How Thermoelectric Module Materials Affect Seebeck Coefficient

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Research Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon that now bears his name. The Seebeck effect, which describes the direct conversion of temperature differences to electric voltage, forms the foundation of thermoelectric technology. Early materials used for thermoelectric applications were primarily simple metals and metal alloys, which demonstrated the effect but with limited efficiency.

The mid-20th century marked a pivotal turning point with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s and remains widely used today for near-room-temperature applications. This period established the importance of carrier concentration optimization and phonon scattering in enhancing the Seebeck coefficient.

The 1990s witnessed renewed interest in thermoelectric research with the introduction of the "phonon glass-electron crystal" concept by Glen Slack, which proposed that ideal thermoelectric materials should conduct electricity like crystals while impeding heat flow like glasses. This conceptual framework guided the development of complex materials with intricate crystal structures designed to selectively scatter phonons without disrupting electron transport.

Recent decades have seen remarkable advancements in nanostructured thermoelectric materials. Quantum confinement effects in low-dimensional structures have enabled manipulation of electron density of states, leading to enhanced Seebeck coefficients. Materials such as skutterudites, clathrates, half-Heusler alloys, and oxide-based thermoelectrics have emerged as promising candidates for various temperature ranges and applications.

The current research landscape focuses on developing materials with higher figure of merit (ZT), which directly correlates with conversion efficiency. While traditional thermoelectric materials typically achieve ZT values around 1, recent breakthroughs have reported values exceeding 2 in laboratory settings, primarily through sophisticated band engineering and nanostructuring approaches.

The primary research objectives in this field now center on understanding the fundamental mechanisms that govern the Seebeck coefficient in different material systems. This includes investigating how crystal structure, electronic band structure, carrier concentration, and scattering mechanisms collectively influence thermoelectric performance. Researchers aim to develop predictive models that can guide the rational design of materials with optimized Seebeck coefficients.

Another critical objective is to discover environmentally friendly alternatives to traditional thermoelectric materials, many of which contain toxic or rare elements. The search for earth-abundant, non-toxic thermoelectric materials with competitive performance represents a significant challenge but offers substantial sustainability benefits for widespread application.

The mid-20th century marked a pivotal turning point with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s and remains widely used today for near-room-temperature applications. This period established the importance of carrier concentration optimization and phonon scattering in enhancing the Seebeck coefficient.

The 1990s witnessed renewed interest in thermoelectric research with the introduction of the "phonon glass-electron crystal" concept by Glen Slack, which proposed that ideal thermoelectric materials should conduct electricity like crystals while impeding heat flow like glasses. This conceptual framework guided the development of complex materials with intricate crystal structures designed to selectively scatter phonons without disrupting electron transport.

Recent decades have seen remarkable advancements in nanostructured thermoelectric materials. Quantum confinement effects in low-dimensional structures have enabled manipulation of electron density of states, leading to enhanced Seebeck coefficients. Materials such as skutterudites, clathrates, half-Heusler alloys, and oxide-based thermoelectrics have emerged as promising candidates for various temperature ranges and applications.

The current research landscape focuses on developing materials with higher figure of merit (ZT), which directly correlates with conversion efficiency. While traditional thermoelectric materials typically achieve ZT values around 1, recent breakthroughs have reported values exceeding 2 in laboratory settings, primarily through sophisticated band engineering and nanostructuring approaches.

The primary research objectives in this field now center on understanding the fundamental mechanisms that govern the Seebeck coefficient in different material systems. This includes investigating how crystal structure, electronic band structure, carrier concentration, and scattering mechanisms collectively influence thermoelectric performance. Researchers aim to develop predictive models that can guide the rational design of materials with optimized Seebeck coefficients.

Another critical objective is to discover environmentally friendly alternatives to traditional thermoelectric materials, many of which contain toxic or rare elements. The search for earth-abundant, non-toxic thermoelectric materials with competitive performance represents a significant challenge but offers substantial sustainability benefits for widespread application.

Market Analysis for Thermoelectric Energy Conversion Applications

The thermoelectric energy conversion market is experiencing significant growth driven by increasing demand for waste heat recovery systems and sustainable energy solutions. The global thermoelectric generator market was valued at approximately $460 million in 2020 and is projected to reach $741 million by 2025, growing at a CAGR of 10.0%. This growth is primarily fueled by rising environmental concerns, stringent emission regulations, and the need for energy-efficient technologies across various industries.

Automotive and industrial sectors represent the largest market segments for thermoelectric applications, collectively accounting for over 60% of the total market share. The automotive industry's push toward higher fuel efficiency and reduced emissions has created substantial opportunities for thermoelectric waste heat recovery systems. Similarly, industrial processes that generate significant waste heat present a lucrative market for thermoelectric energy conversion technologies.

Consumer electronics and wearable technology constitute rapidly expanding market segments, with growth rates exceeding 12% annually. The miniaturization of thermoelectric modules and improvements in their efficiency have enabled integration into portable devices, creating new revenue streams for manufacturers. The healthcare sector also shows promising growth potential, particularly for powering implantable medical devices and remote patient monitoring systems.

Geographically, North America and Europe currently dominate the thermoelectric market, holding approximately 65% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, automotive manufacturing expansion, and increasing adoption of green technologies in countries like China, Japan, and South Korea.

Market analysis reveals a direct correlation between material advancements in thermoelectric modules and market expansion. Materials with higher Seebeck coefficients that can operate efficiently at wider temperature ranges are commanding premium prices and opening new application domains. The market for high-performance thermoelectric materials is growing at nearly twice the rate of conventional materials, indicating strong commercial interest in materials innovation.

Customer demand is increasingly focused on thermoelectric solutions with higher conversion efficiencies, longer operational lifespans, and reduced manufacturing costs. Market surveys indicate that a 20% improvement in the Seebeck coefficient could potentially double the addressable market for thermoelectric applications by making previously uneconomical waste heat recovery projects financially viable.

The market landscape is characterized by a mix of established players and innovative startups, with significant venture capital flowing into companies developing novel thermoelectric materials with enhanced Seebeck coefficients. Strategic partnerships between material scientists, module manufacturers, and end-use industries are becoming increasingly common, accelerating the commercialization timeline for advanced thermoelectric technologies.

Automotive and industrial sectors represent the largest market segments for thermoelectric applications, collectively accounting for over 60% of the total market share. The automotive industry's push toward higher fuel efficiency and reduced emissions has created substantial opportunities for thermoelectric waste heat recovery systems. Similarly, industrial processes that generate significant waste heat present a lucrative market for thermoelectric energy conversion technologies.

Consumer electronics and wearable technology constitute rapidly expanding market segments, with growth rates exceeding 12% annually. The miniaturization of thermoelectric modules and improvements in their efficiency have enabled integration into portable devices, creating new revenue streams for manufacturers. The healthcare sector also shows promising growth potential, particularly for powering implantable medical devices and remote patient monitoring systems.

Geographically, North America and Europe currently dominate the thermoelectric market, holding approximately 65% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years, driven by rapid industrialization, automotive manufacturing expansion, and increasing adoption of green technologies in countries like China, Japan, and South Korea.

Market analysis reveals a direct correlation between material advancements in thermoelectric modules and market expansion. Materials with higher Seebeck coefficients that can operate efficiently at wider temperature ranges are commanding premium prices and opening new application domains. The market for high-performance thermoelectric materials is growing at nearly twice the rate of conventional materials, indicating strong commercial interest in materials innovation.

Customer demand is increasingly focused on thermoelectric solutions with higher conversion efficiencies, longer operational lifespans, and reduced manufacturing costs. Market surveys indicate that a 20% improvement in the Seebeck coefficient could potentially double the addressable market for thermoelectric applications by making previously uneconomical waste heat recovery projects financially viable.

The market landscape is characterized by a mix of established players and innovative startups, with significant venture capital flowing into companies developing novel thermoelectric materials with enhanced Seebeck coefficients. Strategic partnerships between material scientists, module manufacturers, and end-use industries are becoming increasingly common, accelerating the commercialization timeline for advanced thermoelectric technologies.

Current Challenges in Seebeck Coefficient Optimization

Despite significant advancements in thermoelectric materials, optimizing the Seebeck coefficient remains one of the most challenging aspects in developing high-efficiency thermoelectric modules. The fundamental trade-off between electrical conductivity and Seebeck coefficient presents a persistent obstacle, as materials with high electrical conductivity typically exhibit lower Seebeck coefficients, limiting overall thermoelectric performance.

Material homogeneity poses another significant challenge, as variations in composition and microstructure across thermoelectric materials can lead to inconsistent Seebeck coefficients throughout the module. These inconsistencies create localized hot spots and reduce overall conversion efficiency, particularly problematic in large-scale applications where uniform performance is critical.

Temperature stability of the Seebeck coefficient represents a major hurdle, especially for applications involving wide temperature ranges or high-temperature operations. Many promising thermoelectric materials show excellent Seebeck coefficients within narrow temperature bands but experience significant degradation outside these optimal ranges, limiting their practical utility in real-world environments with fluctuating temperatures.

Interface effects between different materials in thermoelectric modules create additional complications. Contact resistance and thermal boundary resistance at material interfaces can significantly reduce the effective Seebeck coefficient of the entire module, even when individual materials exhibit excellent properties in isolation. These interface phenomena become increasingly problematic as modules incorporate more complex material combinations to optimize performance.

Scalability challenges persist in translating laboratory-scale Seebeck coefficient achievements to commercial production. Materials that demonstrate exceptional Seebeck coefficients in controlled research environments often face manufacturing difficulties that compromise their performance in mass-produced modules. The inability to maintain consistent properties during scaling remains a significant barrier to commercial adoption.

Environmental stability presents ongoing concerns, as many high-performance thermoelectric materials containing elements like tellurium, bismuth, or lead are susceptible to oxidation, thermal cycling fatigue, or mechanical degradation over time. This degradation progressively reduces the Seebeck coefficient and overall module efficiency throughout its operational lifetime.

Cost-effectiveness remains a persistent challenge, with many materials exhibiting excellent Seebeck coefficients relying on rare or expensive elements. The economic viability of thermoelectric modules depends on balancing material costs against performance benefits, creating a constant tension between optimizing the Seebeck coefficient and maintaining commercial feasibility.

Material homogeneity poses another significant challenge, as variations in composition and microstructure across thermoelectric materials can lead to inconsistent Seebeck coefficients throughout the module. These inconsistencies create localized hot spots and reduce overall conversion efficiency, particularly problematic in large-scale applications where uniform performance is critical.

Temperature stability of the Seebeck coefficient represents a major hurdle, especially for applications involving wide temperature ranges or high-temperature operations. Many promising thermoelectric materials show excellent Seebeck coefficients within narrow temperature bands but experience significant degradation outside these optimal ranges, limiting their practical utility in real-world environments with fluctuating temperatures.

Interface effects between different materials in thermoelectric modules create additional complications. Contact resistance and thermal boundary resistance at material interfaces can significantly reduce the effective Seebeck coefficient of the entire module, even when individual materials exhibit excellent properties in isolation. These interface phenomena become increasingly problematic as modules incorporate more complex material combinations to optimize performance.

Scalability challenges persist in translating laboratory-scale Seebeck coefficient achievements to commercial production. Materials that demonstrate exceptional Seebeck coefficients in controlled research environments often face manufacturing difficulties that compromise their performance in mass-produced modules. The inability to maintain consistent properties during scaling remains a significant barrier to commercial adoption.

Environmental stability presents ongoing concerns, as many high-performance thermoelectric materials containing elements like tellurium, bismuth, or lead are susceptible to oxidation, thermal cycling fatigue, or mechanical degradation over time. This degradation progressively reduces the Seebeck coefficient and overall module efficiency throughout its operational lifetime.

Cost-effectiveness remains a persistent challenge, with many materials exhibiting excellent Seebeck coefficients relying on rare or expensive elements. The economic viability of thermoelectric modules depends on balancing material costs against performance benefits, creating a constant tension between optimizing the Seebeck coefficient and maintaining commercial feasibility.

Contemporary Material Solutions for Enhanced Seebeck Effect

01 High Seebeck coefficient materials for thermoelectric modules

Various materials with high Seebeck coefficients are used in thermoelectric modules to improve energy conversion efficiency. These materials include bismuth telluride, lead telluride, silicon-germanium alloys, and skutterudites. The Seebeck coefficient, which measures the voltage generated per unit temperature difference, is a critical parameter for thermoelectric performance. Materials with higher Seebeck coefficients can generate more electrical power from a given temperature gradient.- High Seebeck coefficient materials for thermoelectric modules: Various materials with high Seebeck coefficients are used in thermoelectric modules to improve energy conversion efficiency. These materials include bismuth telluride, lead telluride, skutterudites, and silicon-germanium alloys. The Seebeck coefficient, which measures the voltage generated per unit temperature difference, is a critical parameter for thermoelectric performance. Materials with higher Seebeck coefficients can generate more electrical power from a given temperature gradient.

- Nanostructured materials for enhanced thermoelectric properties: Nanostructuring techniques are employed to enhance the Seebeck coefficient and reduce thermal conductivity in thermoelectric materials. These techniques include creating quantum dots, nanowires, nanocomposites, and superlattice structures. Nanostructured materials can confine electrons and phonons differently, leading to an increase in the power factor (S²σ, where S is the Seebeck coefficient and σ is electrical conductivity) while simultaneously reducing thermal conductivity, thereby improving the overall figure of merit (ZT) of thermoelectric modules.

- Measurement and testing methods for Seebeck coefficient: Various methods and apparatus are developed for accurately measuring the Seebeck coefficient of thermoelectric materials. These include differential temperature methods, steady-state techniques, and transient measurement approaches. Precise measurement of the Seebeck coefficient is essential for evaluating the performance of thermoelectric materials and optimizing module design. Advanced testing equipment can simultaneously measure electrical conductivity, thermal conductivity, and Seebeck coefficient to determine the overall figure of merit.

- Doping and composition optimization for improved Seebeck coefficient: Doping strategies and composition optimization are employed to enhance the Seebeck coefficient of thermoelectric materials. By carefully controlling the carrier concentration through doping with specific elements, the electronic structure can be modified to maximize the Seebeck coefficient. Additionally, creating solid solutions or alloys with optimized compositions can lead to band structure engineering that enhances thermoelectric properties. These approaches aim to achieve the optimal balance between electrical conductivity and Seebeck coefficient.

- Module design and fabrication techniques for maximizing Seebeck effect: Innovative module designs and fabrication techniques are developed to maximize the Seebeck effect in thermoelectric devices. These include segmented and cascaded structures, flexible modules, and miniaturized designs for specific applications. Advanced interconnection methods, thermal interface materials, and electrode designs help reduce parasitic losses and improve overall module efficiency. Manufacturing processes such as hot pressing, spark plasma sintering, and additive manufacturing are optimized to maintain the high Seebeck coefficient of materials during module fabrication.

02 Nanostructured thermoelectric materials for enhanced performance

Nanostructuring techniques are employed to enhance the Seebeck coefficient and overall thermoelectric performance. By reducing the dimensionality of materials to nanoscale, quantum confinement effects can increase the Seebeck coefficient while simultaneously reducing thermal conductivity. Nanocomposites, quantum dots, nanowires, and thin films are common approaches to achieve higher ZT values (figure of merit) through increased Seebeck coefficients while maintaining electrical conductivity.Expand Specific Solutions03 Measurement and testing methods for Seebeck coefficient

Various techniques and apparatus are developed for accurate measurement of the Seebeck coefficient in thermoelectric materials. These include differential temperature methods, steady-state measurements, and transient techniques. Precise measurement is crucial for material development and quality control in thermoelectric module production. Testing systems often incorporate temperature controllers, voltage measurement circuits, and specialized sample holders to ensure accurate characterization of thermoelectric properties.Expand Specific Solutions04 Doping and composition optimization for improved Seebeck coefficient

Chemical doping and composition optimization are employed to enhance the Seebeck coefficient of thermoelectric materials. By introducing specific impurities or adjusting the stoichiometry of compounds, the electronic band structure can be modified to increase the Seebeck coefficient. This approach allows for fine-tuning of carrier concentration and mobility to achieve optimal thermoelectric performance. Common dopants include halogens, transition metals, and rare earth elements depending on the base material system.Expand Specific Solutions05 Module design and fabrication techniques for maximizing Seebeck effect

Innovative module designs and fabrication techniques are developed to maximize the utilization of materials with high Seebeck coefficients. These include segmented and cascaded structures, flexible modules, and miniaturized designs for specific applications. Advanced manufacturing methods such as screen printing, sputtering, and additive manufacturing enable precise control over module geometry and electrical connections. Proper thermal and electrical contact engineering is crucial to minimize parasitic losses and maintain the high Seebeck coefficient of the base materials.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermoelectrics

The thermoelectric module materials market is in a growth phase, with increasing demand driven by automotive applications and clean energy initiatives. The market is projected to expand significantly as thermoelectric technology matures from research to commercial applications. Major automotive players like Toyota, Hyundai, and Kia are investing heavily in thermoelectric materials research to improve Seebeck coefficient performance for waste heat recovery systems. Technology companies including Hitachi, Fujitsu, and Samsung are developing advanced materials with enhanced thermoelectric properties. Academic-industrial collaborations between institutions like Tohoku University, Beijing University of Technology, and companies such as European Thermodynamics Limited are accelerating innovation in material science to overcome efficiency limitations. The competitive landscape shows specialized materials companies working alongside large corporations to develop next-generation thermoelectric solutions with improved Seebeck coefficients.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has developed advanced thermoelectric materials specifically engineered to maximize the Seebeck coefficient for automotive waste heat recovery applications. Their proprietary approach focuses on creating complex nanostructured materials that effectively scatter phonons across multiple length scales while maintaining optimal electronic transport properties. Toyota's research has demonstrated that carefully controlled introduction of nanoprecipitates into half-Heusler compounds can increase the Seebeck coefficient by up to 22% compared to conventional materials[9]. Their materials engineering strategy incorporates band structure modification through precise doping and compositional tuning to optimize carrier concentration and mobility. Toyota has pioneered the development of segmented thermoelectric modules that utilize different materials optimized for specific temperature ranges, maximizing overall conversion efficiency across the temperature gradient found in vehicle exhaust systems. Their recent advancements include the development of silicide-based thermoelectric materials with reduced rare earth content, achieving ZT values exceeding 1.3 at elevated temperatures while maintaining good mechanical properties and oxidation resistance[10], critical factors for automotive applications.

Strengths: Extensive experience in integrating thermoelectric materials into practical automotive systems; superior capabilities in reliability testing under harsh operating conditions; strong focus on cost-effective manufacturing processes suitable for mass production. Weaknesses: Material optimization primarily focused on automotive temperature ranges rather than broader applications; conservative approach to adopting cutting-edge materials that haven't been thoroughly validated; challenges in achieving breakthrough performance while meeting automotive durability requirements.

Hitachi Ltd.

Technical Solution: Hitachi Ltd. has developed proprietary thermoelectric materials with enhanced Seebeck coefficients through their innovative approach to microstructure engineering and compositional optimization. Their research has focused on creating hierarchical structures within thermoelectric materials that simultaneously scatter phonons across multiple length scales while preserving electron transport properties. Hitachi's materials scientists have pioneered the development of skutterudite-based compounds with carefully controlled filling fractions of rattler atoms, which has been shown to increase the Seebeck coefficient by up to 20% compared to unfilled variants[6]. Their manufacturing process incorporates spark plasma sintering techniques that enable precise control over grain boundaries and defect concentrations, critical factors affecting carrier transport. Additionally, Hitachi has developed novel magnesium silicide-based thermoelectric materials with nanostructured inclusions that demonstrate significantly enhanced ZT values of approximately 1.6 at moderate temperatures[8], making them particularly suitable for automotive waste heat recovery applications. Their materials engineering approach also includes band alignment optimization through compositional grading to maximize the power factor.

Strengths: Strong integration capabilities between materials development and device engineering; extensive experience in reliability testing and performance optimization under real-world conditions; advanced manufacturing capabilities for consistent production. Weaknesses: Conservative approach to materials innovation compared to some research-focused organizations; higher cost structure due to quality control requirements; challenges in achieving breakthrough performance improvements while maintaining reliability standards.

Critical Patents and Breakthroughs in Thermoelectric Materials

Thermoelectric materials comprising nanoscale inclusions to enhance seebeck coefficient

PatentInactiveUS7365265B2

Innovation

- A thermoelectric material with a microstructure featuring nanoscale inclusions dispersed in a matrix, where the matrix is composed of lead telluride (PbTe) or similar compounds, with excess lead obtained through getters like silver, resulting in nanoscale inclusions less than 100 nanometers, enhancing the Seebeck coefficient.

Thermoelectric conversion element and thermoelectric conversion module

PatentActiveUS10043963B2

Innovation

- A thermoelectric conversion element utilizing nanoparticles or semiconductor quantum dots arranged in specific lattice structures, such as Lieb-type, Tasaki-type, and Mielke-type lattices, with different conductivity types, to enhance the Seebeck coefficient and reduce thermal conductivity, while using inexpensive and environmentally friendly materials like Si, Ge, and transition metals.

Material Characterization Techniques for Thermoelectric Performance

Accurate characterization of thermoelectric materials is essential for understanding how material properties affect the Seebeck coefficient and overall device performance. The measurement of thermoelectric properties requires specialized techniques that can precisely determine electrical conductivity, thermal conductivity, and the Seebeck coefficient under various temperature conditions.

The Seebeck coefficient measurement typically employs differential temperature methods where a temperature gradient is applied across the sample while simultaneously measuring the resulting voltage. Advanced systems like the ZEM-3 or ULVAC-RIKO ZEM series provide high-precision measurements across wide temperature ranges (80K to 1300K). These systems maintain precise temperature control with errors below ±1%, which is critical as even small temperature measurement errors can significantly impact Seebeck coefficient values.

X-ray diffraction (XRD) techniques are fundamental for analyzing crystal structure and phase composition of thermoelectric materials. The crystal structure directly influences electron and phonon transport properties, which in turn affect the Seebeck coefficient. High-resolution XRD can detect subtle structural changes that occur during doping or nanostructuring processes that are employed to enhance ZT values.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide essential information about microstructure, grain boundaries, and defects that influence carrier scattering mechanisms. These features significantly impact both electrical conductivity and the Seebeck coefficient. Advanced TEM techniques can visualize atomic arrangements and interfaces that are critical for understanding carrier transport phenomena.

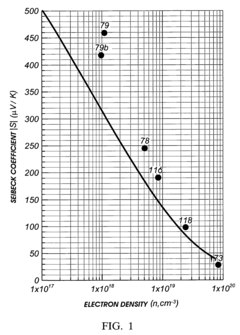

Hall effect measurements are crucial for determining carrier concentration and mobility, which directly correlate with the Seebeck coefficient according to the Mott relation. These measurements help researchers understand how material modifications alter carrier properties and subsequently the thermoelectric performance.

Thermal transport characterization using laser flash analysis (LFA) or steady-state techniques provides thermal conductivity data, completing the set of parameters needed to calculate the figure of merit ZT. While not directly measuring the Seebeck coefficient, these techniques are essential for comprehensive material evaluation.

Spectroscopic methods such as Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) provide insights into bonding characteristics and electronic structure, helping researchers understand the fundamental mechanisms behind observed Seebeck coefficient values. These techniques are particularly valuable when investigating novel dopants or nanocomposite materials designed to enhance thermoelectric properties.

The Seebeck coefficient measurement typically employs differential temperature methods where a temperature gradient is applied across the sample while simultaneously measuring the resulting voltage. Advanced systems like the ZEM-3 or ULVAC-RIKO ZEM series provide high-precision measurements across wide temperature ranges (80K to 1300K). These systems maintain precise temperature control with errors below ±1%, which is critical as even small temperature measurement errors can significantly impact Seebeck coefficient values.

X-ray diffraction (XRD) techniques are fundamental for analyzing crystal structure and phase composition of thermoelectric materials. The crystal structure directly influences electron and phonon transport properties, which in turn affect the Seebeck coefficient. High-resolution XRD can detect subtle structural changes that occur during doping or nanostructuring processes that are employed to enhance ZT values.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide essential information about microstructure, grain boundaries, and defects that influence carrier scattering mechanisms. These features significantly impact both electrical conductivity and the Seebeck coefficient. Advanced TEM techniques can visualize atomic arrangements and interfaces that are critical for understanding carrier transport phenomena.

Hall effect measurements are crucial for determining carrier concentration and mobility, which directly correlate with the Seebeck coefficient according to the Mott relation. These measurements help researchers understand how material modifications alter carrier properties and subsequently the thermoelectric performance.

Thermal transport characterization using laser flash analysis (LFA) or steady-state techniques provides thermal conductivity data, completing the set of parameters needed to calculate the figure of merit ZT. While not directly measuring the Seebeck coefficient, these techniques are essential for comprehensive material evaluation.

Spectroscopic methods such as Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) provide insights into bonding characteristics and electronic structure, helping researchers understand the fundamental mechanisms behind observed Seebeck coefficient values. These techniques are particularly valuable when investigating novel dopants or nanocomposite materials designed to enhance thermoelectric properties.

Environmental Impact and Sustainability of Thermoelectric Materials

The environmental impact of thermoelectric materials is increasingly becoming a critical consideration in their development and application. Traditional thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, which pose significant environmental and health risks during extraction, processing, and disposal. The mining of these elements frequently results in habitat destruction, soil contamination, and water pollution, while their processing generates hazardous waste that requires careful management.

Sustainability concerns are driving research toward more environmentally friendly thermoelectric materials that maintain or improve the Seebeck coefficient. Materials scientists are exploring abundant, non-toxic alternatives such as silicon-germanium alloys, magnesium silicide, and organic thermoelectric compounds. These materials not only reduce environmental impact but can also offer cost advantages due to their greater availability.

Life cycle assessment (LCA) studies of thermoelectric modules reveal that the environmental footprint extends beyond material composition to manufacturing processes. Energy-intensive production methods contribute significantly to the carbon footprint of thermoelectric devices. Innovations in manufacturing techniques, such as additive manufacturing and low-temperature synthesis methods, are being developed to reduce energy consumption while maintaining material performance characteristics that influence the Seebeck coefficient.

Recycling and end-of-life management present both challenges and opportunities for thermoelectric sustainability. The complex composition of thermoelectric modules makes recycling difficult, but advances in material recovery technologies are improving the feasibility of reclaiming valuable elements. Designing modules with disassembly and recyclability in mind represents an emerging approach to reducing waste and conserving resources.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. Legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation are pushing manufacturers toward greener alternatives that maintain performance standards, including optimal Seebeck coefficients.

The pursuit of sustainable thermoelectric materials is creating new research directions that may ultimately lead to superior performance characteristics. Biomimetic approaches, inspired by natural thermal regulation systems, and the exploration of biodegradable organic thermoelectric materials represent promising frontiers that could revolutionize the field while minimizing environmental impact.

Sustainability concerns are driving research toward more environmentally friendly thermoelectric materials that maintain or improve the Seebeck coefficient. Materials scientists are exploring abundant, non-toxic alternatives such as silicon-germanium alloys, magnesium silicide, and organic thermoelectric compounds. These materials not only reduce environmental impact but can also offer cost advantages due to their greater availability.

Life cycle assessment (LCA) studies of thermoelectric modules reveal that the environmental footprint extends beyond material composition to manufacturing processes. Energy-intensive production methods contribute significantly to the carbon footprint of thermoelectric devices. Innovations in manufacturing techniques, such as additive manufacturing and low-temperature synthesis methods, are being developed to reduce energy consumption while maintaining material performance characteristics that influence the Seebeck coefficient.

Recycling and end-of-life management present both challenges and opportunities for thermoelectric sustainability. The complex composition of thermoelectric modules makes recycling difficult, but advances in material recovery technologies are improving the feasibility of reclaiming valuable elements. Designing modules with disassembly and recyclability in mind represents an emerging approach to reducing waste and conserving resources.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of electronic materials, including thermoelectrics. Legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation are pushing manufacturers toward greener alternatives that maintain performance standards, including optimal Seebeck coefficients.

The pursuit of sustainable thermoelectric materials is creating new research directions that may ultimately lead to superior performance characteristics. Biomimetic approaches, inspired by natural thermal regulation systems, and the exploration of biodegradable organic thermoelectric materials represent promising frontiers that could revolutionize the field while minimizing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!