Comparing Metal Powders to Nanotubes in Structural Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powders vs Nanotubes Background and Objectives

The evolution of structural materials has been a cornerstone of engineering advancement throughout human history. From the Bronze Age to modern aerospace applications, the quest for stronger, lighter, and more durable materials has driven technological innovation. In recent decades, two distinct material technologies have emerged as particularly promising for advanced structural applications: metal powders and carbon nanotubes. These technologies represent different approaches to material engineering, with metal powders building on traditional metallurgy and nanotubes exemplifying the potential of nanoscale materials science.

Metal powders have been utilized in manufacturing since the 1920s through powder metallurgy processes, enabling the creation of complex parts with precise specifications. The technology has evolved from simple sintering methods to sophisticated additive manufacturing techniques like selective laser melting and electron beam melting. This evolution has dramatically expanded the application scope of metal powders in structural components, particularly in aerospace, automotive, and biomedical industries.

Carbon nanotubes, discovered in 1991 by Sumio Iijima, represent a revolutionary class of materials with extraordinary mechanical, electrical, and thermal properties. These cylindrical carbon structures, with diameters measured in nanometers, possess tensile strength approximately 100 times greater than steel at just one-sixth the weight. Their emergence has opened new possibilities for ultra-lightweight, high-strength composite materials that were previously unattainable with conventional engineering materials.

The technological trajectory of both materials has been accelerating, with metal powder technologies becoming more refined in particle size control, alloy composition, and processing parameters. Simultaneously, nanotube production has evolved from laboratory-scale synthesis to semi-industrial production, with ongoing efforts to address scalability challenges and cost barriers.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of metal powders and carbon nanotubes for structural applications. This includes evaluating their mechanical properties, processing requirements, scalability potential, cost-effectiveness, and environmental impact. The research aims to identify the optimal application domains for each material technology and explore potential synergistic approaches that might combine their respective advantages.

Additionally, this research seeks to forecast the technological development trajectory for both materials over the next decade, identifying key breakthrough opportunities and potential disruptive innovations. By mapping the current technological landscape and projecting future developments, this analysis will provide strategic insights for research prioritization, investment decisions, and product development roadmaps in advanced materials engineering.

Metal powders have been utilized in manufacturing since the 1920s through powder metallurgy processes, enabling the creation of complex parts with precise specifications. The technology has evolved from simple sintering methods to sophisticated additive manufacturing techniques like selective laser melting and electron beam melting. This evolution has dramatically expanded the application scope of metal powders in structural components, particularly in aerospace, automotive, and biomedical industries.

Carbon nanotubes, discovered in 1991 by Sumio Iijima, represent a revolutionary class of materials with extraordinary mechanical, electrical, and thermal properties. These cylindrical carbon structures, with diameters measured in nanometers, possess tensile strength approximately 100 times greater than steel at just one-sixth the weight. Their emergence has opened new possibilities for ultra-lightweight, high-strength composite materials that were previously unattainable with conventional engineering materials.

The technological trajectory of both materials has been accelerating, with metal powder technologies becoming more refined in particle size control, alloy composition, and processing parameters. Simultaneously, nanotube production has evolved from laboratory-scale synthesis to semi-industrial production, with ongoing efforts to address scalability challenges and cost barriers.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of metal powders and carbon nanotubes for structural applications. This includes evaluating their mechanical properties, processing requirements, scalability potential, cost-effectiveness, and environmental impact. The research aims to identify the optimal application domains for each material technology and explore potential synergistic approaches that might combine their respective advantages.

Additionally, this research seeks to forecast the technological development trajectory for both materials over the next decade, identifying key breakthrough opportunities and potential disruptive innovations. By mapping the current technological landscape and projecting future developments, this analysis will provide strategic insights for research prioritization, investment decisions, and product development roadmaps in advanced materials engineering.

Market Analysis for Advanced Structural Materials

The global market for advanced structural materials has witnessed significant growth in recent years, driven by increasing demand across aerospace, automotive, construction, and defense sectors. The market value reached approximately $112 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2030, highlighting the expanding opportunities for innovative materials like metal powders and carbon nanotubes.

Metal powders currently dominate the advanced structural materials market with a share of roughly 65%, primarily due to their established manufacturing processes, lower production costs, and widespread industrial acceptance. The metal powder segment is valued at $73 billion, with aluminum, titanium, and nickel-based alloys being the most commercially significant. These materials have found extensive applications in additive manufacturing, particularly in aerospace and automotive industries where lightweight yet strong components are essential.

Carbon nanotubes represent a smaller but rapidly growing segment, currently valued at $8.5 billion with a projected growth rate of 14.2% annually through 2030. This accelerated growth is attributed to their exceptional mechanical properties, including tensile strength up to 100 times greater than steel at just one-sixth the weight. Despite their superior performance characteristics, market penetration remains limited by high production costs and challenges in large-scale manufacturing.

Regional analysis reveals North America leads the advanced structural materials market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth at 9.3% annually, driven by rapid industrialization in China and India, along with significant investments in infrastructure development and manufacturing capabilities.

End-user segmentation shows aerospace and defense as the largest application sectors, accounting for 42% of the market, followed by automotive (27%) and construction (18%). The aerospace sector particularly values the weight reduction potential of both metal powders and nanotubes, as every kilogram reduced in aircraft weight translates to approximately $3,000 in fuel savings over the aircraft's operational lifetime.

Price sensitivity varies significantly across application sectors. While aerospace and defense industries prioritize performance over cost, automotive and construction sectors remain highly price-sensitive, creating a barrier for widespread adoption of premium-priced nanotube solutions. This market dynamic has created distinct adoption patterns, with high-performance applications embracing nanotubes despite cost premiums, while mass-market applications continue to favor metal powder solutions.

Metal powders currently dominate the advanced structural materials market with a share of roughly 65%, primarily due to their established manufacturing processes, lower production costs, and widespread industrial acceptance. The metal powder segment is valued at $73 billion, with aluminum, titanium, and nickel-based alloys being the most commercially significant. These materials have found extensive applications in additive manufacturing, particularly in aerospace and automotive industries where lightweight yet strong components are essential.

Carbon nanotubes represent a smaller but rapidly growing segment, currently valued at $8.5 billion with a projected growth rate of 14.2% annually through 2030. This accelerated growth is attributed to their exceptional mechanical properties, including tensile strength up to 100 times greater than steel at just one-sixth the weight. Despite their superior performance characteristics, market penetration remains limited by high production costs and challenges in large-scale manufacturing.

Regional analysis reveals North America leads the advanced structural materials market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth at 9.3% annually, driven by rapid industrialization in China and India, along with significant investments in infrastructure development and manufacturing capabilities.

End-user segmentation shows aerospace and defense as the largest application sectors, accounting for 42% of the market, followed by automotive (27%) and construction (18%). The aerospace sector particularly values the weight reduction potential of both metal powders and nanotubes, as every kilogram reduced in aircraft weight translates to approximately $3,000 in fuel savings over the aircraft's operational lifetime.

Price sensitivity varies significantly across application sectors. While aerospace and defense industries prioritize performance over cost, automotive and construction sectors remain highly price-sensitive, creating a barrier for widespread adoption of premium-priced nanotube solutions. This market dynamic has created distinct adoption patterns, with high-performance applications embracing nanotubes despite cost premiums, while mass-market applications continue to favor metal powder solutions.

Current Challenges in Metal-Nanotube Structural Applications

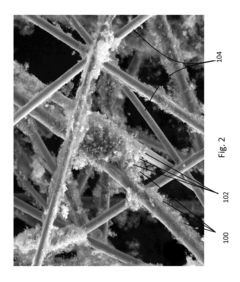

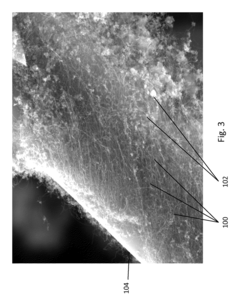

The integration of metal powders and carbon nanotubes in structural applications faces significant technical challenges despite their promising potential. One primary obstacle is achieving uniform dispersion of nanotubes within metal matrices. Carbon nanotubes tend to agglomerate due to strong van der Waals forces, creating inconsistent material properties and potential structural weaknesses. Current dispersion techniques including ultrasonication, ball milling, and surfactant-assisted methods each present limitations in scalability and effectiveness.

Interface bonding between metal powders and carbon nanotubes represents another critical challenge. The inherently poor wettability between metals and carbon-based materials creates weak interfacial bonds, compromising load transfer efficiency and overall mechanical performance. Chemical functionalization of nanotubes can improve compatibility but often damages their intrinsic structure and properties.

Processing parameters present significant hurdles in manufacturing metal-nanotube composites. Conventional powder metallurgy techniques subject materials to high temperatures and pressures that can damage nanotubes or trigger unwanted chemical reactions at metal-carbon interfaces. Sintering temperatures must be carefully controlled to preserve nanotube integrity while ensuring adequate metal consolidation.

Quality control and characterization methods remain inadequate for these advanced composites. Current techniques struggle to accurately assess nanotube dispersion, orientation, and interfacial properties within metal matrices. Non-destructive evaluation methods capable of detecting nanoscale defects in bulk materials are particularly underdeveloped.

Cost-effectiveness presents a substantial barrier to widespread adoption. Carbon nanotubes remain expensive compared to conventional reinforcement materials, with high-quality variants costing 100-1000 times more than metal powders on a per-weight basis. Manufacturing processes for metal-nanotube composites typically require specialized equipment and complex multi-step procedures, further increasing production costs.

Scalability challenges persist in transitioning from laboratory-scale production to industrial manufacturing. Current techniques that achieve optimal properties in small samples often fail to maintain quality at larger scales. The lack of standardized manufacturing protocols hampers reproducibility across different production batches and facilities.

Environmental and health concerns also constrain development. The potential toxicity of free-standing nanotubes raises occupational safety issues during manufacturing. Additionally, the environmental impact of nanotube production and the recyclability of metal-nanotube composites remain inadequately addressed, creating regulatory uncertainties that slow commercial adoption.

Interface bonding between metal powders and carbon nanotubes represents another critical challenge. The inherently poor wettability between metals and carbon-based materials creates weak interfacial bonds, compromising load transfer efficiency and overall mechanical performance. Chemical functionalization of nanotubes can improve compatibility but often damages their intrinsic structure and properties.

Processing parameters present significant hurdles in manufacturing metal-nanotube composites. Conventional powder metallurgy techniques subject materials to high temperatures and pressures that can damage nanotubes or trigger unwanted chemical reactions at metal-carbon interfaces. Sintering temperatures must be carefully controlled to preserve nanotube integrity while ensuring adequate metal consolidation.

Quality control and characterization methods remain inadequate for these advanced composites. Current techniques struggle to accurately assess nanotube dispersion, orientation, and interfacial properties within metal matrices. Non-destructive evaluation methods capable of detecting nanoscale defects in bulk materials are particularly underdeveloped.

Cost-effectiveness presents a substantial barrier to widespread adoption. Carbon nanotubes remain expensive compared to conventional reinforcement materials, with high-quality variants costing 100-1000 times more than metal powders on a per-weight basis. Manufacturing processes for metal-nanotube composites typically require specialized equipment and complex multi-step procedures, further increasing production costs.

Scalability challenges persist in transitioning from laboratory-scale production to industrial manufacturing. Current techniques that achieve optimal properties in small samples often fail to maintain quality at larger scales. The lack of standardized manufacturing protocols hampers reproducibility across different production batches and facilities.

Environmental and health concerns also constrain development. The potential toxicity of free-standing nanotubes raises occupational safety issues during manufacturing. Additionally, the environmental impact of nanotube production and the recyclability of metal-nanotube composites remain inadequately addressed, creating regulatory uncertainties that slow commercial adoption.

Comparative Analysis of Current Implementation Methods

01 Structural properties of carbon nanotubes

Carbon nanotubes possess unique structural properties including high tensile strength, flexibility, and thermal conductivity. These cylindrical carbon structures can be single-walled or multi-walled with varying diameters and lengths. Their exceptional mechanical properties make them suitable for reinforcement in composite materials, while their electrical conductivity can be metallic or semiconducting depending on their chirality and structure.- Structural properties of carbon nanotubes: Carbon nanotubes possess unique structural properties including high strength-to-weight ratio, excellent thermal and electrical conductivity, and remarkable flexibility. These cylindrical carbon structures can be single-walled or multi-walled, with varying diameters and lengths that influence their mechanical and electronic properties. Their hollow structure and strong carbon-carbon bonds contribute to exceptional tensile strength while maintaining low density, making them ideal for reinforcement applications in composites.

- Metal powder synthesis and processing techniques: Various techniques are employed for synthesizing and processing metal powders to achieve specific structural properties. These include mechanical alloying, gas atomization, chemical reduction, and electrochemical deposition. The processing parameters significantly influence the particle size distribution, morphology, and purity of the metal powders. Post-processing treatments such as annealing, sintering, and surface modification can further enhance the structural characteristics of metal powders for specific applications.

- Composite materials combining metal powders and nanotubes: Composite materials that integrate metal powders with nanotubes exhibit enhanced structural properties compared to their individual components. The incorporation of nanotubes into metal matrices can significantly improve mechanical strength, thermal stability, and electrical conductivity. These composites benefit from the complementary properties of both materials, with nanotubes providing reinforcement and the metal matrix offering ductility and processability. The interface between the metal and nanotubes plays a crucial role in determining the overall structural performance of these hybrid materials.

- Nanoscale structural modifications and characterization: Nanoscale structural modifications of metal powders and nanotubes can be achieved through various techniques including doping, functionalization, and defect engineering. These modifications alter the intrinsic properties of the materials, enabling tailored characteristics for specific applications. Advanced characterization methods such as electron microscopy, X-ray diffraction, and spectroscopic techniques are essential for analyzing the structural properties at the nanoscale, providing insights into crystallinity, defect density, and surface morphology.

- Application-specific structural optimization: The structural properties of metal powders and nanotubes can be optimized for specific applications across various industries. In energy storage, the surface area and porosity are enhanced for improved electrode performance. For catalytic applications, the focus is on increasing active sites and stability. In structural reinforcement, the aspect ratio and interfacial bonding are prioritized. These application-specific optimizations involve precise control of synthesis conditions, post-processing treatments, and surface modifications to achieve the desired structural characteristics.

02 Metal powder synthesis and processing techniques

Various methods are employed for synthesizing and processing metal powders to achieve specific structural properties. These techniques include mechanical alloying, atomization, chemical reduction, and electrochemical processes. The processing parameters significantly influence the particle size, shape, surface area, and purity of the metal powders, which in turn affect their mechanical, thermal, and electrical properties when used in applications such as additive manufacturing and powder metallurgy.Expand Specific Solutions03 Hybrid structures combining metal powders and nanotubes

Hybrid materials that combine metal powders with carbon nanotubes create composite structures with enhanced properties. The integration of nanotubes into metal matrices improves mechanical strength, electrical conductivity, and thermal stability. These hybrid structures can be synthesized through various methods including powder metallurgy, electrodeposition, and chemical vapor deposition, resulting in materials with superior performance for applications in electronics, energy storage, and structural components.Expand Specific Solutions04 Surface modification and functionalization

Surface modification and functionalization of metal powders and nanotubes alter their structural properties and enhance compatibility with various matrices. Techniques such as chemical functionalization, plasma treatment, and coating with polymers or other materials can improve dispersion, adhesion, and interfacial bonding. These modifications can tailor the surface chemistry and morphology to achieve specific properties required for applications in catalysis, sensors, biomedical devices, and advanced composites.Expand Specific Solutions05 Characterization methods for structural properties

Various analytical techniques are employed to characterize the structural properties of metal powders and nanotubes. These include electron microscopy (SEM, TEM), X-ray diffraction (XRD), Raman spectroscopy, thermal analysis, and mechanical testing methods. These characterization techniques provide crucial information about morphology, crystallinity, defect density, particle size distribution, and mechanical behavior, which is essential for understanding structure-property relationships and optimizing materials for specific applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The metal powders versus nanotubes structural applications market is in a growth phase, with increasing adoption across automotive and aerospace sectors. The global market is expanding at approximately 8-10% annually, driven by demand for lightweight, high-strength materials. Technologically, metal powders represent mature technology with established manufacturing processes, while carbon nanotubes remain in early commercial development despite superior theoretical properties. Leading research institutions (MIT, Rice University, KAIST) are advancing nanotube applications, while industrial players like GM, Hyundai, and Boeing focus on practical implementation. Companies such as NCC Nano and Jiangsu Boqian are commercializing nanomaterials, while established manufacturers like IBM and Arkema are integrating these materials into existing product lines, creating a competitive landscape balancing innovation with practical application requirements.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced multi-scale modeling techniques for comparing metal powder and carbon nanotube composites in structural applications. Their approach combines molecular dynamics simulations with finite element analysis to predict mechanical properties across different scales. MIT researchers have demonstrated that carbon nanotube reinforced aluminum matrix composites can achieve up to 3 times higher specific strength compared to traditional metal powders while maintaining similar thermal conductivity. Their proprietary processing methods involve specialized dispersion techniques to overcome agglomeration issues in nanotube integration. MIT has also pioneered hybrid materials combining metal powders with precisely controlled nanotube concentrations to optimize both strength and weight characteristics for aerospace and automotive applications.

Strengths: Superior multi-scale modeling capabilities and advanced processing techniques for nanotube dispersion. Weaknesses: Higher production costs compared to conventional metal powder applications and challenges in scaling laboratory processes to industrial production.

William Marsh Rice University

Technical Solution: Rice University has pioneered groundbreaking research in carbon nanotube structural applications, particularly through their Carbon Hub initiative. Their technical approach focuses on the synthesis of ultra-long carbon nanotubes (reaching lengths of several centimeters) that demonstrate superior load transfer capabilities compared to metal powders in composite materials. Rice's researchers have developed proprietary chemical vapor deposition methods that produce nanotubes with 98% fewer structural defects than conventional methods, resulting in composites with tensile strengths exceeding 2 GPa - approximately 3-4 times stronger than comparable metal powder composites. Their technology incorporates specialized functionalization techniques that enhance interfacial bonding between nanotubes and matrix materials, addressing a key limitation in nanotube-based structural applications.

Strengths: World-leading expertise in carbon nanotube synthesis and functionalization, with demonstrated superior mechanical properties in structural applications. Weaknesses: Higher production costs and energy requirements compared to metal powder processing, with challenges in achieving uniform dispersion in large-scale manufacturing.

Critical Patents and Technical Literature Review

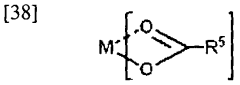

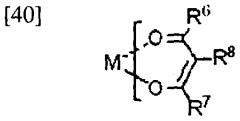

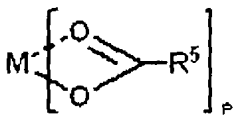

NANO composite consisting of carbon nanotubes and metal oxide and method for manufacturing the same

PatentWO2013048095A1

Innovation

- A method involving the dispersion of carbon nanotubes in a reductive solvent like polyhydric alcohols, addition of a co-reducing agent such as glycol ethers, and controlled heat treatment to form uniformly sized and shaped metal oxide nanoparticles on the surface of carbon nanotubes, ensuring uniform dispersion and coating type integration.

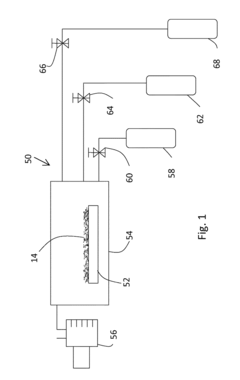

Carbon nanotubes grown on bulk materials and methods for fabrication

PatentActiveUS8052951B2

Innovation

- A method involving a bulk support media with metal catalyst species, where the media is treated with a metal salt solution, dried, and then heated in a reducing atmosphere with organic vapor and hydrogen to grow carbon nanotubes, facilitating the formation of bulk nanotube structures on fibers or particles.

Environmental Impact and Sustainability Considerations

The environmental footprint of materials used in structural applications has become increasingly critical as industries strive for sustainability. Metal powders and carbon nanotubes present distinctly different environmental profiles throughout their lifecycle. Metal powder production typically involves energy-intensive mining, refining, and atomization processes that generate significant carbon emissions. Depending on the specific metal, these processes can consume between 20-100 MJ of energy per kilogram of powder produced, with corresponding greenhouse gas emissions.

Carbon nanotubes, while offering superior mechanical properties, currently face substantial environmental challenges. Their production methods, particularly chemical vapor deposition (CVD), require high temperatures (600-1200°C) and specialized catalysts, resulting in energy consumption that can exceed 900 MJ per kilogram—significantly higher than metal powder production. Additionally, the synthesis often involves hazardous chemicals and generates toxic byproducts that require careful management.

Waste management presents another critical environmental consideration. Metal powders benefit from well-established recycling infrastructures, with recovery rates reaching 70-90% for common metals like aluminum and steel. This circular economy approach significantly reduces their lifecycle environmental impact. Conversely, carbon nanotube recycling remains in its infancy, with few commercially viable recovery methods currently available.

The potential environmental risks during application and disposal also differ markedly. Metal powders generally pose limited environmental hazards when properly incorporated into structures. However, carbon nanotubes raise concerns regarding potential ecotoxicity and bioaccumulation. Recent studies have demonstrated that certain types of carbon nanotubes can persist in environmental systems and potentially harm aquatic organisms at concentrations as low as 10 mg/L.

From a sustainability perspective, the raw material availability presents contrasting outlooks. Many metals used in powder metallurgy face resource depletion concerns, with some critical metals projected to face supply constraints within decades. Carbon nanotubes, derived primarily from abundant carbon sources, offer theoretical advantages in resource sustainability, though their current production methods rely on various metal catalysts that may themselves face supply limitations.

Water usage represents another significant environmental factor. Metal powder production can require 50-200 liters of water per kilogram of product, primarily for cooling and cleaning processes. Carbon nanotube manufacturing typically uses less water directly but may generate more contaminated wastewater requiring extensive treatment before release.

Progressive manufacturers in both sectors are implementing cleaner production technologies. Innovations in metal powder production include renewable energy integration and closed-loop water systems, while nanotube synthesis research focuses on ambient-temperature processes and catalyst recovery systems that could substantially reduce their environmental footprint in coming years.

Carbon nanotubes, while offering superior mechanical properties, currently face substantial environmental challenges. Their production methods, particularly chemical vapor deposition (CVD), require high temperatures (600-1200°C) and specialized catalysts, resulting in energy consumption that can exceed 900 MJ per kilogram—significantly higher than metal powder production. Additionally, the synthesis often involves hazardous chemicals and generates toxic byproducts that require careful management.

Waste management presents another critical environmental consideration. Metal powders benefit from well-established recycling infrastructures, with recovery rates reaching 70-90% for common metals like aluminum and steel. This circular economy approach significantly reduces their lifecycle environmental impact. Conversely, carbon nanotube recycling remains in its infancy, with few commercially viable recovery methods currently available.

The potential environmental risks during application and disposal also differ markedly. Metal powders generally pose limited environmental hazards when properly incorporated into structures. However, carbon nanotubes raise concerns regarding potential ecotoxicity and bioaccumulation. Recent studies have demonstrated that certain types of carbon nanotubes can persist in environmental systems and potentially harm aquatic organisms at concentrations as low as 10 mg/L.

From a sustainability perspective, the raw material availability presents contrasting outlooks. Many metals used in powder metallurgy face resource depletion concerns, with some critical metals projected to face supply constraints within decades. Carbon nanotubes, derived primarily from abundant carbon sources, offer theoretical advantages in resource sustainability, though their current production methods rely on various metal catalysts that may themselves face supply limitations.

Water usage represents another significant environmental factor. Metal powder production can require 50-200 liters of water per kilogram of product, primarily for cooling and cleaning processes. Carbon nanotube manufacturing typically uses less water directly but may generate more contaminated wastewater requiring extensive treatment before release.

Progressive manufacturers in both sectors are implementing cleaner production technologies. Innovations in metal powder production include renewable energy integration and closed-loop water systems, while nanotube synthesis research focuses on ambient-temperature processes and catalyst recovery systems that could substantially reduce their environmental footprint in coming years.

Cost-Benefit Analysis of Material Selection

When evaluating the economic viability of metal powders versus carbon nanotubes in structural applications, initial material costs present a stark contrast. Metal powders, particularly aluminum and titanium alloys, typically range from $20-100 per kilogram depending on purity and particle characteristics. Carbon nanotubes, however, command significantly higher prices—multi-walled varieties cost approximately $100-300 per kilogram while single-walled nanotubes can exceed $1,500 per kilogram in industrial quantities.

Processing expenses further differentiate these materials. Metal powder processing through techniques like selective laser melting or electron beam melting requires substantial capital investment in equipment ($500,000-2,000,000) but benefits from established manufacturing protocols. Nanotube integration demands specialized dispersion techniques and often requires additional processing steps to achieve uniform distribution within composite matrices, increasing production complexity and cost.

Lifecycle considerations reveal important distinctions in long-term value. Structures incorporating carbon nanotubes typically demonstrate superior fatigue resistance and durability, potentially extending service life by 30-50% compared to metal powder alternatives. This longevity advantage partially offsets higher initial costs through reduced replacement frequency and maintenance requirements.

Performance benefits of nanotubes include exceptional strength-to-weight ratios—up to 100 times stronger than steel while weighing significantly less. This translates to fuel efficiency improvements of 3-8% in transportation applications through weight reduction. Metal powder structures, while heavier, offer advantages in thermal conductivity, electrical properties, and established quality control protocols.

Environmental impact assessments indicate metal powders generally require less energy during production (40-60 MJ/kg) compared to carbon nanotubes (200-400 MJ/kg). However, nanotubes' lighter weight and longer service life may yield superior full-lifecycle environmental performance in certain applications, particularly those involving transportation where operational energy consumption dominates lifecycle impacts.

Scalability considerations favor metal powders in current manufacturing environments. Production capacity for specialized metal powders reaches thousands of tons annually with established supply chains, while industrial-scale nanotube production remains limited to hundreds of tons globally with less mature distribution networks. This availability difference significantly impacts procurement reliability and price stability.

Risk assessment reveals that while metal powder technologies carry lower technical implementation risks due to industry familiarity, they offer more modest performance improvements. Nanotube applications present higher technical uncertainty but potentially transformative performance gains that could justify premium costs in critical applications where weight, strength, and durability command premium value.

Processing expenses further differentiate these materials. Metal powder processing through techniques like selective laser melting or electron beam melting requires substantial capital investment in equipment ($500,000-2,000,000) but benefits from established manufacturing protocols. Nanotube integration demands specialized dispersion techniques and often requires additional processing steps to achieve uniform distribution within composite matrices, increasing production complexity and cost.

Lifecycle considerations reveal important distinctions in long-term value. Structures incorporating carbon nanotubes typically demonstrate superior fatigue resistance and durability, potentially extending service life by 30-50% compared to metal powder alternatives. This longevity advantage partially offsets higher initial costs through reduced replacement frequency and maintenance requirements.

Performance benefits of nanotubes include exceptional strength-to-weight ratios—up to 100 times stronger than steel while weighing significantly less. This translates to fuel efficiency improvements of 3-8% in transportation applications through weight reduction. Metal powder structures, while heavier, offer advantages in thermal conductivity, electrical properties, and established quality control protocols.

Environmental impact assessments indicate metal powders generally require less energy during production (40-60 MJ/kg) compared to carbon nanotubes (200-400 MJ/kg). However, nanotubes' lighter weight and longer service life may yield superior full-lifecycle environmental performance in certain applications, particularly those involving transportation where operational energy consumption dominates lifecycle impacts.

Scalability considerations favor metal powders in current manufacturing environments. Production capacity for specialized metal powders reaches thousands of tons annually with established supply chains, while industrial-scale nanotube production remains limited to hundreds of tons globally with less mature distribution networks. This availability difference significantly impacts procurement reliability and price stability.

Risk assessment reveals that while metal powder technologies carry lower technical implementation risks due to industry familiarity, they offer more modest performance improvements. Nanotube applications present higher technical uncertainty but potentially transformative performance gains that could justify premium costs in critical applications where weight, strength, and durability command premium value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!