Research on Hybrid Thermoelectric Modules for Multi-Source Heat Recovery

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Heat Recovery Technology Background and Objectives

Thermoelectric energy conversion technology has evolved significantly since its discovery in the early 19th century. The Seebeck effect, discovered by Thomas Johann Seebeck in 1821, laid the foundation for thermoelectric power generation by demonstrating that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This was followed by the discovery of the Peltier effect in 1834, which established the reversible nature of thermoelectric phenomena.

The practical application of thermoelectric technology gained momentum during the mid-20th century with the development of semiconductor materials. The introduction of bismuth telluride (Bi2Te3) in the 1950s marked a significant advancement, enabling the production of thermoelectric modules with improved efficiency. Since then, the field has witnessed continuous improvements in materials, design, and manufacturing techniques.

In recent decades, waste heat recovery has emerged as a critical focus area due to increasing energy costs and environmental concerns. Industrial processes, automotive engines, and power generation facilities collectively waste enormous amounts of heat energy, presenting a substantial opportunity for thermoelectric recovery systems. The global emphasis on carbon reduction and energy efficiency has further accelerated research in this domain.

Hybrid thermoelectric modules represent the next evolutionary step, designed specifically to harvest heat from multiple sources simultaneously. Unlike conventional thermoelectric generators optimized for single heat sources, hybrid systems can efficiently capture energy from diverse thermal gradients with varying temperatures, flow rates, and temporal characteristics.

The primary objective of this research is to develop advanced hybrid thermoelectric modules capable of efficiently recovering heat from multiple sources in industrial and transportation applications. Specifically, we aim to achieve conversion efficiency improvements of at least 25% compared to conventional single-source modules when operating in multi-source environments.

Additional goals include designing scalable and adaptable module architectures that can be customized for specific application scenarios, reducing manufacturing costs through innovative materials and production techniques, and enhancing system durability to ensure operational lifespans exceeding 10 years under variable thermal cycling conditions.

The research also seeks to address the technical challenges of thermal management across multiple heat sources, optimize electrical configurations for varying input conditions, and develop intelligent control systems that can dynamically adjust to changing thermal environments. By achieving these objectives, hybrid thermoelectric modules could significantly contribute to global energy efficiency efforts and provide a viable solution for recovering currently wasted thermal energy across numerous industries.

The practical application of thermoelectric technology gained momentum during the mid-20th century with the development of semiconductor materials. The introduction of bismuth telluride (Bi2Te3) in the 1950s marked a significant advancement, enabling the production of thermoelectric modules with improved efficiency. Since then, the field has witnessed continuous improvements in materials, design, and manufacturing techniques.

In recent decades, waste heat recovery has emerged as a critical focus area due to increasing energy costs and environmental concerns. Industrial processes, automotive engines, and power generation facilities collectively waste enormous amounts of heat energy, presenting a substantial opportunity for thermoelectric recovery systems. The global emphasis on carbon reduction and energy efficiency has further accelerated research in this domain.

Hybrid thermoelectric modules represent the next evolutionary step, designed specifically to harvest heat from multiple sources simultaneously. Unlike conventional thermoelectric generators optimized for single heat sources, hybrid systems can efficiently capture energy from diverse thermal gradients with varying temperatures, flow rates, and temporal characteristics.

The primary objective of this research is to develop advanced hybrid thermoelectric modules capable of efficiently recovering heat from multiple sources in industrial and transportation applications. Specifically, we aim to achieve conversion efficiency improvements of at least 25% compared to conventional single-source modules when operating in multi-source environments.

Additional goals include designing scalable and adaptable module architectures that can be customized for specific application scenarios, reducing manufacturing costs through innovative materials and production techniques, and enhancing system durability to ensure operational lifespans exceeding 10 years under variable thermal cycling conditions.

The research also seeks to address the technical challenges of thermal management across multiple heat sources, optimize electrical configurations for varying input conditions, and develop intelligent control systems that can dynamically adjust to changing thermal environments. By achieving these objectives, hybrid thermoelectric modules could significantly contribute to global energy efficiency efforts and provide a viable solution for recovering currently wasted thermal energy across numerous industries.

Market Analysis for Hybrid Thermoelectric Solutions

The global market for hybrid thermoelectric solutions is experiencing significant growth, driven by increasing energy efficiency demands and waste heat recovery initiatives across multiple industries. The current market size for thermoelectric generators (TEGs) is estimated at $626 million in 2023, with projections indicating growth to reach $1.4 billion by 2030, representing a compound annual growth rate (CAGR) of approximately 12.2% during the forecast period.

Industrial sectors present the largest market opportunity, particularly manufacturing processes where substantial heat is generated and typically wasted. Automotive applications follow closely, with hybrid thermoelectric modules being integrated into exhaust systems to recover waste heat and improve fuel efficiency. This segment is expected to grow at 14.5% CAGR through 2030, outpacing other application areas.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is projected to witness the fastest growth rate at 15.8% annually, primarily driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting energy efficiency technologies.

Consumer demand for hybrid thermoelectric solutions is primarily influenced by three factors: increasing energy costs, stringent environmental regulations, and corporate sustainability goals. The ability of hybrid thermoelectric modules to simultaneously harvest heat from multiple sources represents a significant value proposition, potentially increasing energy recovery efficiency by 20-30% compared to conventional single-source systems.

Market penetration faces challenges including high initial investment costs, with current hybrid systems priced 40-60% higher than conventional alternatives. Additionally, conversion efficiency limitations remain a technical barrier, with most commercial systems operating at 5-8% efficiency, though laboratory prototypes have demonstrated up to 12% efficiency with multi-source configurations.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and Ferrotec holding approximately 45% combined market share. However, emerging companies specializing in hybrid technologies, such as ThermoAnalytics and Alphabet Energy, are gaining traction with innovative multi-source recovery solutions. Strategic partnerships between technology providers and end-users are becoming increasingly common, accelerating commercialization and market adoption.

Customer willingness to pay correlates strongly with payback period, with market research indicating optimal adoption when ROI can be demonstrated within 3-4 years. This threshold is currently achievable in high-temperature industrial applications but remains challenging in lower-temperature recovery scenarios.

Industrial sectors present the largest market opportunity, particularly manufacturing processes where substantial heat is generated and typically wasted. Automotive applications follow closely, with hybrid thermoelectric modules being integrated into exhaust systems to recover waste heat and improve fuel efficiency. This segment is expected to grow at 14.5% CAGR through 2030, outpacing other application areas.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is projected to witness the fastest growth rate at 15.8% annually, primarily driven by rapid industrialization in China and India, coupled with increasing government initiatives promoting energy efficiency technologies.

Consumer demand for hybrid thermoelectric solutions is primarily influenced by three factors: increasing energy costs, stringent environmental regulations, and corporate sustainability goals. The ability of hybrid thermoelectric modules to simultaneously harvest heat from multiple sources represents a significant value proposition, potentially increasing energy recovery efficiency by 20-30% compared to conventional single-source systems.

Market penetration faces challenges including high initial investment costs, with current hybrid systems priced 40-60% higher than conventional alternatives. Additionally, conversion efficiency limitations remain a technical barrier, with most commercial systems operating at 5-8% efficiency, though laboratory prototypes have demonstrated up to 12% efficiency with multi-source configurations.

The competitive landscape features established players like Gentherm, Laird Thermal Systems, and Ferrotec holding approximately 45% combined market share. However, emerging companies specializing in hybrid technologies, such as ThermoAnalytics and Alphabet Energy, are gaining traction with innovative multi-source recovery solutions. Strategic partnerships between technology providers and end-users are becoming increasingly common, accelerating commercialization and market adoption.

Customer willingness to pay correlates strongly with payback period, with market research indicating optimal adoption when ROI can be demonstrated within 3-4 years. This threshold is currently achievable in high-temperature industrial applications but remains challenging in lower-temperature recovery scenarios.

Current Challenges in Multi-Source Heat Recovery Systems

Despite significant advancements in waste heat recovery technologies, multi-source heat recovery systems face several critical challenges that impede their widespread implementation and optimal performance. The primary obstacle remains the effective integration of diverse heat sources with varying temperature profiles, flow rates, and temporal availability patterns. Industrial environments typically generate heat from multiple processes at different temperature ranges—from high-temperature furnace exhausts (400-800°C) to low-grade waste heat (80-150°C)—making unified recovery systems technically complex.

Thermal management presents another significant challenge, particularly in hybrid thermoelectric module applications. The simultaneous handling of multiple heat sources creates complex thermal gradients that can lead to thermal stress, reduced component lifespan, and decreased conversion efficiency. Current heat exchanger designs struggle to maintain optimal temperature differentials across thermoelectric elements when input conditions fluctuate unpredictably.

Material limitations constitute a substantial barrier to advancement in this field. Existing thermoelectric materials exhibit peak efficiency within narrow temperature ranges, making them ill-suited for the variable conditions of multi-source environments. While bismuth telluride performs adequately at lower temperatures (up to 250°C), and silicon-germanium alloys function at higher temperatures, no single material currently offers high efficiency across the broad temperature spectrum encountered in industrial waste heat scenarios.

Control system complexity represents another formidable challenge. Dynamic load balancing and real-time optimization across multiple heat sources require sophisticated algorithms and sensing technologies that exceed the capabilities of conventional control systems. The interdependence of various recovery subsystems further complicates the development of unified control strategies that can maximize overall system efficiency rather than optimizing individual components.

Economic viability remains problematic due to high initial capital costs and extended payback periods. The custom engineering required for multi-source systems significantly increases implementation expenses compared to single-source solutions. Current cost-benefit analyses often fail to adequately account for the complexity of integrating diverse heat sources, leading to unrealistic performance expectations and financial projections.

Scalability and adaptability issues persist as systems designed for specific industrial configurations prove difficult to replicate or modify for different applications. The bespoke nature of current multi-source recovery solutions limits their broader market adoption and increases engineering costs. Additionally, the lack of standardized evaluation metrics for multi-source systems complicates performance comparisons and technology assessment.

Regulatory frameworks and industry standards specifically addressing multi-source heat recovery systems remain underdeveloped, creating uncertainty for technology developers and potential adopters. This regulatory gap hampers investment and slows the pace of innovation in hybrid thermoelectric technologies for waste heat recovery applications.

Thermal management presents another significant challenge, particularly in hybrid thermoelectric module applications. The simultaneous handling of multiple heat sources creates complex thermal gradients that can lead to thermal stress, reduced component lifespan, and decreased conversion efficiency. Current heat exchanger designs struggle to maintain optimal temperature differentials across thermoelectric elements when input conditions fluctuate unpredictably.

Material limitations constitute a substantial barrier to advancement in this field. Existing thermoelectric materials exhibit peak efficiency within narrow temperature ranges, making them ill-suited for the variable conditions of multi-source environments. While bismuth telluride performs adequately at lower temperatures (up to 250°C), and silicon-germanium alloys function at higher temperatures, no single material currently offers high efficiency across the broad temperature spectrum encountered in industrial waste heat scenarios.

Control system complexity represents another formidable challenge. Dynamic load balancing and real-time optimization across multiple heat sources require sophisticated algorithms and sensing technologies that exceed the capabilities of conventional control systems. The interdependence of various recovery subsystems further complicates the development of unified control strategies that can maximize overall system efficiency rather than optimizing individual components.

Economic viability remains problematic due to high initial capital costs and extended payback periods. The custom engineering required for multi-source systems significantly increases implementation expenses compared to single-source solutions. Current cost-benefit analyses often fail to adequately account for the complexity of integrating diverse heat sources, leading to unrealistic performance expectations and financial projections.

Scalability and adaptability issues persist as systems designed for specific industrial configurations prove difficult to replicate or modify for different applications. The bespoke nature of current multi-source recovery solutions limits their broader market adoption and increases engineering costs. Additionally, the lack of standardized evaluation metrics for multi-source systems complicates performance comparisons and technology assessment.

Regulatory frameworks and industry standards specifically addressing multi-source heat recovery systems remain underdeveloped, creating uncertainty for technology developers and potential adopters. This regulatory gap hampers investment and slows the pace of innovation in hybrid thermoelectric technologies for waste heat recovery applications.

Current Hybrid Thermoelectric Module Designs

01 Thermoelectric module design for waste heat recovery

Specialized thermoelectric modules designed specifically for waste heat recovery applications. These modules are engineered to efficiently convert thermal energy from waste heat sources into electrical power. The designs focus on optimizing the thermoelectric materials, junction configurations, and overall module architecture to maximize energy conversion efficiency under varying temperature gradients typically found in industrial waste heat scenarios.- Thermoelectric module design for waste heat recovery: Specialized thermoelectric modules designed specifically for waste heat recovery applications. These designs focus on optimizing the conversion of thermal energy from waste heat sources into electrical energy. The modules incorporate materials with high Seebeck coefficients and are structured to maximize temperature differentials across the module, thereby enhancing conversion efficiency in industrial waste heat recovery systems.

- Hybrid systems combining thermoelectric modules with other heat recovery technologies: Integration of thermoelectric modules with complementary heat recovery technologies such as heat exchangers, heat pumps, or organic Rankine cycles. These hybrid systems leverage the strengths of multiple technologies to achieve higher overall efficiency in heat recovery. The combined approach allows for cascaded heat recovery, where waste heat not converted by one technology can be utilized by another, maximizing the total energy recovered from thermal sources.

- Vehicle exhaust heat recovery using thermoelectric modules: Application of thermoelectric modules for recovering waste heat from vehicle exhaust systems. These specialized implementations are designed to withstand high temperatures and vibrations while converting exhaust heat into usable electrical energy. The recovered energy can supplement the vehicle's electrical system, reducing alternator load and improving fuel efficiency. Various mounting configurations and heat exchanger designs are employed to optimize heat transfer from exhaust gases to the thermoelectric modules.

- Industrial waste heat recovery systems with thermoelectric modules: Large-scale thermoelectric systems designed for industrial applications where significant waste heat is generated. These systems are engineered to handle high heat loads from industrial processes such as manufacturing, power generation, or chemical production. The modules are often arranged in arrays to maximize surface area for heat capture and may incorporate advanced cooling systems to maintain optimal temperature differentials. Control systems are implemented to manage variable heat inputs and optimize power output under changing conditions.

- Structural innovations for improved thermoelectric heat recovery: Novel structural designs and material configurations that enhance the performance of thermoelectric modules in heat recovery applications. These innovations include segmented or cascaded thermoelectric elements, improved thermal interfaces, and specialized heat spreaders. Advanced manufacturing techniques are employed to create optimized junction structures and reduce thermal resistance. Some designs incorporate flexible or modular configurations to adapt to various heat source geometries, improving versatility and installation efficiency.

02 Hybrid systems combining thermoelectric modules with other heat recovery technologies

Integration of thermoelectric modules with complementary heat recovery technologies to create hybrid systems with enhanced overall efficiency. These systems combine thermoelectric generators with technologies such as heat exchangers, heat pumps, or organic Rankine cycles. The hybrid approach leverages the strengths of each technology to overcome individual limitations, resulting in more effective waste heat utilization across broader temperature ranges and operating conditions.Expand Specific Solutions03 Automotive applications of thermoelectric heat recovery

Implementation of thermoelectric modules in automotive systems to recover waste heat from exhaust gases and engine cooling systems. These applications focus on converting thermal energy that would otherwise be lost to the environment into useful electrical power for vehicle systems. The recovered electricity can supplement the vehicle's electrical system, reducing alternator load and improving fuel efficiency. Designs address challenges related to variable heat sources, space constraints, and durability requirements specific to automotive environments.Expand Specific Solutions04 Industrial waste heat recovery systems using thermoelectric technology

Large-scale thermoelectric systems designed for industrial applications where significant waste heat is generated. These systems are engineered to capture and convert heat from industrial processes such as manufacturing, power generation, and chemical production. The designs incorporate multiple thermoelectric modules arranged in arrays or cascades to handle high heat loads and large temperature differentials. Special attention is given to system integration, heat transfer optimization, and durability under harsh industrial conditions.Expand Specific Solutions05 Novel materials and structures for improved thermoelectric performance

Development of advanced materials and structural designs to enhance the performance of thermoelectric modules for heat recovery applications. These innovations include nanostructured materials, segmented legs, novel semiconductor compounds, and improved contact interfaces. The focus is on increasing the thermoelectric figure of merit (ZT) and reducing thermal resistance to achieve higher conversion efficiencies. Some approaches incorporate flexible or modular designs to accommodate various heat source geometries and operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Field

The hybrid thermoelectric module market for multi-source heat recovery is currently in a growth phase, with increasing adoption across automotive, industrial, and energy sectors. The market is projected to expand significantly due to rising energy efficiency demands and waste heat recovery initiatives. Leading players include established corporations like Toyota Motor Corp., DENSO, and Valeo Thermal Systems, which are leveraging their automotive expertise to develop advanced thermoelectric solutions. Research institutions such as Xi'an Jiaotong University, Korea Electrotechnology Research Institute, and Fraunhofer-Gesellschaft are driving technological innovation through fundamental research. Specialized companies like European Thermodynamics Limited and Alternative Energy Innovations are commercializing novel thermoelectric technologies, while industrial giants including Caterpillar, Komatsu, and Corning are integrating these systems into their product offerings to enhance energy efficiency and meet sustainability goals.

Valeo Thermal Systems Japan Corp.

Technical Solution: Valeo has developed an advanced hybrid thermoelectric system that integrates multiple heat recovery sources from vehicle exhaust, engine cooling, and brake systems. Their technology utilizes segmented thermoelectric materials with different temperature optimization ranges to maximize efficiency across varying thermal gradients. The system incorporates a proprietary heat exchanger design that enhances thermal transfer while minimizing pressure drops in exhaust flow. Valeo's solution includes intelligent thermal management controllers that dynamically adjust the system based on driving conditions, optimizing power generation during both highway cruising and urban stop-start scenarios. Their modules achieve conversion efficiencies of up to 7-8% in real-world automotive applications, significantly higher than conventional single-source recovery systems.

Strengths: Comprehensive integration with existing vehicle thermal systems; proven durability in automotive environments; scalable manufacturing process. Weaknesses: Higher initial cost compared to conventional systems; requires complex control algorithms; performance degradation at extreme temperature fluctuations.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang has pioneered a hybrid thermoelectric solution specifically designed for industrial waste heat recovery applications. Their system combines traditional organic Rankine cycle technology with thermoelectric generators in a cascaded configuration, allowing for optimal energy harvesting across wide temperature differentials (80-600°C). The company's proprietary heat transfer enhancement technology utilizes micro-channel heat exchangers with specially designed turbulators that increase heat transfer coefficients by up to 40% compared to conventional designs. Their modular approach enables scalable implementation in various industrial settings, from steel mills to chemical plants, with power generation capacities ranging from 50kW to 5MW. The system incorporates advanced phase-change materials as thermal buffers to maintain stable operation during process fluctuations, addressing a key challenge in industrial heat recovery applications.

Strengths: Exceptional versatility across industrial applications; high durability in harsh industrial environments; modular design allows for easy maintenance and expansion. Weaknesses: Requires significant initial capital investment; complex installation process; performance optimization needed for each specific industrial process.

Key Patents and Innovations in Thermoelectric Materials

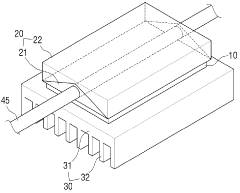

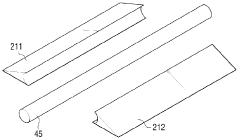

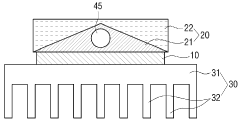

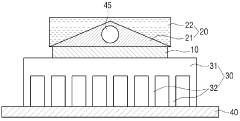

Thermoelectric module for heat recovery attachable to refrigerating and air conditioning apparatus

PatentActiveKR1020180032237A

Innovation

- A thermoelectric module is designed to be directly installed in refrigerant pipes, comprising a thermoelectric element, a heat sink part, and a cold sink part, with a heat collecting plate member and insulating material cover, allowing easy attachment and detachment, and enhancing thermal energy recovery by generating current from refrigerant thermal energy.

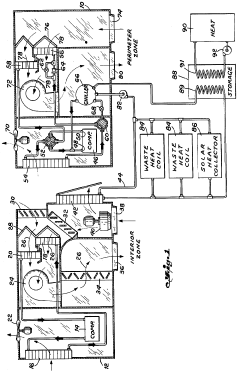

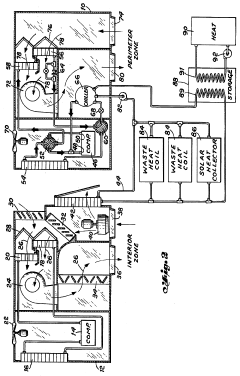

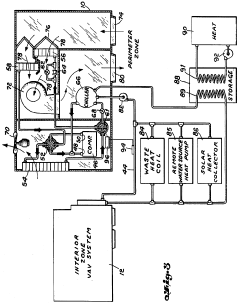

Multi-source heat pump HVAC system

PatentInactiveUS4100763A

Innovation

- A multi-source heat pump system that operates as an air-to-air heat pump during cooling and reverses to a liquid-to-air heat pump during heating, using waste heat recovery coils and a closed liquid circulating loop with storage, eliminating frost issues and optimizing energy use by recovering and storing waste heat.

Energy Conversion Efficiency Metrics and Standards

The standardization of energy conversion efficiency metrics is crucial for the advancement and commercialization of hybrid thermoelectric modules (HTEMs) in multi-source heat recovery applications. Currently, the industry employs several key performance indicators to evaluate thermoelectric technologies, with the figure of merit ZT being the most widely recognized parameter. This dimensionless value combines electrical conductivity, Seebeck coefficient, and thermal conductivity to provide a comprehensive assessment of material efficiency.

For practical applications in waste heat recovery systems, power conversion efficiency (PCE) serves as a more applicable metric, typically ranging from 5-10% in commercial thermoelectric generators. However, traditional efficiency metrics often fail to account for the unique characteristics of hybrid systems that integrate multiple heat sources with varying temperature profiles and intermittent availability.

The International Electrotechnical Commission (IEC) has established standard IEC 62108 for concentrated photovoltaic systems, which provides a foundation for hybrid energy harvesting technologies. Similarly, ASTM International has developed test methods E2781 for thermoelectric materials and devices. These standards, while valuable, require adaptation to address the specific challenges of hybrid thermoelectric modules operating across diverse thermal environments.

Recent developments include the Levelized Cost of Thermoelectric Energy (LCOTE) metric, which incorporates economic factors alongside technical performance parameters. This approach enables more meaningful comparisons between different heat recovery technologies by accounting for installation costs, operational expenses, and system lifespan.

The European Committee for Standardization (CEN) is currently developing a comprehensive framework specifically for waste heat recovery systems, which will include provisions for hybrid thermoelectric technologies. This initiative aims to harmonize testing protocols and reporting methodologies across the European market, potentially serving as a global benchmark.

For multi-source heat recovery applications, researchers have proposed the Effective Heat Recovery Efficiency (EHRE) index, which evaluates performance across fluctuating thermal conditions. This metric considers the system's ability to maintain optimal power output despite variations in heat source availability and temperature differentials, providing a more realistic assessment of real-world performance.

Moving forward, the industry requires standardized test conditions that simulate actual operating environments for hybrid thermoelectric modules, including thermal cycling, variable heat flux, and long-term stability assessments. The development of these comprehensive standards will accelerate market adoption by enabling fair comparisons between competing technologies and providing consumers with reliable performance expectations.

For practical applications in waste heat recovery systems, power conversion efficiency (PCE) serves as a more applicable metric, typically ranging from 5-10% in commercial thermoelectric generators. However, traditional efficiency metrics often fail to account for the unique characteristics of hybrid systems that integrate multiple heat sources with varying temperature profiles and intermittent availability.

The International Electrotechnical Commission (IEC) has established standard IEC 62108 for concentrated photovoltaic systems, which provides a foundation for hybrid energy harvesting technologies. Similarly, ASTM International has developed test methods E2781 for thermoelectric materials and devices. These standards, while valuable, require adaptation to address the specific challenges of hybrid thermoelectric modules operating across diverse thermal environments.

Recent developments include the Levelized Cost of Thermoelectric Energy (LCOTE) metric, which incorporates economic factors alongside technical performance parameters. This approach enables more meaningful comparisons between different heat recovery technologies by accounting for installation costs, operational expenses, and system lifespan.

The European Committee for Standardization (CEN) is currently developing a comprehensive framework specifically for waste heat recovery systems, which will include provisions for hybrid thermoelectric technologies. This initiative aims to harmonize testing protocols and reporting methodologies across the European market, potentially serving as a global benchmark.

For multi-source heat recovery applications, researchers have proposed the Effective Heat Recovery Efficiency (EHRE) index, which evaluates performance across fluctuating thermal conditions. This metric considers the system's ability to maintain optimal power output despite variations in heat source availability and temperature differentials, providing a more realistic assessment of real-world performance.

Moving forward, the industry requires standardized test conditions that simulate actual operating environments for hybrid thermoelectric modules, including thermal cycling, variable heat flux, and long-term stability assessments. The development of these comprehensive standards will accelerate market adoption by enabling fair comparisons between competing technologies and providing consumers with reliable performance expectations.

Environmental Impact and Sustainability Assessment

Hybrid thermoelectric modules for multi-source heat recovery represent a significant opportunity to address environmental challenges while promoting sustainable energy practices. The implementation of these technologies offers substantial environmental benefits through the reduction of waste heat emissions that would otherwise contribute to thermal pollution and increased ambient temperatures in industrial areas. By capturing and converting waste heat into usable electricity, these systems effectively decrease the carbon footprint associated with conventional power generation methods.

The life cycle assessment of hybrid thermoelectric modules reveals favorable sustainability metrics compared to traditional energy recovery systems. Materials used in thermoelectric modules, particularly advanced semiconductor compounds, do present certain environmental concerns regarding extraction and processing. However, the long operational lifespan of these modules, typically exceeding 15-20 years with minimal maintenance requirements, significantly offsets the initial environmental impact of their production.

Energy payback analysis indicates that hybrid thermoelectric systems can recover their embodied energy within 2-5 years depending on the application environment and heat source characteristics. This relatively short energy payback period enhances their overall sustainability profile, particularly when deployed in high-temperature industrial settings where waste heat is abundant and continuous.

The integration of multi-source heat recovery systems contributes meaningfully to circular economy principles by transforming waste streams into valuable energy resources. This approach aligns with global sustainability frameworks and supports industrial symbiosis where the waste outputs from one process become inputs for another, maximizing resource efficiency across industrial ecosystems.

Quantitative environmental impact assessments demonstrate that large-scale implementation of hybrid thermoelectric modules could potentially reduce industrial greenhouse gas emissions by 3-7% in energy-intensive sectors such as steel manufacturing, cement production, and petrochemical processing. This reduction stems not only from the direct energy recovery but also from decreased demand for primary energy generation.

Regulatory compliance considerations are increasingly favorable for thermoelectric heat recovery technologies, with many jurisdictions offering incentives for waste heat recovery implementations as part of broader climate change mitigation strategies. The technology's ability to operate silently, without moving parts, and with minimal water consumption further enhances its environmental credentials compared to alternative heat recovery methods such as Organic Rankine Cycle systems.

Future sustainability improvements for hybrid thermoelectric modules will likely focus on developing more environmentally benign thermoelectric materials, improving end-of-life recycling processes, and enhancing conversion efficiencies to maximize the environmental benefits per unit of installed capacity.

The life cycle assessment of hybrid thermoelectric modules reveals favorable sustainability metrics compared to traditional energy recovery systems. Materials used in thermoelectric modules, particularly advanced semiconductor compounds, do present certain environmental concerns regarding extraction and processing. However, the long operational lifespan of these modules, typically exceeding 15-20 years with minimal maintenance requirements, significantly offsets the initial environmental impact of their production.

Energy payback analysis indicates that hybrid thermoelectric systems can recover their embodied energy within 2-5 years depending on the application environment and heat source characteristics. This relatively short energy payback period enhances their overall sustainability profile, particularly when deployed in high-temperature industrial settings where waste heat is abundant and continuous.

The integration of multi-source heat recovery systems contributes meaningfully to circular economy principles by transforming waste streams into valuable energy resources. This approach aligns with global sustainability frameworks and supports industrial symbiosis where the waste outputs from one process become inputs for another, maximizing resource efficiency across industrial ecosystems.

Quantitative environmental impact assessments demonstrate that large-scale implementation of hybrid thermoelectric modules could potentially reduce industrial greenhouse gas emissions by 3-7% in energy-intensive sectors such as steel manufacturing, cement production, and petrochemical processing. This reduction stems not only from the direct energy recovery but also from decreased demand for primary energy generation.

Regulatory compliance considerations are increasingly favorable for thermoelectric heat recovery technologies, with many jurisdictions offering incentives for waste heat recovery implementations as part of broader climate change mitigation strategies. The technology's ability to operate silently, without moving parts, and with minimal water consumption further enhances its environmental credentials compared to alternative heat recovery methods such as Organic Rankine Cycle systems.

Future sustainability improvements for hybrid thermoelectric modules will likely focus on developing more environmentally benign thermoelectric materials, improving end-of-life recycling processes, and enhancing conversion efficiencies to maximize the environmental benefits per unit of installed capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!