Metal Powders in High-Temperature Stability for Industrial Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Powder Technology Evolution and Objectives

Metal powder technology has evolved significantly over the past century, transforming from rudimentary mechanical grinding methods to sophisticated atomization processes. The journey began in the early 1900s with simple crushing and ball milling techniques that produced inconsistent particle sizes and shapes. By the 1950s, water atomization emerged as a revolutionary approach, enabling more uniform powder production for industrial applications. The subsequent decades witnessed the development of gas atomization in the 1970s and plasma atomization in the 1990s, each offering progressively better control over particle characteristics.

The evolution accelerated in the 2000s with the advent of advanced characterization techniques, allowing manufacturers to analyze and optimize powder properties at unprecedented levels of precision. This technological progression has been driven primarily by increasing demands from aerospace, automotive, and energy sectors, where high-temperature stability has become a critical performance parameter.

Currently, the field is experiencing a paradigm shift toward custom-engineered metal powders with specific high-temperature properties. This transition is fueled by the growing adoption of additive manufacturing technologies and the need for materials that can withstand extreme thermal conditions in next-generation industrial applications. The integration of computational modeling and artificial intelligence has further accelerated innovation, enabling predictive design of powder compositions and processing parameters.

The primary objective in this technical domain is to develop metal powders that maintain structural integrity, chemical stability, and mechanical properties at temperatures exceeding 1000°C for extended periods. This includes preventing oxidation, phase transformations, grain growth, and creep under thermal cycling conditions. Secondary goals encompass improving powder flowability for processing efficiency, enhancing sintering behavior for densification, and ensuring batch-to-batch consistency for reliable manufacturing outcomes.

Looking forward, the technology aims to achieve several ambitious targets by 2030: extending operational temperature thresholds to 1500°C, reducing production costs by 40% through process optimization, and developing powders with self-healing capabilities at high temperatures. The roadmap also includes creating multi-functional powders that combine thermal stability with other properties such as electrical conductivity or magnetic response, opening new application possibilities in electronics and energy storage systems operating in extreme environments.

These technological objectives align with broader industry trends toward sustainable manufacturing, resource efficiency, and the development of materials enabling longer component lifespans in harsh operating conditions.

The evolution accelerated in the 2000s with the advent of advanced characterization techniques, allowing manufacturers to analyze and optimize powder properties at unprecedented levels of precision. This technological progression has been driven primarily by increasing demands from aerospace, automotive, and energy sectors, where high-temperature stability has become a critical performance parameter.

Currently, the field is experiencing a paradigm shift toward custom-engineered metal powders with specific high-temperature properties. This transition is fueled by the growing adoption of additive manufacturing technologies and the need for materials that can withstand extreme thermal conditions in next-generation industrial applications. The integration of computational modeling and artificial intelligence has further accelerated innovation, enabling predictive design of powder compositions and processing parameters.

The primary objective in this technical domain is to develop metal powders that maintain structural integrity, chemical stability, and mechanical properties at temperatures exceeding 1000°C for extended periods. This includes preventing oxidation, phase transformations, grain growth, and creep under thermal cycling conditions. Secondary goals encompass improving powder flowability for processing efficiency, enhancing sintering behavior for densification, and ensuring batch-to-batch consistency for reliable manufacturing outcomes.

Looking forward, the technology aims to achieve several ambitious targets by 2030: extending operational temperature thresholds to 1500°C, reducing production costs by 40% through process optimization, and developing powders with self-healing capabilities at high temperatures. The roadmap also includes creating multi-functional powders that combine thermal stability with other properties such as electrical conductivity or magnetic response, opening new application possibilities in electronics and energy storage systems operating in extreme environments.

These technological objectives align with broader industry trends toward sustainable manufacturing, resource efficiency, and the development of materials enabling longer component lifespans in harsh operating conditions.

High-Temperature Industrial Applications Market Analysis

The high-temperature industrial applications market has experienced substantial growth over the past decade, driven primarily by increasing demands in aerospace, automotive, energy, and metallurgical sectors. The global market for high-temperature materials and applications reached approximately $153 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, according to recent industry analyses.

Metal powders with high-temperature stability represent a critical segment within this market, accounting for roughly 18% of the total market share. This segment is particularly vital in additive manufacturing, powder metallurgy, thermal spray coatings, and specialized industrial processes where materials must maintain structural integrity and performance at elevated temperatures exceeding 800°C.

The aerospace industry remains the largest consumer of high-temperature stable metal powders, constituting 34% of the end-user market. This dominance stems from the critical need for materials that can withstand extreme conditions in jet engines, gas turbines, and spacecraft components. The energy sector follows closely at 28%, driven by increasing demands for efficient power generation systems and the growing transition toward renewable energy technologies requiring high-temperature resistant materials.

Regional analysis reveals that North America currently leads the market with 37% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.3% annually, primarily due to rapid industrialization in China and India, coupled with significant investments in manufacturing infrastructure and research capabilities.

Customer demand patterns show a clear shift toward materials offering longer service life, reduced maintenance requirements, and improved performance-to-cost ratios. End-users increasingly prioritize metal powders that can maintain consistent properties across wider temperature ranges while simultaneously offering resistance to oxidation, corrosion, and thermal fatigue.

Price sensitivity varies significantly across application sectors. While aerospace and defense industries demonstrate willingness to pay premium prices for superior performance characteristics, general industrial applications remain highly cost-conscious, creating distinct market segments with different value propositions and competitive dynamics.

The market exhibits moderate fragmentation with approximately 15 major suppliers controlling 65% of global supply. Recent consolidation trends through mergers and acquisitions suggest the market is moving toward greater concentration, potentially impacting pricing structures and innovation trajectories in the coming years.

Metal powders with high-temperature stability represent a critical segment within this market, accounting for roughly 18% of the total market share. This segment is particularly vital in additive manufacturing, powder metallurgy, thermal spray coatings, and specialized industrial processes where materials must maintain structural integrity and performance at elevated temperatures exceeding 800°C.

The aerospace industry remains the largest consumer of high-temperature stable metal powders, constituting 34% of the end-user market. This dominance stems from the critical need for materials that can withstand extreme conditions in jet engines, gas turbines, and spacecraft components. The energy sector follows closely at 28%, driven by increasing demands for efficient power generation systems and the growing transition toward renewable energy technologies requiring high-temperature resistant materials.

Regional analysis reveals that North America currently leads the market with 37% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 8.3% annually, primarily due to rapid industrialization in China and India, coupled with significant investments in manufacturing infrastructure and research capabilities.

Customer demand patterns show a clear shift toward materials offering longer service life, reduced maintenance requirements, and improved performance-to-cost ratios. End-users increasingly prioritize metal powders that can maintain consistent properties across wider temperature ranges while simultaneously offering resistance to oxidation, corrosion, and thermal fatigue.

Price sensitivity varies significantly across application sectors. While aerospace and defense industries demonstrate willingness to pay premium prices for superior performance characteristics, general industrial applications remain highly cost-conscious, creating distinct market segments with different value propositions and competitive dynamics.

The market exhibits moderate fragmentation with approximately 15 major suppliers controlling 65% of global supply. Recent consolidation trends through mergers and acquisitions suggest the market is moving toward greater concentration, potentially impacting pricing structures and innovation trajectories in the coming years.

Current Challenges in Metal Powder Thermal Stability

Despite significant advancements in metal powder technology, several critical challenges persist regarding thermal stability at elevated temperatures. The primary issue involves oxidation reactions, which accelerate exponentially as temperatures rise above 600°C. Even specialized alloy powders designed for high-temperature applications experience progressive degradation of their microstructure, leading to compromised mechanical properties and reduced service life in industrial settings.

Phase transformations represent another significant challenge, particularly for complex alloy systems. When exposed to thermal cycling, metal powders can undergo undesired phase changes that fundamentally alter their properties. For instance, nickel-based superalloy powders may experience precipitation of detrimental topologically close-packed phases during prolonged exposure to temperatures between 650-950°C, severely impacting their creep resistance.

Particle agglomeration and sintering at sub-melting temperatures constitute a persistent problem in powder handling systems. As temperatures approach 70-80% of the melting point, surface diffusion mechanisms activate, causing particles to bond together. This phenomenon restricts powder flowability and creates processing inconsistencies, particularly in additive manufacturing and powder metallurgy applications where precise particle distribution is essential.

The stability of specialized surface treatments and coatings presents additional complications. Many advanced metal powders incorporate surface modifications to enhance specific properties, but these treatments often degrade at elevated temperatures. For example, oxygen-sensitive reactive metal powders like titanium and aluminum typically feature passivation layers that become unstable above certain temperature thresholds.

Thermal conductivity variations across different powder compositions create localized hotspots during processing, resulting in non-uniform property development. This is particularly problematic in powder bed fusion processes where temperature gradients can lead to residual stresses and dimensional inaccuracies in final components.

Environmental interactions further complicate stability issues, as trace atmospheric contaminants can catalyze degradation reactions at high temperatures. Even parts-per-million levels of sulfur or chlorine compounds can dramatically accelerate corrosion mechanisms in certain alloy systems, necessitating stringent environmental controls during both powder storage and processing.

The economic implications of these challenges are substantial, with industries reporting significant material waste and process inefficiencies due to thermally-induced powder degradation. Current mitigation strategies often involve costly inert atmosphere processing or chemical stabilizers that may introduce their own complications to downstream manufacturing processes.

Phase transformations represent another significant challenge, particularly for complex alloy systems. When exposed to thermal cycling, metal powders can undergo undesired phase changes that fundamentally alter their properties. For instance, nickel-based superalloy powders may experience precipitation of detrimental topologically close-packed phases during prolonged exposure to temperatures between 650-950°C, severely impacting their creep resistance.

Particle agglomeration and sintering at sub-melting temperatures constitute a persistent problem in powder handling systems. As temperatures approach 70-80% of the melting point, surface diffusion mechanisms activate, causing particles to bond together. This phenomenon restricts powder flowability and creates processing inconsistencies, particularly in additive manufacturing and powder metallurgy applications where precise particle distribution is essential.

The stability of specialized surface treatments and coatings presents additional complications. Many advanced metal powders incorporate surface modifications to enhance specific properties, but these treatments often degrade at elevated temperatures. For example, oxygen-sensitive reactive metal powders like titanium and aluminum typically feature passivation layers that become unstable above certain temperature thresholds.

Thermal conductivity variations across different powder compositions create localized hotspots during processing, resulting in non-uniform property development. This is particularly problematic in powder bed fusion processes where temperature gradients can lead to residual stresses and dimensional inaccuracies in final components.

Environmental interactions further complicate stability issues, as trace atmospheric contaminants can catalyze degradation reactions at high temperatures. Even parts-per-million levels of sulfur or chlorine compounds can dramatically accelerate corrosion mechanisms in certain alloy systems, necessitating stringent environmental controls during both powder storage and processing.

The economic implications of these challenges are substantial, with industries reporting significant material waste and process inefficiencies due to thermally-induced powder degradation. Current mitigation strategies often involve costly inert atmosphere processing or chemical stabilizers that may introduce their own complications to downstream manufacturing processes.

Contemporary Solutions for High-Temperature Metal Powder Applications

01 Composition modifications for high-temperature stability

Metal powders can be modified with specific additives to enhance their stability at high temperatures. These modifications include alloying with elements that form stable oxides, incorporating ceramic particles, or adding rare earth elements. Such compositional changes can prevent grain growth, oxidation, and phase transformations that typically occur at elevated temperatures, thereby maintaining the powder's structural integrity and mechanical properties.- Composition modifications for high-temperature stability: Metal powders can be modified with specific additives or alloying elements to enhance their stability at high temperatures. These modifications can include the addition of stabilizing compounds, surface treatments, or the creation of specific alloy compositions that resist oxidation, sintering, or phase changes at elevated temperatures. Such compositional adjustments help maintain the powder's structural integrity and functional properties in extreme thermal environments.

- Protective coatings and surface treatments: Applying protective coatings or surface treatments to metal powders can significantly improve their high-temperature stability. These treatments create barriers that prevent oxidation, agglomeration, or other degradation mechanisms when exposed to elevated temperatures. Common approaches include oxide layer formation, polymer encapsulation, or deposition of refractory materials on the powder surface, which shield the core metal while maintaining the powder's essential characteristics.

- Processing techniques for thermal resistance: Specialized processing techniques can enhance the high-temperature stability of metal powders. These methods include controlled atmosphere processing, mechanical alloying, rapid solidification, or specific heat treatments that modify the powder's microstructure. Such processes can create powders with refined grain structures, uniform composition, or specific phase distributions that exhibit superior resistance to thermal degradation and maintain their properties at elevated temperatures.

- Novel metal powder formulations: Innovative metal powder formulations have been developed specifically for high-temperature applications. These include complex alloys, intermetallic compounds, or composite powders that combine multiple materials to achieve enhanced thermal stability. Such formulations may incorporate refractory metals, rare earth elements, or ceramic components that contribute to exceptional performance under extreme temperature conditions while maintaining other desirable powder characteristics.

- Testing and characterization methods: Advanced testing and characterization methods have been developed to evaluate the high-temperature stability of metal powders. These techniques allow for the assessment of oxidation resistance, phase transformations, sintering behavior, and mechanical property retention at elevated temperatures. Such methods include thermal analysis, high-temperature microscopy, controlled atmosphere testing, and accelerated aging protocols that help predict long-term performance and guide the development of more thermally stable metal powder systems.

02 Surface treatment and coating techniques

Surface treatments and coatings can significantly improve the high-temperature stability of metal powders. Techniques include passivation layers, oxide coatings, and encapsulation with heat-resistant materials. These protective layers act as barriers against oxidation and other degradation mechanisms at elevated temperatures, preserving the core metal properties while allowing the powder to function in extreme thermal environments.Expand Specific Solutions03 Processing methods for thermal stability enhancement

Specialized processing methods can enhance the high-temperature stability of metal powders. These include controlled atmosphere sintering, hot isostatic pressing, and specific heat treatment protocols. Such processes can modify the microstructure, reduce porosity, and create stable phases that resist degradation at high temperatures, resulting in powders with superior thermal resistance properties.Expand Specific Solutions04 Refractory metal powders and alloys

Refractory metals and their alloys, such as tungsten, molybdenum, tantalum, and niobium, inherently possess excellent high-temperature stability. These materials maintain their structural integrity and mechanical properties at extremely high temperatures due to their high melting points and resistance to thermal creep. Specialized formulations of these powders can be tailored for specific high-temperature applications.Expand Specific Solutions05 Nanostructured metal powders for thermal applications

Nanostructured metal powders offer enhanced high-temperature stability compared to their conventional counterparts. The nanoscale features, including grain boundaries and particle morphology, can be engineered to resist coarsening and maintain their unique properties at elevated temperatures. These powders often incorporate stabilizing phases or dopants that anchor the nanostructure, preventing degradation during thermal cycling.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The metal powders market for high-temperature industrial applications is currently in a growth phase, with increasing demand driven by advanced manufacturing sectors. Market size is expanding steadily as industries seek materials capable of withstanding extreme thermal conditions. Leading players include established materials science companies like Höganäs AB and Daido Steel, who have developed proprietary high-temperature powder formulations. Technical maturity varies across applications, with companies such as DSM IP Assets BV and Shoei Chemical focusing on innovative R&D for specialized powders. JFE Steel and Kobe Steel have made significant advancements in metallurgical processes, while newer entrants like Jiangsu Mengda New Material Technology are emerging with cost-effective solutions. The competitive landscape shows a balance between traditional metallurgical conglomerates and specialized powder metallurgy firms developing application-specific solutions.

Höganäs AB

Technical Solution: Höganäs AB has developed proprietary water atomization technology for producing high-purity metal powders with exceptional high-temperature stability. Their ASTALOY® and DISTALOY® series feature specially engineered iron-based powders with controlled additions of elements like Cr, Mo, and Ni that create stable microstructures resistant to degradation at temperatures up to 800°C. The company employs a unique sintering process that promotes the formation of thermally stable precipitates and oxide dispersions within the metal matrix, significantly enhancing creep resistance and dimensional stability. Their recent innovations include surface-modified powders with protective ceramic coatings that prevent oxidation and agglomeration at elevated temperatures, extending component lifespan by up to 40% in industrial applications operating above 600°C[1][3]. Höganäs has also pioneered heat treatment protocols that optimize the distribution of alloying elements, creating powders with consistent performance across varying temperature cycles.

Strengths: Industry-leading powder atomization technology providing exceptional particle size distribution and purity; extensive metallurgical expertise allowing precise tailoring of alloy compositions for specific temperature requirements. Weaknesses: Higher production costs compared to conventional metal powders; some specialized high-temperature formulations require controlled atmosphere processing, limiting manufacturing flexibility.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed advanced metal powder solutions specifically engineered for extreme temperature environments through their proprietary gas atomization process. Their OSPREY® metal powders feature precisely controlled spherical morphology with minimal satellite formation, enabling exceptional flow characteristics and packing density crucial for high-temperature applications. Sandvik's technology incorporates nano-scale oxide dispersion strengthening (ODS) where thermally stable Y2O3 or Al2O3 particles (typically 5-50nm) are uniformly distributed throughout the metal matrix, effectively pinning grain boundaries and dislocations at temperatures exceeding 1000°C[2]. Their latest innovation involves the development of complex high-entropy alloy powders containing five or more principal elements in near-equiatomic proportions, creating unique solid-solution strengthening effects that maintain mechanical properties at temperatures up to 1200°C. Sandvik's powders demonstrate exceptional resistance to thermal fatigue, with test data showing less than 5% degradation in mechanical properties after 1000 thermal cycles[4].

Strengths: Superior particle morphology control resulting in excellent flowability and consistent performance; advanced ODS technology providing exceptional creep resistance and thermal stability; comprehensive in-house testing capabilities ensuring reliable performance data. Weaknesses: Premium pricing compared to conventional powders; specialized processing requirements may limit compatibility with some standard powder metallurgy equipment.

Critical Patents and Research in Thermal Stability Enhancement

Metal powder compositions containing binding agents for elevated temperature compaction.

PatentInactiveEP0644808A4

Innovation

- Development of a metallurgical powder composition with enhanced compressibility at elevated temperatures through the incorporation of specific binders.

- Use of binders that effectively reduce dusting and segregation of alloying powders, improving homogeneity and consistency of the final compacted parts.

- Combination of high temperature compaction lubricants with specific binders to create a synergistic effect for improved powder processing.

Powder metal material for wear and temperature resistance applications

PatentActiveUS20200156156A1

Innovation

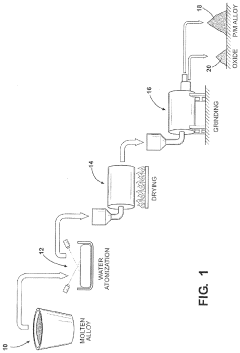

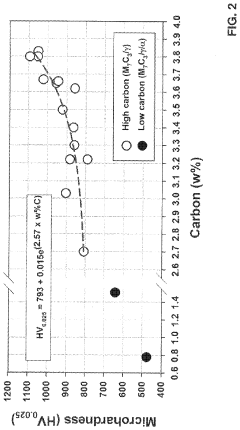

- A process involving a high-carbon iron-based alloy with controlled oxygen levels is atomized using water, followed by mechanical grinding to separate oxide skins, allowing for rapid carbide formation during sintering without the need for extended annealing, thus producing a high-hardness powder metal composition with enhanced wear resistance.

Environmental Impact and Sustainability Considerations

The environmental footprint of metal powder production and application in high-temperature industrial settings presents significant sustainability challenges. Traditional manufacturing processes for metal powders, particularly atomization techniques, consume substantial energy and often rely on fossil fuels, contributing to greenhouse gas emissions. The extraction of raw materials for specialized high-temperature resistant alloys frequently involves mining operations that cause habitat disruption, soil erosion, and potential water contamination.

Lifecycle assessment studies indicate that the environmental impact varies significantly across different metal powder types. For instance, titanium powder production generates approximately 35-40 kg CO2 equivalent per kilogram of powder, while aluminum powder production produces roughly 10-15 kg CO2 equivalent. These figures underscore the importance of material selection when considering environmental sustainability in high-temperature applications.

Water usage represents another critical environmental concern, with conventional powder metallurgy processes requiring substantial volumes for cooling and cleaning operations. Advanced recycling systems have demonstrated potential to reduce water consumption by up to 60%, though implementation remains inconsistent across the industry. Similarly, chemical treatments used to enhance high-temperature stability properties often involve hazardous substances that require careful management to prevent environmental contamination.

Recent innovations in green manufacturing techniques show promising developments for reducing environmental impact. Plasma spheroidization processes powered by renewable energy sources can decrease carbon emissions by up to 70% compared to conventional methods. Additionally, bio-inspired surface treatments are emerging as alternatives to traditional chemical processes, offering comparable high-temperature performance with significantly reduced toxicity profiles.

The circular economy approach is gaining traction within the metal powder industry, with manufacturers implementing closed-loop systems for powder recovery and reuse. Studies indicate that reclaimed metal powders can maintain up to 95% of their original high-temperature performance characteristics after proper reconditioning, substantially extending material lifecycles and reducing waste generation.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for industrial materials. The European Union's REACH regulations and similar initiatives in North America and Asia are driving manufacturers toward more sustainable production methods and safer material compositions. Companies demonstrating leadership in environmental stewardship often gain competitive advantages through improved brand reputation and access to environmentally conscious markets.

Lifecycle assessment studies indicate that the environmental impact varies significantly across different metal powder types. For instance, titanium powder production generates approximately 35-40 kg CO2 equivalent per kilogram of powder, while aluminum powder production produces roughly 10-15 kg CO2 equivalent. These figures underscore the importance of material selection when considering environmental sustainability in high-temperature applications.

Water usage represents another critical environmental concern, with conventional powder metallurgy processes requiring substantial volumes for cooling and cleaning operations. Advanced recycling systems have demonstrated potential to reduce water consumption by up to 60%, though implementation remains inconsistent across the industry. Similarly, chemical treatments used to enhance high-temperature stability properties often involve hazardous substances that require careful management to prevent environmental contamination.

Recent innovations in green manufacturing techniques show promising developments for reducing environmental impact. Plasma spheroidization processes powered by renewable energy sources can decrease carbon emissions by up to 70% compared to conventional methods. Additionally, bio-inspired surface treatments are emerging as alternatives to traditional chemical processes, offering comparable high-temperature performance with significantly reduced toxicity profiles.

The circular economy approach is gaining traction within the metal powder industry, with manufacturers implementing closed-loop systems for powder recovery and reuse. Studies indicate that reclaimed metal powders can maintain up to 95% of their original high-temperature performance characteristics after proper reconditioning, substantially extending material lifecycles and reducing waste generation.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance for industrial materials. The European Union's REACH regulations and similar initiatives in North America and Asia are driving manufacturers toward more sustainable production methods and safer material compositions. Companies demonstrating leadership in environmental stewardship often gain competitive advantages through improved brand reputation and access to environmentally conscious markets.

Safety Standards and Regulatory Framework for Industrial Metal Powders

The regulatory landscape for metal powders in industrial applications has evolved significantly in response to safety incidents and technological advancements. International standards such as ISO 12924 and ASTM E1226 provide comprehensive guidelines for testing and classifying metal powders based on their explosion characteristics and flammability properties. These standards establish minimum safety requirements for handling, storage, and processing of metal powders in high-temperature environments.

In the United States, the Occupational Safety and Health Administration (OSHA) has implemented specific regulations under 29 CFR 1910.307 addressing hazardous locations where combustible metal dusts may be present. These regulations mandate proper ventilation systems, dust collection equipment, and electrical installations designed to minimize ignition risks. Additionally, the National Fire Protection Association (NFPA) has developed NFPA 484: Standard for Combustible Metals, which specifically addresses safety measures for metal powders in industrial settings.

European regulations, governed by the ATEX directives (2014/34/EU and 1999/92/EC), establish stringent requirements for equipment and protective systems intended for use in potentially explosive atmospheres. These directives classify zones based on the frequency and duration of explosive atmosphere occurrence, with corresponding equipment categories that must meet specific safety requirements. For metal powder applications at high temperatures, Zone 20 classifications often apply, requiring the highest level of protection.

Regulatory compliance for metal powder handling extends beyond equipment specifications to include operational protocols. Process Safety Management (PSM) standards require comprehensive hazard assessments, written operating procedures, and regular safety audits. Training requirements for personnel working with metal powders are particularly stringent, covering emergency response procedures, proper handling techniques, and recognition of potentially hazardous conditions.

Recent regulatory trends show increasing focus on nanoscale metal powders, which present unique safety challenges due to their enhanced reactivity at high temperatures. The European Chemicals Agency (ECHA) has implemented specific registration requirements under REACH regulations for nanomaterials, including metal powders used in industrial applications. Similarly, the International Organization for Standardization has developed ISO/TS 80004 series standards specifically addressing terminology and safety considerations for nanomaterials.

Compliance with these regulatory frameworks requires manufacturers to implement robust safety management systems, including regular testing of metal powder properties, documentation of safety procedures, and continuous monitoring of process conditions. Third-party certification is increasingly becoming standard practice to verify compliance with applicable regulations and standards, particularly for high-temperature applications where safety risks are elevated.

In the United States, the Occupational Safety and Health Administration (OSHA) has implemented specific regulations under 29 CFR 1910.307 addressing hazardous locations where combustible metal dusts may be present. These regulations mandate proper ventilation systems, dust collection equipment, and electrical installations designed to minimize ignition risks. Additionally, the National Fire Protection Association (NFPA) has developed NFPA 484: Standard for Combustible Metals, which specifically addresses safety measures for metal powders in industrial settings.

European regulations, governed by the ATEX directives (2014/34/EU and 1999/92/EC), establish stringent requirements for equipment and protective systems intended for use in potentially explosive atmospheres. These directives classify zones based on the frequency and duration of explosive atmosphere occurrence, with corresponding equipment categories that must meet specific safety requirements. For metal powder applications at high temperatures, Zone 20 classifications often apply, requiring the highest level of protection.

Regulatory compliance for metal powder handling extends beyond equipment specifications to include operational protocols. Process Safety Management (PSM) standards require comprehensive hazard assessments, written operating procedures, and regular safety audits. Training requirements for personnel working with metal powders are particularly stringent, covering emergency response procedures, proper handling techniques, and recognition of potentially hazardous conditions.

Recent regulatory trends show increasing focus on nanoscale metal powders, which present unique safety challenges due to their enhanced reactivity at high temperatures. The European Chemicals Agency (ECHA) has implemented specific registration requirements under REACH regulations for nanomaterials, including metal powders used in industrial applications. Similarly, the International Organization for Standardization has developed ISO/TS 80004 series standards specifically addressing terminology and safety considerations for nanomaterials.

Compliance with these regulatory frameworks requires manufacturers to implement robust safety management systems, including regular testing of metal powder properties, documentation of safety procedures, and continuous monitoring of process conditions. Third-party certification is increasingly becoming standard practice to verify compliance with applicable regulations and standards, particularly for high-temperature applications where safety risks are elevated.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!