the aerospace manufacturing supply chain, particularly for specialized alloy compositions developed specifically for extreme aerospace environments.

Regulatory hurdles compound these challenges, as certification of powder-based components for flight-critical applications requires extensive testing and validation. The aerospace industry's stringent safety requirements necessitate comprehensive material traceability and process documentation, which adds complexity to the implementation of new powder metallurgy technologies.

Environmental and safety concerns also impact development, with fine metal powders presenting explosion and inhalation hazards that require sophisticated containment systems and handling protocols. These safety requirements add another layer of complexity and cost to powder metallurgy operations in aerospace manufacturing facilities.

Contemporary Metal Powder Solutions for Aerospace Components

01 Production methods for metal powders

Various methods are employed for producing metal powders, including atomization, mechanical milling, chemical reduction, and electrolytic deposition. These processes control particle size, shape, and distribution, which are critical for downstream applications. Atomization involves breaking up molten metal into droplets that solidify into powder particles, while mechanical milling reduces larger metal pieces into fine powders through repeated impact and fracturing.- Production methods for metal powders: Various methods are employed to produce metal powders with specific characteristics. These include atomization techniques, chemical reduction processes, electrolytic deposition, and mechanical milling. Each method yields powders with different particle sizes, shapes, and purity levels, which are crucial for their intended applications. The production process significantly influences the powder's properties such as flowability, compressibility, and sintering behavior.

- Metal powder compositions and alloys: Metal powders can be formulated as pure metals or as alloys combining multiple metallic elements to achieve enhanced properties. These compositions may include iron-based, copper-based, aluminum-based, or nickel-based alloys, among others. Additives and dopants are often incorporated to modify specific characteristics such as hardness, corrosion resistance, or magnetic properties. The precise control of composition is essential for meeting the requirements of various industrial applications.

- Applications in additive manufacturing and 3D printing: Metal powders are extensively used in additive manufacturing technologies, including selective laser melting, electron beam melting, and direct metal laser sintering. These processes require powders with specific particle size distributions, flowability, and packing density to ensure consistent layer formation and final part quality. The development of specialized powders has enabled the production of complex geometries and functionally graded materials that were previously impossible to manufacture.

- Surface treatments and coatings for metal powders: Surface modification techniques are applied to metal powders to enhance their performance characteristics. These treatments include oxidation prevention coatings, functionalization for improved bonding, and encapsulation with polymers or ceramics. Surface-treated powders exhibit better stability, reduced agglomeration, and improved compatibility with matrix materials in composite applications. These modifications are particularly important for powders used in harsh environments or specialized applications.

- Powder metallurgy processing techniques: Powder metallurgy involves the processing of metal powders through compaction and sintering to create solid components. Advanced techniques include hot isostatic pressing, spark plasma sintering, and metal injection molding. These processes allow for precise control of density, porosity, and microstructure in the final products. The selection of appropriate processing parameters is critical for achieving desired mechanical properties and dimensional accuracy in the manufactured parts.

02 Metal powder compositions and alloys

Metal powder compositions often include specific alloys designed for enhanced properties such as corrosion resistance, strength, or magnetic characteristics. These compositions may combine various metals like iron, nickel, copper, aluminum, and titanium with additional elements to achieve desired performance characteristics. Some compositions also incorporate non-metallic additives to improve sintering behavior, reduce oxidation, or enhance specific functional properties in the final product.Expand Specific Solutions03 Applications in additive manufacturing and 3D printing

Metal powders are extensively used in additive manufacturing processes such as selective laser melting, electron beam melting, and direct metal laser sintering. These powders require specific characteristics including spherical morphology, controlled particle size distribution, and excellent flowability to ensure uniform layer deposition and consistent part quality. Advanced powder formulations enable the production of complex geometries with mechanical properties comparable to traditionally manufactured components.Expand Specific Solutions04 Surface treatments and coatings for metal powders

Surface treatments and coatings are applied to metal powders to enhance their performance characteristics and processability. These treatments may include passivation to prevent oxidation, application of coupling agents to improve bonding with matrix materials, or functional coatings that impart specific properties. Modified surface chemistry can improve powder flowability, reduce agglomeration, enhance sintering behavior, and provide protection against environmental degradation during storage and processing.Expand Specific Solutions05 Specialized metal powders for catalytic applications

Metal powders with high surface area and specific compositions are developed for catalytic applications in various industries. These powders often feature nanoscale dimensions, controlled porosity, and precisely engineered surface properties to maximize catalytic activity. Noble metals, transition metals, and their alloys are commonly used, sometimes supported on carrier materials to improve stability and efficiency. The catalytic performance is optimized through careful control of particle size, morphology, and surface chemistry.Expand Specific Solutions

Leading Manufacturers and Aerospace Industry Stakeholders

The metal powders market in aerospace is experiencing robust growth, currently in a mature expansion phase with increasing adoption across critical applications. The global market size is estimated to reach $4-5 billion by 2025, driven by demand for lightweight, high-performance components. Technologically, the field shows varying maturity levels, with companies like Rolls-Royce, Boeing, and Carpenter Technology leading innovation in high-performance alloys. Höganäs AB and Hoeganaes Corp. dominate traditional powder metallurgy, while GKN Sinter Metals and Hexcel Corp. excel in specialized aerospace applications. Research institutions like Central South University and University of Maryland are advancing fundamental technologies, collaborating with industry leaders to develop next-generation metal powder solutions for extreme aerospace environments.

Höganäs AB

Technical Solution: Höganäs AB has pioneered advanced metal powder solutions specifically engineered for aerospace applications. Their technology focuses on high-performance powder metallurgy (PM) components that meet the stringent requirements of aerospace systems. The company has developed proprietary atomization processes that produce ultra-clean, spherical metal powders with precise particle size distribution and chemical homogeneity[1]. These powders are optimized for additive manufacturing techniques including selective laser melting (SLM) and electron beam melting (EBM). Höganäs has also created specialized nickel-based superalloy powders that maintain exceptional mechanical properties at elevated temperatures up to 1000°C, critical for jet engine components[2]. Their Digital Metal® technology enables the production of small, complex components with exceptional surface finish and dimensional accuracy, achieving tolerances previously unattainable with conventional PM methods[3].

Strengths: Industry-leading powder purity and consistency; proprietary atomization technology; extensive aerospace material qualification programs; global production capacity. Weaknesses: Higher cost compared to conventional manufacturing materials; limited application in very large structural components; requires specialized handling and processing equipment.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a comprehensive metal powder technology platform specifically for aerospace propulsion systems. Their approach centers on high-temperature superalloy powders engineered for critical rotating components in jet engines. The company has pioneered a proprietary powder processing technique called "Net-Shape HIP" (Hot Isostatic Pressing) that combines powder metallurgy with near-net shape manufacturing to produce complex engine components with minimal machining requirements[1]. This process utilizes specially formulated nickel and titanium-based powders with controlled microstructures. Rolls-Royce has also developed advanced powder-based repair technologies for in-service components, extending engine life cycles significantly[2]. Their metal powder innovation extends to thermal barrier coatings, where specialized ceramic-metallic powder blends are plasma-sprayed onto engine components to provide thermal protection in the hottest sections of gas turbines, enabling higher operating temperatures and improved efficiency[3].

Strengths: Vertically integrated powder-to-component capability; extensive in-house testing and qualification infrastructure; proven implementation in flight-critical applications. Weaknesses: Technologies primarily optimized for their own engine platforms; high capital investment requirements; longer development cycles compared to some specialized powder manufacturers.

Critical Patents and Research in Aerospace Metal Powder Innovation

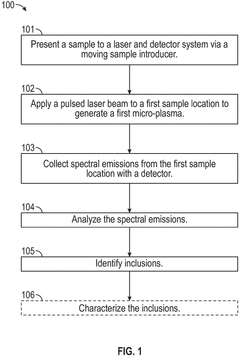

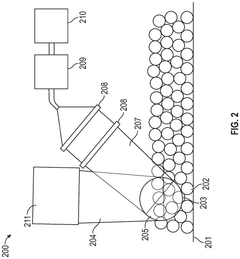

Method for rapid characterization of metallic powders

PatentPendingEP4589285A1

Innovation

- A method utilizing a laser and detector system to generate micro-plasmas in metallic powder samples, analyzing spectral emissions to identify and characterize inclusions, including non-metallic and off-chemistry metallic particles, with optional additional spectroscopy systems for enhanced analysis.

Surface Additive For Three-Dimensional Metal Printing Compositions

PatentActiveUS20200306830A1

Innovation

- A polymeric surface additive prepared by emulsion polymerization is applied to the 3D metal printing powder, which improves flow and blocking performance, and is compatible with the powder's chemistry, allowing for high-density and strong parts without leaving contaminants behind during the sintering process.

Sustainability Challenges in Aerospace Metal Powder Production

The aerospace industry's reliance on metal powders for advanced manufacturing processes has created significant sustainability challenges that demand immediate attention. The production of these specialized powders typically involves energy-intensive processes that contribute substantially to carbon emissions. Traditional powder manufacturing methods such as gas atomization and plasma atomization require extremely high temperatures, consuming vast amounts of electricity often derived from fossil fuels. This energy footprint represents one of the most pressing environmental concerns in the aerospace supply chain.

Raw material extraction presents another critical sustainability challenge. Many aerospace-grade metal powders require rare or strategic elements that are mined using environmentally destructive practices. The extraction of titanium, nickel, and aluminum—key metals for aerospace applications—often results in habitat destruction, water pollution, and soil contamination. Furthermore, these resources are finite, raising serious questions about long-term supply security for the aerospace sector.

Water usage in metal powder production constitutes a significant environmental burden. The processing and purification stages require substantial volumes of water, which becomes contaminated with metal particles and chemical agents. Proper treatment of this industrial wastewater represents both a technical challenge and a considerable expense for manufacturers, particularly in regions facing water scarcity.

The lifecycle management of metal powders presents additional sustainability concerns. Unused or contaminated powders from additive manufacturing processes cannot always be effectively recycled, creating waste management issues. The fine particle nature of these materials also presents occupational health risks, requiring sophisticated containment systems that further increase the environmental footprint of production facilities.

Regulatory pressures are mounting globally, with increasingly stringent environmental standards being applied to industrial processes. Metal powder producers face growing compliance costs related to emissions control, waste management, and chemical safety. These regulatory frameworks, while necessary for environmental protection, add complexity to the production economics and may impact supply chain resilience for aerospace manufacturers.

Innovation in sustainable powder production technologies offers promising pathways forward. Emerging techniques such as hydrogen-based reduction processes and renewable energy-powered atomization systems demonstrate potential for significantly reduced environmental impacts. Additionally, closed-loop recycling systems for powder recovery and reuse are being developed to minimize waste and conserve valuable materials, though these technologies remain at various stages of commercial readiness.

Raw material extraction presents another critical sustainability challenge. Many aerospace-grade metal powders require rare or strategic elements that are mined using environmentally destructive practices. The extraction of titanium, nickel, and aluminum—key metals for aerospace applications—often results in habitat destruction, water pollution, and soil contamination. Furthermore, these resources are finite, raising serious questions about long-term supply security for the aerospace sector.

Water usage in metal powder production constitutes a significant environmental burden. The processing and purification stages require substantial volumes of water, which becomes contaminated with metal particles and chemical agents. Proper treatment of this industrial wastewater represents both a technical challenge and a considerable expense for manufacturers, particularly in regions facing water scarcity.

The lifecycle management of metal powders presents additional sustainability concerns. Unused or contaminated powders from additive manufacturing processes cannot always be effectively recycled, creating waste management issues. The fine particle nature of these materials also presents occupational health risks, requiring sophisticated containment systems that further increase the environmental footprint of production facilities.

Regulatory pressures are mounting globally, with increasingly stringent environmental standards being applied to industrial processes. Metal powder producers face growing compliance costs related to emissions control, waste management, and chemical safety. These regulatory frameworks, while necessary for environmental protection, add complexity to the production economics and may impact supply chain resilience for aerospace manufacturers.

Innovation in sustainable powder production technologies offers promising pathways forward. Emerging techniques such as hydrogen-based reduction processes and renewable energy-powered atomization systems demonstrate potential for significantly reduced environmental impacts. Additionally, closed-loop recycling systems for powder recovery and reuse are being developed to minimize waste and conserve valuable materials, though these technologies remain at various stages of commercial readiness.

Certification Standards and Quality Control Requirements

In the aerospace industry, metal powder certification standards are governed by stringent regulatory frameworks established by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the International Organization for Standardization (ISO). These standards ensure that metal powders used in critical aerospace components meet specific requirements for chemical composition, particle size distribution, flowability, and mechanical properties. ASTM International has developed several standards specifically for metal powders in additive manufacturing, including ASTM F3049 for characterization and ASTM F3055 for qualification of powder bed fusion processes.

Quality control for aerospace metal powders involves comprehensive testing protocols at multiple stages of the production process. Powder manufacturers must implement statistical process control methods to monitor variations in powder characteristics and ensure batch-to-batch consistency. X-ray diffraction (XRD) and scanning electron microscopy (SEM) are commonly employed to verify crystallographic structure and morphology, while laser diffraction techniques assess particle size distribution with precision down to the micrometer level.

Traceability requirements represent another critical aspect of aerospace metal powder certification. Each batch of powder must be traceable throughout its entire lifecycle, from raw material sourcing to final component production. This includes detailed documentation of processing parameters, handling procedures, and storage conditions. The aerospace industry typically requires retention of powder samples from each production batch for potential future analysis in case of component failure or performance issues.

Non-destructive testing (NDT) methodologies play a vital role in quality assurance for components manufactured from metal powders. Techniques such as computed tomography (CT) scanning, ultrasonic testing, and eddy current inspection are employed to detect internal defects, porosity, or inclusions that could compromise structural integrity. These inspection protocols must be validated through correlation studies with destructive testing results to establish reliable acceptance criteria.

Environmental control during powder handling and storage represents a significant quality control challenge. Aerospace-grade metal powders are highly susceptible to contamination and oxidation, which can dramatically alter their performance characteristics. ISO 14644 clean room standards are often applied to powder handling facilities, with requirements for controlled humidity, temperature, and particulate levels. Additionally, specialized containers with inert gas environments are utilized to prevent degradation during transportation and storage periods.

Quality control for aerospace metal powders involves comprehensive testing protocols at multiple stages of the production process. Powder manufacturers must implement statistical process control methods to monitor variations in powder characteristics and ensure batch-to-batch consistency. X-ray diffraction (XRD) and scanning electron microscopy (SEM) are commonly employed to verify crystallographic structure and morphology, while laser diffraction techniques assess particle size distribution with precision down to the micrometer level.

Traceability requirements represent another critical aspect of aerospace metal powder certification. Each batch of powder must be traceable throughout its entire lifecycle, from raw material sourcing to final component production. This includes detailed documentation of processing parameters, handling procedures, and storage conditions. The aerospace industry typically requires retention of powder samples from each production batch for potential future analysis in case of component failure or performance issues.

Non-destructive testing (NDT) methodologies play a vital role in quality assurance for components manufactured from metal powders. Techniques such as computed tomography (CT) scanning, ultrasonic testing, and eddy current inspection are employed to detect internal defects, porosity, or inclusions that could compromise structural integrity. These inspection protocols must be validated through correlation studies with destructive testing results to establish reliable acceptance criteria.

Environmental control during powder handling and storage represents a significant quality control challenge. Aerospace-grade metal powders are highly susceptible to contamination and oxidation, which can dramatically alter their performance characteristics. ISO 14644 clean room standards are often applied to powder handling facilities, with requirements for controlled humidity, temperature, and particulate levels. Additionally, specialized containers with inert gas environments are utilized to prevent degradation during transportation and storage periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!