Thermoelectric Module Optimization for High-Temperature Applications

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century, beginning with the Seebeck effect in 1821, followed by the Peltier effect in 1834, and the Thomson effect in 1851. These three phenomena collectively form the foundation of thermoelectric principles that enable direct conversion between thermal and electrical energy. The field remained largely theoretical until the mid-20th century when semiconductor materials research accelerated development of practical thermoelectric devices.

The evolution of thermoelectric materials has progressed through several generations. First-generation materials included bismuth telluride (Bi₂Te₃) compounds, which still dominate low-temperature applications. Second-generation materials introduced lead telluride (PbTe) and silicon-germanium (SiGe) alloys, extending operational temperature ranges. Current third-generation materials explore complex structures including skutterudites, clathrates, and half-Heusler compounds specifically designed for high-temperature applications exceeding 400°C.

High-temperature thermoelectric applications represent a critical frontier in waste heat recovery systems, particularly in industrial processes, automotive exhaust systems, and power generation facilities where temperatures can exceed 600°C. The technical objective for high-temperature thermoelectric module optimization centers on developing materials and module architectures that maintain structural integrity and conversion efficiency under extreme thermal conditions.

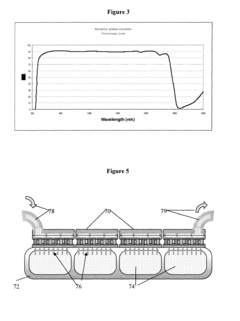

Key performance metrics driving development include the dimensionless figure of merit (ZT), which ideally should exceed 2.0 for commercial viability in high-temperature applications. Current state-of-the-art materials achieve ZT values of 1.5-1.8 in laboratory settings, indicating significant room for improvement. Additional objectives include enhancing thermal stability, reducing material degradation rates, and minimizing thermal expansion mismatches that lead to mechanical failures.

The technological trajectory points toward multi-layered, segmented thermoelectric modules that optimize performance across broad temperature gradients. These advanced designs incorporate different thermoelectric materials strategically positioned to operate in their optimal temperature ranges within a single module. Concurrent development focuses on protective coatings, advanced interconnect technologies, and novel packaging solutions to withstand oxidation and sublimation effects prevalent at elevated temperatures.

Industry projections suggest that successful optimization of high-temperature thermoelectric modules could unlock a potential market exceeding $3.5 billion by 2030, primarily driven by industrial waste heat recovery applications and increasingly stringent energy efficiency regulations worldwide. The technology's evolution aligns with global sustainability initiatives and circular economy principles by converting previously wasted thermal energy into valuable electricity.

The evolution of thermoelectric materials has progressed through several generations. First-generation materials included bismuth telluride (Bi₂Te₃) compounds, which still dominate low-temperature applications. Second-generation materials introduced lead telluride (PbTe) and silicon-germanium (SiGe) alloys, extending operational temperature ranges. Current third-generation materials explore complex structures including skutterudites, clathrates, and half-Heusler compounds specifically designed for high-temperature applications exceeding 400°C.

High-temperature thermoelectric applications represent a critical frontier in waste heat recovery systems, particularly in industrial processes, automotive exhaust systems, and power generation facilities where temperatures can exceed 600°C. The technical objective for high-temperature thermoelectric module optimization centers on developing materials and module architectures that maintain structural integrity and conversion efficiency under extreme thermal conditions.

Key performance metrics driving development include the dimensionless figure of merit (ZT), which ideally should exceed 2.0 for commercial viability in high-temperature applications. Current state-of-the-art materials achieve ZT values of 1.5-1.8 in laboratory settings, indicating significant room for improvement. Additional objectives include enhancing thermal stability, reducing material degradation rates, and minimizing thermal expansion mismatches that lead to mechanical failures.

The technological trajectory points toward multi-layered, segmented thermoelectric modules that optimize performance across broad temperature gradients. These advanced designs incorporate different thermoelectric materials strategically positioned to operate in their optimal temperature ranges within a single module. Concurrent development focuses on protective coatings, advanced interconnect technologies, and novel packaging solutions to withstand oxidation and sublimation effects prevalent at elevated temperatures.

Industry projections suggest that successful optimization of high-temperature thermoelectric modules could unlock a potential market exceeding $3.5 billion by 2030, primarily driven by industrial waste heat recovery applications and increasingly stringent energy efficiency regulations worldwide. The technology's evolution aligns with global sustainability initiatives and circular economy principles by converting previously wasted thermal energy into valuable electricity.

Market Analysis for High-Temperature Thermoelectric Applications

The high-temperature thermoelectric module market is experiencing significant growth driven by increasing demand for waste heat recovery systems across multiple industries. Current market valuation stands at approximately 450 million USD with projections indicating growth to reach 720 million USD by 2028, representing a compound annual growth rate of 8.2%. This growth trajectory is primarily fueled by industrial sectors seeking energy efficiency improvements and sustainable energy solutions.

The automotive sector represents the largest market segment, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators to recover waste heat from exhaust systems, improving fuel efficiency by 3-5% in conventional vehicles. This application is particularly valuable as regulatory pressures for reduced emissions continue to intensify globally.

Industrial manufacturing constitutes the second-largest market segment at 28%, where high-temperature processes in steel, glass, and cement production generate substantial waste heat that can be recovered through thermoelectric modules. The aerospace industry, though smaller at 15% market share, represents the fastest-growing segment with 12.3% annual growth as manufacturers seek lightweight power generation solutions for next-generation aircraft and spacecraft systems.

Geographically, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the most rapid growth rate at 10.5% annually, driven by China's aggressive industrial modernization and Japan's advanced automotive sector. Emerging economies in this region are increasingly adopting waste heat recovery technologies as part of their industrial development strategies.

Customer requirements vary significantly across applications, with automotive and aerospace sectors prioritizing reliability and weight considerations, while industrial applications focus on durability under extreme conditions and long operational lifespans. The common denominator across all sectors is the demand for improved conversion efficiency, with customers seeking modules that can achieve at least 8-10% efficiency at operating temperatures above 500°C.

Market barriers include the relatively high initial cost of high-temperature thermoelectric systems, with current prices averaging 15-20 USD per watt of generation capacity. This represents a significant hurdle for widespread adoption, particularly in price-sensitive markets. Additionally, the technical complexity of integrating these systems into existing industrial processes creates implementation challenges that slow market penetration.

Future market growth will likely be catalyzed by advancements in material science that improve conversion efficiency and reduce manufacturing costs. The development of new skutterudite and half-Heusler alloys specifically engineered for high-temperature applications could potentially double current efficiency rates, dramatically improving return-on-investment calculations for potential customers.

The automotive sector represents the largest market segment, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators to recover waste heat from exhaust systems, improving fuel efficiency by 3-5% in conventional vehicles. This application is particularly valuable as regulatory pressures for reduced emissions continue to intensify globally.

Industrial manufacturing constitutes the second-largest market segment at 28%, where high-temperature processes in steel, glass, and cement production generate substantial waste heat that can be recovered through thermoelectric modules. The aerospace industry, though smaller at 15% market share, represents the fastest-growing segment with 12.3% annual growth as manufacturers seek lightweight power generation solutions for next-generation aircraft and spacecraft systems.

Geographically, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is demonstrating the most rapid growth rate at 10.5% annually, driven by China's aggressive industrial modernization and Japan's advanced automotive sector. Emerging economies in this region are increasingly adopting waste heat recovery technologies as part of their industrial development strategies.

Customer requirements vary significantly across applications, with automotive and aerospace sectors prioritizing reliability and weight considerations, while industrial applications focus on durability under extreme conditions and long operational lifespans. The common denominator across all sectors is the demand for improved conversion efficiency, with customers seeking modules that can achieve at least 8-10% efficiency at operating temperatures above 500°C.

Market barriers include the relatively high initial cost of high-temperature thermoelectric systems, with current prices averaging 15-20 USD per watt of generation capacity. This represents a significant hurdle for widespread adoption, particularly in price-sensitive markets. Additionally, the technical complexity of integrating these systems into existing industrial processes creates implementation challenges that slow market penetration.

Future market growth will likely be catalyzed by advancements in material science that improve conversion efficiency and reduce manufacturing costs. The development of new skutterudite and half-Heusler alloys specifically engineered for high-temperature applications could potentially double current efficiency rates, dramatically improving return-on-investment calculations for potential customers.

Current Challenges in High-Temperature Thermoelectric Materials

Despite significant advancements in thermoelectric technology, high-temperature applications continue to face substantial technical barriers. The primary challenge remains the inherent trade-off between thermal conductivity and electrical conductivity in thermoelectric materials. As operating temperatures increase beyond 400°C, most conventional thermoelectric materials experience severe performance degradation due to thermal instability, oxidation, and sublimation effects.

Material degradation presents a critical obstacle, with many promising thermoelectric compounds suffering from decomposition, phase transitions, or mechanical failure under sustained high-temperature operation. For instance, bismuth telluride (Bi₂Te₃), while efficient at moderate temperatures, becomes unstable above 300°C, limiting its application in high-temperature waste heat recovery systems.

Thermal cycling poses another significant challenge, as repeated heating and cooling cycles induce mechanical stress at material interfaces, leading to microcrack formation and eventual device failure. The coefficient of thermal expansion mismatch between different components exacerbates this issue, particularly at the junction between the thermoelectric material and metal contacts.

Contact resistance increases dramatically at elevated temperatures, creating parasitic losses that significantly reduce overall system efficiency. Current metallization techniques struggle to maintain low-resistance electrical connections while preventing interdiffusion between the contact layer and thermoelectric material at temperatures exceeding 500°C.

Manufacturing scalability remains problematic for high-temperature thermoelectric modules. Advanced materials like skutterudites, half-Heusler alloys, and silicon-germanium compounds that perform well at high temperatures often involve expensive rare earth elements and complex fabrication processes, limiting commercial viability.

Environmental stability presents additional concerns, as many high-performance thermoelectric materials contain toxic or scarce elements. Tellurium, antimony, and lead—common constituents in thermoelectric compounds—face increasing regulatory scrutiny and supply chain constraints, necessitating alternative material development.

Thermal management becomes increasingly difficult at higher operating temperatures, requiring sophisticated heat transfer solutions to maintain the temperature gradient essential for thermoelectric conversion while preventing thermal runaway conditions. Current heat exchanger designs struggle to efficiently transfer heat to and from thermoelectric modules in extreme temperature environments.

Measurement and characterization methodologies for high-temperature thermoelectric properties remain inconsistent across the industry, complicating material comparison and performance validation. Standard testing protocols often fail to accurately predict long-term performance under actual operating conditions, leading to discrepancies between laboratory results and field performance.

Material degradation presents a critical obstacle, with many promising thermoelectric compounds suffering from decomposition, phase transitions, or mechanical failure under sustained high-temperature operation. For instance, bismuth telluride (Bi₂Te₃), while efficient at moderate temperatures, becomes unstable above 300°C, limiting its application in high-temperature waste heat recovery systems.

Thermal cycling poses another significant challenge, as repeated heating and cooling cycles induce mechanical stress at material interfaces, leading to microcrack formation and eventual device failure. The coefficient of thermal expansion mismatch between different components exacerbates this issue, particularly at the junction between the thermoelectric material and metal contacts.

Contact resistance increases dramatically at elevated temperatures, creating parasitic losses that significantly reduce overall system efficiency. Current metallization techniques struggle to maintain low-resistance electrical connections while preventing interdiffusion between the contact layer and thermoelectric material at temperatures exceeding 500°C.

Manufacturing scalability remains problematic for high-temperature thermoelectric modules. Advanced materials like skutterudites, half-Heusler alloys, and silicon-germanium compounds that perform well at high temperatures often involve expensive rare earth elements and complex fabrication processes, limiting commercial viability.

Environmental stability presents additional concerns, as many high-performance thermoelectric materials contain toxic or scarce elements. Tellurium, antimony, and lead—common constituents in thermoelectric compounds—face increasing regulatory scrutiny and supply chain constraints, necessitating alternative material development.

Thermal management becomes increasingly difficult at higher operating temperatures, requiring sophisticated heat transfer solutions to maintain the temperature gradient essential for thermoelectric conversion while preventing thermal runaway conditions. Current heat exchanger designs struggle to efficiently transfer heat to and from thermoelectric modules in extreme temperature environments.

Measurement and characterization methodologies for high-temperature thermoelectric properties remain inconsistent across the industry, complicating material comparison and performance validation. Standard testing protocols often fail to accurately predict long-term performance under actual operating conditions, leading to discrepancies between laboratory results and field performance.

State-of-the-Art High-Temperature Thermoelectric Solutions

01 Material selection and composition for thermoelectric modules

The selection and composition of thermoelectric materials significantly impact module efficiency. Optimizing material properties such as Seebeck coefficient, electrical conductivity, and thermal conductivity can enhance the figure of merit (ZT). Advanced materials including bismuth telluride compounds, skutterudites, and nanostructured materials are being developed to improve thermoelectric performance. Doping and alloying techniques can further optimize carrier concentration and reduce thermal conductivity while maintaining electrical conductivity.- Material selection and composition for thermoelectric modules: The selection and composition of thermoelectric materials significantly impact module efficiency. Optimizing material properties such as Seebeck coefficient, electrical conductivity, and thermal conductivity can enhance the figure of merit (ZT). Advanced materials including bismuth telluride compounds, skutterudites, and nanostructured materials are being developed to improve thermoelectric performance. Doping and alloying techniques can further optimize carrier concentration and reduce thermal conductivity while maintaining electrical conductivity.

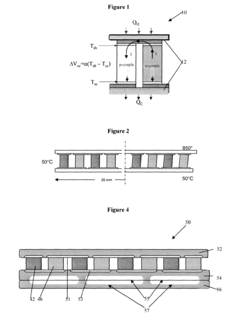

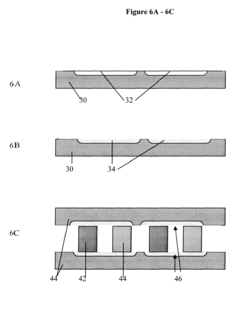

- Structural design and geometry optimization: The physical structure and geometry of thermoelectric modules significantly affect their performance. Optimizing leg dimensions, cross-sectional areas, and aspect ratios can enhance power output and efficiency. Advanced designs include segmented and cascaded structures that utilize different materials optimized for specific temperature ranges. Miniaturization and micro-fabrication techniques enable higher packing density and improved thermal management. Novel geometrical configurations such as ring-shaped and cylindrical modules can be tailored for specific applications.

- Thermal management and interface optimization: Effective thermal management is crucial for thermoelectric module performance. Optimizing heat transfer at interfaces between thermoelectric elements and heat exchangers reduces thermal resistance and temperature drops. Advanced thermal interface materials, surface treatments, and bonding techniques improve thermal contact. Heat spreading structures and heat sink designs enhance temperature uniformity and heat dissipation. Active cooling methods and heat pipe integration can further improve thermal management in high-power applications.

- Electrical connection and circuit optimization: Electrical connection design significantly impacts thermoelectric module efficiency. Optimizing electrode materials, thickness, and contact resistance reduces electrical losses. Advanced interconnection techniques minimize parasitic resistance while maintaining mechanical strength. Circuit configurations can be tailored to specific operating conditions, with series and parallel arrangements optimized for voltage or current requirements. Maximum power point tracking systems dynamically adjust electrical load to maintain optimal operating conditions as temperature differentials change.

- Manufacturing processes and quality control: Manufacturing processes significantly influence thermoelectric module performance and reliability. Advanced fabrication techniques such as spark plasma sintering, hot pressing, and molecular beam epitaxy can produce materials with enhanced thermoelectric properties. Precision assembly methods ensure consistent thermal and electrical contacts. Quality control measures including thermal imaging, electrical characterization, and accelerated life testing help identify defects and predict long-term performance. Automated manufacturing processes improve consistency and reduce variation between modules.

02 Structural design and geometry optimization

The physical structure and geometry of thermoelectric modules significantly affect their performance. Optimizing parameters such as leg height, cross-sectional area, and aspect ratio can maximize power output and efficiency. Advanced designs include segmented and cascaded structures that utilize different materials optimized for specific temperature ranges. Miniaturization and micro-fabrication techniques enable higher packing density and improved thermal management. Innovative geometries such as annular, cylindrical, or flexible configurations can be tailored for specific applications.Expand Specific Solutions03 Thermal interface and heat transfer optimization

Effective thermal management is crucial for thermoelectric module performance. Optimizing thermal interfaces between the module and heat source/sink reduces contact resistance and improves heat transfer. Advanced heat exchanger designs, including heat pipes, micro-channel heat sinks, and phase change materials, can enhance temperature gradients across the module. Proper thermal spreading techniques ensure uniform temperature distribution, preventing hot spots and thermal stress. Integration with cooling systems and heat recovery mechanisms maximizes overall system efficiency.Expand Specific Solutions04 Electrical circuit and interconnection optimization

The electrical configuration of thermoelectric modules significantly impacts power output and efficiency. Optimizing electrical connections, including series and parallel arrangements of thermoelectric elements, can match load requirements and maximize power transfer. Advanced interconnection technologies using low-resistance materials and bonding techniques reduce parasitic losses. Integrated power conditioning circuits, including maximum power point tracking systems, optimize electrical output under varying conditions. Novel electrode designs and contact materials minimize electrical resistance while ensuring mechanical stability.Expand Specific Solutions05 Manufacturing processes and quality control

Advanced manufacturing techniques significantly impact thermoelectric module performance and reliability. Precision fabrication methods ensure dimensional accuracy and consistency of thermoelectric elements. Automated assembly processes improve module uniformity and reduce defects. Quality control measures, including thermal imaging and electrical testing, identify performance variations. Post-processing treatments such as annealing and surface modification optimize material properties and interfaces. Reliability testing under thermal cycling and mechanical stress ensures long-term performance stability in various operating environments.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

Thermoelectric module optimization for high-temperature applications is currently in a growth phase, with the market expanding at approximately 8-10% annually and expected to reach $750 million by 2028. The competitive landscape features established industrial players like LG Innotek, Toshiba, and Kyocera dominating commercial applications, while specialized companies such as Hi-Z Technology and KELK Ltd. focus on niche high-temperature solutions. Research institutions including Industrial Technology Research Institute and Northwestern Polytechnical University are advancing fundamental technologies. Technical maturity varies significantly across application temperatures, with modules for moderate temperatures (200-400°C) being commercially viable, while solutions for extreme temperatures (>600°C) remain predominantly in research phases, creating opportunities for innovation in materials and manufacturing processes.

Toshiba Materials Co., Ltd.

Technical Solution: Toshiba Materials has developed advanced high-temperature thermoelectric modules based on their proprietary p-type and n-type skutterudite materials, optimized for waste heat recovery in industrial applications. Their technology utilizes a segmented leg design with different material compositions optimized for specific temperature ranges, enabling efficient operation across temperature gradients from 200°C to over 600°C. Toshiba's modules incorporate specialized diffusion barrier layers between the thermoelectric elements and electrodes, preventing harmful interdiffusion at elevated temperatures while maintaining low contact resistance. Their manufacturing process features precision hot-pressing techniques that achieve optimal density and microstructure control, resulting in thermoelectric materials with ZT values consistently above 1.2 at high temperatures. The modules employ a proprietary stress management system with engineered compliance structures that accommodate differential thermal expansion during operation, significantly reducing mechanical failures while maintaining electrical performance integrity over thousands of thermal cycles.

Strengths: Backed by Toshiba's extensive manufacturing infrastructure and quality control systems; proven reliability in industrial environments; comprehensive material-to-module development capabilities; strong intellectual property position. Weaknesses: Conservative design approach may limit maximum performance compared to some emerging technologies; higher initial cost compared to conventional heat exchangers; requires specialized system integration expertise for optimal implementation.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed an innovative high-temperature thermoelectric module optimization platform combining advanced materials science with precision manufacturing techniques. Their approach utilizes segmented leg structures with cascaded materials optimized for different temperature ranges, enabling efficient operation across broad temperature gradients (200-700°C). ITRI's technology incorporates rare-earth skutterudites and half-Heusler compounds with nano-inclusions that effectively scatter phonons while preserving electron transport, achieving ZT values of 1.3-1.8 at elevated temperatures. Their modules feature proprietary diffusion barrier layers that prevent interdiffusion between thermoelectric elements and electrodes at high temperatures, significantly enhancing long-term stability. ITRI has also pioneered stress-relief structures within module designs that accommodate differential thermal expansion, reducing mechanical failures during thermal cycling while maintaining excellent electrical contact resistance.

Strengths: Comprehensive materials-to-module development capability; strong intellectual property portfolio; extensive testing facilities for performance validation under realistic conditions; collaborative approach with industry partners for rapid commercialization. Weaknesses: Technology still transitioning from laboratory to full commercial scale; requires further optimization for cost-effective mass production; some material systems still dependent on critical raw materials with supply chain concerns.

Key Patents and Technical Breakthroughs in Thermoelectric Modules

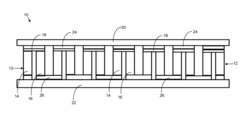

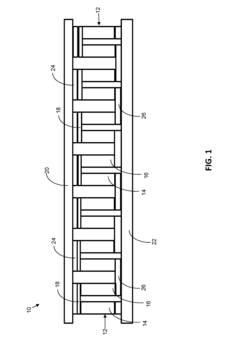

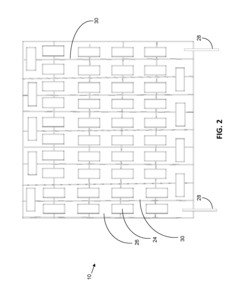

Large footprint, high power density thermoelectric modules for high temperature applications

PatentInactiveUS20160247996A1

Innovation

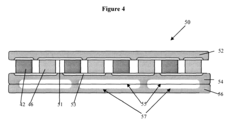

- A thermoelectric module design featuring a compliant thermal interface between a thermally conductive dielectric top common header and subheaders, allowing for larger dimensions and reduced thermal mismatch stress, combined with high-temperature thermoelectric materials and a segmented copper bus for series connection of P-N couples.

Glass-ceramic thermoelectric module

PatentInactiveEP1965446A1

Innovation

- A thermoelectric module utilizing glass-ceramic substrates with a low coefficient of thermal expansion (<10 x 10^-7/°C) and ductile conductors like silver or platinum alloys, which can withstand temperatures up to 1000°C, paired with p- and n-type materials, to minimize thermal mismatch and enhance heat-to-electrical energy conversion efficiency.

Thermal Management Strategies for Extreme Environments

Managing thermal challenges in extreme environments is critical for the successful implementation of thermoelectric modules in high-temperature applications. These environments, characterized by temperatures exceeding 500°C, require specialized thermal management strategies to ensure optimal performance and longevity of thermoelectric systems.

Active cooling mechanisms represent a primary approach for extreme thermal environments. Advanced liquid cooling systems utilizing high-temperature fluids such as molten salts or specialized synthetic oils can effectively dissipate heat from thermoelectric modules operating in extreme conditions. These systems often incorporate multi-stage heat exchangers designed to handle the substantial temperature differentials present in high-temperature applications.

Thermal isolation techniques constitute another essential strategy. Implementing advanced ceramic or composite materials with exceptionally low thermal conductivity creates effective thermal barriers between the heat source and sensitive components. Multi-layer insulation systems, incorporating vacuum gaps or aerogel-based materials, can significantly reduce thermal transfer in extreme temperature gradients.

Heat spreading technologies have evolved specifically for high-temperature thermoelectric applications. Diamond-based composites and advanced carbon materials offer superior thermal conductivity while maintaining structural integrity at elevated temperatures. These materials facilitate more uniform heat distribution across thermoelectric modules, preventing localized hotspots that could lead to thermal stress and premature failure.

Phase change materials (PCMs) engineered for high-temperature operation provide thermal buffering capabilities in fluctuating thermal environments. Silicon-carbide based PCMs and metallic alloys with high melting points can absorb substantial thermal energy during temperature spikes, releasing it gradually to maintain more consistent operating conditions for thermoelectric modules.

Adaptive thermal management systems represent the cutting edge of extreme environment solutions. These systems incorporate temperature-sensitive actuators and microcontrollers that dynamically adjust cooling parameters based on real-time thermal conditions. Machine learning algorithms can optimize these systems by predicting thermal behavior and preemptively adjusting cooling responses before critical thresholds are reached.

Radiation shielding becomes particularly important in aerospace and nuclear applications where thermoelectric modules face both extreme temperatures and radiation exposure. Multi-layer shields combining high-Z materials with thermal management layers protect sensitive semiconductor components while maintaining thermal performance parameters.

Active cooling mechanisms represent a primary approach for extreme thermal environments. Advanced liquid cooling systems utilizing high-temperature fluids such as molten salts or specialized synthetic oils can effectively dissipate heat from thermoelectric modules operating in extreme conditions. These systems often incorporate multi-stage heat exchangers designed to handle the substantial temperature differentials present in high-temperature applications.

Thermal isolation techniques constitute another essential strategy. Implementing advanced ceramic or composite materials with exceptionally low thermal conductivity creates effective thermal barriers between the heat source and sensitive components. Multi-layer insulation systems, incorporating vacuum gaps or aerogel-based materials, can significantly reduce thermal transfer in extreme temperature gradients.

Heat spreading technologies have evolved specifically for high-temperature thermoelectric applications. Diamond-based composites and advanced carbon materials offer superior thermal conductivity while maintaining structural integrity at elevated temperatures. These materials facilitate more uniform heat distribution across thermoelectric modules, preventing localized hotspots that could lead to thermal stress and premature failure.

Phase change materials (PCMs) engineered for high-temperature operation provide thermal buffering capabilities in fluctuating thermal environments. Silicon-carbide based PCMs and metallic alloys with high melting points can absorb substantial thermal energy during temperature spikes, releasing it gradually to maintain more consistent operating conditions for thermoelectric modules.

Adaptive thermal management systems represent the cutting edge of extreme environment solutions. These systems incorporate temperature-sensitive actuators and microcontrollers that dynamically adjust cooling parameters based on real-time thermal conditions. Machine learning algorithms can optimize these systems by predicting thermal behavior and preemptively adjusting cooling responses before critical thresholds are reached.

Radiation shielding becomes particularly important in aerospace and nuclear applications where thermoelectric modules face both extreme temperatures and radiation exposure. Multi-layer shields combining high-Z materials with thermal management layers protect sensitive semiconductor components while maintaining thermal performance parameters.

Material Science Innovations for Thermoelectric Performance

Recent advancements in material science have revolutionized thermoelectric performance for high-temperature applications. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) face significant limitations above 250°C, necessitating the development of novel compounds capable of withstanding extreme thermal conditions while maintaining efficiency.

Skutterudite-based materials have emerged as promising candidates, demonstrating remarkable thermal stability at temperatures exceeding 600°C. Their unique cage-like crystal structure allows for the incorporation of "rattler" atoms that effectively scatter phonons while minimally affecting electron transport, resulting in significantly reduced thermal conductivity. Recent innovations in filled skutterudites (CoSb₃) with rare earth elements have achieved ZT values approaching 1.4 at 550°C.

Half-Heusler alloys represent another breakthrough material class, offering exceptional mechanical strength and thermal stability. These intermetallic compounds, typically composed of XYZ elements (where X and Y are transition metals and Z is a main group element), exhibit ZT values of 1.0-1.2 at temperatures between 400-700°C. Recent compositional engineering efforts have focused on optimizing the power factor through band structure modifications.

Silicon-germanium (SiGe) alloys continue to demonstrate reliability in extreme temperature environments (800-1000°C), making them ideal for space applications and concentrated solar thermal systems. Nanostructuring techniques have substantially improved their thermoelectric performance by introducing phonon-scattering interfaces while preserving electrical conductivity.

Oxide-based thermoelectrics, particularly layered cobaltites like Ca₃Co₄O₉, have gained attention for their exceptional oxidation resistance and thermal stability above 900°C. While their ZT values remain modest (0.3-0.5), their chemical stability and abundance make them attractive for industrial waste heat recovery applications where durability outweighs peak efficiency.

Advanced manufacturing techniques have further enhanced material performance through precise microstructural control. Spark plasma sintering enables the creation of dense nanostructured materials with optimized grain boundaries that selectively scatter phonons. Meanwhile, molecular beam epitaxy allows for atomic-level control of superlattice structures, creating quantum confinement effects that enhance the Seebeck coefficient.

The integration of 2D materials like graphene and transition metal dichalcogenides as nanoinclusions has demonstrated promising results in disrupting thermal transport pathways while preserving electrical conductivity. These hybrid materials represent a frontier in thermoelectric research, potentially enabling ZT values exceeding 2.0 at operational temperatures above 500°C.

Skutterudite-based materials have emerged as promising candidates, demonstrating remarkable thermal stability at temperatures exceeding 600°C. Their unique cage-like crystal structure allows for the incorporation of "rattler" atoms that effectively scatter phonons while minimally affecting electron transport, resulting in significantly reduced thermal conductivity. Recent innovations in filled skutterudites (CoSb₃) with rare earth elements have achieved ZT values approaching 1.4 at 550°C.

Half-Heusler alloys represent another breakthrough material class, offering exceptional mechanical strength and thermal stability. These intermetallic compounds, typically composed of XYZ elements (where X and Y are transition metals and Z is a main group element), exhibit ZT values of 1.0-1.2 at temperatures between 400-700°C. Recent compositional engineering efforts have focused on optimizing the power factor through band structure modifications.

Silicon-germanium (SiGe) alloys continue to demonstrate reliability in extreme temperature environments (800-1000°C), making them ideal for space applications and concentrated solar thermal systems. Nanostructuring techniques have substantially improved their thermoelectric performance by introducing phonon-scattering interfaces while preserving electrical conductivity.

Oxide-based thermoelectrics, particularly layered cobaltites like Ca₃Co₄O₉, have gained attention for their exceptional oxidation resistance and thermal stability above 900°C. While their ZT values remain modest (0.3-0.5), their chemical stability and abundance make them attractive for industrial waste heat recovery applications where durability outweighs peak efficiency.

Advanced manufacturing techniques have further enhanced material performance through precise microstructural control. Spark plasma sintering enables the creation of dense nanostructured materials with optimized grain boundaries that selectively scatter phonons. Meanwhile, molecular beam epitaxy allows for atomic-level control of superlattice structures, creating quantum confinement effects that enhance the Seebeck coefficient.

The integration of 2D materials like graphene and transition metal dichalcogenides as nanoinclusions has demonstrated promising results in disrupting thermal transport pathways while preserving electrical conductivity. These hybrid materials represent a frontier in thermoelectric research, potentially enabling ZT values exceeding 2.0 at operational temperatures above 500°C.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!