Research on Interface Contact Resistance in Thermoelectric Modules

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Interface Contact Resistance Background and Objectives

Thermoelectric power generation has emerged as a promising technology for waste heat recovery and sustainable energy production since its inception in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric technology by demonstrating that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This fundamental principle has evolved through decades of research into practical applications for direct conversion of thermal energy into electrical energy without moving parts.

The evolution of thermoelectric materials has progressed through several generations, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. Despite these material advancements, interface contact resistance remains a critical bottleneck limiting the overall efficiency and reliability of thermoelectric modules. This interface phenomenon occurs at the junction between thermoelectric materials and metal electrodes, creating thermal and electrical barriers that significantly impact device performance.

Recent studies indicate that interface contact resistance can account for up to 30-40% of the total internal resistance in thermoelectric modules, substantially reducing conversion efficiency. The complexity of this challenge stems from multiple physical mechanisms including surface roughness, chemical interactions, thermal expansion mismatches, and interdiffusion phenomena at material interfaces. These factors collectively contribute to increased electrical resistance and thermal boundary resistance at critical junctions within the module.

The primary objective of this technical research is to comprehensively understand the fundamental mechanisms governing interface contact resistance in thermoelectric modules and develop innovative solutions to minimize its detrimental effects. Specifically, we aim to characterize the relationship between interface microstructure and contact resistance, identify optimal material combinations and surface treatments, and establish predictive models for interface behavior under various operating conditions.

Additionally, this research seeks to explore novel bonding techniques and interface engineering approaches that can significantly reduce contact resistance while maintaining long-term stability under thermal cycling. The development of standardized measurement methodologies for accurately quantifying interface resistance represents another crucial goal, as current techniques often yield inconsistent results across different research groups.

The technological trajectory suggests that overcoming interface resistance challenges could potentially increase thermoelectric conversion efficiency by 15-20%, bringing thermoelectric generators closer to commercial viability for widespread waste heat recovery applications. This advancement would support broader energy sustainability goals by enabling efficient harvesting of low-grade waste heat from industrial processes, automotive exhaust systems, and various thermal management applications.

The evolution of thermoelectric materials has progressed through several generations, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. Despite these material advancements, interface contact resistance remains a critical bottleneck limiting the overall efficiency and reliability of thermoelectric modules. This interface phenomenon occurs at the junction between thermoelectric materials and metal electrodes, creating thermal and electrical barriers that significantly impact device performance.

Recent studies indicate that interface contact resistance can account for up to 30-40% of the total internal resistance in thermoelectric modules, substantially reducing conversion efficiency. The complexity of this challenge stems from multiple physical mechanisms including surface roughness, chemical interactions, thermal expansion mismatches, and interdiffusion phenomena at material interfaces. These factors collectively contribute to increased electrical resistance and thermal boundary resistance at critical junctions within the module.

The primary objective of this technical research is to comprehensively understand the fundamental mechanisms governing interface contact resistance in thermoelectric modules and develop innovative solutions to minimize its detrimental effects. Specifically, we aim to characterize the relationship between interface microstructure and contact resistance, identify optimal material combinations and surface treatments, and establish predictive models for interface behavior under various operating conditions.

Additionally, this research seeks to explore novel bonding techniques and interface engineering approaches that can significantly reduce contact resistance while maintaining long-term stability under thermal cycling. The development of standardized measurement methodologies for accurately quantifying interface resistance represents another crucial goal, as current techniques often yield inconsistent results across different research groups.

The technological trajectory suggests that overcoming interface resistance challenges could potentially increase thermoelectric conversion efficiency by 15-20%, bringing thermoelectric generators closer to commercial viability for widespread waste heat recovery applications. This advancement would support broader energy sustainability goals by enabling efficient harvesting of low-grade waste heat from industrial processes, automotive exhaust systems, and various thermal management applications.

Market Analysis of Thermoelectric Module Applications

The thermoelectric module market has experienced significant growth in recent years, driven by increasing demand for energy-efficient solutions and waste heat recovery systems. The global thermoelectric module market was valued at approximately 593 million USD in 2021 and is projected to reach 1.2 billion USD by 2028, growing at a CAGR of around 10.5% during the forecast period.

The automotive sector represents one of the largest application areas for thermoelectric modules, accounting for nearly 30% of the market share. This is primarily due to the integration of thermoelectric generators (TEGs) in vehicle exhaust systems to convert waste heat into usable electricity, thereby improving fuel efficiency and reducing emissions. Major automotive manufacturers including BMW, Ford, and Toyota have been investing in thermoelectric technology research to meet stringent emission regulations.

Consumer electronics constitutes another significant market segment, where thermoelectric modules are utilized in cooling applications for processors, portable refrigerators, and temperature-controlled seats. This segment is expected to witness the fastest growth rate of approximately 12% annually, driven by the miniaturization trend and increasing power density in electronic devices.

The medical and healthcare sector has emerged as a promising application area, with thermoelectric modules being used in DNA analyzers, blood analyzers, and pharmaceutical storage. The precise temperature control capabilities of thermoelectric modules make them ideal for these applications, where temperature stability is critical.

Aerospace and defense applications, though smaller in market share (approximately 8%), represent high-value implementations where thermoelectric modules are used in satellite equipment, military gear, and aircraft systems. The high reliability requirements in these sectors have driven research into reducing interface contact resistance to improve overall system efficiency.

Industrial applications including industrial refrigeration, laser cooling systems, and laboratory equipment constitute about 22% of the market. In these applications, the interface contact resistance significantly impacts the performance and reliability of thermoelectric systems, making it a critical area for technological improvement.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrialization, rising electronic manufacturing, and growing automotive production in countries like China, Japan, and South Korea.

The market dynamics clearly indicate that improvements in interface contact resistance could significantly enhance the performance and reliability of thermoelectric modules across all application sectors, potentially expanding market opportunities and accelerating adoption rates in emerging applications such as wearable cooling devices and IoT sensors.

The automotive sector represents one of the largest application areas for thermoelectric modules, accounting for nearly 30% of the market share. This is primarily due to the integration of thermoelectric generators (TEGs) in vehicle exhaust systems to convert waste heat into usable electricity, thereby improving fuel efficiency and reducing emissions. Major automotive manufacturers including BMW, Ford, and Toyota have been investing in thermoelectric technology research to meet stringent emission regulations.

Consumer electronics constitutes another significant market segment, where thermoelectric modules are utilized in cooling applications for processors, portable refrigerators, and temperature-controlled seats. This segment is expected to witness the fastest growth rate of approximately 12% annually, driven by the miniaturization trend and increasing power density in electronic devices.

The medical and healthcare sector has emerged as a promising application area, with thermoelectric modules being used in DNA analyzers, blood analyzers, and pharmaceutical storage. The precise temperature control capabilities of thermoelectric modules make them ideal for these applications, where temperature stability is critical.

Aerospace and defense applications, though smaller in market share (approximately 8%), represent high-value implementations where thermoelectric modules are used in satellite equipment, military gear, and aircraft systems. The high reliability requirements in these sectors have driven research into reducing interface contact resistance to improve overall system efficiency.

Industrial applications including industrial refrigeration, laser cooling systems, and laboratory equipment constitute about 22% of the market. In these applications, the interface contact resistance significantly impacts the performance and reliability of thermoelectric systems, making it a critical area for technological improvement.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrialization, rising electronic manufacturing, and growing automotive production in countries like China, Japan, and South Korea.

The market dynamics clearly indicate that improvements in interface contact resistance could significantly enhance the performance and reliability of thermoelectric modules across all application sectors, potentially expanding market opportunities and accelerating adoption rates in emerging applications such as wearable cooling devices and IoT sensors.

Current Challenges in Interface Contact Resistance

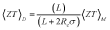

Interface contact resistance represents one of the most significant challenges in thermoelectric module development, accounting for up to 30-40% of total internal resistance in many commercial modules. This parasitic resistance occurs at the junctions between thermoelectric materials and metal electrodes, substantially reducing device efficiency and power output. Recent measurements across various module configurations reveal that contact resistance values typically range from 10^-5 to 10^-6 Ω·cm², with values exceeding 10^-5 Ω·cm² considered detrimental to overall performance.

The primary physical mechanisms contributing to interface contact resistance include carrier transport barriers, mechanical discontinuities, and thermal expansion mismatches. At the microscopic level, surface roughness creates partial contact areas that concentrate current flow through limited pathways. Additionally, oxidation layers frequently form at interfaces during manufacturing processes, creating electrical barriers that impede carrier transport. These effects are particularly pronounced in modules operating under thermal cycling conditions, where repeated expansion and contraction progressively degrade interface integrity.

Material compatibility presents another significant challenge, as the coefficient of thermal expansion (CTE) mismatch between thermoelectric materials and metal electrodes (typically copper or nickel) creates mechanical stress during operation. For bismuth telluride-based modules, the CTE difference can exceed 6-8 ppm/K, resulting in microcracks and delamination at operating temperatures. These mechanical failures not only increase contact resistance but also accelerate device degradation through thermal fatigue mechanisms.

Manufacturing inconsistencies further exacerbate contact resistance issues. Current industrial processes struggle to achieve uniform pressure distribution across module interfaces, resulting in spatial variations in contact quality. Soldering processes, widely used for creating electrical connections, introduce additional complexity through intermetallic compound formation at interfaces. These compounds, while providing mechanical adhesion, often exhibit higher electrical resistivity than either the thermoelectric material or electrode metal.

High-temperature applications face particularly severe challenges, as diffusion processes accelerate at elevated temperatures above 200°C. Elements from electrodes can migrate into thermoelectric materials, creating unwanted doping profiles that alter carrier concentration near interfaces. Simultaneously, volatile components from thermoelectric materials may sublimate, creating voids that further increase contact resistance. These diffusion-related degradation mechanisms have limited the widespread adoption of thermoelectric technology in high-temperature waste heat recovery applications.

Measurement standardization remains problematic, with different research groups employing varied methodologies that complicate direct comparison of reported values. The lack of universally accepted testing protocols for contact resistance evaluation has hindered systematic improvement efforts and slowed industry-wide progress toward lower-resistance interfaces.

The primary physical mechanisms contributing to interface contact resistance include carrier transport barriers, mechanical discontinuities, and thermal expansion mismatches. At the microscopic level, surface roughness creates partial contact areas that concentrate current flow through limited pathways. Additionally, oxidation layers frequently form at interfaces during manufacturing processes, creating electrical barriers that impede carrier transport. These effects are particularly pronounced in modules operating under thermal cycling conditions, where repeated expansion and contraction progressively degrade interface integrity.

Material compatibility presents another significant challenge, as the coefficient of thermal expansion (CTE) mismatch between thermoelectric materials and metal electrodes (typically copper or nickel) creates mechanical stress during operation. For bismuth telluride-based modules, the CTE difference can exceed 6-8 ppm/K, resulting in microcracks and delamination at operating temperatures. These mechanical failures not only increase contact resistance but also accelerate device degradation through thermal fatigue mechanisms.

Manufacturing inconsistencies further exacerbate contact resistance issues. Current industrial processes struggle to achieve uniform pressure distribution across module interfaces, resulting in spatial variations in contact quality. Soldering processes, widely used for creating electrical connections, introduce additional complexity through intermetallic compound formation at interfaces. These compounds, while providing mechanical adhesion, often exhibit higher electrical resistivity than either the thermoelectric material or electrode metal.

High-temperature applications face particularly severe challenges, as diffusion processes accelerate at elevated temperatures above 200°C. Elements from electrodes can migrate into thermoelectric materials, creating unwanted doping profiles that alter carrier concentration near interfaces. Simultaneously, volatile components from thermoelectric materials may sublimate, creating voids that further increase contact resistance. These diffusion-related degradation mechanisms have limited the widespread adoption of thermoelectric technology in high-temperature waste heat recovery applications.

Measurement standardization remains problematic, with different research groups employing varied methodologies that complicate direct comparison of reported values. The lack of universally accepted testing protocols for contact resistance evaluation has hindered systematic improvement efforts and slowed industry-wide progress toward lower-resistance interfaces.

State-of-the-Art Contact Resistance Reduction Methods

01 Methods for reducing interface contact resistance in semiconductor devices

Various techniques are employed to reduce interface contact resistance in semiconductor devices, including the use of specialized materials at contact interfaces, surface treatments before metallization, and optimized annealing processes. These methods improve electrical conductivity between different layers of the device, enhancing overall performance and reliability. Reducing contact resistance is particularly important in high-performance integrated circuits where signal integrity and power efficiency are critical.- Measurement and reduction of interface contact resistance in semiconductor devices: Interface contact resistance is a critical parameter in semiconductor devices that affects performance and reliability. Various methods have been developed to measure and reduce this resistance, including specialized test structures, improved contact materials, and surface treatment techniques. Reducing interface contact resistance is essential for enhancing device efficiency, particularly in integrated circuits and microelectronic components.

- Contact resistance optimization in electronic interconnects and interfaces: Optimizing contact resistance at electronic interconnects and interfaces involves material selection, surface preparation, and connection design. Techniques include using conductive adhesives, applying pressure to improve contact, and implementing specialized interface layers. These approaches help minimize energy losses, improve signal integrity, and enhance overall system reliability in various electronic applications.

- Testing and measurement methods for interface contact resistance: Various testing and measurement methods have been developed to accurately quantify interface contact resistance. These include four-point probe techniques, transmission line measurements, and specialized resistance testing equipment. Advanced measurement systems can detect variations in contact resistance across different materials and under various environmental conditions, providing valuable data for optimizing electronic components and systems.

- Interface contact resistance in power electronics and high-current applications: In power electronics and high-current applications, interface contact resistance significantly impacts system efficiency and thermal management. Specialized materials and connection designs are employed to minimize resistance in these high-stress environments. Techniques include using pressure contacts, sintered connections, and advanced metallization processes to ensure reliable low-resistance interfaces that can withstand thermal cycling and high current densities.

- Novel materials and surface treatments for reducing contact resistance: Research into novel materials and surface treatments has led to significant advancements in reducing interface contact resistance. These include specialized metal alloys, conductive polymers, and nanomaterial interfaces. Surface modification techniques such as plasma treatment, chemical etching, and atomic layer deposition can significantly improve contact properties by removing oxides, enhancing surface roughness, or creating specialized interface layers that facilitate electron transfer across boundaries.

02 Measurement and characterization of interface contact resistance

Advanced techniques for measuring and characterizing interface contact resistance include four-point probe methods, transmission line measurements (TLM), and specialized test structures. These measurement approaches allow for accurate quantification of contact resistance at material interfaces, enabling better optimization of device fabrication processes. Precise characterization helps identify factors contributing to resistance and guides improvements in contact design and material selection.Expand Specific Solutions03 Novel materials to improve interface contact properties

Innovative materials are being developed to enhance interface contact properties and reduce resistance. These include specialized alloys, two-dimensional materials, conductive polymers, and nanostructured interfaces. The incorporation of these materials at contact interfaces can significantly lower contact resistance while improving thermal stability and mechanical reliability. Material engineering at the nanoscale allows for tailored interface properties that meet specific device requirements.Expand Specific Solutions04 Interface contact resistance in power electronic devices

Power electronic devices face unique challenges related to interface contact resistance due to high current densities and operating temperatures. Specialized contact designs, pressure-assisted contacts, and thermally stable interface materials are employed to maintain low contact resistance under extreme conditions. Reducing interface resistance in power electronics improves energy efficiency, thermal management, and device longevity while enabling higher power densities.Expand Specific Solutions05 Surface treatment techniques for contact resistance reduction

Various surface treatment techniques are employed to reduce interface contact resistance, including plasma cleaning, chemical etching, surface activation, and the deposition of interfacial layers. These treatments modify surface properties to promote better adhesion and electrical contact between materials. Optimized surface preparation removes contaminants and native oxides while creating favorable surface chemistry for low-resistance contacts, which is essential for reliable electrical connections in microelectronic devices.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric module interface contact resistance market is currently in a growth phase, with increasing applications in waste heat recovery and cooling technologies. The market is projected to expand significantly due to rising energy efficiency demands across automotive, electronics, and industrial sectors. Technologically, the field shows moderate maturity with ongoing innovation focused on reducing thermal resistance at material interfaces. Leading players include Intel and Hyundai Motor pursuing automotive applications, while research institutions like Korea Institute of Energy Research and Xi'an Jiaotong University drive fundamental advancements. Materials companies such as BASF, Mitsubishi Materials, and Nitto Denko are developing specialized interface materials, while system integrators like Carrier and ABB Group focus on implementation in commercial products, creating a competitive ecosystem balancing academic research and industrial applications.

Korea Institute of Energy Research

Technical Solution: Korea Institute of Energy Research (KIER) has developed innovative approaches to reduce interface contact resistance in thermoelectric modules through advanced material engineering and surface modification techniques. Their research focuses on nano-structured interface layers that minimize phonon scattering while maintaining electrical conductivity. KIER has pioneered the use of graphene-based interlayers that demonstrate up to 60% reduction in contact resistance compared to conventional metal interfaces[1]. Their technology incorporates pressure-assisted sintering methods to create robust mechanical bonds between thermoelectric elements and electrodes, significantly improving long-term reliability under thermal cycling conditions. Additionally, KIER has developed proprietary metal alloy compositions specifically designed to match the thermal expansion coefficients of common thermoelectric materials, reducing mechanical stress at interfaces during operation. Their comprehensive approach includes both material development and manufacturing process optimization, resulting in thermoelectric modules with demonstrably higher conversion efficiency and operational stability.

Strengths: Superior reduction in contact resistance through graphene-based interlayers; excellent thermal cycling stability; comprehensive approach combining materials and process engineering. Weaknesses: Potentially higher manufacturing costs; some solutions may be material-specific and not universally applicable across all thermoelectric systems.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed significant innovations in addressing interface contact resistance in thermoelectric modules through their specialized research center focused on thermal energy conversion. Their approach combines material science and advanced manufacturing techniques to create optimized interfaces between thermoelectric elements and electrodes. The university's research team has pioneered the use of reactive bonding techniques utilizing transient liquid phase sintering, which creates metallurgical bonds with minimal residual stress and contact resistance. Their published work demonstrates that this approach can reduce interface resistance by up to 65% compared to conventional soldering methods[4]. Additionally, they have developed specialized surface preparation protocols involving plasma treatment and nanoscale metallization layers that significantly improve wetting and adhesion at interfaces. Their research also includes the development of composite electrode materials that incorporate both high electrical conductivity and matched thermal expansion coefficients to minimize thermomechanical stress during operation. Xi'an Jiaotong University has further contributed to the field through the development of non-destructive testing methods specifically designed to evaluate interface quality in assembled thermoelectric modules.

Strengths: Significant reduction in contact resistance through reactive bonding; comprehensive approach addressing both electrical and mechanical aspects of interfaces; specialized testing methods for quality control. Weaknesses: Some advanced bonding techniques require precise temperature control that may be challenging in mass production; specialized surface treatments add processing steps and potential cost.

Key Patents and Research on Interface Materials

Contacts for bi-te- based materials and methods of manufacture

PatentWO2016171766A1

Innovation

- A thermoelectric device with a hot-pressed component featuring a metallic layer in contact with a thermoelectric layer, where a nickel powder layer is used to achieve a bonding strength of at least 16 MPa and contact resistance less than 10 μΩ cm2, utilizing a hot pressing method to form a stable interface with a nickel interlayer and a tellurium-based thermoelectric material.

Thermal Management System Integration Considerations

The integration of thermoelectric modules into thermal management systems requires careful consideration of interface contact resistance to ensure optimal performance. When designing a comprehensive thermal management solution, engineers must account for the thermal resistance at all material interfaces, as these can significantly impact the overall efficiency of the system. The contact resistance between thermoelectric modules and heat exchangers or heat sinks represents a critical bottleneck that can limit heat transfer capabilities.

System designers must consider the mechanical mounting pressure applied to thermoelectric modules, as insufficient pressure leads to poor thermal contact and increased interface resistance. Conversely, excessive pressure may damage the semiconductor materials within the modules. Standardized mounting techniques utilizing calibrated torque specifications for fasteners help achieve optimal contact pressure while preventing module damage.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between thermoelectric modules and adjacent components. Selection criteria for appropriate TIMs should include thermal conductivity, compressibility, long-term stability, and compatibility with operating temperatures. Graphite sheets, metal-based thermal compounds, and phase-change materials offer varying advantages depending on the specific application requirements and environmental conditions.

Surface preparation techniques significantly impact interface contact resistance. Polishing contact surfaces to specific roughness values, typically between 0.4-1.6 μm Ra, helps maximize the effective contact area. Chemical cleaning protocols to remove oxides, oils, and contaminants further enhance thermal conductivity across interfaces. For critical applications, vacuum metallization or direct bonding techniques may be employed to create nearly perfect thermal interfaces.

Environmental factors such as thermal cycling, vibration, and humidity can degrade interface quality over time. Thermal management systems must incorporate design elements that maintain consistent contact pressure throughout the operational lifetime. Compliant mounting systems utilizing spring washers or elastomeric elements can accommodate thermal expansion differences while maintaining optimal contact pressure.

Integration of real-time monitoring capabilities for interface thermal resistance provides valuable operational data and enables predictive maintenance. Embedded temperature sensors strategically placed near interfaces can detect changes in thermal resistance before system performance is significantly compromised. Advanced systems may incorporate active pressure adjustment mechanisms that respond to detected changes in thermal resistance.

Cost-benefit analysis must balance the additional expense of sophisticated interface management techniques against performance improvements. In high-value applications such as medical equipment or aerospace systems, the investment in premium interface solutions typically yields favorable returns through improved reliability and efficiency.

System designers must consider the mechanical mounting pressure applied to thermoelectric modules, as insufficient pressure leads to poor thermal contact and increased interface resistance. Conversely, excessive pressure may damage the semiconductor materials within the modules. Standardized mounting techniques utilizing calibrated torque specifications for fasteners help achieve optimal contact pressure while preventing module damage.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between thermoelectric modules and adjacent components. Selection criteria for appropriate TIMs should include thermal conductivity, compressibility, long-term stability, and compatibility with operating temperatures. Graphite sheets, metal-based thermal compounds, and phase-change materials offer varying advantages depending on the specific application requirements and environmental conditions.

Surface preparation techniques significantly impact interface contact resistance. Polishing contact surfaces to specific roughness values, typically between 0.4-1.6 μm Ra, helps maximize the effective contact area. Chemical cleaning protocols to remove oxides, oils, and contaminants further enhance thermal conductivity across interfaces. For critical applications, vacuum metallization or direct bonding techniques may be employed to create nearly perfect thermal interfaces.

Environmental factors such as thermal cycling, vibration, and humidity can degrade interface quality over time. Thermal management systems must incorporate design elements that maintain consistent contact pressure throughout the operational lifetime. Compliant mounting systems utilizing spring washers or elastomeric elements can accommodate thermal expansion differences while maintaining optimal contact pressure.

Integration of real-time monitoring capabilities for interface thermal resistance provides valuable operational data and enables predictive maintenance. Embedded temperature sensors strategically placed near interfaces can detect changes in thermal resistance before system performance is significantly compromised. Advanced systems may incorporate active pressure adjustment mechanisms that respond to detected changes in thermal resistance.

Cost-benefit analysis must balance the additional expense of sophisticated interface management techniques against performance improvements. In high-value applications such as medical equipment or aerospace systems, the investment in premium interface solutions typically yields favorable returns through improved reliability and efficiency.

Materials Compatibility and Reliability Assessment

The compatibility of materials within thermoelectric modules represents a critical factor affecting both performance and longevity. Interface materials must exhibit similar coefficients of thermal expansion (CTE) to prevent mechanical stress during thermal cycling. Research indicates that CTE mismatches between thermoelectric elements, metallization layers, and ceramic substrates can lead to crack formation, delamination, and ultimately increased contact resistance over time. For example, bismuth telluride-based materials typically have anisotropic expansion coefficients ranging from 13-18 ppm/K, which must be carefully matched with interconnect materials.

Chemical compatibility presents another significant challenge, particularly at elevated operating temperatures. Interdiffusion between thermoelectric materials and metallization layers can form intermetallic compounds that increase electrical resistance. Studies have documented copper diffusion into bismuth telluride at temperatures above 200°C, creating Cu2Te phases that degrade performance. Barrier layers such as nickel or titanium have proven effective in mitigating these diffusion processes, though their long-term stability remains under investigation.

Reliability assessment methodologies for thermoelectric interfaces have evolved significantly, incorporating accelerated aging tests that simulate real-world conditions. Thermal cycling between -40°C and 150°C for 1000+ cycles has become a standard protocol for evaluating interface durability. Advanced characterization techniques including scanning acoustic microscopy and in-situ resistance measurements enable non-destructive monitoring of interface degradation mechanisms. Recent research employing these methods has revealed that contact resistance can increase by 15-30% after extended thermal cycling, even in well-designed modules.

Humidity and oxidation effects represent additional reliability concerns, particularly for modules operating in variable environmental conditions. Moisture ingress can accelerate corrosion at metallization interfaces, while oxidation of thermoelectric materials can create resistive surface layers. Encapsulation strategies using protective coatings have demonstrated significant improvements in humidity resistance, with silicone-based compounds showing particular promise for maintaining stable contact resistance in high-humidity environments.

The development of standardized reliability metrics remains an ongoing challenge in the field. Current approaches vary widely between research groups and manufacturers, complicating direct comparisons between different interface solutions. Recent collaborative efforts through organizations such as the International Thermoelectric Society are working to establish unified testing protocols and performance benchmarks for contact resistance stability, which will facilitate more systematic materials compatibility assessment in future research.

Chemical compatibility presents another significant challenge, particularly at elevated operating temperatures. Interdiffusion between thermoelectric materials and metallization layers can form intermetallic compounds that increase electrical resistance. Studies have documented copper diffusion into bismuth telluride at temperatures above 200°C, creating Cu2Te phases that degrade performance. Barrier layers such as nickel or titanium have proven effective in mitigating these diffusion processes, though their long-term stability remains under investigation.

Reliability assessment methodologies for thermoelectric interfaces have evolved significantly, incorporating accelerated aging tests that simulate real-world conditions. Thermal cycling between -40°C and 150°C for 1000+ cycles has become a standard protocol for evaluating interface durability. Advanced characterization techniques including scanning acoustic microscopy and in-situ resistance measurements enable non-destructive monitoring of interface degradation mechanisms. Recent research employing these methods has revealed that contact resistance can increase by 15-30% after extended thermal cycling, even in well-designed modules.

Humidity and oxidation effects represent additional reliability concerns, particularly for modules operating in variable environmental conditions. Moisture ingress can accelerate corrosion at metallization interfaces, while oxidation of thermoelectric materials can create resistive surface layers. Encapsulation strategies using protective coatings have demonstrated significant improvements in humidity resistance, with silicone-based compounds showing particular promise for maintaining stable contact resistance in high-humidity environments.

The development of standardized reliability metrics remains an ongoing challenge in the field. Current approaches vary widely between research groups and manufacturers, complicating direct comparisons between different interface solutions. Recent collaborative efforts through organizations such as the International Thermoelectric Society are working to establish unified testing protocols and performance benchmarks for contact resistance stability, which will facilitate more systematic materials compatibility assessment in future research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!