Analysis of Thermal Gradient Management in Thermoelectric Modules

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Module Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The fundamental principles of thermoelectric effects—Seebeck, Peltier, and Thomson effects—have remained unchanged, but their practical applications have undergone remarkable transformations over the decades.

In the mid-20th century, thermoelectric modules were primarily used in niche applications such as space exploration, where reliability outweighed efficiency concerns. The 1950s and 1960s marked the beginning of semiconductor-based thermoelectric materials, particularly bismuth telluride (Bi2Te3), which remains a commercial standard today. This period established the foundation for modern thermoelectric module design.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructured materials and quantum well concepts. These innovations aimed to address the inherent efficiency limitations of thermoelectric systems, characterized by the dimensionless figure of merit ZT. Historically, commercial thermoelectric materials struggled to exceed ZT values of 1, limiting their practical applications.

Recent technological advancements have focused on optimizing thermal gradient management within thermoelectric modules. This approach recognizes that effective temperature differential maintenance across the module is crucial for maximizing power generation or cooling efficiency. Innovations in heat exchanger design, thermal interface materials, and module architecture have contributed significantly to performance improvements without necessarily requiring breakthroughs in material properties.

The current technological objectives center on several key areas. First, increasing the ZT value of thermoelectric materials beyond 2.0 at commercially viable costs remains a primary goal. Second, developing more effective thermal management systems to maintain optimal temperature gradients across modules under varying operating conditions. Third, improving manufacturing techniques to reduce contact resistance between elements, which significantly impacts overall system efficiency.

Looking forward, the field aims to achieve conversion efficiencies exceeding 15% for power generation applications and coefficient of performance values above 2 for cooling applications. These targets would position thermoelectric technology as a competitive solution for waste heat recovery in industrial processes, automotive applications, and potentially residential cogeneration systems.

The evolution trajectory suggests that hybrid approaches—combining advanced materials with sophisticated thermal gradient management techniques—will likely yield the most significant performance improvements in the near term, while novel materials research continues to pursue longer-term efficiency breakthroughs.

In the mid-20th century, thermoelectric modules were primarily used in niche applications such as space exploration, where reliability outweighed efficiency concerns. The 1950s and 1960s marked the beginning of semiconductor-based thermoelectric materials, particularly bismuth telluride (Bi2Te3), which remains a commercial standard today. This period established the foundation for modern thermoelectric module design.

The 1990s witnessed a renaissance in thermoelectric research with the introduction of nanostructured materials and quantum well concepts. These innovations aimed to address the inherent efficiency limitations of thermoelectric systems, characterized by the dimensionless figure of merit ZT. Historically, commercial thermoelectric materials struggled to exceed ZT values of 1, limiting their practical applications.

Recent technological advancements have focused on optimizing thermal gradient management within thermoelectric modules. This approach recognizes that effective temperature differential maintenance across the module is crucial for maximizing power generation or cooling efficiency. Innovations in heat exchanger design, thermal interface materials, and module architecture have contributed significantly to performance improvements without necessarily requiring breakthroughs in material properties.

The current technological objectives center on several key areas. First, increasing the ZT value of thermoelectric materials beyond 2.0 at commercially viable costs remains a primary goal. Second, developing more effective thermal management systems to maintain optimal temperature gradients across modules under varying operating conditions. Third, improving manufacturing techniques to reduce contact resistance between elements, which significantly impacts overall system efficiency.

Looking forward, the field aims to achieve conversion efficiencies exceeding 15% for power generation applications and coefficient of performance values above 2 for cooling applications. These targets would position thermoelectric technology as a competitive solution for waste heat recovery in industrial processes, automotive applications, and potentially residential cogeneration systems.

The evolution trajectory suggests that hybrid approaches—combining advanced materials with sophisticated thermal gradient management techniques—will likely yield the most significant performance improvements in the near term, while novel materials research continues to pursue longer-term efficiency breakthroughs.

Market Applications and Demand Analysis for Thermoelectric Solutions

The thermoelectric solutions market has experienced significant growth in recent years, driven by increasing demand for energy-efficient technologies and sustainable energy solutions. The global thermoelectric market was valued at approximately 593 million USD in 2020 and is projected to reach 1,054 million USD by 2027, growing at a CAGR of 8.5% during the forecast period. This growth is primarily fueled by the rising need for waste heat recovery systems across various industries.

The automotive sector represents one of the largest application areas for thermoelectric modules, particularly for improving fuel efficiency through waste heat recovery and providing comfort features like climate-controlled seating. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) to convert exhaust heat into usable electricity, thereby reducing fuel consumption and emissions.

Consumer electronics constitutes another significant market segment, where thermoelectric cooling solutions are employed in portable refrigerators, temperature-controlled containers, and electronic device cooling. The miniaturization trend in electronics has created a growing demand for efficient thermal management solutions that can operate in confined spaces without moving parts.

Medical and healthcare applications represent a rapidly expanding market for thermoelectric modules, particularly in DNA sequencing equipment, PCR devices, blood analyzers, and pharmaceutical storage. The precise temperature control capabilities of thermoelectric solutions make them ideal for these sensitive applications where temperature stability is critical.

Industrial applications, including process cooling, laser diode temperature stabilization, and laboratory equipment, form another substantial market segment. Industries are increasingly adopting thermoelectric solutions for spot cooling of electronic components and maintaining optimal operating temperatures for sensitive equipment.

The aerospace and defense sectors utilize thermoelectric modules for thermal management in satellite systems, night vision equipment, and infrared detectors. These applications require highly reliable cooling solutions capable of operating in extreme environments.

Geographically, North America and Europe currently dominate the thermoelectric market due to stringent environmental regulations and advanced technological infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, increasing automotive production, and growing electronics manufacturing activities in countries like China, Japan, and South Korea.

The market demand is increasingly shifting toward higher efficiency modules with improved thermal gradient management capabilities. End-users are seeking solutions that can maintain optimal temperature differentials while minimizing energy consumption, highlighting the critical importance of advanced thermal gradient management technologies in modern thermoelectric applications.

The automotive sector represents one of the largest application areas for thermoelectric modules, particularly for improving fuel efficiency through waste heat recovery and providing comfort features like climate-controlled seating. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) to convert exhaust heat into usable electricity, thereby reducing fuel consumption and emissions.

Consumer electronics constitutes another significant market segment, where thermoelectric cooling solutions are employed in portable refrigerators, temperature-controlled containers, and electronic device cooling. The miniaturization trend in electronics has created a growing demand for efficient thermal management solutions that can operate in confined spaces without moving parts.

Medical and healthcare applications represent a rapidly expanding market for thermoelectric modules, particularly in DNA sequencing equipment, PCR devices, blood analyzers, and pharmaceutical storage. The precise temperature control capabilities of thermoelectric solutions make them ideal for these sensitive applications where temperature stability is critical.

Industrial applications, including process cooling, laser diode temperature stabilization, and laboratory equipment, form another substantial market segment. Industries are increasingly adopting thermoelectric solutions for spot cooling of electronic components and maintaining optimal operating temperatures for sensitive equipment.

The aerospace and defense sectors utilize thermoelectric modules for thermal management in satellite systems, night vision equipment, and infrared detectors. These applications require highly reliable cooling solutions capable of operating in extreme environments.

Geographically, North America and Europe currently dominate the thermoelectric market due to stringent environmental regulations and advanced technological infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, increasing automotive production, and growing electronics manufacturing activities in countries like China, Japan, and South Korea.

The market demand is increasingly shifting toward higher efficiency modules with improved thermal gradient management capabilities. End-users are seeking solutions that can maintain optimal temperature differentials while minimizing energy consumption, highlighting the critical importance of advanced thermal gradient management technologies in modern thermoelectric applications.

Current Thermal Gradient Management Challenges and Limitations

Thermoelectric modules (TEMs) face significant challenges in thermal gradient management that limit their widespread adoption and efficiency. The primary limitation stems from the inherent thermal conductivity of materials used in these modules, which creates a counterproductive heat flow that reduces the temperature differential necessary for optimal power generation. This parasitic heat transfer substantially diminishes the Seebeck effect efficiency, particularly in applications requiring high power density.

Material interface issues present another critical challenge. Contact resistance at junctions between different materials in the thermoelectric assembly creates thermal bottlenecks that impede heat flow and reduce overall system performance. These interface problems are exacerbated by thermal expansion mismatches during temperature cycling, leading to mechanical stress, delamination, and eventual performance degradation over time.

Current heat dissipation technologies employed with TEMs often prove inadequate for maintaining optimal thermal gradients. Conventional heat sinks and cooling systems struggle to efficiently remove heat from the cold side while maintaining the hot side at elevated temperatures. This limitation becomes particularly pronounced in compact applications where space constraints prevent the implementation of large-scale thermal management solutions.

The dynamic nature of operating environments poses additional challenges. TEMs must maintain stable thermal gradients despite fluctuating ambient conditions, varying heat source temperatures, and changing load demands. Current control systems lack the sophistication to rapidly adjust to these changing conditions, resulting in suboptimal performance across diverse operating scenarios.

Manufacturing inconsistencies further complicate thermal gradient management. Variations in material properties, dimensional tolerances, and assembly quality lead to unpredictable thermal behavior across supposedly identical modules. These inconsistencies make it difficult to develop standardized thermal management approaches that work reliably across production batches.

Energy density limitations represent another significant barrier. Current TEM designs struggle to maintain substantial thermal gradients in compact form factors, restricting their application in portable or space-constrained devices. The trade-off between module size and thermal gradient capability continues to challenge engineers seeking to implement thermoelectric solutions in miniaturized systems.

Finally, cost considerations severely limit the implementation of advanced thermal gradient management techniques. High-performance thermal interface materials, precision manufacturing processes, and sophisticated control systems significantly increase system costs, making TEMs economically unviable for many potential applications despite their technical benefits. This economic barrier has slowed research progress and commercial adoption of more effective thermal gradient management solutions.

Material interface issues present another critical challenge. Contact resistance at junctions between different materials in the thermoelectric assembly creates thermal bottlenecks that impede heat flow and reduce overall system performance. These interface problems are exacerbated by thermal expansion mismatches during temperature cycling, leading to mechanical stress, delamination, and eventual performance degradation over time.

Current heat dissipation technologies employed with TEMs often prove inadequate for maintaining optimal thermal gradients. Conventional heat sinks and cooling systems struggle to efficiently remove heat from the cold side while maintaining the hot side at elevated temperatures. This limitation becomes particularly pronounced in compact applications where space constraints prevent the implementation of large-scale thermal management solutions.

The dynamic nature of operating environments poses additional challenges. TEMs must maintain stable thermal gradients despite fluctuating ambient conditions, varying heat source temperatures, and changing load demands. Current control systems lack the sophistication to rapidly adjust to these changing conditions, resulting in suboptimal performance across diverse operating scenarios.

Manufacturing inconsistencies further complicate thermal gradient management. Variations in material properties, dimensional tolerances, and assembly quality lead to unpredictable thermal behavior across supposedly identical modules. These inconsistencies make it difficult to develop standardized thermal management approaches that work reliably across production batches.

Energy density limitations represent another significant barrier. Current TEM designs struggle to maintain substantial thermal gradients in compact form factors, restricting their application in portable or space-constrained devices. The trade-off between module size and thermal gradient capability continues to challenge engineers seeking to implement thermoelectric solutions in miniaturized systems.

Finally, cost considerations severely limit the implementation of advanced thermal gradient management techniques. High-performance thermal interface materials, precision manufacturing processes, and sophisticated control systems significantly increase system costs, making TEMs economically unviable for many potential applications despite their technical benefits. This economic barrier has slowed research progress and commercial adoption of more effective thermal gradient management solutions.

State-of-the-Art Thermal Gradient Management Solutions

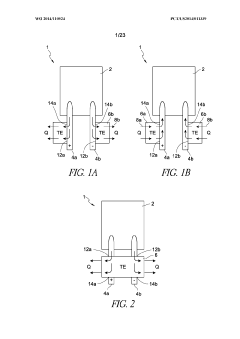

01 Thermoelectric module design for enhanced thermal gradient

Specific designs of thermoelectric modules can enhance the thermal gradient between hot and cold sides, improving energy conversion efficiency. These designs include optimized semiconductor material arrangements, specialized junction configurations, and structural modifications that maximize the temperature difference across the module. Enhanced thermal gradients lead to greater thermoelectric power generation through the Seebeck effect.- Thermoelectric module design for enhanced thermal gradient: Specific designs of thermoelectric modules can enhance the thermal gradient between hot and cold sides, improving energy conversion efficiency. These designs include optimized semiconductor material selection, specialized junction configurations, and geometric arrangements that maximize the temperature difference across the module. Enhanced thermal gradients lead to greater thermoelectric power generation through the Seebeck effect.

- Thermal management systems for thermoelectric modules: Thermal management systems are crucial for maintaining optimal thermal gradients in thermoelectric modules. These systems include heat sinks, heat exchangers, cooling fins, and thermal interface materials that efficiently transfer heat to and from the module surfaces. Proper thermal management prevents overheating, ensures consistent temperature differentials, and extends the operational lifespan of thermoelectric devices.

- Applications of thermal gradient in thermoelectric cooling: Thermoelectric modules utilize thermal gradients for cooling applications through the Peltier effect. When electric current flows through the module, heat is transferred from one side to the other, creating a temperature differential that can be used for refrigeration, climate control, and electronic component cooling. These solid-state cooling solutions offer advantages such as compact size, no moving parts, and precise temperature control.

- Materials innovation for improved thermal gradient performance: Advanced materials play a critical role in enhancing thermal gradient capabilities of thermoelectric modules. Novel semiconductor compounds, nanostructured materials, and composite thermoelectric elements can significantly improve the temperature differential and conversion efficiency. Research focuses on materials with high Seebeck coefficients, low thermal conductivity, and high electrical conductivity to maximize the figure of merit (ZT) for better performance.

- Energy harvesting from thermal gradients: Thermoelectric modules can harvest energy from natural or industrial thermal gradients, converting waste heat into useful electricity. These systems capture temperature differences between heat sources (such as industrial processes, combustion engines, or geothermal sources) and heat sinks (ambient air or water). The harvested energy can power sensors, IoT devices, or supplement power grids, contributing to energy efficiency and sustainability goals.

02 Cooling and heat dissipation systems for thermoelectric modules

Effective cooling and heat dissipation systems are crucial for maintaining optimal thermal gradients in thermoelectric modules. These systems include heat sinks, cooling fins, liquid cooling mechanisms, and advanced thermal interface materials that efficiently transfer heat away from the cold side of the module. Proper heat management prevents thermal equilibrium and maintains the temperature differential necessary for effective thermoelectric operation.Expand Specific Solutions03 Material innovations for improved thermoelectric performance

Advanced materials can significantly improve the performance of thermoelectric modules by enhancing thermal gradient maintenance. These innovations include nanostructured materials, semiconductor alloys with low thermal conductivity but high electrical conductivity, and composite materials that optimize the ZT value (figure of merit). Material selection and engineering directly impact the module's ability to maintain thermal gradients under various operating conditions.Expand Specific Solutions04 Thermal gradient enhancement techniques for power generation

Various techniques can be employed to enhance thermal gradients specifically for power generation applications. These include concentrated heat source utilization, multi-stage cascaded modules, thermal concentration techniques, and strategic placement of modules in environments with natural temperature differentials. Enhanced thermal gradients directly correlate with increased power output in thermoelectric generators.Expand Specific Solutions05 Thermal management systems for maintaining gradient stability

Specialized thermal management systems help maintain stable thermal gradients in thermoelectric modules under varying operating conditions. These systems include active temperature control mechanisms, thermal isolation structures, dynamic load management, and feedback control systems that adjust to changing environmental conditions. Maintaining gradient stability is essential for consistent performance in applications ranging from cooling to power generation.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermal gradient management in thermoelectric modules market is currently in a growth phase, with increasing applications across automotive, electronics, and energy sectors. The global market size is estimated to reach $2-3 billion by 2025, driven by demand for waste heat recovery solutions and energy efficiency improvements. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include Gentherm, which specializes in automotive thermal management applications, and O-Flexx Technologies, focused on thermoelectric generators. Research institutions like Industrial Technology Research Institute and Korea Advanced Institute of Science & Technology are advancing fundamental technologies, while companies like Robert Bosch and LG Innotek are integrating thermoelectric solutions into broader product ecosystems, indicating growing commercial viability.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced Climate Control Seat (CCS) technology utilizing distributed thermoelectric modules with sophisticated thermal gradient management. Their proprietary system employs a network of micro-TEMs strategically positioned to create optimized thermal zones, coupled with advanced heat spreading materials to manage thermal gradients effectively. The company's thermal management solution incorporates phase-change materials at TEM interfaces to buffer temperature fluctuations and maintain stable thermal gradients across operating conditions. Gentherm's approach includes dynamic control algorithms that continuously adjust power distribution to individual TEMs based on real-time temperature sensing, effectively preventing hotspots and thermal runaway conditions. Their latest generation systems incorporate 3D thermal modeling to predict and compensate for thermal gradient variations under different load conditions.

Strengths: Industry-leading expertise in automotive thermal comfort applications with proven reliability in high-volume production. Comprehensive system integration capabilities combining TEMs with complementary thermal management components. Weaknesses: Solutions primarily optimized for comfort applications rather than high-power density industrial applications, potentially limiting thermal gradient management capabilities in extreme temperature environments.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a multi-layered approach to thermal gradient management in thermoelectric modules for automotive and industrial applications. Their technology utilizes precision-engineered heat spreaders with variable thermal conductivity regions to optimize heat flux across thermoelectric junctions. The company's thermal gradient control system incorporates micro-channel liquid cooling directly integrated with thermoelectric elements, allowing for precise temperature differential maintenance even under variable load conditions. Bosch's proprietary thermal interface materials feature nanoscale surface engineering to minimize contact resistance at critical thermal boundaries. Their system architecture employs distributed temperature sensing with closed-loop control algorithms that dynamically adjust thermal gradients to maximize conversion efficiency. Additionally, Bosch has developed specialized ceramic substrates with tailored thermal expansion properties to maintain mechanical integrity across steep thermal gradients.

Strengths: Exceptional manufacturing precision and quality control processes ensure consistent thermal performance across production units. Extensive experience in harsh environment applications provides robust solutions for challenging thermal conditions. Weaknesses: Higher system complexity and integration requirements may increase costs and limit applicability in simpler, cost-sensitive applications.

Key Patents and Research Breakthroughs in Thermal Interface Materials

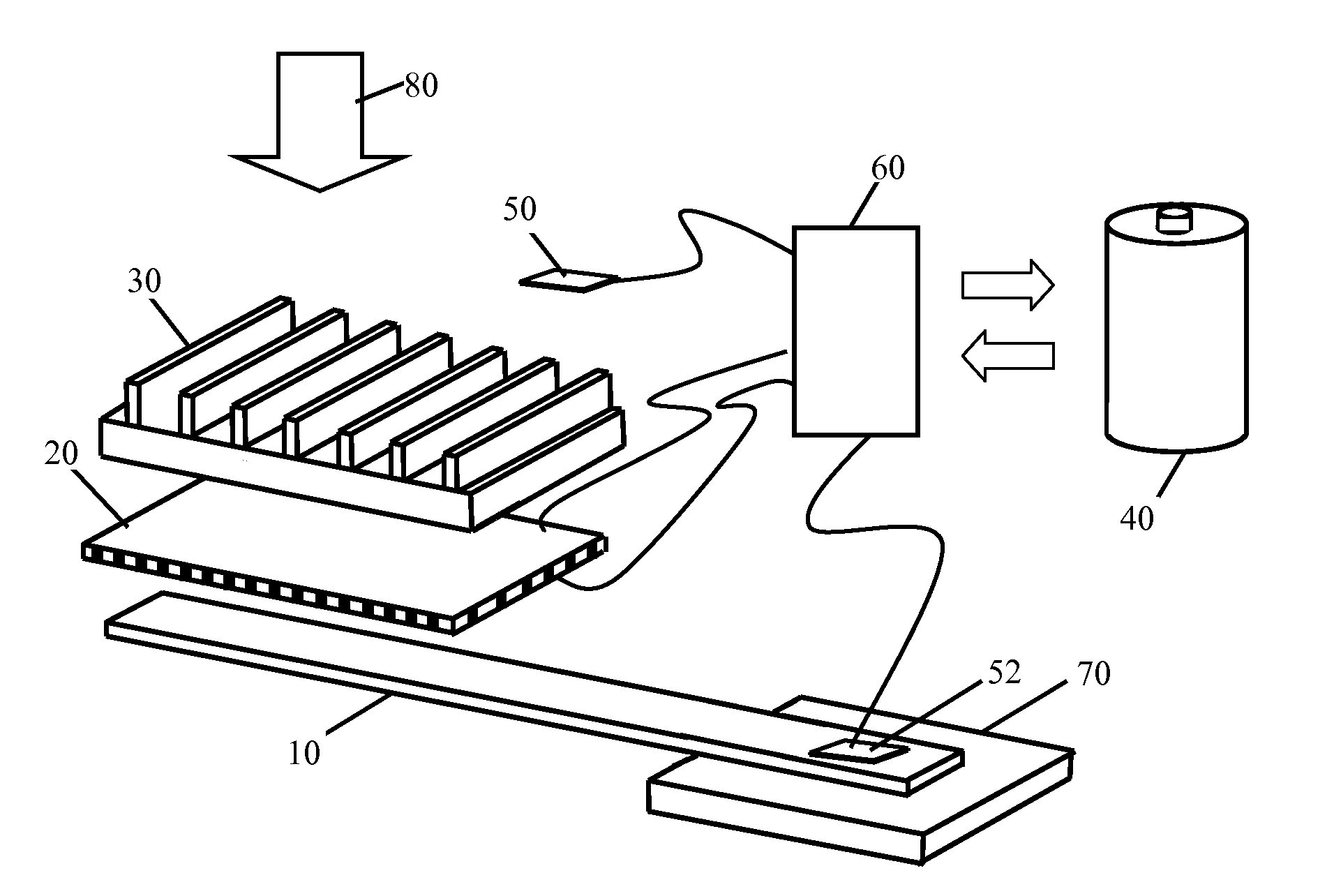

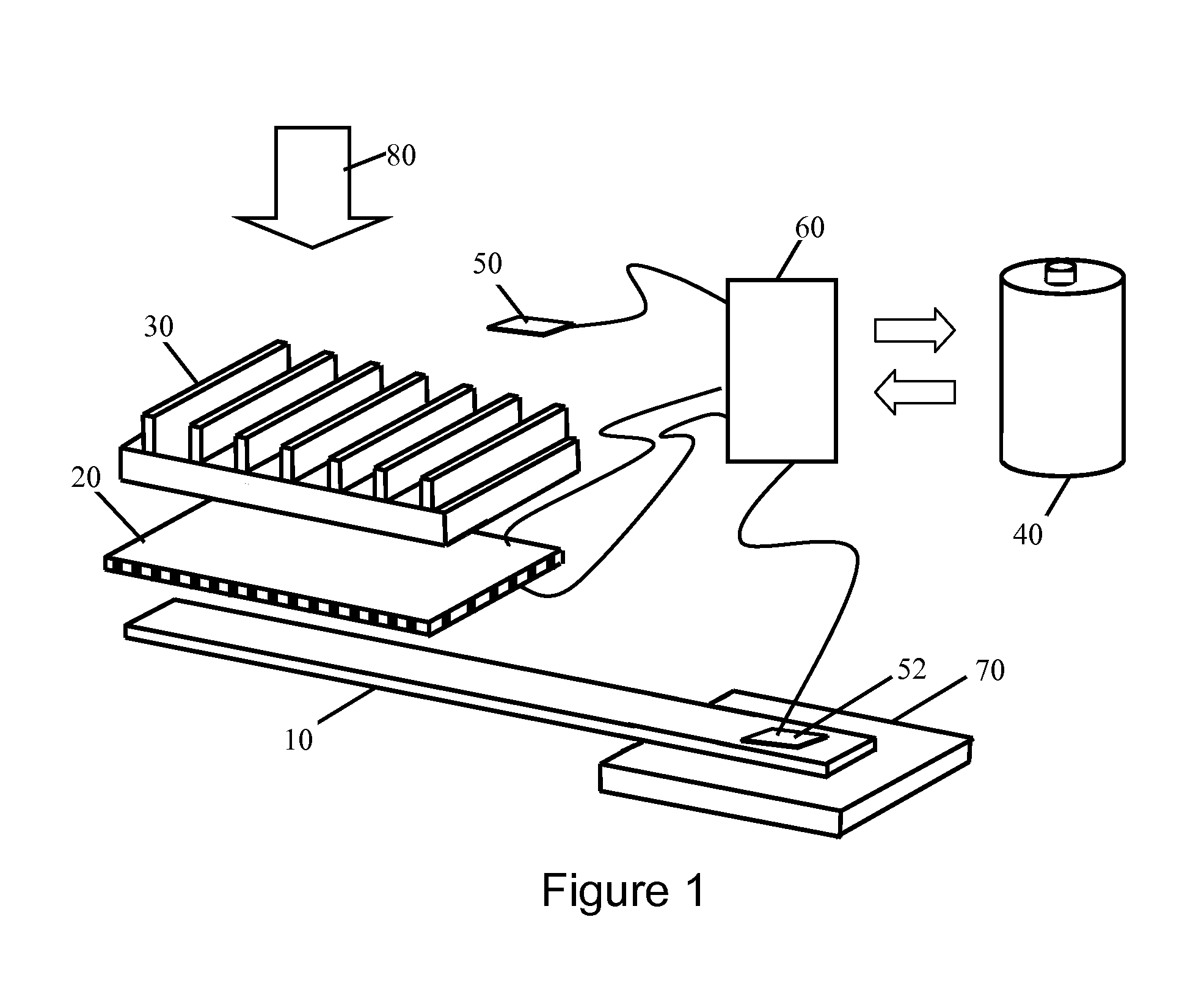

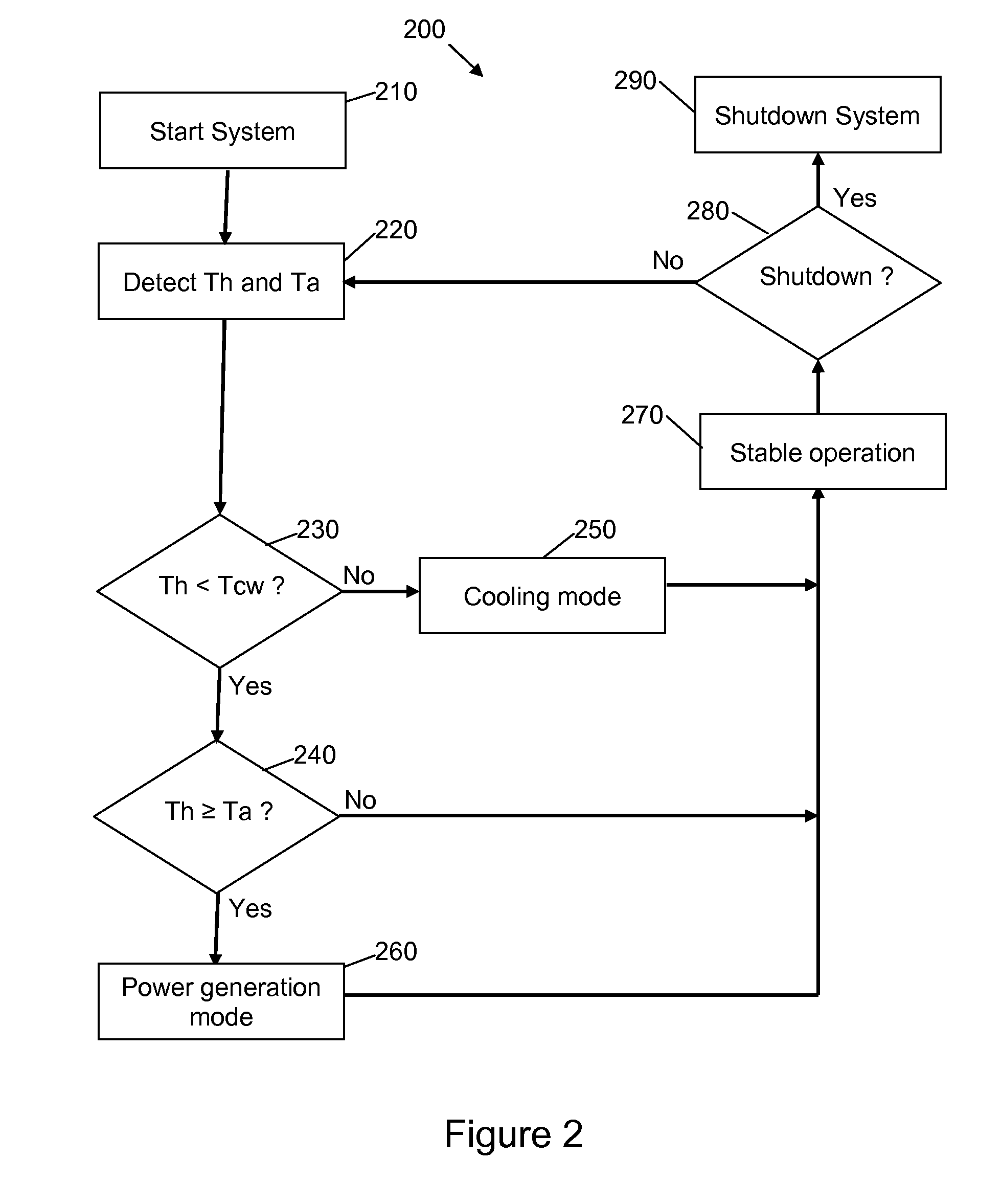

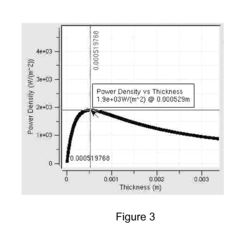

Dynamic switching thermoelectric thermal management systems and methods

PatentInactiveUS20120096871A1

Innovation

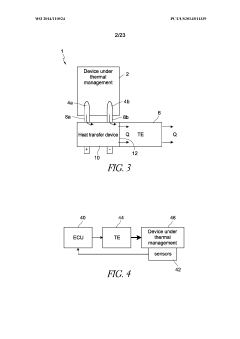

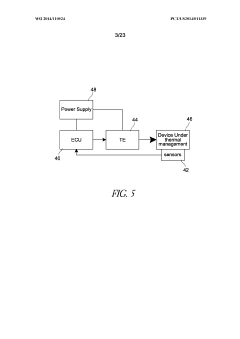

- A dynamic switching thermoelectric thermal management system that integrates a thermoelectric module, heat spreader, heat dissipation device, energy storage device, and programmable microchip, dynamically switching between power generation and cooling modes based on temperature differences to optimize energy recovery and temperature control.

Thermoelectric-based thermal management of electrical devices

PatentWO2014110524A1

Innovation

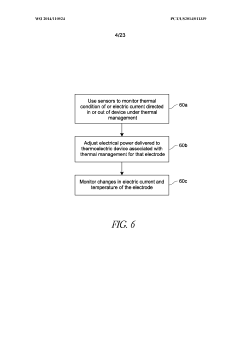

- Implementing a thermoelectric-based thermal management system that uses thermoelectric devices to directly or indirectly cool or heat current-carrying electrical conductors, such as electrodes, to maintain optimal temperature ranges by transferring thermal energy between a main surface and a waste surface, with a controller adjusting electric power to manage thermal gradients.

Energy Efficiency and Sustainability Considerations

The energy efficiency of thermoelectric modules represents a critical factor in their commercial viability and environmental impact. Current thermoelectric systems typically operate at 5-8% efficiency, significantly lower than competing technologies. This efficiency challenge directly correlates with thermal gradient management, as optimal temperature differentials are essential for maximizing the Seebeck effect while minimizing energy losses.

Sustainability considerations must be integrated throughout the thermoelectric module lifecycle. The manufacturing process involves several rare earth elements and specialized materials with significant environmental footprints. Tellurium, bismuth, and antimony—key components in many high-performance thermoelectric materials—face supply constraints and extraction-related environmental concerns. A comprehensive life cycle assessment reveals that the environmental benefits of waste heat recovery applications can offset manufacturing impacts within 1-3 years of operation, depending on application intensity.

Energy payback calculations demonstrate that thermoelectric modules with improved thermal gradient management can achieve energy return on investment 30-40% faster than conventional designs. This improvement stems from maintaining optimal temperature differentials across the module, reducing thermal cycling stress, and extending operational lifespans. Advanced thermal interface materials and precision manufacturing techniques contribute significantly to these efficiency gains.

From a circular economy perspective, thermoelectric modules present both challenges and opportunities. Their solid-state nature enables operational lifespans exceeding 15 years when thermal gradients are properly managed, but end-of-life recycling remains technically challenging due to the composite nature of module construction. Emerging recycling technologies utilizing selective chemical processes show promise for recovering up to 85% of critical materials.

The integration of thermoelectric systems into renewable energy frameworks offers substantial sustainability benefits. When coupled with solar thermal systems, properly managed thermoelectric modules can boost overall system efficiency by 12-18% by converting otherwise wasted thermal energy. Similarly, industrial waste heat recovery applications demonstrate potential carbon emission reductions of 0.8-1.2 tons CO₂ equivalent per kilowatt of installed capacity annually.

Future sustainability improvements will likely emerge from materials innovation, with research focusing on abundant, non-toxic alternatives to current thermoelectric compounds. Silicon-germanium alloys, magnesium silicide, and organic thermoelectric materials show particular promise for reducing environmental impact while maintaining performance when thermal gradients are optimally managed.

Sustainability considerations must be integrated throughout the thermoelectric module lifecycle. The manufacturing process involves several rare earth elements and specialized materials with significant environmental footprints. Tellurium, bismuth, and antimony—key components in many high-performance thermoelectric materials—face supply constraints and extraction-related environmental concerns. A comprehensive life cycle assessment reveals that the environmental benefits of waste heat recovery applications can offset manufacturing impacts within 1-3 years of operation, depending on application intensity.

Energy payback calculations demonstrate that thermoelectric modules with improved thermal gradient management can achieve energy return on investment 30-40% faster than conventional designs. This improvement stems from maintaining optimal temperature differentials across the module, reducing thermal cycling stress, and extending operational lifespans. Advanced thermal interface materials and precision manufacturing techniques contribute significantly to these efficiency gains.

From a circular economy perspective, thermoelectric modules present both challenges and opportunities. Their solid-state nature enables operational lifespans exceeding 15 years when thermal gradients are properly managed, but end-of-life recycling remains technically challenging due to the composite nature of module construction. Emerging recycling technologies utilizing selective chemical processes show promise for recovering up to 85% of critical materials.

The integration of thermoelectric systems into renewable energy frameworks offers substantial sustainability benefits. When coupled with solar thermal systems, properly managed thermoelectric modules can boost overall system efficiency by 12-18% by converting otherwise wasted thermal energy. Similarly, industrial waste heat recovery applications demonstrate potential carbon emission reductions of 0.8-1.2 tons CO₂ equivalent per kilowatt of installed capacity annually.

Future sustainability improvements will likely emerge from materials innovation, with research focusing on abundant, non-toxic alternatives to current thermoelectric compounds. Silicon-germanium alloys, magnesium silicide, and organic thermoelectric materials show particular promise for reducing environmental impact while maintaining performance when thermal gradients are optimally managed.

Material Science Advancements for Enhanced Thermoelectric Performance

Recent advancements in material science have significantly contributed to enhancing the performance of thermoelectric modules, particularly in thermal gradient management. The development of novel materials with improved thermoelectric properties has been a focal point of research over the past decade, with substantial progress in increasing the figure of merit (ZT) values.

Nanostructured materials have emerged as promising candidates for thermoelectric applications due to their ability to scatter phonons while maintaining electron transport. Silicon-germanium alloys, bismuth telluride compounds, and lead telluride-based materials have demonstrated remarkable improvements in thermal conductivity reduction without compromising electrical conductivity, thereby enhancing the overall efficiency of thermoelectric modules.

The incorporation of quantum dots, nanowires, and superlattice structures has revolutionized thermoelectric material design. These nanostructures create energy filtering effects and quantum confinement phenomena that optimize the power factor while simultaneously reducing thermal conductivity. Research has shown that carefully engineered nanocomposites can achieve ZT values exceeding 2.0 at operating temperatures, a significant improvement over conventional bulk materials.

Skutterudites and half-Heusler compounds represent another class of advanced thermoelectric materials with intrinsic "rattling" structures that effectively scatter phonons. The introduction of heavy atoms into these structures creates localized vibrational modes that disrupt heat flow without affecting charge carrier transport, resulting in enhanced thermoelectric performance across wider temperature gradients.

Polymer-based thermoelectric materials have also gained attention for their flexibility, low cost, and eco-friendliness. Although their ZT values remain lower than inorganic counterparts, recent developments in conductive polymers and organic-inorganic hybrids show promising results for low-temperature applications and wearable thermoelectric generators.

Interface engineering between different materials has proven crucial for optimizing thermal gradient management. Researchers have developed sophisticated techniques to create controlled interfaces that selectively scatter phonons while allowing electrons to pass through, effectively decoupling thermal and electrical transport properties. These engineered interfaces have led to significant improvements in maintaining stable temperature differentials across thermoelectric modules.

The emergence of topological insulators as potential thermoelectric materials represents one of the most exciting frontiers in the field. These materials exhibit unique surface states that can potentially lead to unprecedented thermoelectric performance by exploiting the topologically protected surface states for electrical conduction while maintaining low thermal conductivity in the bulk.

Nanostructured materials have emerged as promising candidates for thermoelectric applications due to their ability to scatter phonons while maintaining electron transport. Silicon-germanium alloys, bismuth telluride compounds, and lead telluride-based materials have demonstrated remarkable improvements in thermal conductivity reduction without compromising electrical conductivity, thereby enhancing the overall efficiency of thermoelectric modules.

The incorporation of quantum dots, nanowires, and superlattice structures has revolutionized thermoelectric material design. These nanostructures create energy filtering effects and quantum confinement phenomena that optimize the power factor while simultaneously reducing thermal conductivity. Research has shown that carefully engineered nanocomposites can achieve ZT values exceeding 2.0 at operating temperatures, a significant improvement over conventional bulk materials.

Skutterudites and half-Heusler compounds represent another class of advanced thermoelectric materials with intrinsic "rattling" structures that effectively scatter phonons. The introduction of heavy atoms into these structures creates localized vibrational modes that disrupt heat flow without affecting charge carrier transport, resulting in enhanced thermoelectric performance across wider temperature gradients.

Polymer-based thermoelectric materials have also gained attention for their flexibility, low cost, and eco-friendliness. Although their ZT values remain lower than inorganic counterparts, recent developments in conductive polymers and organic-inorganic hybrids show promising results for low-temperature applications and wearable thermoelectric generators.

Interface engineering between different materials has proven crucial for optimizing thermal gradient management. Researchers have developed sophisticated techniques to create controlled interfaces that selectively scatter phonons while allowing electrons to pass through, effectively decoupling thermal and electrical transport properties. These engineered interfaces have led to significant improvements in maintaining stable temperature differentials across thermoelectric modules.

The emergence of topological insulators as potential thermoelectric materials represents one of the most exciting frontiers in the field. These materials exhibit unique surface states that can potentially lead to unprecedented thermoelectric performance by exploiting the topologically protected surface states for electrical conduction while maintaining low thermal conductivity in the bulk.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!