Research on Thermoelectric Module Integration in Wearable Devices

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Integration Goals

Thermoelectric technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect, which demonstrated that temperature differences between two dissimilar electrical conductors can produce voltage. The subsequent discovery of the Peltier effect in 1834 established the foundation for modern thermoelectric cooling and power generation applications. Over the past two decades, thermoelectric technology has transitioned from bulky, inefficient systems to increasingly miniaturized and efficient modules suitable for integration into portable and wearable devices.

The evolution of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which determines conversion efficiency. Traditional bismuth telluride (Bi2Te3) compounds have been the commercial standard for near-room-temperature applications, but recent advancements in nanostructured materials, quantum dot superlattices, and skutterudites have pushed ZT values from approximately 1.0 to exceeding 2.0 in laboratory settings, significantly enhancing potential efficiency.

Manufacturing techniques have similarly progressed from basic bulk material processing to sophisticated thin-film deposition, printing technologies, and MEMS fabrication approaches. These advancements have enabled the production of flexible thermoelectric modules with thicknesses below 1mm, making them increasingly suitable for wearable applications. The miniaturization trend has been accompanied by improvements in thermal interface materials and interconnect technologies that enhance overall system performance.

The primary integration goal for thermoelectric modules in wearable devices is to develop self-powered systems that can harvest body heat to extend battery life or potentially eliminate the need for conventional batteries altogether. This requires achieving power densities of 1-10 mW/cm² at body-ambient temperature differentials of typically 5-15°C, a challenging target given the limited temperature gradient available in wearable scenarios.

Secondary integration goals include developing modules that are mechanically flexible to conform to body contours, biocompatible for long-term skin contact, and sufficiently durable to withstand the mechanical stresses of daily wear. Weight and thickness constraints are particularly stringent, with target specifications of less than 2mm thickness and weights below 5g/cm² to ensure user comfort and adoption.

From a manufacturing perspective, integration goals focus on developing scalable production methods compatible with existing wearable device assembly processes, while maintaining costs below $5 per module to enable mass-market adoption. Environmental considerations are increasingly important, with efforts directed toward reducing or eliminating toxic elements like tellurium and lead from thermoelectric materials, and developing end-of-life recycling protocols.

The evolution of thermoelectric materials has been marked by continuous improvements in the figure of merit (ZT), which determines conversion efficiency. Traditional bismuth telluride (Bi2Te3) compounds have been the commercial standard for near-room-temperature applications, but recent advancements in nanostructured materials, quantum dot superlattices, and skutterudites have pushed ZT values from approximately 1.0 to exceeding 2.0 in laboratory settings, significantly enhancing potential efficiency.

Manufacturing techniques have similarly progressed from basic bulk material processing to sophisticated thin-film deposition, printing technologies, and MEMS fabrication approaches. These advancements have enabled the production of flexible thermoelectric modules with thicknesses below 1mm, making them increasingly suitable for wearable applications. The miniaturization trend has been accompanied by improvements in thermal interface materials and interconnect technologies that enhance overall system performance.

The primary integration goal for thermoelectric modules in wearable devices is to develop self-powered systems that can harvest body heat to extend battery life or potentially eliminate the need for conventional batteries altogether. This requires achieving power densities of 1-10 mW/cm² at body-ambient temperature differentials of typically 5-15°C, a challenging target given the limited temperature gradient available in wearable scenarios.

Secondary integration goals include developing modules that are mechanically flexible to conform to body contours, biocompatible for long-term skin contact, and sufficiently durable to withstand the mechanical stresses of daily wear. Weight and thickness constraints are particularly stringent, with target specifications of less than 2mm thickness and weights below 5g/cm² to ensure user comfort and adoption.

From a manufacturing perspective, integration goals focus on developing scalable production methods compatible with existing wearable device assembly processes, while maintaining costs below $5 per module to enable mass-market adoption. Environmental considerations are increasingly important, with efforts directed toward reducing or eliminating toxic elements like tellurium and lead from thermoelectric materials, and developing end-of-life recycling protocols.

Market Demand for Self-Powered Wearable Devices

The wearable device market has experienced exponential growth over the past decade, with global revenues reaching $61.3 billion in 2022 and projected to surpass $165 billion by 2028. Within this expanding ecosystem, self-powered wearable devices represent a particularly promising segment, addressing one of the most significant pain points for users: battery life and charging requirements.

Consumer research indicates that approximately 74% of wearable device users cite battery limitations as their primary frustration, with 68% expressing strong interest in devices that could operate without regular charging. This demand is especially pronounced in healthcare monitoring applications, where continuous operation is critical for collecting reliable biometric data.

The healthcare wearables sector, valued at $18.9 billion in 2022, demonstrates particularly strong demand for self-powered solutions. Medical professionals and patients alike require devices that can function reliably for extended periods without interruption, especially for monitoring chronic conditions such as diabetes, cardiovascular disease, and sleep disorders.

Athletic and fitness markets also show substantial interest in self-powered wearables. Professional sports teams and serious athletes increasingly rely on continuous biometric monitoring during training and competition, creating demand for devices that can operate throughout multi-day events without charging interruptions.

Consumer convenience represents another significant market driver. Industry surveys reveal that 82% of potential wearable device customers consider charging requirements when making purchasing decisions, with 57% indicating they would pay a premium of 15-30% for devices with significantly reduced charging needs or self-powering capabilities.

The military and industrial sectors present additional high-value market opportunities for self-powered wearables. These environments often lack convenient charging infrastructure while requiring reliable operation in remote or hazardous conditions. Military applications alone represent a $3.7 billion market segment for specialized wearable technology.

Geographically, North America and Europe currently demonstrate the highest demand for self-powered wearable solutions, though the Asia-Pacific region shows the fastest growth rate at 24.3% annually, driven by rapid technology adoption in China, Japan, and South Korea.

Market forecasts indicate that thermoelectric energy harvesting specifically could capture 27% of the self-powered wearables market by 2026, representing a significant opportunity for companies developing this technology. This growth is supported by increasing consumer environmental consciousness, with 63% of surveyed consumers expressing preference for sustainable, energy-efficient wearable solutions.

Consumer research indicates that approximately 74% of wearable device users cite battery limitations as their primary frustration, with 68% expressing strong interest in devices that could operate without regular charging. This demand is especially pronounced in healthcare monitoring applications, where continuous operation is critical for collecting reliable biometric data.

The healthcare wearables sector, valued at $18.9 billion in 2022, demonstrates particularly strong demand for self-powered solutions. Medical professionals and patients alike require devices that can function reliably for extended periods without interruption, especially for monitoring chronic conditions such as diabetes, cardiovascular disease, and sleep disorders.

Athletic and fitness markets also show substantial interest in self-powered wearables. Professional sports teams and serious athletes increasingly rely on continuous biometric monitoring during training and competition, creating demand for devices that can operate throughout multi-day events without charging interruptions.

Consumer convenience represents another significant market driver. Industry surveys reveal that 82% of potential wearable device customers consider charging requirements when making purchasing decisions, with 57% indicating they would pay a premium of 15-30% for devices with significantly reduced charging needs or self-powering capabilities.

The military and industrial sectors present additional high-value market opportunities for self-powered wearables. These environments often lack convenient charging infrastructure while requiring reliable operation in remote or hazardous conditions. Military applications alone represent a $3.7 billion market segment for specialized wearable technology.

Geographically, North America and Europe currently demonstrate the highest demand for self-powered wearable solutions, though the Asia-Pacific region shows the fastest growth rate at 24.3% annually, driven by rapid technology adoption in China, Japan, and South Korea.

Market forecasts indicate that thermoelectric energy harvesting specifically could capture 27% of the self-powered wearables market by 2026, representing a significant opportunity for companies developing this technology. This growth is supported by increasing consumer environmental consciousness, with 63% of surveyed consumers expressing preference for sustainable, energy-efficient wearable solutions.

Current Challenges in Thermoelectric Module Miniaturization

The integration of thermoelectric modules (TEMs) into wearable devices presents significant miniaturization challenges that currently impede widespread commercial adoption. Conventional TEMs typically measure several millimeters in thickness and centimeters in lateral dimensions, making them incompatible with the form factor requirements of modern wearable technology. This size constraint represents a fundamental barrier to effective integration, as wearables demand components that are not only small but also lightweight and flexible.

Material limitations constitute another critical challenge. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) offer reasonable efficiency but present difficulties in scaling down to micro-dimensions while maintaining performance. When miniaturized, these materials often experience substantial decreases in the figure of merit (ZT), resulting in reduced conversion efficiency. Additionally, many high-performance thermoelectric materials contain toxic or rare elements, raising concerns about sustainability and biocompatibility in wearable applications.

Thermal management represents a persistent obstacle in miniaturized TEM design. The effectiveness of thermoelectric generation depends on maintaining temperature differentials across the module, which becomes increasingly difficult as device dimensions shrink. The human body's natural thermal regulation mechanisms tend to equalize temperatures rapidly, diminishing the available thermal gradient. Furthermore, miniaturized TEMs must contend with increased thermal resistance and parasitic heat flows that can significantly reduce energy harvesting capabilities.

Manufacturing scalability presents substantial technical hurdles. Current fabrication techniques for micro-scale TEMs often involve complex, multi-step processes that are difficult to scale for mass production. Techniques such as thin-film deposition, microfabrication, and precision assembly require specialized equipment and expertise, driving up production costs. The yield rates for miniaturized TEMs remain suboptimal, further complicating commercial viability.

Mechanical durability poses another significant challenge. Wearable devices undergo constant mechanical stress through bending, stretching, and compression during normal use. Miniaturized TEMs must withstand these forces while maintaining electrical connections and thermal interfaces. Traditional thermoelectric materials are inherently brittle, and the numerous interconnects in miniaturized designs create multiple potential failure points under mechanical strain.

Power output limitations remain a fundamental constraint. As TEMs decrease in size, their power generation capacity diminishes proportionally. Current miniaturized TEMs typically generate power in the microwatt to milliwatt range, which is insufficient for many wearable applications beyond low-power sensing. This output limitation restricts the potential applications and value proposition of thermoelectric-powered wearables in the consumer market.

Integration with flexible substrates presents additional complexity. Achieving conformable, skin-compatible thermoelectric modules requires novel approaches to module design and interconnection. The mismatch in mechanical properties between rigid thermoelectric elements and flexible substrates creates stress concentrations that can lead to premature device failure or performance degradation over time.

Material limitations constitute another critical challenge. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) offer reasonable efficiency but present difficulties in scaling down to micro-dimensions while maintaining performance. When miniaturized, these materials often experience substantial decreases in the figure of merit (ZT), resulting in reduced conversion efficiency. Additionally, many high-performance thermoelectric materials contain toxic or rare elements, raising concerns about sustainability and biocompatibility in wearable applications.

Thermal management represents a persistent obstacle in miniaturized TEM design. The effectiveness of thermoelectric generation depends on maintaining temperature differentials across the module, which becomes increasingly difficult as device dimensions shrink. The human body's natural thermal regulation mechanisms tend to equalize temperatures rapidly, diminishing the available thermal gradient. Furthermore, miniaturized TEMs must contend with increased thermal resistance and parasitic heat flows that can significantly reduce energy harvesting capabilities.

Manufacturing scalability presents substantial technical hurdles. Current fabrication techniques for micro-scale TEMs often involve complex, multi-step processes that are difficult to scale for mass production. Techniques such as thin-film deposition, microfabrication, and precision assembly require specialized equipment and expertise, driving up production costs. The yield rates for miniaturized TEMs remain suboptimal, further complicating commercial viability.

Mechanical durability poses another significant challenge. Wearable devices undergo constant mechanical stress through bending, stretching, and compression during normal use. Miniaturized TEMs must withstand these forces while maintaining electrical connections and thermal interfaces. Traditional thermoelectric materials are inherently brittle, and the numerous interconnects in miniaturized designs create multiple potential failure points under mechanical strain.

Power output limitations remain a fundamental constraint. As TEMs decrease in size, their power generation capacity diminishes proportionally. Current miniaturized TEMs typically generate power in the microwatt to milliwatt range, which is insufficient for many wearable applications beyond low-power sensing. This output limitation restricts the potential applications and value proposition of thermoelectric-powered wearables in the consumer market.

Integration with flexible substrates presents additional complexity. Achieving conformable, skin-compatible thermoelectric modules requires novel approaches to module design and interconnection. The mismatch in mechanical properties between rigid thermoelectric elements and flexible substrates creates stress concentrations that can lead to premature device failure or performance degradation over time.

Existing Thermoelectric Integration Approaches

01 Thermoelectric module structure and materials

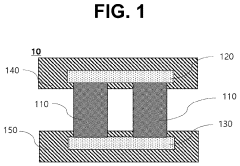

Thermoelectric modules are constructed with specific materials and structural designs to optimize energy conversion efficiency. These modules typically consist of p-type and n-type semiconductor materials arranged in arrays and connected electrically in series and thermally in parallel. Advanced material compositions, including bismuth telluride compounds and other semiconductor alloys, are used to enhance the Seebeck coefficient and reduce thermal conductivity, thereby improving the figure of merit (ZT) of the module.- Thermoelectric module structure and materials: Thermoelectric modules are constructed with specific materials and structural designs to optimize energy conversion efficiency. These modules typically consist of p-type and n-type semiconductor materials arranged in pairs and connected electrically in series but thermally in parallel. The selection of semiconductor materials with high Seebeck coefficients and low thermal conductivity is crucial for maximizing the thermoelectric figure of merit (ZT). Advanced structural designs may include multi-layer configurations or nano-structured materials to enhance performance.

- Cooling and temperature control applications: Thermoelectric modules are widely used for precise temperature control and cooling applications. By applying an electric current to the module, heat can be pumped from one side to the other, creating a temperature differential (Peltier effect). This enables applications in electronic device cooling, refrigeration without moving parts, temperature-controlled scientific equipment, and medical devices. These solid-state cooling solutions offer advantages such as compact size, no moving parts, and precise temperature control capabilities.

- Power generation from waste heat: Thermoelectric modules can convert waste heat into useful electrical energy through the Seebeck effect. When a temperature gradient is applied across the module, it generates an electrical voltage that can be harnessed. This capability is particularly valuable for recovering waste heat from industrial processes, vehicle exhaust systems, and other heat-producing applications. The efficiency of power generation depends on the temperature differential and the thermoelectric properties of the materials used in the module.

- Manufacturing and assembly techniques: Specialized manufacturing and assembly techniques are employed to produce high-performance thermoelectric modules. These include methods for creating electrical connections between thermoelectric elements, bonding techniques for attaching elements to ceramic substrates, and processes for ensuring thermal isolation between hot and cold sides. Advanced manufacturing approaches may incorporate automated assembly, precision deposition of materials, and quality control measures to ensure consistent performance and reliability of the modules.

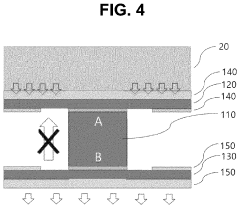

- Integration with other systems and performance enhancement: Thermoelectric modules are often integrated with other systems to enhance overall performance and functionality. This includes combination with heat exchangers, thermal interface materials, and electronic control systems. Performance enhancement strategies involve optimizing thermal management, reducing contact resistance, and implementing advanced control algorithms. Integration approaches may also include hybrid systems that combine thermoelectric modules with other energy conversion technologies to achieve higher efficiency or specific operational characteristics.

02 Cooling and temperature management systems

Thermoelectric modules are utilized in cooling applications where precise temperature control is required. These systems leverage the Peltier effect to create temperature differentials when electrical current is applied. The modules can be integrated into various cooling systems including electronic device cooling, refrigeration units, and climate control systems. Efficient heat dissipation mechanisms, such as heat sinks and thermal interface materials, are crucial components that work alongside thermoelectric modules to manage temperature and improve overall system performance.Expand Specific Solutions03 Energy harvesting applications

Thermoelectric modules can convert waste heat into usable electrical energy through the Seebeck effect. These energy harvesting applications are particularly valuable in industrial settings, automotive exhaust systems, and remote power generation. By capturing temperature differentials between hot and cold surfaces, thermoelectric generators produce electricity without moving parts, offering reliable power generation for low-power electronics and sensors in environments where conventional power sources are impractical.Expand Specific Solutions04 Manufacturing and assembly techniques

Advanced manufacturing and assembly techniques are essential for producing high-performance thermoelectric modules. These include precision deposition methods, micro-fabrication processes, and specialized bonding techniques to create reliable electrical and thermal connections between components. Innovations in manufacturing processes focus on improving contact resistance, ensuring uniform heat distribution, and enhancing mechanical stability to withstand thermal cycling. Automated assembly methods and quality control procedures help maintain consistency and reliability in module production.Expand Specific Solutions05 Integration with electronic devices and systems

Thermoelectric modules are increasingly integrated into electronic devices and systems for various applications. These include thermal management of processors and other heat-generating components, temperature-controlled storage for sensitive materials, and wearable cooling or heating devices. Integration challenges involve miniaturization, power management, and compatibility with existing electronic systems. Advanced control circuits and sensors are often incorporated to optimize the performance of thermoelectric modules based on real-time temperature and power requirements.Expand Specific Solutions

Leading Companies in Wearable Thermoelectric Solutions

The thermoelectric module integration in wearable devices market is currently in its growth phase, with increasing adoption across healthcare and consumer electronics sectors. The global market size is estimated to reach $175 million by 2027, growing at a CAGR of approximately 9.5%. Technologically, the field is advancing from early-stage development toward commercial maturity, with companies at varying levels of innovation. Leading players like LG Innotek and Samsung Electro Mechanics are leveraging their electronics expertise to develop miniaturized, efficient modules, while research-focused organizations such as IMEC and Korea Electrotechnology Research Institute are advancing fundamental technologies. Specialized firms like Embr Labs and Thermogentech are creating application-specific solutions, while established electronics manufacturers including Panasonic, Murata, and TDK are integrating thermoelectric capabilities into their broader product ecosystems.

Stichting IMEC Nederland

Technical Solution: IMEC has developed an advanced thermoelectric module integration platform for wearable applications that focuses on ultra-low power operation and miniaturization. Their technology utilizes silicon-based MEMS fabrication techniques to create highly integrated thermoelectric structures with feature sizes below 10 micrometers. This approach enables unprecedented integration density and thermal response times. IMEC's solution incorporates novel semiconductor materials including silicon-germanium superlattices and skutterudite compounds that offer improved figure of merit (ZT) values compared to conventional bismuth telluride. Their platform includes specialized thermal interface materials that maximize heat transfer between the skin and the thermoelectric elements while maintaining wearer comfort. IMEC has pioneered advanced power management circuitry that enables dynamic adjustment of thermoelectric operation based on activity levels and environmental conditions. Their technology also features wireless power transfer capabilities specifically optimized for wearable thermoelectric applications, eliminating the need for bulky batteries in certain use cases. The platform includes comprehensive sensor integration for closed-loop temperature control and physiological monitoring.

Strengths: Cutting-edge semiconductor fabrication techniques enabling extreme miniaturization; excellent integration with other electronic components; superior power efficiency compared to conventional thermoelectric modules; strong intellectual property portfolio. Weaknesses: Higher manufacturing complexity requiring specialized fabrication facilities; currently higher cost than conventional approaches; limited to smaller temperature differentials compared to bulk thermoelectric materials.

Embr Labs Ip LLC

Technical Solution: Embr Labs has developed a proprietary thermoelectric module integration system specifically designed for wearable devices that focuses on personal thermal comfort. Their flagship technology, the Embr Wave wristband, utilizes precision thermoelectric cooling and heating elements that create cooling or warming sensations on the wearer's wrist. The system employs advanced thermal algorithms that dynamically adjust temperature output based on user preferences and environmental conditions. Their patented design incorporates miniaturized Peltier elements arranged in a curved configuration to maximize skin contact while maintaining flexibility. The technology includes thermal spreading techniques to distribute temperature sensations effectively across the skin's thermoreceptors, triggering the body's natural thermoregulation response without changing core body temperature. Embr's solution also features advanced power management systems that optimize battery life while delivering meaningful thermal sensations, with typical operation lasting 2-3 days on a single charge.

Strengths: Highly specialized in thermal comfort wearables with proven market products; excellent miniaturization of thermoelectric components; sophisticated thermal algorithms for personalized experiences. Weaknesses: Limited to comfort applications rather than medical or industrial uses; relatively high power consumption compared to passive wearables; thermal effects are localized rather than whole-body.

Key Patents in Wearable Thermoelectric Technology

Bidirectional stretchable and flexible wearable thermoelectric module

PatentActiveUS11839157B2

Innovation

- A stretchable and flexible thermoelectric module is developed, comprising deformable electrodes and elastic composites with metal nano materials, allowing for both heating and cooling by reversing current direction, and featuring a specific electrode structure for improved thermal conductivity and mechanical flexibility.

Wearable thermoelectric device

PatentInactiveKR1020170048657A

Innovation

- A wearable thermoelectric device with an air pocket forming member, such as linear objects or fibers, is installed on the body-facing surface to trap air and prevent thermal energy loss, enhancing thermal energy transfer to the thermoelectric module.

Energy Harvesting Efficiency Optimization

Optimizing energy harvesting efficiency represents a critical challenge in thermoelectric module integration for wearable devices. Current thermoelectric generators (TEGs) in wearable applications typically demonstrate conversion efficiencies ranging from 1-5%, significantly lower than theoretical maximums. This efficiency gap stems from multiple factors including thermal interface resistance, heat flux limitations across the human body-device boundary, and size constraints inherent to wearable form factors.

Material selection plays a fundamental role in efficiency optimization. Advanced bismuth telluride (Bi₂Te₃) compounds with nanostructured modifications have demonstrated improved figure of merit (ZT) values approaching 1.5 at room temperature, compared to conventional materials with ZT values of 0.8-1.0. Recent research incorporating skutterudite and half-Heusler alloys shows promising results for body-temperature range applications, potentially increasing conversion efficiency by 15-20%.

Thermal management strategies significantly impact harvesting performance. Implementation of optimized heat spreaders and thermal interface materials can reduce thermal resistance by up to 40%. Novel flexible thermal conductors utilizing graphene and carbon nanotube composites have demonstrated thermal conductivity improvements of 35-60% while maintaining the flexibility required for wearable applications. These advancements help maximize temperature differentials across the thermoelectric elements.

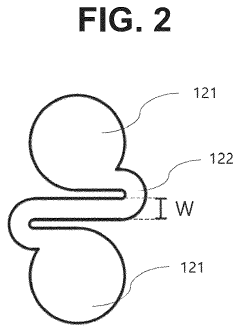

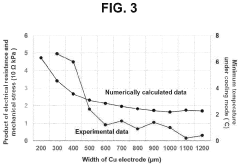

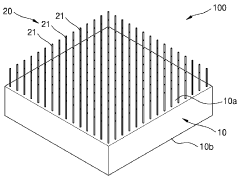

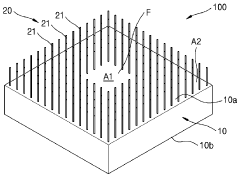

Geometric optimization of thermoelectric modules presents another efficiency frontier. Research indicates that reducing thermoelectric leg dimensions to micro-scale (50-200μm) can enhance power density by 30-45% compared to conventional millimeter-scale elements. Additionally, optimized aspect ratios between 2:1 and 3:1 (height:width) have demonstrated superior performance in body-heat harvesting scenarios, balancing internal resistance with thermal gradient maintenance.

Circuit integration techniques further enhance system-level efficiency. Maximum power point tracking (MPPT) circuits specifically designed for low-voltage TEG outputs have shown 25-40% improvements in harvested energy compared to direct coupling approaches. Ultra-low power DC-DC converters with sub-threshold operation capabilities now achieve conversion efficiencies exceeding 80% even at the microwatt power levels typical of body-heat harvesting.

Hybrid energy harvesting approaches that combine thermoelectric generation with complementary technologies such as piezoelectric or photovoltaic elements demonstrate particular promise. Recent prototypes implementing such hybrid systems have achieved 50-70% increases in total energy capture compared to thermoelectric-only solutions, while maintaining form factors suitable for wearable applications.

Material selection plays a fundamental role in efficiency optimization. Advanced bismuth telluride (Bi₂Te₃) compounds with nanostructured modifications have demonstrated improved figure of merit (ZT) values approaching 1.5 at room temperature, compared to conventional materials with ZT values of 0.8-1.0. Recent research incorporating skutterudite and half-Heusler alloys shows promising results for body-temperature range applications, potentially increasing conversion efficiency by 15-20%.

Thermal management strategies significantly impact harvesting performance. Implementation of optimized heat spreaders and thermal interface materials can reduce thermal resistance by up to 40%. Novel flexible thermal conductors utilizing graphene and carbon nanotube composites have demonstrated thermal conductivity improvements of 35-60% while maintaining the flexibility required for wearable applications. These advancements help maximize temperature differentials across the thermoelectric elements.

Geometric optimization of thermoelectric modules presents another efficiency frontier. Research indicates that reducing thermoelectric leg dimensions to micro-scale (50-200μm) can enhance power density by 30-45% compared to conventional millimeter-scale elements. Additionally, optimized aspect ratios between 2:1 and 3:1 (height:width) have demonstrated superior performance in body-heat harvesting scenarios, balancing internal resistance with thermal gradient maintenance.

Circuit integration techniques further enhance system-level efficiency. Maximum power point tracking (MPPT) circuits specifically designed for low-voltage TEG outputs have shown 25-40% improvements in harvested energy compared to direct coupling approaches. Ultra-low power DC-DC converters with sub-threshold operation capabilities now achieve conversion efficiencies exceeding 80% even at the microwatt power levels typical of body-heat harvesting.

Hybrid energy harvesting approaches that combine thermoelectric generation with complementary technologies such as piezoelectric or photovoltaic elements demonstrate particular promise. Recent prototypes implementing such hybrid systems have achieved 50-70% increases in total energy capture compared to thermoelectric-only solutions, while maintaining form factors suitable for wearable applications.

Thermal Management Strategies for Body-Worn Devices

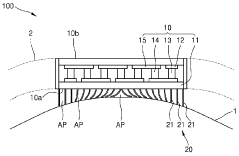

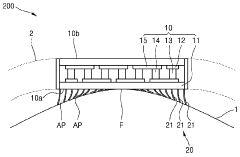

Effective thermal management is critical for the successful integration of thermoelectric modules in wearable devices. As these devices operate in direct contact with human skin, they face unique challenges related to heat dissipation, user comfort, and power efficiency. The primary thermal management challenge stems from the limited surface area available for heat exchange and the necessity to maintain skin-contact temperatures within safe and comfortable ranges (typically 35-40°C).

Several strategies have emerged to address these thermal constraints. Passive cooling techniques utilize materials with high thermal conductivity to efficiently spread heat across larger surface areas. These include the integration of graphene sheets, carbon fiber composites, and specialized thermal interface materials that maximize heat transfer while maintaining flexibility. Such materials can be strategically placed between the thermoelectric module and the external environment to facilitate heat dissipation without adding significant bulk.

Active cooling approaches incorporate miniaturized heat sinks, often made from aluminum or copper alloys with optimized fin designs. These components can be combined with micro-fans or fluid-based cooling systems for enhanced thermal performance. Recent innovations include phase-change materials (PCMs) that absorb excess heat during peak operation and release it gradually when the device load decreases, effectively smoothing thermal fluctuations.

Thermal isolation techniques represent another important strategy, particularly for devices that generate localized heat. By implementing thermal barriers between hot components and skin-contact surfaces, designers can redirect heat flow away from the user. Aerogel-based insulators and vacuum-gap structures have shown promising results in this regard, offering exceptional thermal resistance in ultra-thin form factors suitable for wearable applications.

Computational thermal modeling has become an essential tool in optimizing these strategies. Advanced simulation techniques allow designers to predict temperature distributions across complex geometries and material interfaces, enabling iterative refinement before physical prototyping. These models increasingly incorporate bioheat transfer equations to account for the unique thermal characteristics of human tissue, including blood perfusion effects and metabolic heat generation.

Adaptive thermal management systems represent the cutting edge of this field, using temperature sensors and microcontrollers to dynamically adjust cooling parameters based on activity levels, environmental conditions, and user preferences. These systems can modulate the power supplied to thermoelectric modules or adjust the operation of auxiliary cooling components to maintain optimal thermal conditions while minimizing energy consumption.

Several strategies have emerged to address these thermal constraints. Passive cooling techniques utilize materials with high thermal conductivity to efficiently spread heat across larger surface areas. These include the integration of graphene sheets, carbon fiber composites, and specialized thermal interface materials that maximize heat transfer while maintaining flexibility. Such materials can be strategically placed between the thermoelectric module and the external environment to facilitate heat dissipation without adding significant bulk.

Active cooling approaches incorporate miniaturized heat sinks, often made from aluminum or copper alloys with optimized fin designs. These components can be combined with micro-fans or fluid-based cooling systems for enhanced thermal performance. Recent innovations include phase-change materials (PCMs) that absorb excess heat during peak operation and release it gradually when the device load decreases, effectively smoothing thermal fluctuations.

Thermal isolation techniques represent another important strategy, particularly for devices that generate localized heat. By implementing thermal barriers between hot components and skin-contact surfaces, designers can redirect heat flow away from the user. Aerogel-based insulators and vacuum-gap structures have shown promising results in this regard, offering exceptional thermal resistance in ultra-thin form factors suitable for wearable applications.

Computational thermal modeling has become an essential tool in optimizing these strategies. Advanced simulation techniques allow designers to predict temperature distributions across complex geometries and material interfaces, enabling iterative refinement before physical prototyping. These models increasingly incorporate bioheat transfer equations to account for the unique thermal characteristics of human tissue, including blood perfusion effects and metabolic heat generation.

Adaptive thermal management systems represent the cutting edge of this field, using temperature sensors and microcontrollers to dynamically adjust cooling parameters based on activity levels, environmental conditions, and user preferences. These systems can modulate the power supplied to thermoelectric modules or adjust the operation of auxiliary cooling components to maintain optimal thermal conditions while minimizing energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!