Why Thermoelectric Module Enables Miniaturized Energy Harvesting

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Energy Harvesting Background and Objectives

Thermoelectric energy harvesting represents a significant advancement in sustainable energy technology, with roots dating back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect in 1821. This phenomenon, where temperature differences are directly converted into electrical voltage, has evolved from a scientific curiosity into a practical energy solution over the past two centuries. The technology has seen accelerated development particularly since the 1950s with the introduction of semiconductor materials, and further advancement in the 1990s with the emergence of nano-structured thermoelectric materials.

The evolution of thermoelectric technology has been characterized by continuous improvements in conversion efficiency, material performance, and manufacturing techniques. Modern thermoelectric modules utilize advanced semiconductor materials such as bismuth telluride, lead telluride, and silicon-germanium alloys, each optimized for specific temperature ranges and applications. The figure of merit (ZT), which measures thermoelectric material efficiency, has improved from less than 1.0 in traditional materials to exceeding 2.0 in some laboratory-developed nanostructured materials.

The miniaturization trend in thermoelectric energy harvesting aligns with broader technological shifts toward smaller, more efficient electronic devices. This trend is driven by advancements in thin-film deposition techniques, microfabrication processes, and novel material compositions that maintain performance at reduced scales. The development of flexible thermoelectric generators (TEGs) represents another significant innovation, enabling integration into wearable devices and curved surfaces.

The primary objective of thermoelectric energy harvesting technology is to efficiently convert waste heat into usable electrical energy at increasingly smaller scales. This includes capturing low-grade heat (typically below 200°C) from industrial processes, automotive exhaust systems, electronic devices, and even the human body. Specific technical goals include improving the power density of thermoelectric modules, enhancing conversion efficiency at lower temperature differentials, and reducing manufacturing costs to enable widespread commercial adoption.

Looking forward, the technology trajectory points toward further miniaturization, with research focused on micro and nano-scale thermoelectric generators capable of powering wireless sensor networks, Internet of Things (IoT) devices, and medical implants. The integration of thermoelectric harvesting with other energy sources in hybrid systems represents another promising direction, potentially addressing the intermittency issues common to many renewable energy technologies.

The ultimate vision for miniaturized thermoelectric energy harvesting is to create self-powered electronic systems that can operate indefinitely by scavenging ambient thermal energy, thereby eliminating the need for battery replacement and reducing electronic waste while enabling new applications in remote monitoring, healthcare, and environmental sensing.

The evolution of thermoelectric technology has been characterized by continuous improvements in conversion efficiency, material performance, and manufacturing techniques. Modern thermoelectric modules utilize advanced semiconductor materials such as bismuth telluride, lead telluride, and silicon-germanium alloys, each optimized for specific temperature ranges and applications. The figure of merit (ZT), which measures thermoelectric material efficiency, has improved from less than 1.0 in traditional materials to exceeding 2.0 in some laboratory-developed nanostructured materials.

The miniaturization trend in thermoelectric energy harvesting aligns with broader technological shifts toward smaller, more efficient electronic devices. This trend is driven by advancements in thin-film deposition techniques, microfabrication processes, and novel material compositions that maintain performance at reduced scales. The development of flexible thermoelectric generators (TEGs) represents another significant innovation, enabling integration into wearable devices and curved surfaces.

The primary objective of thermoelectric energy harvesting technology is to efficiently convert waste heat into usable electrical energy at increasingly smaller scales. This includes capturing low-grade heat (typically below 200°C) from industrial processes, automotive exhaust systems, electronic devices, and even the human body. Specific technical goals include improving the power density of thermoelectric modules, enhancing conversion efficiency at lower temperature differentials, and reducing manufacturing costs to enable widespread commercial adoption.

Looking forward, the technology trajectory points toward further miniaturization, with research focused on micro and nano-scale thermoelectric generators capable of powering wireless sensor networks, Internet of Things (IoT) devices, and medical implants. The integration of thermoelectric harvesting with other energy sources in hybrid systems represents another promising direction, potentially addressing the intermittency issues common to many renewable energy technologies.

The ultimate vision for miniaturized thermoelectric energy harvesting is to create self-powered electronic systems that can operate indefinitely by scavenging ambient thermal energy, thereby eliminating the need for battery replacement and reducing electronic waste while enabling new applications in remote monitoring, healthcare, and environmental sensing.

Market Analysis for Miniaturized Energy Harvesting Solutions

The global market for miniaturized energy harvesting solutions is experiencing robust growth, driven by the proliferation of Internet of Things (IoT) devices, wearable technology, and autonomous sensors. Current market valuations indicate that the miniaturized energy harvesting sector reached approximately $460 million in 2022, with projections suggesting a compound annual growth rate of 13.2% through 2028, potentially reaching $980 million by that time.

Thermoelectric modules represent a significant segment within this market, accounting for roughly 24% of the total miniaturized energy harvesting solutions. Their appeal stems from their ability to convert waste heat into usable electricity without moving parts, offering reliability and longevity advantages over alternative technologies.

Consumer electronics remains the largest application sector, constituting 38% of the market share, followed by industrial automation at 27%, healthcare devices at 19%, and environmental monitoring at 16%. The demand is particularly strong in regions with advanced manufacturing capabilities, with North America leading at 35% market share, followed by Europe at 30%, Asia-Pacific at 28%, and other regions accounting for the remaining 7%.

Key market drivers include the growing need for maintenance-free power sources in remote sensing applications, increasing deployment of wireless sensor networks in industrial environments, and the expanding wearable technology ecosystem. The miniaturization trend in electronics has created a parallel demand for equally compact power solutions, positioning thermoelectric modules as an ideal candidate due to their scalability and form factor flexibility.

Customer requirements are evolving toward higher power density, improved conversion efficiency, and enhanced thermal management capabilities. Market research indicates that end-users prioritize energy output consistency, operational lifespan, and integration simplicity when selecting energy harvesting solutions. Thermoelectric modules address these needs through their solid-state operation and adaptability to various temperature differential scenarios.

Pricing trends show gradual cost reduction as manufacturing processes improve and economies of scale take effect. The average price per unit has decreased by approximately 8% annually over the past three years, making thermoelectric solutions increasingly competitive against traditional battery technologies when considering total lifetime costs.

Market penetration faces challenges related to initial cost barriers, technical integration complexity, and competition from alternative energy harvesting technologies such as piezoelectric and photovoltaic solutions. However, thermoelectric modules maintain competitive advantages in applications where consistent temperature differentials exist and where maintenance-free operation is critical.

Thermoelectric modules represent a significant segment within this market, accounting for roughly 24% of the total miniaturized energy harvesting solutions. Their appeal stems from their ability to convert waste heat into usable electricity without moving parts, offering reliability and longevity advantages over alternative technologies.

Consumer electronics remains the largest application sector, constituting 38% of the market share, followed by industrial automation at 27%, healthcare devices at 19%, and environmental monitoring at 16%. The demand is particularly strong in regions with advanced manufacturing capabilities, with North America leading at 35% market share, followed by Europe at 30%, Asia-Pacific at 28%, and other regions accounting for the remaining 7%.

Key market drivers include the growing need for maintenance-free power sources in remote sensing applications, increasing deployment of wireless sensor networks in industrial environments, and the expanding wearable technology ecosystem. The miniaturization trend in electronics has created a parallel demand for equally compact power solutions, positioning thermoelectric modules as an ideal candidate due to their scalability and form factor flexibility.

Customer requirements are evolving toward higher power density, improved conversion efficiency, and enhanced thermal management capabilities. Market research indicates that end-users prioritize energy output consistency, operational lifespan, and integration simplicity when selecting energy harvesting solutions. Thermoelectric modules address these needs through their solid-state operation and adaptability to various temperature differential scenarios.

Pricing trends show gradual cost reduction as manufacturing processes improve and economies of scale take effect. The average price per unit has decreased by approximately 8% annually over the past three years, making thermoelectric solutions increasingly competitive against traditional battery technologies when considering total lifetime costs.

Market penetration faces challenges related to initial cost barriers, technical integration complexity, and competition from alternative energy harvesting technologies such as piezoelectric and photovoltaic solutions. However, thermoelectric modules maintain competitive advantages in applications where consistent temperature differentials exist and where maintenance-free operation is critical.

Current Thermoelectric Module Technologies and Limitations

Thermoelectric modules (TEMs) currently available in the market primarily utilize the Seebeck effect, where a temperature difference across the module generates electrical voltage. The most common commercial TEMs employ bismuth telluride (Bi2Te3) semiconductor materials due to their relatively high figure of merit (ZT) values at room temperature, typically ranging from 0.8 to 1.0. These modules are constructed with alternating p-type and n-type semiconductor legs connected electrically in series and thermally in parallel, sandwiched between ceramic plates that provide electrical insulation and mechanical stability.

Despite decades of research, thermoelectric technology faces significant limitations that hinder widespread adoption in miniaturized energy harvesting applications. The conversion efficiency of commercial TEMs remains low, typically between 5-8% under optimal temperature differentials, which presents a major challenge for applications with limited thermal gradients. This efficiency constraint is fundamentally tied to the ZT value of available materials, which has seen only incremental improvements despite substantial research efforts.

Manufacturing constraints further limit miniaturization capabilities. Current production methods struggle to reliably produce thermoelectric legs below 0.5mm in cross-section while maintaining performance, creating a bottleneck for micro-scale applications. Additionally, the rigid ceramic substrates traditionally used in TEMs limit flexibility and integration options for curved or irregular surfaces common in wearable or implantable devices.

Thermal management represents another significant challenge. As TEMs scale down, the ratio of active material to packaging decreases, resulting in higher thermal resistance and reduced power density. Heat flux management becomes increasingly difficult at smaller scales, where thermal interfaces and contact resistances dominate system performance. This is particularly problematic in body-powered applications where temperature differentials may be only a few degrees Celsius.

Cost factors also impede widespread adoption, with high-quality TEMs utilizing relatively expensive materials like tellurium, which has limited global supply. Manufacturing processes for miniaturized modules require precision equipment and complex assembly techniques that drive up production costs significantly compared to conventional power sources.

Recent advancements in thin-film and flexible thermoelectric technologies show promise for overcoming some of these limitations. Techniques such as screen printing, electrodeposition, and physical vapor deposition enable thinner profiles and potentially lower manufacturing costs. However, these approaches typically result in lower ZT values compared to bulk materials, creating a performance-miniaturization tradeoff that researchers continue to address through novel material compositions and nanostructuring techniques.

Despite decades of research, thermoelectric technology faces significant limitations that hinder widespread adoption in miniaturized energy harvesting applications. The conversion efficiency of commercial TEMs remains low, typically between 5-8% under optimal temperature differentials, which presents a major challenge for applications with limited thermal gradients. This efficiency constraint is fundamentally tied to the ZT value of available materials, which has seen only incremental improvements despite substantial research efforts.

Manufacturing constraints further limit miniaturization capabilities. Current production methods struggle to reliably produce thermoelectric legs below 0.5mm in cross-section while maintaining performance, creating a bottleneck for micro-scale applications. Additionally, the rigid ceramic substrates traditionally used in TEMs limit flexibility and integration options for curved or irregular surfaces common in wearable or implantable devices.

Thermal management represents another significant challenge. As TEMs scale down, the ratio of active material to packaging decreases, resulting in higher thermal resistance and reduced power density. Heat flux management becomes increasingly difficult at smaller scales, where thermal interfaces and contact resistances dominate system performance. This is particularly problematic in body-powered applications where temperature differentials may be only a few degrees Celsius.

Cost factors also impede widespread adoption, with high-quality TEMs utilizing relatively expensive materials like tellurium, which has limited global supply. Manufacturing processes for miniaturized modules require precision equipment and complex assembly techniques that drive up production costs significantly compared to conventional power sources.

Recent advancements in thin-film and flexible thermoelectric technologies show promise for overcoming some of these limitations. Techniques such as screen printing, electrodeposition, and physical vapor deposition enable thinner profiles and potentially lower manufacturing costs. However, these approaches typically result in lower ZT values compared to bulk materials, creating a performance-miniaturization tradeoff that researchers continue to address through novel material compositions and nanostructuring techniques.

State-of-the-Art Miniaturized Thermoelectric Solutions

01 Micro-scale thermoelectric module design

Miniaturization of thermoelectric modules through micro-scale design approaches involves reducing the size of thermoelectric elements while maintaining or improving performance. These designs incorporate thin-film technology and microfabrication techniques to create compact modules suitable for small electronic devices. The reduced scale allows for integration into space-constrained applications while providing efficient thermal energy conversion.- Miniaturization through advanced materials and structures: Advanced materials and innovative structures are employed to reduce the size of thermoelectric modules while maintaining or improving performance. These approaches include using nanomaterials, thin films, and specialized semiconductor materials that offer higher efficiency in smaller dimensions. The structural design focuses on optimizing the arrangement of thermoelectric elements to achieve maximum power density in minimal space.

- Integration techniques for compact thermoelectric devices: Various integration techniques are developed to create more compact thermoelectric modules suitable for miniaturized applications. These include direct integration with electronic components, embedding thermoelectric elements into existing structures, and developing modular designs that can be easily incorporated into small devices. These integration approaches enable thermoelectric functionality in space-constrained applications.

- Microfabrication processes for thermoelectric modules: Specialized microfabrication processes are utilized to create extremely small thermoelectric modules. These processes include MEMS (Micro-Electro-Mechanical Systems) techniques, thin-film deposition methods, and precision etching processes that allow for the creation of microscale thermoelectric elements. These manufacturing approaches enable the production of thermoelectric modules with dimensions in the micrometer range.

- Thermal management solutions for miniaturized modules: Innovative thermal management solutions are developed to address the challenges of heat dissipation in miniaturized thermoelectric modules. These include specialized heat sink designs, thermal interface materials, and cooling mechanisms that efficiently transfer heat in compact spaces. Effective thermal management is crucial for maintaining the performance and reliability of miniaturized thermoelectric modules.

- Flexible and wearable thermoelectric technologies: Development of flexible and wearable thermoelectric modules represents a significant advancement in miniaturization. These modules utilize flexible substrates, stretchable interconnects, and conformable designs that can adapt to curved surfaces. Such technologies enable thermoelectric functionality in wearable devices, medical implants, and other applications requiring both small size and mechanical flexibility.

02 Advanced materials for miniaturized thermoelectric devices

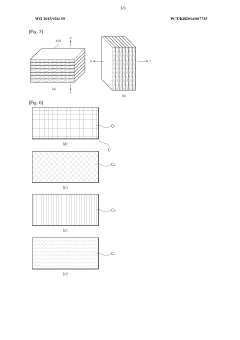

Novel materials are being developed specifically for miniaturized thermoelectric applications, including nanostructured semiconductors, quantum dot superlattices, and advanced alloys. These materials offer improved figure of merit (ZT) values at smaller scales, enabling more efficient energy conversion in compact form factors. Material innovations focus on enhancing thermal conductivity properties while reducing overall module dimensions.Expand Specific Solutions03 Fabrication techniques for miniature thermoelectric modules

Specialized fabrication methods enable the production of miniaturized thermoelectric modules, including MEMS-based approaches, thin-film deposition, and precision micromachining. These techniques allow for the creation of ultra-thin thermoelectric elements with precise dimensional control and improved thermal interfaces. Advanced manufacturing processes help overcome challenges related to electrical connections and thermal management at reduced scales.Expand Specific Solutions04 Integration solutions for compact thermoelectric systems

Integration strategies for miniaturized thermoelectric modules focus on embedding these devices into complex systems with minimal space requirements. This includes 3D packaging approaches, flexible substrate integration, and direct-on-chip mounting techniques. These solutions address thermal interface challenges while enabling thermoelectric functionality in wearable devices, IoT sensors, and other space-constrained applications.Expand Specific Solutions05 Performance optimization for small-scale thermoelectric modules

Techniques to optimize the performance of miniaturized thermoelectric modules include novel heat flow path designs, improved electrical contact configurations, and thermal management strategies specific to small-scale applications. These approaches focus on maximizing power density and conversion efficiency despite the reduced dimensions. Optimization methods include computational modeling to predict performance and identify ideal geometric configurations for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

Thermoelectric module technology for miniaturized energy harvesting is evolving rapidly, currently transitioning from early adoption to growth phase. The global market is expanding, projected to reach significant scale as demand for self-powered IoT devices increases. Technologically, companies demonstrate varying maturity levels: established players like Murata, Toshiba, Kyocera, and LG Innotek lead with commercial solutions, while Alternative Energy Innovations and Prime Photonics represent innovative scale-ups. Academic institutions (MIT, Michigan, Zhejiang University) contribute fundamental research advancements. The competitive landscape features electronics conglomerates leveraging manufacturing expertise alongside specialized thermoelectric companies developing proprietary technologies for miniaturization, efficiency improvements, and application-specific solutions across automotive, industrial, and consumer electronics sectors.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced miniaturized thermoelectric modules (TEMs) utilizing bismuth telluride-based semiconductor materials with optimized doping profiles. Their proprietary micro-fabrication techniques enable the creation of ultra-thin thermoelectric elements (50-100μm) arranged in high-density arrays. These modules incorporate specialized thermal interface materials to maximize heat transfer efficiency across miniaturized junctions. Murata's design employs a flexible substrate architecture that allows for conformal application to irregular heat sources, particularly valuable for wearable applications. Their modules achieve power densities of 10-30μW/cm² at temperature differentials as low as 2-5°C, making them suitable for body heat harvesting applications. The company has also developed proprietary low-resistance electrical interconnects that minimize parasitic losses in these small-scale devices.

Strengths: Superior manufacturing precision allowing for extremely thin thermoelectric elements; excellent integration capabilities with other electronic components; proven reliability in commercial applications. Weaknesses: Higher production costs compared to conventional modules; limited temperature range operation; requires specialized assembly techniques.

Toshiba Corp.

Technical Solution: Toshiba has pioneered silicon-based MEMS thermoelectric modules that enable unprecedented miniaturization for energy harvesting applications. Their approach utilizes semiconductor fabrication techniques to create thousands of thermocouples on a single silicon wafer with element dimensions in the micrometer range. The company's proprietary design incorporates vacuum encapsulation to minimize convective heat losses, significantly improving conversion efficiency in miniaturized form factors. Toshiba's modules feature specialized thermal isolation structures that maintain temperature gradients across extremely small distances, enabling power generation from subtle thermal differences. Their technology achieves conversion efficiencies of approximately 7-9% in modules less than 1mm thick, representing a significant advancement over conventional bulk thermoelectric materials. The modules incorporate integrated power management circuitry that optimizes energy extraction from variable heat sources.

Strengths: Exceptional miniaturization capabilities through semiconductor manufacturing processes; high integration potential with electronic systems; excellent thermal isolation techniques. Weaknesses: Higher initial investment costs; more complex manufacturing process; potential brittleness issues in certain applications.

Key Patents and Innovations in Thermoelectric Module Design

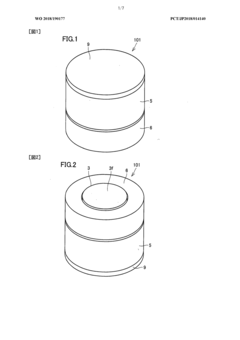

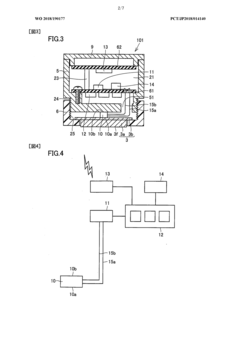

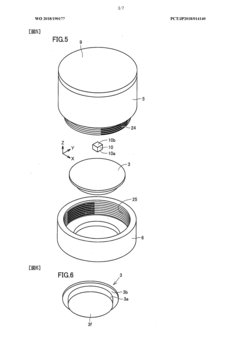

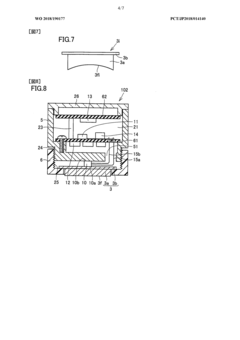

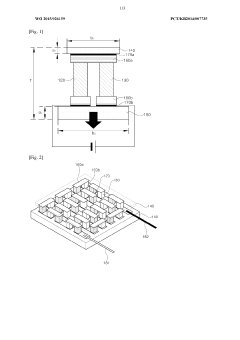

Thermoelectric conversion element module

PatentWO2018190177A1

Innovation

- A thermoelectric conversion element module with a heat receiving part in contact with a heat source, a thermoelectric conversion element, and a heat dissipation part with an internal space, where the thermoelectric conversion element is sandwiched between the heat receiving and heat dissipation parts, allowing for a compact design.

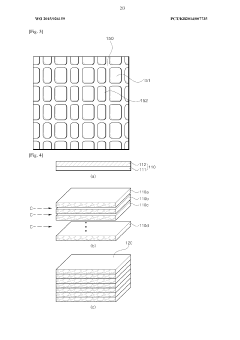

Thermoelectric module, and heat conversion apparatus comprising same

PatentWO2015026159A1

Innovation

- The solution involves forming substrates with different areas to enhance heat dissipation efficiency, allowing for the removal of heat sinks and achieving miniaturization and thinning of thermoelectric modules by increasing the heat transfer rate, and incorporating a conductive pattern layer to improve electrical conductivity and reduce thickness.

Integration Challenges with IoT and Wearable Applications

The integration of thermoelectric modules into IoT and wearable applications presents significant challenges despite their promising potential for miniaturized energy harvesting. The primary obstacle lies in the dimensional constraints of wearable devices, which demand extremely compact power solutions while maintaining sufficient energy output. Thermoelectric modules must be redesigned with ultra-thin profiles and flexible substrates to conform to the curved surfaces of wearable devices without compromising user comfort or aesthetic appeal.

Thermal management represents another critical challenge. Effective thermoelectric generation requires maintaining temperature differentials, yet the limited space in miniaturized applications restricts the implementation of traditional heat sinks and thermal management systems. Engineers must develop novel thermal interfaces that can efficiently transfer heat while remaining compact and lightweight, often requiring advanced materials with superior thermal conductivity properties.

Electrical integration poses additional complexities. The low-voltage output characteristic of thermoelectric modules necessitates sophisticated power management circuits to boost and stabilize the harvested energy for practical use in IoT applications. These circuits must themselves be miniaturized while handling variable input conditions resulting from fluctuating temperature differentials in real-world environments.

Manufacturing scalability presents significant hurdles for widespread adoption. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The industry requires innovations in manufacturing techniques to enable cost-effective mass production of miniaturized thermoelectric modules with consistent performance characteristics.

Durability and reliability concerns are particularly pronounced in wearable applications. Thermoelectric modules must withstand mechanical stresses from repeated bending, stretching, and compression while maintaining performance over thousands of thermal cycles. The integration of these modules with textiles and flexible substrates demands novel encapsulation methods to protect against moisture, sweat, and environmental contaminants without adding significant bulk.

Compatibility with existing IoT ecosystems represents a final integration challenge. Thermoelectric power solutions must interface seamlessly with standardized communication protocols and power requirements of commercial IoT platforms. This necessitates the development of adaptive power management systems that can intelligently allocate harvested energy based on application priorities and available thermal resources.

Thermal management represents another critical challenge. Effective thermoelectric generation requires maintaining temperature differentials, yet the limited space in miniaturized applications restricts the implementation of traditional heat sinks and thermal management systems. Engineers must develop novel thermal interfaces that can efficiently transfer heat while remaining compact and lightweight, often requiring advanced materials with superior thermal conductivity properties.

Electrical integration poses additional complexities. The low-voltage output characteristic of thermoelectric modules necessitates sophisticated power management circuits to boost and stabilize the harvested energy for practical use in IoT applications. These circuits must themselves be miniaturized while handling variable input conditions resulting from fluctuating temperature differentials in real-world environments.

Manufacturing scalability presents significant hurdles for widespread adoption. Current production methods for high-performance thermoelectric materials often involve complex processes that are difficult to scale economically. The industry requires innovations in manufacturing techniques to enable cost-effective mass production of miniaturized thermoelectric modules with consistent performance characteristics.

Durability and reliability concerns are particularly pronounced in wearable applications. Thermoelectric modules must withstand mechanical stresses from repeated bending, stretching, and compression while maintaining performance over thousands of thermal cycles. The integration of these modules with textiles and flexible substrates demands novel encapsulation methods to protect against moisture, sweat, and environmental contaminants without adding significant bulk.

Compatibility with existing IoT ecosystems represents a final integration challenge. Thermoelectric power solutions must interface seamlessly with standardized communication protocols and power requirements of commercial IoT platforms. This necessitates the development of adaptive power management systems that can intelligently allocate harvested energy based on application priorities and available thermal resources.

Sustainability Impact and Environmental Benefits

Thermoelectric modules represent a significant advancement in sustainable energy technology, offering environmental benefits that extend far beyond their compact size. These miniaturized energy harvesting systems capture waste heat—an abundant yet often overlooked energy resource—and convert it into usable electricity without producing emissions or requiring additional fuel inputs. This waste heat recovery capability addresses a critical inefficiency in industrial processes, transportation systems, and consumer electronics where up to 60% of primary energy is typically lost as heat.

The environmental impact of thermoelectric modules is particularly noteworthy in reducing carbon footprints. By generating electricity from otherwise wasted thermal energy, these systems effectively decrease the demand for grid electricity, much of which still comes from fossil fuel sources in many regions. Calculations suggest that widespread implementation of thermoelectric waste heat recovery could reduce global carbon emissions by several percentage points, contributing meaningfully to climate change mitigation efforts.

Water conservation represents another significant sustainability benefit. Unlike conventional power generation methods that often require substantial water resources for cooling, thermoelectric modules operate without water consumption. This characteristic makes them especially valuable in water-stressed regions where energy-water nexus challenges are particularly acute.

From a lifecycle perspective, thermoelectric modules offer impressive sustainability credentials. The materials used in modern modules are increasingly selected for their reduced environmental impact, with research focusing on replacing rare or toxic elements with abundant, environmentally benign alternatives. Many modules utilize materials that can be recycled at end-of-life, further enhancing their environmental profile. Their solid-state design, containing no moving parts, results in exceptional durability and longevity, minimizing replacement frequency and associated resource consumption.

The decentralized nature of thermoelectric energy harvesting also contributes to grid resilience and energy democratization. By enabling local energy generation at the point of heat production, these systems reduce transmission losses and infrastructure requirements. This distributed generation model aligns with sustainable development goals by providing energy access options in remote or underserved communities where conventional grid connections may be impractical or prohibitively expensive.

As miniaturization continues to advance, thermoelectric modules are increasingly finding applications in self-powered sensors and IoT devices, eliminating the need for battery replacement and disposal. This application alone represents a significant environmental benefit, as billions of disposable batteries are discarded annually worldwide, contributing to electronic waste challenges and potential toxic material leaching.

The environmental impact of thermoelectric modules is particularly noteworthy in reducing carbon footprints. By generating electricity from otherwise wasted thermal energy, these systems effectively decrease the demand for grid electricity, much of which still comes from fossil fuel sources in many regions. Calculations suggest that widespread implementation of thermoelectric waste heat recovery could reduce global carbon emissions by several percentage points, contributing meaningfully to climate change mitigation efforts.

Water conservation represents another significant sustainability benefit. Unlike conventional power generation methods that often require substantial water resources for cooling, thermoelectric modules operate without water consumption. This characteristic makes them especially valuable in water-stressed regions where energy-water nexus challenges are particularly acute.

From a lifecycle perspective, thermoelectric modules offer impressive sustainability credentials. The materials used in modern modules are increasingly selected for their reduced environmental impact, with research focusing on replacing rare or toxic elements with abundant, environmentally benign alternatives. Many modules utilize materials that can be recycled at end-of-life, further enhancing their environmental profile. Their solid-state design, containing no moving parts, results in exceptional durability and longevity, minimizing replacement frequency and associated resource consumption.

The decentralized nature of thermoelectric energy harvesting also contributes to grid resilience and energy democratization. By enabling local energy generation at the point of heat production, these systems reduce transmission losses and infrastructure requirements. This distributed generation model aligns with sustainable development goals by providing energy access options in remote or underserved communities where conventional grid connections may be impractical or prohibitively expensive.

As miniaturization continues to advance, thermoelectric modules are increasingly finding applications in self-powered sensors and IoT devices, eliminating the need for battery replacement and disposal. This application alone represents a significant environmental benefit, as billions of disposable batteries are discarded annually worldwide, contributing to electronic waste challenges and potential toxic material leaching.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!