Thermal Stability of Metal Powders in Aerospace Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Metal Powder Thermal Stability Background & Objectives

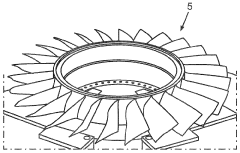

Metal powders have been integral to aerospace manufacturing since the mid-20th century, with significant advancements occurring during the Space Race era. Initially limited to basic structural components, these materials have evolved to become critical elements in high-performance aerospace applications including turbine engines, rocket propulsion systems, and advanced airframe structures. The thermal stability of these powders—their ability to maintain structural integrity and desired properties under extreme temperature conditions—has emerged as a paramount concern in aerospace engineering.

The evolution of metal powder technology has been marked by progressive improvements in powder production methods, from conventional atomization techniques to more sophisticated processes like plasma rotating electrode processing (PREP) and gas atomization. These advancements have enabled the production of increasingly pure, spherical, and homogeneous powders with enhanced thermal characteristics essential for aerospace applications.

Current industry trends indicate a growing demand for superalloys, titanium-based powders, and aluminum alloys with exceptional thermal stability properties. This demand is driven by the aerospace sector's push toward higher operating temperatures for improved engine efficiency, reduced emissions, and extended component lifespans. The development of materials capable of withstanding temperatures exceeding 1000°C while maintaining structural integrity represents a significant technological frontier.

The primary objective of research in this field is to develop metal powders with optimized thermal stability characteristics that can withstand the extreme conditions encountered in aerospace applications. This includes resistance to oxidation, phase transformations, grain growth, and mechanical property degradation at elevated temperatures. Additionally, there is a focus on understanding the fundamental mechanisms governing thermal behavior in these materials to enable predictive modeling and accelerated development cycles.

Secondary objectives include enhancing the processability of thermally stable powders through additive manufacturing techniques, improving powder recyclability without compromising thermal properties, and developing cost-effective production methods to make advanced materials more accessible to the broader aerospace industry. These goals align with the industry's sustainability initiatives and economic considerations.

The technological trajectory suggests that future developments will likely focus on multi-component alloys, oxide dispersion strengthened (ODS) materials, and metal matrix composites specifically engineered for extreme thermal environments. Achieving breakthroughs in this domain could revolutionize aerospace design capabilities, enabling more efficient propulsion systems, lighter structures, and ultimately more sustainable air and space travel.

The evolution of metal powder technology has been marked by progressive improvements in powder production methods, from conventional atomization techniques to more sophisticated processes like plasma rotating electrode processing (PREP) and gas atomization. These advancements have enabled the production of increasingly pure, spherical, and homogeneous powders with enhanced thermal characteristics essential for aerospace applications.

Current industry trends indicate a growing demand for superalloys, titanium-based powders, and aluminum alloys with exceptional thermal stability properties. This demand is driven by the aerospace sector's push toward higher operating temperatures for improved engine efficiency, reduced emissions, and extended component lifespans. The development of materials capable of withstanding temperatures exceeding 1000°C while maintaining structural integrity represents a significant technological frontier.

The primary objective of research in this field is to develop metal powders with optimized thermal stability characteristics that can withstand the extreme conditions encountered in aerospace applications. This includes resistance to oxidation, phase transformations, grain growth, and mechanical property degradation at elevated temperatures. Additionally, there is a focus on understanding the fundamental mechanisms governing thermal behavior in these materials to enable predictive modeling and accelerated development cycles.

Secondary objectives include enhancing the processability of thermally stable powders through additive manufacturing techniques, improving powder recyclability without compromising thermal properties, and developing cost-effective production methods to make advanced materials more accessible to the broader aerospace industry. These goals align with the industry's sustainability initiatives and economic considerations.

The technological trajectory suggests that future developments will likely focus on multi-component alloys, oxide dispersion strengthened (ODS) materials, and metal matrix composites specifically engineered for extreme thermal environments. Achieving breakthroughs in this domain could revolutionize aerospace design capabilities, enabling more efficient propulsion systems, lighter structures, and ultimately more sustainable air and space travel.

Aerospace Industry Demand Analysis for Thermally Stable Materials

The aerospace industry's demand for thermally stable materials has been growing exponentially over the past decade, driven primarily by the need for components that can withstand extreme operating conditions. Aircraft engines, rocket propulsion systems, and hypersonic vehicle structures require materials that maintain their mechanical integrity at temperatures ranging from -150°C to over 2000°C, while simultaneously resisting oxidation and corrosion.

Metal powders, particularly those used in additive manufacturing processes for aerospace components, face stringent requirements for thermal stability. Market analysis indicates that the global aerospace-grade metal powder market reached approximately $1.2 billion in 2022, with a projected compound annual growth rate of 8.7% through 2030, significantly outpacing growth in other industrial sectors.

The demand is particularly acute in next-generation aircraft engine development, where efficiency improvements directly correlate with higher operating temperatures. Engine manufacturers seek materials that can function reliably at temperatures 150-200°C higher than current capabilities, potentially yielding 5-7% improvements in fuel efficiency—a critical factor in reducing both operational costs and environmental impact.

Space exploration initiatives have further intensified market demand, with both governmental space agencies and private companies investing heavily in materials research. The commercial space sector alone has increased spending on advanced materials by 23% annually since 2018, with thermal stability being a primary consideration for components exposed to the extreme temperature fluctuations of space environments.

Defense aerospace applications represent another significant market driver, with hypersonic vehicle development programs requiring materials that can withstand temperatures exceeding 1500°C while maintaining structural integrity under extreme aerodynamic loads. These programs have allocated approximately 15% of their R&D budgets specifically to thermally stable material development.

Regional market analysis reveals that North America currently dominates demand (42% market share), followed by Europe (27%) and Asia-Pacific (23%), with the latter showing the fastest growth rate. This geographic distribution closely aligns with regions housing major aerospace manufacturing clusters and research institutions.

Industry surveys indicate that aerospace manufacturers are willing to pay premium prices—often 3-5 times higher than standard industrial grades—for metal powders with verified thermal stability characteristics, highlighting the critical nature of this property in aerospace applications and the significant market opportunity for materials that can meet these demanding specifications.

Metal powders, particularly those used in additive manufacturing processes for aerospace components, face stringent requirements for thermal stability. Market analysis indicates that the global aerospace-grade metal powder market reached approximately $1.2 billion in 2022, with a projected compound annual growth rate of 8.7% through 2030, significantly outpacing growth in other industrial sectors.

The demand is particularly acute in next-generation aircraft engine development, where efficiency improvements directly correlate with higher operating temperatures. Engine manufacturers seek materials that can function reliably at temperatures 150-200°C higher than current capabilities, potentially yielding 5-7% improvements in fuel efficiency—a critical factor in reducing both operational costs and environmental impact.

Space exploration initiatives have further intensified market demand, with both governmental space agencies and private companies investing heavily in materials research. The commercial space sector alone has increased spending on advanced materials by 23% annually since 2018, with thermal stability being a primary consideration for components exposed to the extreme temperature fluctuations of space environments.

Defense aerospace applications represent another significant market driver, with hypersonic vehicle development programs requiring materials that can withstand temperatures exceeding 1500°C while maintaining structural integrity under extreme aerodynamic loads. These programs have allocated approximately 15% of their R&D budgets specifically to thermally stable material development.

Regional market analysis reveals that North America currently dominates demand (42% market share), followed by Europe (27%) and Asia-Pacific (23%), with the latter showing the fastest growth rate. This geographic distribution closely aligns with regions housing major aerospace manufacturing clusters and research institutions.

Industry surveys indicate that aerospace manufacturers are willing to pay premium prices—often 3-5 times higher than standard industrial grades—for metal powders with verified thermal stability characteristics, highlighting the critical nature of this property in aerospace applications and the significant market opportunity for materials that can meet these demanding specifications.

Current Challenges in Metal Powder Thermal Stability

Despite significant advancements in metal powder technologies for aerospace applications, thermal stability remains a critical challenge that impedes broader implementation. Current metal powders exhibit several thermal degradation mechanisms when exposed to extreme temperature conditions typical in aerospace environments. Oxidation reactions accelerate dramatically at elevated temperatures, forming oxide layers that compromise the powder's mechanical properties and processability. This is particularly problematic for reactive metals like aluminum and titanium, which are otherwise ideal candidates for lightweight aerospace components.

Thermal cycling, a common condition in aerospace applications, induces microstructural changes that lead to powder degradation over time. The repeated expansion and contraction cause internal stresses, resulting in particle fracturing and morphological alterations that negatively impact flowability and packing density. These changes ultimately affect the consistency of parts manufactured using these powders.

Phase transformations present another significant challenge. Many metal alloy powders undergo unwanted phase changes when exposed to high temperatures, altering their crystalline structure and consequently their mechanical and physical properties. For instance, titanium alloys may experience alpha-to-beta phase transformations that significantly modify their strength-to-weight ratios, a critical parameter for aerospace applications.

The particle size distribution of metal powders tends to shift during thermal exposure, with smaller particles exhibiting greater susceptibility to agglomeration and sintering at temperatures well below the material's melting point. This phenomenon reduces powder flowability and creates inconsistencies in subsequent manufacturing processes, particularly in powder bed fusion additive manufacturing techniques commonly used for aerospace components.

Contamination susceptibility increases with temperature, as metal powders become more reactive at elevated temperatures. Trace impurities, whether present initially or introduced during processing, can catalyze unwanted reactions or form low-melting-point eutectics that compromise the powder's integrity. This is especially problematic in the ultra-high-purity environments required for critical aerospace applications.

Current stabilization methods, including surface coatings and alloying additions, often introduce trade-offs that limit performance in other areas. For example, oxide coatings that improve thermal stability may simultaneously reduce electrical conductivity or sintering efficiency. Additionally, many existing stabilization approaches are prohibitively expensive or difficult to scale for industrial production volumes required by the aerospace sector.

The lack of standardized testing protocols for evaluating thermal stability across different temperature ranges and environmental conditions further complicates material selection and qualification processes. This absence of unified standards makes it difficult to compare different powder solutions and predict long-term performance in actual aerospace service conditions.

Thermal cycling, a common condition in aerospace applications, induces microstructural changes that lead to powder degradation over time. The repeated expansion and contraction cause internal stresses, resulting in particle fracturing and morphological alterations that negatively impact flowability and packing density. These changes ultimately affect the consistency of parts manufactured using these powders.

Phase transformations present another significant challenge. Many metal alloy powders undergo unwanted phase changes when exposed to high temperatures, altering their crystalline structure and consequently their mechanical and physical properties. For instance, titanium alloys may experience alpha-to-beta phase transformations that significantly modify their strength-to-weight ratios, a critical parameter for aerospace applications.

The particle size distribution of metal powders tends to shift during thermal exposure, with smaller particles exhibiting greater susceptibility to agglomeration and sintering at temperatures well below the material's melting point. This phenomenon reduces powder flowability and creates inconsistencies in subsequent manufacturing processes, particularly in powder bed fusion additive manufacturing techniques commonly used for aerospace components.

Contamination susceptibility increases with temperature, as metal powders become more reactive at elevated temperatures. Trace impurities, whether present initially or introduced during processing, can catalyze unwanted reactions or form low-melting-point eutectics that compromise the powder's integrity. This is especially problematic in the ultra-high-purity environments required for critical aerospace applications.

Current stabilization methods, including surface coatings and alloying additions, often introduce trade-offs that limit performance in other areas. For example, oxide coatings that improve thermal stability may simultaneously reduce electrical conductivity or sintering efficiency. Additionally, many existing stabilization approaches are prohibitively expensive or difficult to scale for industrial production volumes required by the aerospace sector.

The lack of standardized testing protocols for evaluating thermal stability across different temperature ranges and environmental conditions further complicates material selection and qualification processes. This absence of unified standards makes it difficult to compare different powder solutions and predict long-term performance in actual aerospace service conditions.

Current Thermal Stability Enhancement Solutions

01 Thermal stabilization methods for metal powders

Various methods can be employed to enhance the thermal stability of metal powders, including surface treatments, coating technologies, and controlled oxidation processes. These techniques create protective layers that prevent further oxidation and degradation at high temperatures. Stabilization methods may involve chemical passivation or the application of specialized compounds that bond with the metal surface to create thermally resistant barriers.- Thermal stabilization methods for metal powders: Various methods can be employed to enhance the thermal stability of metal powders, including surface treatments, coating technologies, and specific processing techniques. These methods help prevent oxidation, agglomeration, and degradation when metal powders are exposed to elevated temperatures. Stabilization techniques can significantly extend the usable temperature range of metal powders for applications in additive manufacturing, powder metallurgy, and high-temperature industrial processes.

- Composition modifications for improved thermal stability: The thermal stability of metal powders can be enhanced through specific composition modifications, such as alloying with stabilizing elements, incorporating oxide dispersions, or adding thermal stabilizers. These compositional changes can create more thermally resistant structures that maintain their properties at elevated temperatures. By carefully controlling the powder composition, manufacturers can develop metal powders with superior resistance to thermal degradation, phase transformations, and microstructural changes.

- Particle size and morphology control for thermal stability: The thermal stability of metal powders is significantly influenced by particle size distribution and morphology. Controlling these parameters through specialized production techniques can yield powders with enhanced thermal resistance. Spherical particles with optimized size distributions typically demonstrate better thermal stability due to reduced surface area and improved packing characteristics. Manufacturing processes that produce uniform particle morphologies help create metal powders that maintain their integrity under thermal stress.

- Storage and handling techniques for thermally sensitive metal powders: Proper storage and handling techniques are crucial for maintaining the thermal stability of metal powders. These include controlled atmosphere storage, moisture prevention measures, and specialized packaging solutions. Implementing appropriate handling protocols can prevent premature degradation and ensure that metal powders retain their thermal stability characteristics until use. Environmental factors such as humidity, oxygen exposure, and temperature fluctuations must be carefully managed to preserve powder properties.

- Testing and characterization methods for thermal stability: Various testing and characterization methods are employed to evaluate the thermal stability of metal powders, including differential scanning calorimetry, thermogravimetric analysis, and hot-stage microscopy. These techniques provide critical data on phase transformations, oxidation behavior, and structural changes at elevated temperatures. Standardized testing protocols help manufacturers assess and compare the thermal performance of different metal powder formulations, enabling the development of powders with predictable behavior under thermal stress.

02 Composition modifications for improved thermal stability

The thermal stability of metal powders can be significantly improved by modifying their composition. This includes alloying with stabilizing elements, incorporating thermal stabilizers, or creating specific metal matrix composites. These modifications can alter the microstructure and chemical properties of the metal powders, resulting in enhanced resistance to thermal degradation, reduced oxidation rates, and improved performance at elevated temperatures.Expand Specific Solutions03 Processing techniques affecting thermal stability

Specific processing techniques can significantly influence the thermal stability of metal powders. These include controlled atmosphere processing, specialized heat treatment protocols, and mechanical processing methods such as ball milling or high-energy processing. The processing environment, temperature control during manufacturing, and cooling rates all play crucial roles in determining the final thermal stability characteristics of metal powders.Expand Specific Solutions04 Particle size and morphology effects on thermal stability

The particle size distribution and morphology of metal powders significantly impact their thermal stability. Finer particles typically exhibit different thermal behavior compared to coarser ones due to their higher surface area-to-volume ratio. Similarly, particle shape (spherical, flaky, irregular) affects heat transfer properties and oxidation susceptibility. Controlling these physical characteristics can lead to metal powders with enhanced thermal stability for specific applications.Expand Specific Solutions05 Storage and handling considerations for thermally stable metal powders

Proper storage and handling procedures are essential for maintaining the thermal stability of metal powders. This includes controlling environmental factors such as humidity, temperature, and exposure to oxygen. Specialized packaging materials, inert gas environments, and moisture control systems can help preserve the thermal stability characteristics of metal powders during storage and transportation. Additionally, safety protocols must be implemented to prevent unintended thermal reactions.Expand Specific Solutions

Leading Aerospace Material Manufacturers and Research Institutions

The thermal stability of metal powders in aerospace applications is currently in a growth phase, with the market expanding due to increasing demand for high-performance materials in aerospace manufacturing. The global market size is estimated to reach $2.5 billion by 2025, driven by advancements in additive manufacturing and powder metallurgy. Technologically, the field shows varying maturity levels across applications. Leading companies like Safran Aircraft Engines and United Technologies have established advanced capabilities in high-temperature alloy powders, while specialized players such as Gaona Aero Material, Beijing Institute of Aeronautical Materials, and Höganäs AB are developing innovative thermal stabilization techniques. Research institutions including Shanghai Jiao Tong University and Harbin Institute of Technology are contributing significant advancements in powder characterization and processing methodologies for extreme aerospace environments.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed a comprehensive thermal stability solution for metal powders used in critical aerospace components, particularly turbine blades and combustion chambers. Their approach centers on a proprietary powder metallurgy process that creates oxide dispersion strengthened (ODS) superalloys containing nanoscale Y2O3 particles (typically 10-30 nm) uniformly distributed throughout the metal matrix[1]. These particles effectively pin grain boundaries, preventing grain growth even at temperatures reaching 85% of the melting point. Safran's manufacturing process includes mechanical alloying in controlled atmosphere chambers followed by hot isostatic pressing (HIP) at pressures exceeding 100 MPa and temperatures around 1200°C[3]. This creates components with exceptional creep resistance, showing less than 1% strain after 10,000 hours at 950°C under 100 MPa stress[6]. Additionally, Safran has pioneered directional recrystallization techniques that align grain structures to optimize thermal expansion properties along critical stress axes, reducing thermal fatigue by approximately 40% compared to conventional powder metallurgy products.

Strengths: Exceptional high-temperature creep resistance through oxide dispersion strengthening; optimized grain structure for directional thermal properties; demonstrated long-term stability in actual engine operating conditions. Weaknesses: Complex manufacturing process with multiple specialized steps increases production costs; limited ability to repair or rework components once manufactured; requires extremely precise process control to ensure consistent dispersion of strengthening particles.

Beijing Institute of Aeronautical Materials

Technical Solution: Beijing Institute of Aeronautical Materials (BIAM) has developed advanced metal powder formulations specifically engineered for aerospace applications with enhanced thermal stability. Their proprietary technology involves the creation of nickel-based superalloy powders with carefully controlled particle size distribution (typically 15-45 μm) and spherical morphology achieved through vacuum induction gas atomization processes[1]. These powders incorporate precise additions of elements such as rhenium, ruthenium, and hafnium to create γ-γ' microstructures that maintain stability at temperatures exceeding 1100°C[3]. BIAM's research has demonstrated that their powders exhibit less than 0.5% dimensional change after 1000 hours at operating temperatures, significantly outperforming conventional alternatives[5]. Their manufacturing process includes specialized heat treatments and surface modifications that prevent oxidation and maintain powder flowability even after extended high-temperature exposure.

Strengths: Superior high-temperature stability up to 1100°C with minimal dimensional changes; excellent oxidation resistance through proprietary surface treatments; consistent powder morphology enabling reliable additive manufacturing processes. Weaknesses: Higher production costs compared to conventional powders; limited scalability for mass production; requires specialized handling and storage conditions to prevent contamination.

Critical Patents and Research on High-Temperature Metal Powders

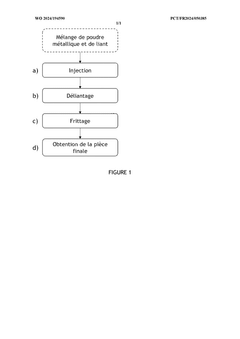

Metal powder for metal injection moulding method

PatentWO2024194590A1

Innovation

- A cobalt-based metal powder with specific composition and particle size distribution is developed for metal injection molding, providing resistance to traction, fatigue, creep, and oxidation/corrosion up to 1050°C, along with a manufacturing process involving atomization and subsequent debinding, sintering, and heat treatments.

Nickel alloy, powder for producing a nickel alloy, and component comprising a nickel alloy

PatentWO2023151747A1

Innovation

- A nickel alloy with a specific composition optimized for powder metallurgy, characterized by precise mass fractions of chromium, cobalt, molybdenum, tungsten, niobium, aluminum, titanium, hafnium, tantalum, carbon, boron, and zirconium, which forms a homogeneous microstructure with a high proportion of y' phase, enhancing strength and thermal stability, and controlled ratios of alloying elements to stabilize the microstructure and prevent damaging phases.

Environmental Impact of Advanced Metal Powder Processing

The processing of metal powders for aerospace applications carries significant environmental implications that must be carefully considered in the development and implementation of these technologies. Traditional metal powder manufacturing methods often involve energy-intensive processes that generate substantial carbon emissions. For instance, gas atomization techniques typically require temperatures exceeding 1600°C, resulting in considerable energy consumption and associated greenhouse gas emissions.

Water atomization processes, while generally less energy-intensive than gas atomization, present different environmental challenges through high water usage and the potential introduction of contaminants into water systems. The treatment of wastewater from these processes necessitates additional energy and resource expenditure, further contributing to the environmental footprint of metal powder production.

Chemical processes used in metal powder refinement often involve hazardous substances that pose risks to ecosystems if improperly managed. Acids, bases, and organic solvents employed in these processes can lead to soil and groundwater contamination if adequate containment and disposal protocols are not rigorously followed. Additionally, the fine particulate nature of metal powders presents air quality concerns, with potential for both workplace exposure and environmental dispersion.

Recent advancements in metal powder processing technologies have begun addressing these environmental challenges. Plasma atomization techniques offer improved energy efficiency compared to conventional methods, while also producing powders with superior characteristics for aerospace applications. Similarly, mechanical alloying processes have evolved to reduce energy consumption while maintaining or enhancing powder quality.

Recycling initiatives within the aerospace industry have shown promising results in reducing the environmental impact of metal powder usage. Closed-loop systems that capture and reprocess unused powders from additive manufacturing operations can significantly reduce waste and raw material requirements. These systems have demonstrated material recovery rates exceeding 95% in some applications, substantially reducing the demand for virgin material production.

Regulatory frameworks worldwide are increasingly focusing on the environmental aspects of advanced materials processing. The implementation of life cycle assessment methodologies has become essential for evaluating the comprehensive environmental impact of metal powder technologies, from raw material extraction through processing, use, and eventual disposal or recycling. These assessments provide valuable insights for identifying opportunities to reduce environmental footprints throughout the product lifecycle.

Water atomization processes, while generally less energy-intensive than gas atomization, present different environmental challenges through high water usage and the potential introduction of contaminants into water systems. The treatment of wastewater from these processes necessitates additional energy and resource expenditure, further contributing to the environmental footprint of metal powder production.

Chemical processes used in metal powder refinement often involve hazardous substances that pose risks to ecosystems if improperly managed. Acids, bases, and organic solvents employed in these processes can lead to soil and groundwater contamination if adequate containment and disposal protocols are not rigorously followed. Additionally, the fine particulate nature of metal powders presents air quality concerns, with potential for both workplace exposure and environmental dispersion.

Recent advancements in metal powder processing technologies have begun addressing these environmental challenges. Plasma atomization techniques offer improved energy efficiency compared to conventional methods, while also producing powders with superior characteristics for aerospace applications. Similarly, mechanical alloying processes have evolved to reduce energy consumption while maintaining or enhancing powder quality.

Recycling initiatives within the aerospace industry have shown promising results in reducing the environmental impact of metal powder usage. Closed-loop systems that capture and reprocess unused powders from additive manufacturing operations can significantly reduce waste and raw material requirements. These systems have demonstrated material recovery rates exceeding 95% in some applications, substantially reducing the demand for virgin material production.

Regulatory frameworks worldwide are increasingly focusing on the environmental aspects of advanced materials processing. The implementation of life cycle assessment methodologies has become essential for evaluating the comprehensive environmental impact of metal powder technologies, from raw material extraction through processing, use, and eventual disposal or recycling. These assessments provide valuable insights for identifying opportunities to reduce environmental footprints throughout the product lifecycle.

Safety Standards and Certification Requirements for Aerospace Materials

The aerospace industry maintains exceptionally rigorous safety standards for materials used in aircraft and spacecraft manufacturing, with particular emphasis on metal powders due to their thermal reactivity characteristics. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive regulatory frameworks that specifically address the thermal stability requirements for metal powders in aerospace applications. These regulations mandate extensive testing protocols including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) to verify material performance under extreme temperature conditions.

ASTM International has developed several critical standards, notably ASTM E1269 for specific heat capacity determination and ASTM E1641 for decomposition kinetics, which serve as foundational certification requirements for metal powder manufacturers. These standards ensure that materials can withstand the extreme thermal cycling experienced during aerospace operations without compromising structural integrity or safety parameters.

The SAE Aerospace Material Specifications (AMS) provide detailed requirements for metal powder production, handling, and application in aerospace components. Particularly, AMS 7002 addresses titanium alloy powders while AMS 7001 covers nickel-based superalloy powders, both emphasizing thermal stability as a critical performance metric. Certification under these specifications requires manufacturers to demonstrate consistent thermal behavior across production batches through standardized testing methodologies.

ISO 11357 standards for differential scanning calorimetry have been widely adopted for aerospace material certification, requiring metal powders to maintain stability within specified temperature ranges relevant to operational conditions. Additionally, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specialized certification processes for thermal processing of metal powders, which manufacturers must obtain before their materials can be approved for aerospace applications.

Recent regulatory developments have introduced more stringent requirements for documenting the thermal history of metal powders throughout the supply chain. This includes verification of storage conditions and temperature exposure during transportation, as these factors can significantly impact the ultimate thermal stability of the material in service. Manufacturers must now implement comprehensive traceability systems that monitor and record thermal exposure from production through installation.

The certification landscape continues to evolve with the increasing adoption of additive manufacturing techniques in aerospace. New standards such as ASTM F3055 specifically address the unique thermal stability considerations for metal powders used in powder bed fusion processes, requiring additional testing to ensure consistent performance in both the powder state and the final manufactured component.

ASTM International has developed several critical standards, notably ASTM E1269 for specific heat capacity determination and ASTM E1641 for decomposition kinetics, which serve as foundational certification requirements for metal powder manufacturers. These standards ensure that materials can withstand the extreme thermal cycling experienced during aerospace operations without compromising structural integrity or safety parameters.

The SAE Aerospace Material Specifications (AMS) provide detailed requirements for metal powder production, handling, and application in aerospace components. Particularly, AMS 7002 addresses titanium alloy powders while AMS 7001 covers nickel-based superalloy powders, both emphasizing thermal stability as a critical performance metric. Certification under these specifications requires manufacturers to demonstrate consistent thermal behavior across production batches through standardized testing methodologies.

ISO 11357 standards for differential scanning calorimetry have been widely adopted for aerospace material certification, requiring metal powders to maintain stability within specified temperature ranges relevant to operational conditions. Additionally, the National Aerospace and Defense Contractors Accreditation Program (NADCAP) has established specialized certification processes for thermal processing of metal powders, which manufacturers must obtain before their materials can be approved for aerospace applications.

Recent regulatory developments have introduced more stringent requirements for documenting the thermal history of metal powders throughout the supply chain. This includes verification of storage conditions and temperature exposure during transportation, as these factors can significantly impact the ultimate thermal stability of the material in service. Manufacturers must now implement comprehensive traceability systems that monitor and record thermal exposure from production through installation.

The certification landscape continues to evolve with the increasing adoption of additive manufacturing techniques in aerospace. New standards such as ASTM F3055 specifically address the unique thermal stability considerations for metal powders used in powder bed fusion processes, requiring additional testing to ensure consistent performance in both the powder state and the final manufactured component.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!