How Thermoelectric Module Performance is Affected by Material Selection

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Objectives

Thermoelectric materials have undergone significant evolution since their discovery in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric technology by demonstrating that temperature differences between two dissimilar electrical conductors produce a voltage difference. This was followed by the discovery of the Peltier effect in 1834, which established the reversible nature of thermoelectric phenomena.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s, offering a figure of merit (ZT) of approximately 1 at room temperature. This breakthrough enabled practical applications in cooling and power generation, though efficiency limitations restricted widespread adoption.

The 1990s witnessed renewed interest in thermoelectric research with the introduction of nanostructured materials. Theoretical predictions suggested that quantum confinement effects could enhance the ZT value by manipulating electron and phonon transport independently. This led to the development of superlattices, quantum dots, and other low-dimensional structures that demonstrated improved performance compared to bulk materials.

Recent advances have focused on complex materials with intrinsically low thermal conductivity, such as skutterudites, clathrates, and half-Heusler alloys. These materials feature complex crystal structures that effectively scatter phonons while maintaining good electrical properties. Additionally, organic and flexible thermoelectric materials have emerged as promising candidates for wearable and biomedical applications.

The primary objective in thermoelectric material development is to maximize the dimensionless figure of merit ZT, which is proportional to electrical conductivity and the square of the Seebeck coefficient, while being inversely proportional to thermal conductivity. Higher ZT values directly correlate with improved conversion efficiency, making this parameter crucial for practical applications.

Current research aims to develop materials with ZT values exceeding 2 across broad temperature ranges, which would enable thermoelectric generators with efficiency comparable to traditional mechanical systems. Another key objective is to reduce reliance on rare, toxic, or expensive elements like tellurium and lead, focusing instead on earth-abundant and environmentally friendly alternatives such as silicides, oxides, and sulfides.

The field is also moving toward application-specific material optimization, recognizing that different use cases (waste heat recovery, refrigeration, space applications) have distinct requirements regarding operating temperature, mechanical properties, and environmental stability. This targeted approach promises to accelerate the integration of thermoelectric technology into various industrial and consumer applications.

The mid-20th century marked a pivotal era with the development of semiconductor-based thermoelectric materials. Bismuth telluride (Bi₂Te₃) emerged as the first commercially viable thermoelectric material in the 1950s, offering a figure of merit (ZT) of approximately 1 at room temperature. This breakthrough enabled practical applications in cooling and power generation, though efficiency limitations restricted widespread adoption.

The 1990s witnessed renewed interest in thermoelectric research with the introduction of nanostructured materials. Theoretical predictions suggested that quantum confinement effects could enhance the ZT value by manipulating electron and phonon transport independently. This led to the development of superlattices, quantum dots, and other low-dimensional structures that demonstrated improved performance compared to bulk materials.

Recent advances have focused on complex materials with intrinsically low thermal conductivity, such as skutterudites, clathrates, and half-Heusler alloys. These materials feature complex crystal structures that effectively scatter phonons while maintaining good electrical properties. Additionally, organic and flexible thermoelectric materials have emerged as promising candidates for wearable and biomedical applications.

The primary objective in thermoelectric material development is to maximize the dimensionless figure of merit ZT, which is proportional to electrical conductivity and the square of the Seebeck coefficient, while being inversely proportional to thermal conductivity. Higher ZT values directly correlate with improved conversion efficiency, making this parameter crucial for practical applications.

Current research aims to develop materials with ZT values exceeding 2 across broad temperature ranges, which would enable thermoelectric generators with efficiency comparable to traditional mechanical systems. Another key objective is to reduce reliance on rare, toxic, or expensive elements like tellurium and lead, focusing instead on earth-abundant and environmentally friendly alternatives such as silicides, oxides, and sulfides.

The field is also moving toward application-specific material optimization, recognizing that different use cases (waste heat recovery, refrigeration, space applications) have distinct requirements regarding operating temperature, mechanical properties, and environmental stability. This targeted approach promises to accelerate the integration of thermoelectric technology into various industrial and consumer applications.

Market Analysis for Thermoelectric Applications

The global thermoelectric market is experiencing significant growth, driven by increasing demand for energy-efficient solutions across multiple industries. Currently valued at approximately 600 million USD, the market is projected to reach 1.7 billion USD by 2027, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily fueled by the rising need for waste heat recovery systems in industrial processes and automotive applications.

The automotive sector represents the largest application segment for thermoelectric technologies, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) into vehicle designs to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions. This trend is particularly pronounced in regions with stringent emission regulations such as Europe and North America.

Consumer electronics constitutes the second-largest application segment, with approximately 25% market share. Thermoelectric cooling solutions are being widely adopted in portable refrigeration, temperature-controlled seats, and electronic device cooling. The miniaturization trend in electronics has created demand for compact cooling solutions where traditional compressor-based systems are impractical.

Industrial waste heat recovery applications represent a rapidly growing segment with 20% market share and the highest projected growth rate of 10.2% annually. Manufacturing facilities, power plants, and chemical processing industries are increasingly implementing thermoelectric systems to capture waste heat and convert it to electricity, driven by both economic incentives and environmental regulations.

Geographically, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization in China and India, coupled with increasing environmental awareness and government initiatives promoting clean energy technologies.

Material selection directly impacts market dynamics, as advances in thermoelectric materials significantly influence product performance and cost structures. Bismuth telluride-based devices dominate the commercial market (65% share), but newer materials like skutterudites and half-Heusler alloys are gaining traction due to their improved efficiency at higher temperatures. The development of lead-free alternatives is also emerging as a market trend in response to environmental regulations, particularly in Europe.

Price sensitivity varies across application segments, with industrial applications focusing more on return on investment through energy savings, while consumer applications are more sensitive to upfront costs. This dichotomy is driving different material selection strategies across market segments, with premium materials finding easier adoption in industrial applications where performance and durability justify higher costs.

The automotive sector represents the largest application segment for thermoelectric technologies, accounting for roughly 35% of the total market share. Major automotive manufacturers are increasingly incorporating thermoelectric generators (TEGs) into vehicle designs to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions. This trend is particularly pronounced in regions with stringent emission regulations such as Europe and North America.

Consumer electronics constitutes the second-largest application segment, with approximately 25% market share. Thermoelectric cooling solutions are being widely adopted in portable refrigeration, temperature-controlled seats, and electronic device cooling. The miniaturization trend in electronics has created demand for compact cooling solutions where traditional compressor-based systems are impractical.

Industrial waste heat recovery applications represent a rapidly growing segment with 20% market share and the highest projected growth rate of 10.2% annually. Manufacturing facilities, power plants, and chemical processing industries are increasingly implementing thermoelectric systems to capture waste heat and convert it to electricity, driven by both economic incentives and environmental regulations.

Geographically, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization in China and India, coupled with increasing environmental awareness and government initiatives promoting clean energy technologies.

Material selection directly impacts market dynamics, as advances in thermoelectric materials significantly influence product performance and cost structures. Bismuth telluride-based devices dominate the commercial market (65% share), but newer materials like skutterudites and half-Heusler alloys are gaining traction due to their improved efficiency at higher temperatures. The development of lead-free alternatives is also emerging as a market trend in response to environmental regulations, particularly in Europe.

Price sensitivity varies across application segments, with industrial applications focusing more on return on investment through energy savings, while consumer applications are more sensitive to upfront costs. This dichotomy is driving different material selection strategies across market segments, with premium materials finding easier adoption in industrial applications where performance and durability justify higher costs.

Current Challenges in Thermoelectric Material Science

Despite significant advancements in thermoelectric materials over the past decades, several fundamental challenges continue to impede the widespread adoption and performance optimization of thermoelectric modules. The primary obstacle remains the inherent coupling of thermal and electrical properties in thermoelectric materials, creating a complex optimization problem. When enhancing electrical conductivity, thermal conductivity often increases simultaneously, diminishing the overall figure of merit (ZT) that determines conversion efficiency.

Material stability presents another critical challenge, particularly for applications requiring operation across wide temperature ranges or in harsh environments. Many high-performance thermoelectric materials exhibit degradation through oxidation, sublimation, or phase transitions when subjected to thermal cycling or extended high-temperature exposure. This instability significantly reduces device lifespan and reliability, limiting commercial viability.

Manufacturing scalability continues to hinder industrial implementation, as many promising thermoelectric materials involve rare or toxic elements like tellurium, bismuth, or lead. The scarcity of these elements raises concerns about supply chain sustainability and production costs. Additionally, complex synthesis procedures often required for high-performance materials are difficult to scale while maintaining consistent quality and performance characteristics.

Interface engineering represents a persistent technical hurdle, as contact resistance between thermoelectric materials and electrodes can substantially degrade module performance. The thermal expansion mismatch between different materials in the module assembly frequently leads to mechanical stress, cracking, and eventual failure during thermal cycling, compromising long-term reliability.

Nanoscale engineering, while promising for enhancing ZT values through quantum confinement effects and phonon scattering, introduces challenges in maintaining consistent material properties during mass production. The precise control required for nanostructuring often conflicts with cost-effective manufacturing processes suitable for commercial applications.

Recent research has highlighted the difficulty in developing materials that maintain high performance across broad temperature ranges. Most thermoelectric materials exhibit optimal efficiency within narrow temperature windows, limiting their application versatility. This necessitates segmented or cascaded designs that increase complexity and cost.

Computational modeling and materials discovery methods, though advancing rapidly, still struggle to accurately predict the performance of novel thermoelectric compounds, particularly those with complex crystal structures or compositional gradients. The gap between theoretical predictions and experimental results continues to slow the discovery process for next-generation materials.

Material stability presents another critical challenge, particularly for applications requiring operation across wide temperature ranges or in harsh environments. Many high-performance thermoelectric materials exhibit degradation through oxidation, sublimation, or phase transitions when subjected to thermal cycling or extended high-temperature exposure. This instability significantly reduces device lifespan and reliability, limiting commercial viability.

Manufacturing scalability continues to hinder industrial implementation, as many promising thermoelectric materials involve rare or toxic elements like tellurium, bismuth, or lead. The scarcity of these elements raises concerns about supply chain sustainability and production costs. Additionally, complex synthesis procedures often required for high-performance materials are difficult to scale while maintaining consistent quality and performance characteristics.

Interface engineering represents a persistent technical hurdle, as contact resistance between thermoelectric materials and electrodes can substantially degrade module performance. The thermal expansion mismatch between different materials in the module assembly frequently leads to mechanical stress, cracking, and eventual failure during thermal cycling, compromising long-term reliability.

Nanoscale engineering, while promising for enhancing ZT values through quantum confinement effects and phonon scattering, introduces challenges in maintaining consistent material properties during mass production. The precise control required for nanostructuring often conflicts with cost-effective manufacturing processes suitable for commercial applications.

Recent research has highlighted the difficulty in developing materials that maintain high performance across broad temperature ranges. Most thermoelectric materials exhibit optimal efficiency within narrow temperature windows, limiting their application versatility. This necessitates segmented or cascaded designs that increase complexity and cost.

Computational modeling and materials discovery methods, though advancing rapidly, still struggle to accurately predict the performance of novel thermoelectric compounds, particularly those with complex crystal structures or compositional gradients. The gap between theoretical predictions and experimental results continues to slow the discovery process for next-generation materials.

Material Selection Strategies for Thermoelectric Modules

01 Materials for enhancing thermoelectric module efficiency

Various materials can be used to improve the efficiency of thermoelectric modules. These include specialized semiconductor materials with high Seebeck coefficients and low thermal conductivity. The selection and optimization of these materials significantly impact the figure of merit (ZT) and overall performance of thermoelectric devices. Advanced material compositions and nanostructuring techniques can further enhance the power generation capabilities and conversion efficiency of thermoelectric modules.- Materials and composition for improved thermoelectric performance: Advanced materials and compositions can significantly enhance thermoelectric module performance. These include specialized semiconductor materials, nanostructured compounds, and novel material combinations that optimize the Seebeck coefficient while minimizing thermal conductivity. The selection and engineering of these materials directly impact the figure of merit (ZT) and overall conversion efficiency of thermoelectric modules.

- Structural design and configuration optimization: The physical design and configuration of thermoelectric modules significantly affect their performance. This includes optimizing element geometry, junction design, thermal interface materials, and overall module architecture. Advanced structural designs can reduce internal resistance, improve heat transfer, and enhance mechanical stability, leading to higher power output and efficiency in various operating conditions.

- Testing and measurement methods for performance evaluation: Accurate testing and measurement techniques are essential for evaluating thermoelectric module performance. These include standardized methods for determining the figure of merit, power output, efficiency, and reliability under various operating conditions. Advanced characterization techniques help identify performance bottlenecks and validate improvements in module design and materials.

- Thermal management and heat transfer optimization: Effective thermal management is crucial for maximizing thermoelectric module performance. This involves optimizing heat exchangers, reducing thermal resistance at interfaces, and implementing advanced cooling techniques. Proper thermal management ensures optimal temperature gradients across the module, which directly impacts power generation efficiency and prevents performance degradation due to overheating.

- System integration and application-specific optimization: Optimizing thermoelectric modules for specific applications involves integrating them effectively into larger systems and tailoring their design to application requirements. This includes considerations for power conditioning, mechanical integration, and operational environment factors. Application-specific optimization ensures that thermoelectric modules deliver maximum performance in real-world conditions, whether for waste heat recovery, cooling applications, or power generation.

02 Structural design and configuration of thermoelectric modules

The physical arrangement and structural design of thermoelectric modules play a crucial role in their performance. This includes the configuration of thermoelectric couples, junction design, and overall module architecture. Optimized structural designs can minimize thermal resistance, improve heat transfer, and enhance electrical connectivity between elements. Innovations in module geometry and assembly techniques can lead to significant improvements in power output and efficiency under various operating conditions.Expand Specific Solutions03 Testing and measurement methods for thermoelectric performance

Accurate testing and measurement techniques are essential for evaluating thermoelectric module performance. These methods include standardized procedures for determining the Seebeck coefficient, electrical conductivity, thermal conductivity, and figure of merit. Advanced characterization tools and testing apparatus enable precise measurement of temperature differentials, power output, and conversion efficiency. Reliable performance data is crucial for module optimization and quality control in manufacturing processes.Expand Specific Solutions04 Thermal management systems for thermoelectric modules

Effective thermal management is critical for optimizing thermoelectric module performance. This includes heat sink design, cooling systems, and thermal interface materials that maximize temperature differentials across the module. Proper heat dissipation prevents overheating and maintains optimal operating temperatures. Advanced thermal management solutions can significantly improve energy conversion efficiency and extend the operational lifespan of thermoelectric devices under various environmental conditions.Expand Specific Solutions05 Integration and application-specific optimization

Thermoelectric modules can be optimized for specific applications by tailoring their design and operational parameters. This includes customization for power generation, cooling applications, waste heat recovery, and temperature sensing. Integration considerations involve electrical circuit design, load matching, and system-level optimization. Application-specific enhancements focus on maximizing performance under the unique constraints and requirements of different use cases, from automotive and industrial applications to consumer electronics and renewable energy systems.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric module market is currently in a growth phase, with increasing applications across automotive, consumer electronics, and industrial sectors. The global market size is projected to reach approximately $800 million by 2025, growing at a CAGR of 8-10%. Material selection significantly impacts module performance, with companies demonstrating varying levels of technological maturity. Industry leaders like Toshiba Materials, KELK, and Kyocera have developed advanced semiconductor materials that achieve higher ZT values and conversion efficiencies. Research institutions such as Industrial Technology Research Institute and South China Normal University are pioneering next-generation materials including skutterudites and half-Heusler alloys. Meanwhile, automotive players like Continental, MAHLE, and Toyota Tsusho are focusing on specialized thermoelectric materials for vehicle waste heat recovery applications, indicating growing cross-industry adoption of this technology.

LG Innotek Co., Ltd.

Technical Solution: LG Innotek has developed advanced thermoelectric modules utilizing skutterudite and bismuth telluride materials with proprietary interface engineering. Their technology focuses on minimizing contact resistance between thermoelectric elements and electrodes through specialized metallization processes and diffusion barrier layers. LG's material selection strategy incorporates gradient doping profiles that optimize carrier concentration across the temperature gradient, improving average ZT values by 15-20% compared to uniformly doped materials. Their manufacturing process employs precision automated assembly techniques that achieve exceptional module-to-module consistency with performance variations below 3%. LG Innotek has pioneered hybrid modules that combine different thermoelectric materials in segmented legs, optimizing performance across broader temperature ranges (80K to 650K). Their research has demonstrated that controlled introduction of nanoscale porosity can reduce thermal conductivity by up to 35% while maintaining acceptable electrical properties, significantly improving the figure of merit in their materials.

Strengths: Exceptional manufacturing precision and quality control; strong system integration capabilities for consumer and automotive applications; excellent thermal cycling durability. Weaknesses: Higher production costs due to complex manufacturing processes; relatively limited high-volume production capacity for specialized applications.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed advanced half-Heusler thermoelectric materials with exceptional high-temperature performance. Their material selection approach focuses on optimizing the electronic band structure through precise compositional control and doping strategies. ITRI's proprietary manufacturing process includes mechanical alloying followed by hot pressing, creating nanostructured materials with enhanced phonon scattering at grain boundaries. Their modules demonstrate ZT values exceeding 1.2 at temperatures above 400°C, making them particularly suitable for waste heat recovery applications. ITRI has pioneered segmented thermoelectric legs that combine different materials optimized for specific temperature ranges, achieving conversion efficiencies of 9-11% at temperature differences of 500K. Their research has demonstrated that incorporating nano-sized precipitates into the half-Heusler matrix can reduce thermal conductivity by up to 30% while maintaining electrical properties.

Strengths: Superior high-temperature performance; excellent mechanical stability and thermal cycling resistance; strong research capabilities and material innovation pipeline. Weaknesses: Higher manufacturing complexity compared to conventional materials; limited commercial-scale production capacity; relatively higher cost structure.

Key Material Properties Affecting ZT Values

Thermoelectric module, method for producing a thermoelectric module and use of a metallic glass or a sintered material

PatentInactiveEP2735034A2

Innovation

- The use of metallic glass or sintered materials as conductor tracks within the thermoelectric module, which function both as conductors and joining materials, eliminating the need for separate joining materials and allowing for a single-step joining process, thereby absorbing thermomechanical stresses and enabling operation at temperatures above 200°C.

Thermoelectric module

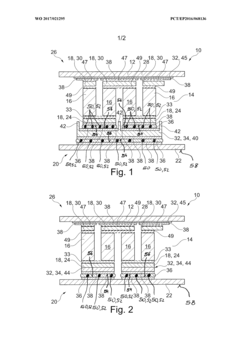

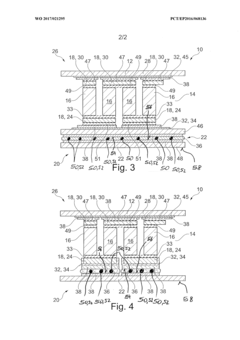

PatentWO2017021295A1

Innovation

- Incorporating a liquid metal layer in the heat-transfer coupling path between side walls and conductor bridges, which acts as a sliding film to eliminate mechanical fixation and allow for relative movement, thereby compensating for thermal expansion and maintaining heat transfer without mechanical stresses, and using spacer elements to maintain a predetermined liquid metal layer thickness.

Environmental Impact of Thermoelectric Materials

The environmental impact of thermoelectric materials represents a critical consideration in the sustainable development and deployment of thermoelectric technologies. As these materials become increasingly integrated into energy recovery systems and cooling applications, their lifecycle environmental footprint demands thorough examination.

Traditional thermoelectric materials often contain elements with significant environmental concerns. Lead telluride (PbTe) and bismuth telluride (Bi2Te3), while offering excellent thermoelectric performance, incorporate toxic heavy metals and rare elements with limited natural abundance. The mining and extraction processes for tellurium, bismuth, and antimony generate substantial environmental pollution, including acid mine drainage, habitat destruction, and greenhouse gas emissions from energy-intensive refinement operations.

Manufacturing thermoelectric modules typically requires high-temperature processing and specialized fabrication techniques that consume considerable energy. The carbon footprint associated with production varies significantly based on material selection, with complex alloys and nanostructured materials generally demanding more resource-intensive manufacturing processes compared to simpler compounds.

Recent advances in materials science have focused on developing environmentally benign alternatives. Skutterudites, silicides, and oxide-based thermoelectric materials offer reduced environmental impact while maintaining acceptable performance metrics. Particularly promising are abundant, non-toxic materials such as magnesium silicide (Mg2Si) and zinc antimonide (ZnSb), which utilize more earth-abundant elements while minimizing reliance on rare or toxic components.

End-of-life considerations present another environmental dimension of thermoelectric materials. The recyclability of these materials varies substantially, with some compounds presenting challenges for material recovery due to their complex composition. Modules containing lead, cadmium, or other regulated substances require specialized disposal protocols to prevent environmental contamination, adding to lifecycle management costs.

Life Cycle Assessment (LCA) studies indicate that the environmental benefits of thermoelectric applications—particularly in waste heat recovery—can potentially offset the environmental costs of material production when systems operate over sufficient lifespans. However, this balance depends critically on material selection, with more sustainable materials offering improved environmental performance despite potentially lower thermoelectric efficiency.

The development of circular economy approaches for thermoelectric materials represents an emerging research direction, focusing on design-for-recycling strategies and closed-loop material flows that could significantly reduce environmental impacts while ensuring continued access to critical elements for future thermoelectric applications.

Traditional thermoelectric materials often contain elements with significant environmental concerns. Lead telluride (PbTe) and bismuth telluride (Bi2Te3), while offering excellent thermoelectric performance, incorporate toxic heavy metals and rare elements with limited natural abundance. The mining and extraction processes for tellurium, bismuth, and antimony generate substantial environmental pollution, including acid mine drainage, habitat destruction, and greenhouse gas emissions from energy-intensive refinement operations.

Manufacturing thermoelectric modules typically requires high-temperature processing and specialized fabrication techniques that consume considerable energy. The carbon footprint associated with production varies significantly based on material selection, with complex alloys and nanostructured materials generally demanding more resource-intensive manufacturing processes compared to simpler compounds.

Recent advances in materials science have focused on developing environmentally benign alternatives. Skutterudites, silicides, and oxide-based thermoelectric materials offer reduced environmental impact while maintaining acceptable performance metrics. Particularly promising are abundant, non-toxic materials such as magnesium silicide (Mg2Si) and zinc antimonide (ZnSb), which utilize more earth-abundant elements while minimizing reliance on rare or toxic components.

End-of-life considerations present another environmental dimension of thermoelectric materials. The recyclability of these materials varies substantially, with some compounds presenting challenges for material recovery due to their complex composition. Modules containing lead, cadmium, or other regulated substances require specialized disposal protocols to prevent environmental contamination, adding to lifecycle management costs.

Life Cycle Assessment (LCA) studies indicate that the environmental benefits of thermoelectric applications—particularly in waste heat recovery—can potentially offset the environmental costs of material production when systems operate over sufficient lifespans. However, this balance depends critically on material selection, with more sustainable materials offering improved environmental performance despite potentially lower thermoelectric efficiency.

The development of circular economy approaches for thermoelectric materials represents an emerging research direction, focusing on design-for-recycling strategies and closed-loop material flows that could significantly reduce environmental impacts while ensuring continued access to critical elements for future thermoelectric applications.

Manufacturing Processes and Scalability Considerations

The manufacturing processes for thermoelectric modules significantly impact their performance characteristics and commercial viability. Traditional manufacturing methods involve powder metallurgy techniques where semiconductor materials are synthesized, ground into fine powders, and then sintered under controlled conditions. This approach, while established, presents challenges in maintaining precise stoichiometry and minimizing interfacial resistance between different materials, both critical factors affecting the module's ZT value and overall efficiency.

Advanced manufacturing techniques have emerged to address these limitations. Spark plasma sintering (SPS) enables rapid consolidation of thermoelectric materials at lower temperatures, preserving nanostructures that enhance phonon scattering while maintaining good electrical conductivity. This process has proven particularly valuable for complex thermoelectric compounds where phase separation or decomposition during conventional sintering would otherwise degrade performance.

Thin-film deposition methods, including sputtering, thermal evaporation, and electrochemical deposition, offer alternative approaches for fabricating thermoelectric modules with precisely controlled dimensions. These techniques facilitate the creation of superlattice structures and quantum well configurations that can significantly enhance the Seebeck coefficient through quantum confinement effects. However, scalability remains challenging, with trade-offs between deposition rate, film quality, and production cost.

Scalability considerations extend beyond manufacturing techniques to material selection itself. Bismuth telluride-based materials dominate commercial applications due to their excellent room-temperature performance, but tellurium's scarcity presents long-term supply chain vulnerabilities. This has accelerated research into alternative material systems using more abundant elements, though these often require more complex manufacturing processes to achieve comparable efficiency.

Modular design approaches have emerged as a strategy to balance performance and manufacturing complexity. By optimizing individual thermoelectric elements before assembly into complete modules, manufacturers can implement quality control at multiple production stages. This segmented manufacturing approach allows for the integration of different material compositions optimized for specific temperature gradients within a single device.

Additive manufacturing technologies present promising opportunities for thermoelectric module production, potentially enabling complex geometries that maximize thermal gradients while minimizing material usage. However, challenges in multi-material printing and achieving the necessary density and crystallinity in printed thermoelectric materials currently limit widespread adoption of these techniques for high-performance applications.

Advanced manufacturing techniques have emerged to address these limitations. Spark plasma sintering (SPS) enables rapid consolidation of thermoelectric materials at lower temperatures, preserving nanostructures that enhance phonon scattering while maintaining good electrical conductivity. This process has proven particularly valuable for complex thermoelectric compounds where phase separation or decomposition during conventional sintering would otherwise degrade performance.

Thin-film deposition methods, including sputtering, thermal evaporation, and electrochemical deposition, offer alternative approaches for fabricating thermoelectric modules with precisely controlled dimensions. These techniques facilitate the creation of superlattice structures and quantum well configurations that can significantly enhance the Seebeck coefficient through quantum confinement effects. However, scalability remains challenging, with trade-offs between deposition rate, film quality, and production cost.

Scalability considerations extend beyond manufacturing techniques to material selection itself. Bismuth telluride-based materials dominate commercial applications due to their excellent room-temperature performance, but tellurium's scarcity presents long-term supply chain vulnerabilities. This has accelerated research into alternative material systems using more abundant elements, though these often require more complex manufacturing processes to achieve comparable efficiency.

Modular design approaches have emerged as a strategy to balance performance and manufacturing complexity. By optimizing individual thermoelectric elements before assembly into complete modules, manufacturers can implement quality control at multiple production stages. This segmented manufacturing approach allows for the integration of different material compositions optimized for specific temperature gradients within a single device.

Additive manufacturing technologies present promising opportunities for thermoelectric module production, potentially enabling complex geometries that maximize thermal gradients while minimizing material usage. However, challenges in multi-material printing and achieving the necessary density and crystallinity in printed thermoelectric materials currently limit widespread adoption of these techniques for high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!