Why Thermoelectric Module Improves Low-Temperature Energy Harvesting

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Energy Harvesting Background and Objectives

Thermoelectric energy harvesting represents a significant frontier in sustainable energy technologies, with roots dating back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect in 1821. This phenomenon, where temperature differences are directly converted into electrical voltage, has evolved from a scientific curiosity into a practical energy solution over the past two centuries. The technology has seen accelerated development particularly since the 1950s with the advent of semiconductor materials, enabling more efficient conversion processes.

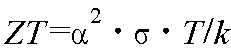

Recent technological advancements have shifted focus toward low-temperature energy harvesting applications, where thermoelectric modules demonstrate particular promise. These applications target temperature differentials below 100°C, which are abundant in industrial waste heat, automotive exhaust systems, geothermal sources, and even human body heat. The evolution of thermoelectric materials with improved figure of merit (ZT) values has been crucial in making low-temperature harvesting increasingly viable.

The primary objective of thermoelectric module implementation in low-temperature energy harvesting is to capture and convert otherwise wasted thermal energy into usable electricity. This aligns with global sustainability goals by improving overall energy efficiency without requiring additional fuel consumption. Furthermore, thermoelectric technology offers unique advantages in this context due to its solid-state operation, absence of moving parts, scalability, and long operational lifespan.

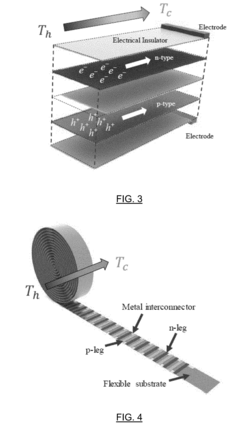

Current technological trends point toward the development of flexible thermoelectric generators, nanostructured materials, and hybrid systems that combine thermoelectric technology with other energy harvesting methods. These innovations aim to overcome traditional limitations in conversion efficiency while expanding application possibilities. The integration of Internet of Things (IoT) devices with self-powering capabilities represents a particularly promising direction, potentially eliminating the need for battery replacement in remote sensing applications.

The technical objectives for advancing thermoelectric modules in low-temperature applications include improving the thermoelectric figure of merit (ZT) at ambient and near-ambient temperatures, developing cost-effective manufacturing processes, and creating more adaptable module designs that can conform to various heat source geometries. Additionally, research aims to enhance thermal interface materials to maximize heat transfer efficiency at the critical junctions between heat sources and thermoelectric elements.

As global energy demands continue to rise alongside environmental concerns, thermoelectric energy harvesting at low temperatures represents a strategic technological pathway toward more sustainable energy systems. The ability to convert previously untapped low-grade heat into electricity without carbon emissions positions this technology as an important contributor to future distributed energy generation paradigms.

Recent technological advancements have shifted focus toward low-temperature energy harvesting applications, where thermoelectric modules demonstrate particular promise. These applications target temperature differentials below 100°C, which are abundant in industrial waste heat, automotive exhaust systems, geothermal sources, and even human body heat. The evolution of thermoelectric materials with improved figure of merit (ZT) values has been crucial in making low-temperature harvesting increasingly viable.

The primary objective of thermoelectric module implementation in low-temperature energy harvesting is to capture and convert otherwise wasted thermal energy into usable electricity. This aligns with global sustainability goals by improving overall energy efficiency without requiring additional fuel consumption. Furthermore, thermoelectric technology offers unique advantages in this context due to its solid-state operation, absence of moving parts, scalability, and long operational lifespan.

Current technological trends point toward the development of flexible thermoelectric generators, nanostructured materials, and hybrid systems that combine thermoelectric technology with other energy harvesting methods. These innovations aim to overcome traditional limitations in conversion efficiency while expanding application possibilities. The integration of Internet of Things (IoT) devices with self-powering capabilities represents a particularly promising direction, potentially eliminating the need for battery replacement in remote sensing applications.

The technical objectives for advancing thermoelectric modules in low-temperature applications include improving the thermoelectric figure of merit (ZT) at ambient and near-ambient temperatures, developing cost-effective manufacturing processes, and creating more adaptable module designs that can conform to various heat source geometries. Additionally, research aims to enhance thermal interface materials to maximize heat transfer efficiency at the critical junctions between heat sources and thermoelectric elements.

As global energy demands continue to rise alongside environmental concerns, thermoelectric energy harvesting at low temperatures represents a strategic technological pathway toward more sustainable energy systems. The ability to convert previously untapped low-grade heat into electricity without carbon emissions positions this technology as an important contributor to future distributed energy generation paradigms.

Market Analysis for Low-Temperature Energy Recovery Solutions

The global market for low-temperature energy recovery solutions has experienced significant growth in recent years, driven by increasing focus on energy efficiency and sustainability across industries. The market size for waste heat recovery systems was valued at approximately $54 billion in 2020 and is projected to reach $80 billion by 2026, growing at a CAGR of around 8.5%. Within this broader market, low-temperature energy harvesting represents a rapidly expanding segment with particular relevance to thermoelectric module applications.

Industrial sectors constitute the largest market for low-temperature energy recovery technologies, accounting for nearly 60% of the total market share. Manufacturing processes in steel, cement, glass, and chemical industries generate substantial amounts of low-grade waste heat below 200°C, presenting significant recovery opportunities. The automotive sector follows as the second-largest market segment, where thermoelectric generators can convert waste heat from exhaust systems into usable electricity.

Regional analysis reveals North America and Europe as leading markets for low-temperature energy recovery solutions, primarily due to stringent environmental regulations and high energy costs. However, the Asia-Pacific region is witnessing the fastest growth rate, fueled by rapid industrialization in China and India, alongside increasing government initiatives promoting energy efficiency.

Market drivers for thermoelectric-based low-temperature energy harvesting include rising energy prices, growing emphasis on industrial energy efficiency, and increasing adoption of IoT devices requiring autonomous power sources. The push toward carbon neutrality has further accelerated demand, with many corporations setting ambitious sustainability targets that necessitate comprehensive energy recovery strategies.

Consumer demand patterns indicate a growing preference for integrated energy management systems that incorporate low-temperature recovery technologies. End-users increasingly prioritize solutions offering quick return on investment, minimal maintenance requirements, and compatibility with existing infrastructure. The average payback period for industrial low-temperature recovery systems currently ranges from 2 to 5 years, depending on application scale and energy prices.

Pricing trends show gradual cost reduction for thermoelectric modules, with average prices decreasing by approximately 15% over the past five years due to manufacturing improvements and increased production volumes. This price reduction has expanded the range of economically viable applications, particularly in smaller-scale and consumer-oriented markets.

Market challenges include high initial capital costs, technical limitations in conversion efficiency, and integration complexities with existing systems. Additionally, fluctuating energy prices can impact ROI calculations, creating uncertainty for potential adopters. Despite these challenges, the market outlook remains positive, with technological advancements in thermoelectric materials expected to further enhance performance and expand application possibilities.

Industrial sectors constitute the largest market for low-temperature energy recovery technologies, accounting for nearly 60% of the total market share. Manufacturing processes in steel, cement, glass, and chemical industries generate substantial amounts of low-grade waste heat below 200°C, presenting significant recovery opportunities. The automotive sector follows as the second-largest market segment, where thermoelectric generators can convert waste heat from exhaust systems into usable electricity.

Regional analysis reveals North America and Europe as leading markets for low-temperature energy recovery solutions, primarily due to stringent environmental regulations and high energy costs. However, the Asia-Pacific region is witnessing the fastest growth rate, fueled by rapid industrialization in China and India, alongside increasing government initiatives promoting energy efficiency.

Market drivers for thermoelectric-based low-temperature energy harvesting include rising energy prices, growing emphasis on industrial energy efficiency, and increasing adoption of IoT devices requiring autonomous power sources. The push toward carbon neutrality has further accelerated demand, with many corporations setting ambitious sustainability targets that necessitate comprehensive energy recovery strategies.

Consumer demand patterns indicate a growing preference for integrated energy management systems that incorporate low-temperature recovery technologies. End-users increasingly prioritize solutions offering quick return on investment, minimal maintenance requirements, and compatibility with existing infrastructure. The average payback period for industrial low-temperature recovery systems currently ranges from 2 to 5 years, depending on application scale and energy prices.

Pricing trends show gradual cost reduction for thermoelectric modules, with average prices decreasing by approximately 15% over the past five years due to manufacturing improvements and increased production volumes. This price reduction has expanded the range of economically viable applications, particularly in smaller-scale and consumer-oriented markets.

Market challenges include high initial capital costs, technical limitations in conversion efficiency, and integration complexities with existing systems. Additionally, fluctuating energy prices can impact ROI calculations, creating uncertainty for potential adopters. Despite these challenges, the market outlook remains positive, with technological advancements in thermoelectric materials expected to further enhance performance and expand application possibilities.

Current Challenges in Low-Temperature Thermoelectric Technology

Despite significant advancements in thermoelectric technology, low-temperature energy harvesting faces several critical challenges that limit widespread commercial adoption. The primary obstacle remains the inherently low conversion efficiency of thermoelectric modules at small temperature differentials. Current commercial thermoelectric generators typically achieve only 2-5% efficiency when operating with temperature differences below 100°C, making economic viability difficult to achieve in many potential applications.

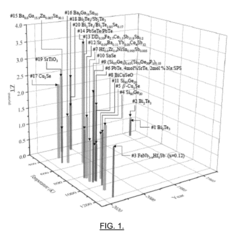

Material limitations constitute another significant barrier. Conventional thermoelectric materials like bismuth telluride (Bi₂Te₃) perform adequately at room temperature but struggle to maintain optimal figure of merit (ZT) values at the lower end of the temperature spectrum. The search for materials with enhanced ZT values below 100°C continues to challenge researchers, with complex trade-offs between electrical conductivity, thermal conductivity, and Seebeck coefficient proving difficult to optimize simultaneously.

Thermal management issues present additional complications in low-temperature applications. Maintaining stable temperature differentials across thermoelectric modules becomes particularly challenging when ambient conditions fluctuate or when heat sources provide inconsistent thermal energy. The parasitic heat losses through conduction, convection, and radiation often overwhelm the useful temperature gradient, especially in miniaturized or portable systems where insulation options are limited.

Manufacturing scalability represents another significant hurdle. Current production methods for high-quality thermoelectric modules involve complex processes including precise doping, specialized sintering techniques, and meticulous assembly. These requirements drive up costs substantially, with prices typically exceeding $10 per watt of generating capacity—far higher than competing energy harvesting technologies like photovoltaics.

System integration challenges further complicate implementation. Low-temperature thermoelectric generators produce variable, low-voltage DC output that requires sophisticated power management circuitry to convert into usable electricity. The additional components not only increase system complexity and cost but also introduce power losses that further reduce overall efficiency.

Durability and reliability concerns persist in real-world applications. Thermal cycling, mechanical stress, and environmental exposure can lead to performance degradation over time. Contact resistance between thermoelectric elements and heat exchangers tends to increase with repeated thermal cycling, progressively reducing system efficiency. Current modules typically demonstrate 10-15% performance degradation after 5,000 hours of operation in variable temperature conditions.

Addressing these interconnected challenges requires multidisciplinary approaches spanning materials science, thermal engineering, electronics, and manufacturing technology. Recent research directions include nanostructured materials, flexible thermoelectric generators, hybrid energy harvesting systems, and advanced thermal interface materials—all aiming to overcome the fundamental limitations that currently restrict low-temperature thermoelectric technology.

Material limitations constitute another significant barrier. Conventional thermoelectric materials like bismuth telluride (Bi₂Te₃) perform adequately at room temperature but struggle to maintain optimal figure of merit (ZT) values at the lower end of the temperature spectrum. The search for materials with enhanced ZT values below 100°C continues to challenge researchers, with complex trade-offs between electrical conductivity, thermal conductivity, and Seebeck coefficient proving difficult to optimize simultaneously.

Thermal management issues present additional complications in low-temperature applications. Maintaining stable temperature differentials across thermoelectric modules becomes particularly challenging when ambient conditions fluctuate or when heat sources provide inconsistent thermal energy. The parasitic heat losses through conduction, convection, and radiation often overwhelm the useful temperature gradient, especially in miniaturized or portable systems where insulation options are limited.

Manufacturing scalability represents another significant hurdle. Current production methods for high-quality thermoelectric modules involve complex processes including precise doping, specialized sintering techniques, and meticulous assembly. These requirements drive up costs substantially, with prices typically exceeding $10 per watt of generating capacity—far higher than competing energy harvesting technologies like photovoltaics.

System integration challenges further complicate implementation. Low-temperature thermoelectric generators produce variable, low-voltage DC output that requires sophisticated power management circuitry to convert into usable electricity. The additional components not only increase system complexity and cost but also introduce power losses that further reduce overall efficiency.

Durability and reliability concerns persist in real-world applications. Thermal cycling, mechanical stress, and environmental exposure can lead to performance degradation over time. Contact resistance between thermoelectric elements and heat exchangers tends to increase with repeated thermal cycling, progressively reducing system efficiency. Current modules typically demonstrate 10-15% performance degradation after 5,000 hours of operation in variable temperature conditions.

Addressing these interconnected challenges requires multidisciplinary approaches spanning materials science, thermal engineering, electronics, and manufacturing technology. Recent research directions include nanostructured materials, flexible thermoelectric generators, hybrid energy harvesting systems, and advanced thermal interface materials—all aiming to overcome the fundamental limitations that currently restrict low-temperature thermoelectric technology.

Existing Low-Temperature Thermoelectric Module Solutions

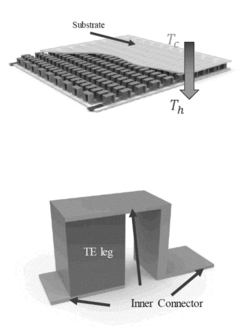

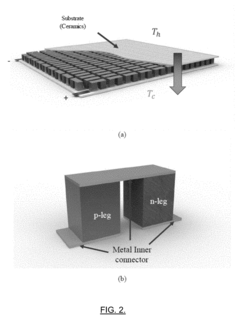

01 Thermoelectric module design for improved energy harvesting

Specific designs of thermoelectric modules can enhance energy harvesting efficiency. These designs focus on optimizing the structure and arrangement of thermoelectric elements to maximize power generation from temperature differentials. Innovations include specialized semiconductor materials, improved thermal interfaces, and novel geometrical configurations that increase the conversion efficiency of thermal energy into electrical energy.- Thermoelectric module design for improved energy harvesting: Advanced designs of thermoelectric modules can significantly improve energy harvesting efficiency. These designs focus on optimizing the structure and materials of the module to maximize the conversion of temperature differences into electrical energy. Innovations include specialized semiconductor arrangements, improved thermal interfaces, and novel junction configurations that enhance the Seebeck effect. These design improvements allow for more efficient capture of waste heat and conversion to usable electricity.

- Integration of thermoelectric modules in vehicle systems: Thermoelectric modules can be integrated into vehicle systems to harvest energy from waste heat produced by engines, exhaust systems, and other components. This recovered energy can be used to power auxiliary systems, improve fuel efficiency, or charge batteries in electric and hybrid vehicles. The integration involves strategic placement of thermoelectric generators at heat sources within the vehicle, along with appropriate power management systems to utilize the harvested energy effectively.

- Power management systems for thermoelectric energy harvesting: Specialized power management systems are essential for optimizing the output from thermoelectric energy harvesters. These systems include voltage regulators, DC-DC converters, and energy storage solutions that can handle the variable and often low-voltage output from thermoelectric modules. Advanced power management circuits can track the maximum power point, adapt to changing temperature differentials, and efficiently store harvested energy for later use, significantly improving the overall effectiveness of thermoelectric energy harvesting systems.

- Wearable and portable thermoelectric energy harvesting devices: Thermoelectric modules can be incorporated into wearable and portable devices to harvest energy from body heat or environmental temperature differences. These compact systems can power sensors, medical devices, or consumer electronics without the need for traditional batteries. The designs focus on flexibility, comfort, and efficient operation at the relatively small temperature differentials available in these applications. Miniaturization techniques and flexible substrates enable these modules to conform to various shapes while maintaining energy harvesting capabilities.

- Material innovations for enhanced thermoelectric performance: Novel materials and material combinations are being developed to enhance the performance of thermoelectric modules. These include nanostructured materials, semiconductor alloys, and composite materials that offer improved thermoelectric properties such as higher Seebeck coefficients and lower thermal conductivity. Material innovations focus on increasing the figure of merit (ZT) of thermoelectric materials, which directly impacts energy conversion efficiency. Advanced manufacturing techniques like thin-film deposition and nanostructuring are employed to optimize material properties for specific temperature ranges and applications.

02 Waste heat recovery systems using thermoelectric modules

Thermoelectric modules can be integrated into systems designed to recover waste heat from various sources such as industrial processes, vehicle exhaust systems, or electronic devices. These systems capture thermal energy that would otherwise be lost and convert it into usable electrical power. The implementation includes heat exchangers, thermal management components, and power conditioning circuits to optimize the energy harvesting process.Expand Specific Solutions03 Power management circuits for thermoelectric energy harvesting

Specialized power management circuits are essential for efficient thermoelectric energy harvesting. These circuits include DC-DC converters, voltage regulators, and maximum power point tracking systems that optimize the extraction of energy from thermoelectric modules operating under varying temperature conditions. The circuits ensure that the low voltage output from thermoelectric generators is effectively converted to usable power for practical applications.Expand Specific Solutions04 Wearable and portable thermoelectric energy harvesting devices

Thermoelectric modules can be incorporated into wearable and portable devices to harvest body heat or environmental temperature differentials. These applications include smart clothing, wearable health monitors, and portable electronics that can generate their own power from ambient temperature differences. The designs focus on flexibility, comfort, and miniaturization while maintaining efficient energy conversion.Expand Specific Solutions05 Integration of thermoelectric modules with other renewable energy systems

Thermoelectric modules can be combined with other renewable energy technologies such as solar panels, wind turbines, or geothermal systems to create hybrid energy harvesting solutions. These integrated systems leverage multiple energy sources to improve overall efficiency and reliability. The complementary nature of different energy harvesting methods allows for more consistent power generation across varying environmental conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

Thermoelectric module technology for low-temperature energy harvesting is evolving rapidly in a growing market estimated to reach significant scale by 2030. The industry is transitioning from early development to commercial adoption phase, with varying levels of technical maturity across players. Leading companies like LG Innotek, Kyocera, and KELK have established advanced thermoelectric solutions, while research institutions such as MIT and Industrial Technology Research Institute continue pushing boundaries in material science. Automotive manufacturers including Hyundai, Kia, and Honda are increasingly integrating these technologies for waste heat recovery. The competitive landscape features both specialized thermoelectric module manufacturers and diversified electronics corporations developing proprietary solutions to address efficiency challenges at low temperature differentials.

LG Innotek Co., Ltd.

Technical Solution: LG Innotek has developed a proprietary thermoelectric module technology specifically designed for low-temperature energy harvesting applications. Their modules utilize advanced bismuth-telluride alloys with precisely controlled doping profiles that optimize carrier concentration for room-temperature operation. LG's manufacturing process incorporates unique nano-structuring techniques that create controlled interfaces to scatter phonons while allowing electrons to flow freely, significantly improving the ZT value at low temperature differentials. Their modules feature a high-density arrangement of thermoelectric couples (over 100 per cm²) connected through proprietary low-resistance interconnects, maximizing power output from minimal temperature gradients. LG Innotek has also developed specialized ceramic substrates with tailored thermal expansion coefficients that minimize mechanical stress during thermal cycling, enhancing durability in variable ambient conditions typical of energy harvesting applications.

Strengths: Mass production capabilities ensuring consistent quality and competitive pricing; comprehensive integration solutions for various applications; strong reliability testing and quality control processes. Weaknesses: Less specialized in extreme low-temperature differentials compared to research-focused organizations; more conservative material choices prioritizing reliability over cutting-edge performance; higher minimum order quantities limiting accessibility for small-scale applications.

Toshiba Corp.

Technical Solution: Toshiba Corporation has developed advanced thermoelectric modules optimized for low-temperature energy harvesting through their proprietary "n-type/p-type semiconductor co-integration" technology. Their modules utilize bismuth-telluride alloys with precisely engineered nanostructures that create quantum confinement effects, enhancing the Seebeck coefficient at near-ambient temperatures. Toshiba's manufacturing process incorporates unique electrode designs that minimize electrical contact resistance while maintaining thermal barriers, addressing a key efficiency challenge in low-temperature operation. Their modules feature a cascaded architecture with different material compositions optimized for specific temperature ranges, enabling efficient energy capture across fluctuating ambient conditions. Toshiba has also developed specialized power management ICs that work in conjunction with their thermoelectric modules to harvest energy from temperature differentials as low as 1°C, making previously unusable waste heat viable for powering IoT sensors and other low-power electronics.

Strengths: Vertical integration from materials research to system solutions; extensive intellectual property portfolio in thermoelectric technologies; strong manufacturing capabilities ensuring product consistency and reliability. Weaknesses: Higher cost compared to conventional energy harvesting technologies; limited flexibility in module form factors; requires specialized knowledge for optimal system integration.

Key Innovations in Thermoelectric Material Science

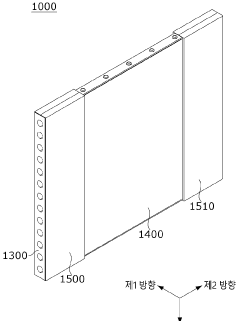

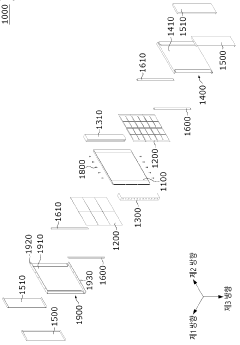

Thermoelectric module

PatentWO2024101926A1

Innovation

- A thermoelectric module design featuring a cooling jacket with a through hole for fluid flow, a thermoelectric element with a semiconductor device and electrodes, and a thermally conductive shield member with overlapping portions to enhance heat transfer and electrical connectivity, allowing for increased temperature difference utilization and efficient power generation.

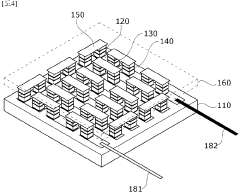

Thermoelectric energy harvesting from pavement structure

PatentInactiveUS20180033937A1

Innovation

- A thermoelectric-based energy harvesting system with a flexible, electrically parallel thermoelectric module structure, integrated with a thermally conductive plate and heat sink, optimized for cross-plane temperature gradients, and fabricated using 3D printing for durability and large-area energy harvesting, addressing the limitations of traditional serial structures and heat exchanger designs.

Environmental Impact and Sustainability Assessment

Thermoelectric modules represent a significant advancement in sustainable energy technology, particularly in the realm of low-temperature energy harvesting. The environmental implications of this technology extend far beyond mere energy generation capabilities. By capturing waste heat that would otherwise be released into the atmosphere, thermoelectric modules contribute substantially to reducing thermal pollution, which can disrupt local ecosystems and aquatic environments.

The life cycle assessment of thermoelectric modules reveals favorable environmental metrics compared to conventional energy technologies. These modules typically contain semiconductor materials like bismuth telluride, which require careful sourcing and eventual disposal. However, their long operational lifespan—often exceeding 200,000 hours—significantly offsets the initial environmental footprint of material extraction and manufacturing processes.

From a carbon footprint perspective, thermoelectric energy harvesting systems demonstrate remarkable advantages. Once installed, these systems generate electricity with zero direct emissions, potentially displacing fossil fuel-based electricity generation. Quantitative analyses indicate that a medium-scale thermoelectric waste heat recovery system can reduce carbon emissions by 1.5-2.5 tons annually per kilowatt of installed capacity, depending on the energy mix it replaces.

The resource efficiency of thermoelectric modules also warrants attention in sustainability assessments. Unlike many renewable energy technologies that require substantial land use or specialized installation conditions, thermoelectric harvesters can be integrated into existing industrial processes, buildings, and even consumer products with minimal additional resource requirements. This characteristic makes them particularly valuable in urban environments where space constraints limit other renewable energy options.

Circular economy principles are increasingly being applied to thermoelectric module design and deployment. Recent innovations focus on improving material recoverability at end-of-life, with some manufacturers implementing take-back programs to reclaim valuable elements from decommissioned modules. Additionally, research into bio-based and less toxic thermoelectric materials shows promise for reducing the technology's dependence on rare or environmentally problematic elements.

The scalability of thermoelectric technology further enhances its sustainability profile. From milliwatt-scale applications in self-powered sensors to kilowatt-scale industrial waste heat recovery systems, thermoelectric modules can be deployed across diverse settings with proportional environmental benefits. This versatility enables incremental adoption pathways that align with gradual decarbonization strategies across multiple sectors.

The life cycle assessment of thermoelectric modules reveals favorable environmental metrics compared to conventional energy technologies. These modules typically contain semiconductor materials like bismuth telluride, which require careful sourcing and eventual disposal. However, their long operational lifespan—often exceeding 200,000 hours—significantly offsets the initial environmental footprint of material extraction and manufacturing processes.

From a carbon footprint perspective, thermoelectric energy harvesting systems demonstrate remarkable advantages. Once installed, these systems generate electricity with zero direct emissions, potentially displacing fossil fuel-based electricity generation. Quantitative analyses indicate that a medium-scale thermoelectric waste heat recovery system can reduce carbon emissions by 1.5-2.5 tons annually per kilowatt of installed capacity, depending on the energy mix it replaces.

The resource efficiency of thermoelectric modules also warrants attention in sustainability assessments. Unlike many renewable energy technologies that require substantial land use or specialized installation conditions, thermoelectric harvesters can be integrated into existing industrial processes, buildings, and even consumer products with minimal additional resource requirements. This characteristic makes them particularly valuable in urban environments where space constraints limit other renewable energy options.

Circular economy principles are increasingly being applied to thermoelectric module design and deployment. Recent innovations focus on improving material recoverability at end-of-life, with some manufacturers implementing take-back programs to reclaim valuable elements from decommissioned modules. Additionally, research into bio-based and less toxic thermoelectric materials shows promise for reducing the technology's dependence on rare or environmentally problematic elements.

The scalability of thermoelectric technology further enhances its sustainability profile. From milliwatt-scale applications in self-powered sensors to kilowatt-scale industrial waste heat recovery systems, thermoelectric modules can be deployed across diverse settings with proportional environmental benefits. This versatility enables incremental adoption pathways that align with gradual decarbonization strategies across multiple sectors.

Cost-Benefit Analysis of Thermoelectric Implementation

The implementation of thermoelectric modules for low-temperature energy harvesting requires careful cost-benefit analysis to determine economic viability. Initial capital expenditure for thermoelectric systems remains relatively high, with quality modules ranging from $5-30 per unit depending on size, efficiency rating, and manufacturing precision. When scaled to industrial applications, installation costs typically add 30-45% to hardware expenses, creating significant entry barriers for widespread adoption.

Operating costs present a more favorable picture. Thermoelectric modules contain no moving parts, resulting in minimal maintenance requirements compared to traditional energy generation systems. Lifecycle analysis indicates maintenance costs averaging just 2-5% of initial investment annually, with expected operational lifespans of 15-25 years under proper thermal management conditions. This long-term reliability significantly enhances return on investment calculations.

Energy conversion efficiency remains a critical economic factor. Current commercial thermoelectric modules achieve 5-8% efficiency at low temperature differentials (20-100°C), substantially lower than conventional power generation methods. However, when harvesting otherwise wasted heat in industrial processes, this efficiency becomes economically viable as the input energy cost approaches zero. Sensitivity analysis shows that for waste heat applications, payback periods typically range from 3-7 years depending on installation complexity and energy prices.

Environmental benefits provide additional economic value through regulatory compliance and sustainability initiatives. Quantitative assessment of carbon reduction potential indicates that each kilowatt of energy harvested through thermoelectric systems potentially offsets 0.4-0.6 metric tons of CO2 annually when replacing grid electricity from fossil sources. In jurisdictions with carbon pricing mechanisms, this represents $8-30 per ton in additional economic benefit.

Scalability economics demonstrate interesting patterns. While per-unit costs decrease with volume manufacturing, system integration complexity increases with scale. Optimal economic efficiency typically occurs at medium-scale implementations (50-500kW capacity), where component costs benefit from volume pricing while avoiding the exponential increase in system engineering complexity found in larger installations. This "sweet spot" for implementation provides guidance for phased deployment strategies that maximize economic returns.

Operating costs present a more favorable picture. Thermoelectric modules contain no moving parts, resulting in minimal maintenance requirements compared to traditional energy generation systems. Lifecycle analysis indicates maintenance costs averaging just 2-5% of initial investment annually, with expected operational lifespans of 15-25 years under proper thermal management conditions. This long-term reliability significantly enhances return on investment calculations.

Energy conversion efficiency remains a critical economic factor. Current commercial thermoelectric modules achieve 5-8% efficiency at low temperature differentials (20-100°C), substantially lower than conventional power generation methods. However, when harvesting otherwise wasted heat in industrial processes, this efficiency becomes economically viable as the input energy cost approaches zero. Sensitivity analysis shows that for waste heat applications, payback periods typically range from 3-7 years depending on installation complexity and energy prices.

Environmental benefits provide additional economic value through regulatory compliance and sustainability initiatives. Quantitative assessment of carbon reduction potential indicates that each kilowatt of energy harvested through thermoelectric systems potentially offsets 0.4-0.6 metric tons of CO2 annually when replacing grid electricity from fossil sources. In jurisdictions with carbon pricing mechanisms, this represents $8-30 per ton in additional economic benefit.

Scalability economics demonstrate interesting patterns. While per-unit costs decrease with volume manufacturing, system integration complexity increases with scale. Optimal economic efficiency typically occurs at medium-scale implementations (50-500kW capacity), where component costs benefit from volume pricing while avoiding the exponential increase in system engineering complexity found in larger installations. This "sweet spot" for implementation provides guidance for phased deployment strategies that maximize economic returns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!