Thermoelectric Module Standards and Certification for Industrial Use

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The initial applications were limited due to low efficiency and material constraints. However, the mid-20th century witnessed substantial advancements with the development of semiconductor-based thermoelectric materials, particularly bismuth telluride alloys, which dramatically improved conversion efficiency.

The 1950s and 1960s marked a pivotal era with the introduction of the Figure of Merit (ZT) concept, providing a standardized measurement for thermoelectric material performance. This period established the foundation for modern thermoelectric modules, though industrial applications remained limited to specialized niches due to efficiency constraints.

From the 1990s through the 2000s, nanotechnology integration revolutionized the field, enabling significant improvements in ZT values through quantum confinement effects and engineered nanostructures. These developments expanded the potential applications of thermoelectric technology across various industrial sectors, from waste heat recovery to precision temperature control systems.

Recent technological evolution has focused on enhancing module reliability, standardization, and certification processes to meet industrial requirements. The absence of universally accepted standards has historically hindered widespread industrial adoption, creating market fragmentation and inconsistent performance metrics across manufacturers.

Current technological objectives center on establishing comprehensive international standards for thermoelectric modules that address performance parameters, reliability testing, safety requirements, and certification protocols. These standards aim to facilitate quality assurance, interoperability, and performance predictability across diverse industrial applications.

Key objectives include developing standardized testing methodologies for thermal cycling endurance, mechanical stress resistance, and long-term performance stability under various environmental conditions. Additionally, there is a growing emphasis on creating certification frameworks that validate compliance with industry-specific requirements, particularly for applications in automotive, aerospace, and industrial process control sectors.

The evolution trajectory is now moving toward integrating thermoelectric technology with Industry 4.0 principles, incorporating smart monitoring capabilities, predictive maintenance features, and interoperability with industrial control systems. This integration necessitates standardized communication protocols and data exchange formats to ensure seamless operation within complex industrial ecosystems.

Future technological objectives include developing standards that accommodate emerging high-performance materials and novel module designs while maintaining backward compatibility with existing industrial systems. The ultimate goal is establishing a globally recognized certification framework that accelerates industrial adoption by providing manufacturers and end-users with clear performance benchmarks and quality assurance mechanisms.

The 1950s and 1960s marked a pivotal era with the introduction of the Figure of Merit (ZT) concept, providing a standardized measurement for thermoelectric material performance. This period established the foundation for modern thermoelectric modules, though industrial applications remained limited to specialized niches due to efficiency constraints.

From the 1990s through the 2000s, nanotechnology integration revolutionized the field, enabling significant improvements in ZT values through quantum confinement effects and engineered nanostructures. These developments expanded the potential applications of thermoelectric technology across various industrial sectors, from waste heat recovery to precision temperature control systems.

Recent technological evolution has focused on enhancing module reliability, standardization, and certification processes to meet industrial requirements. The absence of universally accepted standards has historically hindered widespread industrial adoption, creating market fragmentation and inconsistent performance metrics across manufacturers.

Current technological objectives center on establishing comprehensive international standards for thermoelectric modules that address performance parameters, reliability testing, safety requirements, and certification protocols. These standards aim to facilitate quality assurance, interoperability, and performance predictability across diverse industrial applications.

Key objectives include developing standardized testing methodologies for thermal cycling endurance, mechanical stress resistance, and long-term performance stability under various environmental conditions. Additionally, there is a growing emphasis on creating certification frameworks that validate compliance with industry-specific requirements, particularly for applications in automotive, aerospace, and industrial process control sectors.

The evolution trajectory is now moving toward integrating thermoelectric technology with Industry 4.0 principles, incorporating smart monitoring capabilities, predictive maintenance features, and interoperability with industrial control systems. This integration necessitates standardized communication protocols and data exchange formats to ensure seamless operation within complex industrial ecosystems.

Future technological objectives include developing standards that accommodate emerging high-performance materials and novel module designs while maintaining backward compatibility with existing industrial systems. The ultimate goal is establishing a globally recognized certification framework that accelerates industrial adoption by providing manufacturers and end-users with clear performance benchmarks and quality assurance mechanisms.

Industrial Market Demand Analysis for Thermoelectric Modules

The global thermoelectric module market has demonstrated robust growth, with industrial applications emerging as a significant driver. Current market analysis indicates the industrial sector accounts for approximately 25% of the total thermoelectric module demand, with a compound annual growth rate exceeding the market average by 3-4 percentage points. This accelerated growth stems from increasing industrial automation, energy efficiency mandates, and waste heat recovery initiatives across manufacturing sectors.

Primary industrial applications generating demand include precision temperature control in semiconductor manufacturing, waste heat recovery systems in heavy industries, thermal management in industrial electronics, and temperature-sensitive process control in chemical and pharmaceutical production. The automotive manufacturing sector has also emerged as a substantial consumer, utilizing thermoelectric modules for both comfort applications and engine efficiency improvements.

Market research reveals distinct regional demand patterns. North America and Europe lead in adoption for high-precision industrial applications, while Asia-Pacific demonstrates the fastest growth rate, driven by rapid industrialization in China, South Korea, and emerging Southeast Asian economies. The industrial thermoelectric module market in China alone has expanded by over 30% in the past three years, reflecting the country's manufacturing transformation initiatives.

Customer requirements analysis indicates evolving demand characteristics. Industrial users increasingly prioritize modules with documented performance metrics, reliability certifications, and standardized form factors that facilitate integration into existing systems. Survey data from industrial procurement specialists highlights that 78% of respondents consider standardization and certification as "very important" or "critical" factors in purchasing decisions, ranking above price considerations.

The market demonstrates significant price sensitivity variations by application segment. High-precision applications in semiconductor manufacturing and pharmaceutical processing exhibit lower price elasticity, with customers willing to pay premium prices for modules with superior specifications and certifications. Conversely, general industrial applications show greater price sensitivity, creating distinct market tiers.

Forecast models predict continued market expansion, with particular growth in waste heat recovery applications as energy costs rise and environmental regulations tighten globally. The industrial IoT trend is creating new demand for thermoelectric modules in smart factory environments, where precise temperature control and monitoring are essential components of automated systems. This emerging application segment is projected to grow at twice the rate of traditional industrial applications over the next five years.

Primary industrial applications generating demand include precision temperature control in semiconductor manufacturing, waste heat recovery systems in heavy industries, thermal management in industrial electronics, and temperature-sensitive process control in chemical and pharmaceutical production. The automotive manufacturing sector has also emerged as a substantial consumer, utilizing thermoelectric modules for both comfort applications and engine efficiency improvements.

Market research reveals distinct regional demand patterns. North America and Europe lead in adoption for high-precision industrial applications, while Asia-Pacific demonstrates the fastest growth rate, driven by rapid industrialization in China, South Korea, and emerging Southeast Asian economies. The industrial thermoelectric module market in China alone has expanded by over 30% in the past three years, reflecting the country's manufacturing transformation initiatives.

Customer requirements analysis indicates evolving demand characteristics. Industrial users increasingly prioritize modules with documented performance metrics, reliability certifications, and standardized form factors that facilitate integration into existing systems. Survey data from industrial procurement specialists highlights that 78% of respondents consider standardization and certification as "very important" or "critical" factors in purchasing decisions, ranking above price considerations.

The market demonstrates significant price sensitivity variations by application segment. High-precision applications in semiconductor manufacturing and pharmaceutical processing exhibit lower price elasticity, with customers willing to pay premium prices for modules with superior specifications and certifications. Conversely, general industrial applications show greater price sensitivity, creating distinct market tiers.

Forecast models predict continued market expansion, with particular growth in waste heat recovery applications as energy costs rise and environmental regulations tighten globally. The industrial IoT trend is creating new demand for thermoelectric modules in smart factory environments, where precise temperature control and monitoring are essential components of automated systems. This emerging application segment is projected to grow at twice the rate of traditional industrial applications over the next five years.

Global Standards Landscape and Technical Barriers

The global landscape for thermoelectric module standards and certification presents a complex and fragmented picture, with significant variations across regions and industries. In North America, ASTM International and IEEE have established several standards focusing on thermoelectric material characterization and performance testing methodologies. These standards, including ASTM E2716 for thermal conductivity measurement and IEEE 1834 for thermoelectric device performance evaluation, provide foundational frameworks but lack comprehensive coverage for industrial applications.

The European Union has developed more integrated approaches through CEN (European Committee for Standardization) and the IEC (International Electrotechnical Commission), with standards like IEC 62108 specifically addressing reliability testing for concentrated photovoltaic modules with thermoelectric components. However, these standards often emphasize consumer safety and environmental compliance rather than industrial performance metrics.

In Asia, particularly Japan and China, national standards bodies have created region-specific frameworks that sometimes conflict with international norms. The Japanese Industrial Standards Committee (JISC) has established JIS C 8855 for thermoelectric power generation, while China's GB/T standards focus heavily on material quality and manufacturing processes.

A significant technical barrier emerges from the lack of harmonization between these regional standards, creating compliance challenges for global manufacturers. Companies must navigate multiple certification processes, increasing costs and time-to-market for thermoelectric solutions. This fragmentation particularly impacts small and medium enterprises with limited regulatory resources.

Another critical barrier is the absence of standardized testing protocols for specific industrial environments. While general performance metrics exist, standards rarely address the unique conditions found in automotive, aerospace, or heavy manufacturing applications where temperature extremes, vibration, and electromagnetic interference can significantly impact thermoelectric module performance and longevity.

Certification processes themselves present additional obstacles. The testing infrastructure for thermoelectric modules remains underdeveloped in many regions, with limited accredited laboratories capable of performing comprehensive evaluations. This creates bottlenecks in the certification pipeline and raises questions about the comparability of test results across different facilities.

Emerging technologies present further challenges to the standards landscape. As new thermoelectric materials and manufacturing techniques develop, existing standards struggle to keep pace. The growing integration of thermoelectric modules with IoT systems and smart industrial equipment has created gaps in standards addressing cybersecurity, data integrity, and system interoperability.

The European Union has developed more integrated approaches through CEN (European Committee for Standardization) and the IEC (International Electrotechnical Commission), with standards like IEC 62108 specifically addressing reliability testing for concentrated photovoltaic modules with thermoelectric components. However, these standards often emphasize consumer safety and environmental compliance rather than industrial performance metrics.

In Asia, particularly Japan and China, national standards bodies have created region-specific frameworks that sometimes conflict with international norms. The Japanese Industrial Standards Committee (JISC) has established JIS C 8855 for thermoelectric power generation, while China's GB/T standards focus heavily on material quality and manufacturing processes.

A significant technical barrier emerges from the lack of harmonization between these regional standards, creating compliance challenges for global manufacturers. Companies must navigate multiple certification processes, increasing costs and time-to-market for thermoelectric solutions. This fragmentation particularly impacts small and medium enterprises with limited regulatory resources.

Another critical barrier is the absence of standardized testing protocols for specific industrial environments. While general performance metrics exist, standards rarely address the unique conditions found in automotive, aerospace, or heavy manufacturing applications where temperature extremes, vibration, and electromagnetic interference can significantly impact thermoelectric module performance and longevity.

Certification processes themselves present additional obstacles. The testing infrastructure for thermoelectric modules remains underdeveloped in many regions, with limited accredited laboratories capable of performing comprehensive evaluations. This creates bottlenecks in the certification pipeline and raises questions about the comparability of test results across different facilities.

Emerging technologies present further challenges to the standards landscape. As new thermoelectric materials and manufacturing techniques develop, existing standards struggle to keep pace. The growing integration of thermoelectric modules with IoT systems and smart industrial equipment has created gaps in standards addressing cybersecurity, data integrity, and system interoperability.

Current Certification Frameworks and Testing Protocols

01 Performance testing standards for thermoelectric modules

Standards for testing and evaluating the performance of thermoelectric modules, including efficiency, power output, and thermal conductivity measurements. These standards ensure consistent evaluation methods across the industry and provide reliable performance metrics for module comparison. Testing procedures typically include temperature differential tests, electrical resistance measurements, and thermal cycling to assess durability and long-term stability.- Performance testing standards for thermoelectric modules: Various standards exist for testing the performance of thermoelectric modules, including methods to measure thermal conductivity, electrical resistance, and conversion efficiency. These standards ensure consistent evaluation of module performance across different manufacturers and applications. Testing procedures typically involve measuring temperature differentials, power output, and efficiency under controlled conditions to verify that modules meet specified performance criteria.

- Safety certification requirements for thermoelectric devices: Thermoelectric modules must meet specific safety certification requirements before commercial deployment. These include electrical safety standards to prevent short circuits and overheating, thermal runaway protection, and compliance with hazardous materials regulations. Certification processes typically involve third-party testing of insulation properties, maximum operating temperatures, and durability under various environmental conditions to ensure safe operation throughout the device lifecycle.

- Quality control standards for manufacturing processes: Manufacturing standards for thermoelectric modules focus on ensuring consistent quality and reliability. These standards cover semiconductor material purity, junction formation techniques, electrical contact quality, and module assembly processes. Quality control procedures include in-line testing, statistical process control, and reliability verification through accelerated life testing to ensure modules meet performance specifications and maintain long-term operational stability.

- Environmental compliance and sustainability standards: Environmental standards for thermoelectric modules address sustainability concerns throughout the product lifecycle. These include restrictions on hazardous substances (like lead and cadmium), energy efficiency requirements, and end-of-life recycling protocols. Manufacturers must demonstrate compliance with regional environmental regulations such as RoHS and WEEE directives, while also optimizing material usage and manufacturing processes to reduce environmental impact.

- Application-specific certification standards: Different applications of thermoelectric modules require specialized certification standards. For automotive applications, modules must meet vibration resistance and temperature cycling standards. Medical device applications require biocompatibility testing and sterilization validation. Consumer electronics applications focus on electromagnetic compatibility and low-voltage safety standards. These application-specific certifications ensure that thermoelectric modules perform reliably and safely in their intended operating environments.

02 Safety certification requirements for thermoelectric devices

Safety certification standards that thermoelectric modules must meet for commercial applications, including electrical safety, thermal management, and material compliance. These requirements address potential hazards such as electrical shorts, overheating, and material degradation under operating conditions. Certification processes typically involve testing for electrical isolation, temperature limits, and compliance with international safety standards for electronic components.Expand Specific Solutions03 Material quality and manufacturing standards

Standards governing the quality of materials used in thermoelectric modules and the manufacturing processes employed. These standards ensure consistency in module production, material purity, and structural integrity. They cover aspects such as semiconductor material specifications, electrode materials, thermal interface materials, and assembly techniques to ensure reliable performance and longevity of thermoelectric modules.Expand Specific Solutions04 Environmental compliance and reliability standards

Standards related to environmental compliance, reliability testing, and durability of thermoelectric modules under various operating conditions. These include testing for thermal cycling endurance, humidity resistance, mechanical shock tolerance, and long-term stability. Environmental standards also address the use of hazardous substances, recyclability, and end-of-life considerations for thermoelectric modules in accordance with global environmental regulations.Expand Specific Solutions05 Application-specific certification standards

Specialized certification standards for thermoelectric modules used in specific applications such as automotive, aerospace, medical devices, and consumer electronics. These standards address unique requirements for each application domain, including temperature ranges, vibration resistance, size constraints, and integration specifications. They ensure that thermoelectric modules meet the performance, reliability, and safety requirements specific to their intended use environment.Expand Specific Solutions

Leading Manufacturers and Certification Bodies

The thermoelectric module industry for industrial applications is currently in a growth phase, with increasing demand for energy harvesting and thermal management solutions. The market is projected to expand significantly due to rising energy efficiency requirements and waste heat recovery initiatives. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Major players like Samsung Electro Mechanics, LG Chem, and Kyocera lead with advanced manufacturing capabilities, while European Thermodynamics and KELK focus on specialized thermoelectric solutions. Asian manufacturers dominate production volume, while European and American companies like Robert Bosch and Alternative Energy Innovations concentrate on innovative applications and integration technologies. Certification standards remain under development as the industry works toward global harmonization.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a standardized thermoelectric module platform specifically targeting industrial applications requiring high reliability and consistent performance. Their modules incorporate advanced nano-structured materials that improve ZT values (figure of merit) by approximately 20% compared to conventional bismuth telluride. Panasonic's certification process includes thermal performance validation across -40°C to 200°C operating range, with particular emphasis on stability during thermal cycling. Their industrial modules feature hermetically sealed packaging with specialized ceramic substrates that provide superior thermal stress management and electrical isolation. Panasonic has established comprehensive quality assurance protocols including 100% functional testing of modules against standardized performance metrics and accelerated life testing simulating industrial environments. Their modules comply with international standards including IEC 62830-5 for thermoelectric energy harvesting and have received certification for use in hazardous industrial environments.

Strengths: Exceptional manufacturing consistency with performance variation under 2% between modules; superior hermetic sealing technology providing excellent long-term stability; comprehensive certification documentation facilitating industrial adoption. Weaknesses: Premium pricing positioning limits adoption in cost-sensitive applications; relatively large minimum order quantities; limited customization options for specialized industrial applications.

EUROPEAN THERMODYNAMICS LIMITED

Technical Solution: European Thermodynamics Limited has pioneered a comprehensive certification framework for industrial thermoelectric modules that addresses both performance and safety requirements. Their approach includes standardized testing protocols for thermal conductivity, electrical resistance, and Seebeck coefficient measurements across varying temperature gradients (typically 30°C to 300°C). The company has developed proprietary manufacturing processes that ensure consistent module-to-module performance with less than 3% variation in power output under identical conditions. Their industrial modules undergo accelerated life testing simulating industrial environments with vibration, humidity, and thermal cycling stresses. European Thermodynamics has worked closely with European regulatory bodies to establish certification standards that verify both performance claims and operational safety in industrial settings, including ATEX certification for potentially explosive atmospheres and IP68 ratings for dust and water protection.

Strengths: Comprehensive testing methodology that accurately predicts real-world performance; modules designed specifically for industrial durability requirements; strong compliance with European industrial safety standards. Weaknesses: Limited production capacity compared to larger Asian manufacturers; higher cost structure due to European manufacturing base; somewhat conservative performance specifications compared to cutting-edge research prototypes.

Key Standards and Technical Specifications Review

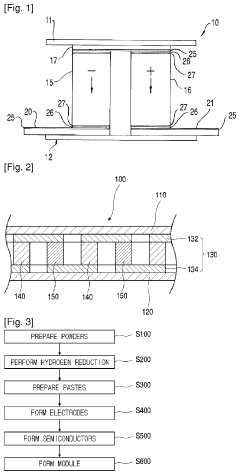

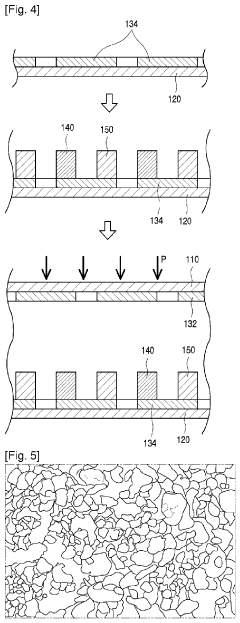

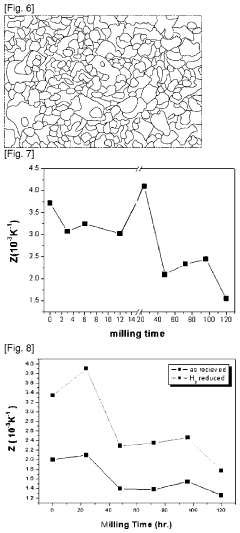

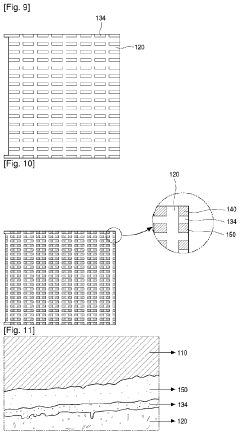

Thermoelectric module

PatentActiveUS10566514B2

Innovation

- A thermoelectric module is fabricated using a screen printing method with electrodes and P-type and N-type semiconductors formed from a paste mixture of thermoelectric powder and an organic solvent, allowing for precise control of thickness and enabling various sizes and shapes, reducing material toxicity and manufacturing complexity.

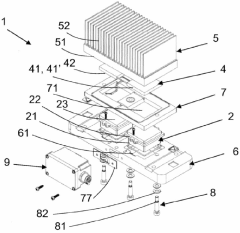

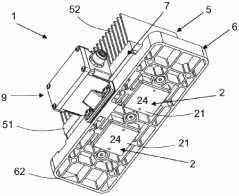

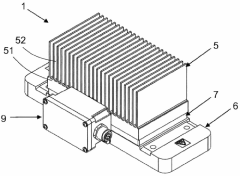

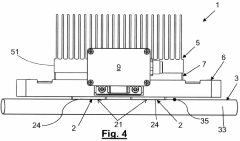

Thermoelectric module for the use of residual heat and industrial processes monitoring system

PatentActiveES2921483A1

Innovation

- Integration of a structural base that manages pressure distribution between the thermoelectric generator and dissipator while allowing direct contact between the heat collector and heat source through an opening.

- Dual-purpose design that not only harvests residual heat for energy generation but also functions as a monitoring system for predictive maintenance in industrial processes.

- Comprehensive system approach combining heat collection, energy generation, and heat dissipation in a single module specifically designed for industrial residual heat utilization.

Regulatory Compliance and International Trade Implications

The global regulatory landscape for thermoelectric modules presents a complex framework that manufacturers and industrial users must navigate. Compliance with international standards such as IEC 62108 for concentrated photovoltaic modules and IEC 61215 for terrestrial photovoltaic modules provides a foundation for thermoelectric module certification, though specific standards for industrial thermoelectric applications remain fragmented. This regulatory gap creates challenges for global market access and trade facilitation.

In major markets like the European Union, thermoelectric modules must comply with the RoHS Directive restricting hazardous substances and the WEEE Directive for electronic waste management. Additionally, the EU's CE marking requirement serves as a passport for product circulation within the European Economic Area, confirming compliance with health, safety, and environmental protection standards. Failure to meet these requirements can result in market exclusion and significant financial penalties.

The United States regulatory framework centers around UL certification, with UL 746B for polymeric materials and UL 1995 for heating and cooling equipment being particularly relevant. The Department of Energy's efficiency standards further impact thermoelectric module applications in HVAC and refrigeration systems. These requirements create technical barriers to trade that manufacturers must overcome through product adaptation or certification processes.

In the Asia-Pacific region, China's CCC certification, Japan's PSE mark, and South Korea's KC mark represent mandatory compliance hurdles for market entry. These certification processes often involve local testing, documentation in national languages, and ongoing compliance monitoring, adding complexity to international trade strategies.

Trade agreements increasingly incorporate mutual recognition arrangements (MRAs) for conformity assessment procedures, potentially reducing duplicate testing requirements. However, the specialized nature of thermoelectric technology often falls outside established MRA frameworks, necessitating multiple certifications for global market access. This regulatory fragmentation increases compliance costs by an estimated 5-15% of product development budgets.

Emerging regulations around critical minerals and supply chain due diligence are creating additional compliance considerations. The EU's Conflict Minerals Regulation and similar frameworks in the US impact thermoelectric module manufacturers who utilize bismuth telluride, antimony, and other materials sourced from regions with governance concerns. These regulations necessitate enhanced supply chain transparency and documentation, affecting international sourcing strategies and potentially reshaping global trade flows in thermoelectric technologies.

In major markets like the European Union, thermoelectric modules must comply with the RoHS Directive restricting hazardous substances and the WEEE Directive for electronic waste management. Additionally, the EU's CE marking requirement serves as a passport for product circulation within the European Economic Area, confirming compliance with health, safety, and environmental protection standards. Failure to meet these requirements can result in market exclusion and significant financial penalties.

The United States regulatory framework centers around UL certification, with UL 746B for polymeric materials and UL 1995 for heating and cooling equipment being particularly relevant. The Department of Energy's efficiency standards further impact thermoelectric module applications in HVAC and refrigeration systems. These requirements create technical barriers to trade that manufacturers must overcome through product adaptation or certification processes.

In the Asia-Pacific region, China's CCC certification, Japan's PSE mark, and South Korea's KC mark represent mandatory compliance hurdles for market entry. These certification processes often involve local testing, documentation in national languages, and ongoing compliance monitoring, adding complexity to international trade strategies.

Trade agreements increasingly incorporate mutual recognition arrangements (MRAs) for conformity assessment procedures, potentially reducing duplicate testing requirements. However, the specialized nature of thermoelectric technology often falls outside established MRA frameworks, necessitating multiple certifications for global market access. This regulatory fragmentation increases compliance costs by an estimated 5-15% of product development budgets.

Emerging regulations around critical minerals and supply chain due diligence are creating additional compliance considerations. The EU's Conflict Minerals Regulation and similar frameworks in the US impact thermoelectric module manufacturers who utilize bismuth telluride, antimony, and other materials sourced from regions with governance concerns. These regulations necessitate enhanced supply chain transparency and documentation, affecting international sourcing strategies and potentially reshaping global trade flows in thermoelectric technologies.

Environmental Impact and Sustainability Considerations

The environmental impact of thermoelectric modules extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. Manufacturing processes for thermoelectric materials often involve rare earth elements and heavy metals such as bismuth, tellurium, and lead, which present significant environmental concerns during extraction and processing. Current industrial standards must evolve to address these impacts by establishing clear guidelines for sustainable sourcing and responsible manufacturing practices.

Energy efficiency represents a critical sustainability consideration for thermoelectric module certification. While these devices offer waste heat recovery capabilities that can improve overall system efficiency, their own conversion efficiency typically ranges from 5-8%. Standards should incorporate minimum efficiency requirements that progressively increase over time, driving technological advancement toward higher performance modules that maximize energy recovery while minimizing resource consumption.

Lifecycle assessment (LCA) methodologies are increasingly being integrated into industrial certification frameworks for thermoelectric technologies. These assessments quantify environmental impacts across production, use, and disposal phases, providing valuable data for manufacturers and end-users. Emerging standards are beginning to require comprehensive LCA documentation as part of certification processes, enabling more informed decision-making regarding environmental tradeoffs in thermoelectric applications.

Waste management and recyclability present particular challenges for thermoelectric module certification. The composite nature of these devices—combining semiconductors, ceramics, and metals—complicates end-of-life processing. Forward-thinking standards are now incorporating design-for-disassembly requirements and establishing recovery targets for critical materials. Some certification systems have begun implementing extended producer responsibility provisions that hold manufacturers accountable for the entire product lifecycle.

Carbon footprint considerations are gaining prominence in thermoelectric module standards. The embodied carbon in these devices must be balanced against their potential for reducing emissions through waste heat recovery applications. Advanced certification frameworks now include carbon accounting methodologies that evaluate net climate impact across various industrial deployment scenarios, providing a more holistic sustainability assessment.

Water usage during manufacturing represents another environmental dimension requiring standardization. Semiconductor processing for thermoelectric materials typically demands significant quantities of ultrapure water. Emerging certification criteria are establishing water efficiency benchmarks and encouraging closed-loop systems that minimize consumption and contamination risks in industrial production environments.

Energy efficiency represents a critical sustainability consideration for thermoelectric module certification. While these devices offer waste heat recovery capabilities that can improve overall system efficiency, their own conversion efficiency typically ranges from 5-8%. Standards should incorporate minimum efficiency requirements that progressively increase over time, driving technological advancement toward higher performance modules that maximize energy recovery while minimizing resource consumption.

Lifecycle assessment (LCA) methodologies are increasingly being integrated into industrial certification frameworks for thermoelectric technologies. These assessments quantify environmental impacts across production, use, and disposal phases, providing valuable data for manufacturers and end-users. Emerging standards are beginning to require comprehensive LCA documentation as part of certification processes, enabling more informed decision-making regarding environmental tradeoffs in thermoelectric applications.

Waste management and recyclability present particular challenges for thermoelectric module certification. The composite nature of these devices—combining semiconductors, ceramics, and metals—complicates end-of-life processing. Forward-thinking standards are now incorporating design-for-disassembly requirements and establishing recovery targets for critical materials. Some certification systems have begun implementing extended producer responsibility provisions that hold manufacturers accountable for the entire product lifecycle.

Carbon footprint considerations are gaining prominence in thermoelectric module standards. The embodied carbon in these devices must be balanced against their potential for reducing emissions through waste heat recovery applications. Advanced certification frameworks now include carbon accounting methodologies that evaluate net climate impact across various industrial deployment scenarios, providing a more holistic sustainability assessment.

Water usage during manufacturing represents another environmental dimension requiring standardization. Semiconductor processing for thermoelectric materials typically demands significant quantities of ultrapure water. Emerging certification criteria are establishing water efficiency benchmarks and encouraging closed-loop systems that minimize consumption and contamination risks in industrial production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!