Research on Thermal Conductivity Optimization in Thermoelectric Modules

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon in 1821. The Seebeck effect, which describes the direct conversion of temperature differences to electric voltage, laid the foundation for thermoelectric materials development. By the mid-20th century, semiconductor-based thermoelectric devices emerged, marking a pivotal advancement in the field with the introduction of bismuth telluride (Bi2Te3) compounds in the 1950s, which remain prevalent in commercial applications today.

The evolution trajectory has been characterized by three distinct waves of innovation. The first wave (1950s-1970s) focused on semiconductor physics and basic material development. The second wave (1980s-2000s) introduced nanostructuring techniques to enhance the figure of merit (ZT), while the current third wave (2000s-present) emphasizes complex material systems, including skutterudites, half-Heusler alloys, and organic thermoelectric materials, aiming to overcome efficiency limitations.

Recent technological advancements have shifted focus toward thermal conductivity optimization as a critical factor in improving thermoelectric efficiency. This approach recognizes that reducing thermal conductivity while maintaining electrical conductivity represents one of the most promising pathways to enhance the ZT value, which directly correlates with conversion efficiency. Innovations in phonon engineering, interface design, and hierarchical architectures have emerged as key strategies in this domain.

The primary objectives of current research on thermal conductivity optimization in thermoelectric modules include achieving ZT values consistently above 2.0 for commercial applications, developing manufacturing techniques that preserve nanoscale thermal barriers while enabling mass production, and creating environmentally sustainable thermoelectric materials that reduce dependence on rare or toxic elements like tellurium and lead.

Additionally, research aims to bridge the gap between laboratory demonstrations and practical applications by addressing challenges in module design, thermal cycling stability, and contact resistance minimization. The ultimate goal is to position thermoelectric technology as a viable solution for waste heat recovery in industrial processes, automotive applications, and distributed power generation, potentially recovering a significant portion of the estimated 60% of global energy production currently lost as waste heat.

Future technological trajectories point toward hybrid systems that combine thermoelectric generators with other energy harvesting technologies, as well as flexible and wearable thermoelectric devices for personalized energy generation. These developments align with broader sustainability objectives and the growing demand for decentralized power solutions in an increasingly electrified global economy.

The evolution trajectory has been characterized by three distinct waves of innovation. The first wave (1950s-1970s) focused on semiconductor physics and basic material development. The second wave (1980s-2000s) introduced nanostructuring techniques to enhance the figure of merit (ZT), while the current third wave (2000s-present) emphasizes complex material systems, including skutterudites, half-Heusler alloys, and organic thermoelectric materials, aiming to overcome efficiency limitations.

Recent technological advancements have shifted focus toward thermal conductivity optimization as a critical factor in improving thermoelectric efficiency. This approach recognizes that reducing thermal conductivity while maintaining electrical conductivity represents one of the most promising pathways to enhance the ZT value, which directly correlates with conversion efficiency. Innovations in phonon engineering, interface design, and hierarchical architectures have emerged as key strategies in this domain.

The primary objectives of current research on thermal conductivity optimization in thermoelectric modules include achieving ZT values consistently above 2.0 for commercial applications, developing manufacturing techniques that preserve nanoscale thermal barriers while enabling mass production, and creating environmentally sustainable thermoelectric materials that reduce dependence on rare or toxic elements like tellurium and lead.

Additionally, research aims to bridge the gap between laboratory demonstrations and practical applications by addressing challenges in module design, thermal cycling stability, and contact resistance minimization. The ultimate goal is to position thermoelectric technology as a viable solution for waste heat recovery in industrial processes, automotive applications, and distributed power generation, potentially recovering a significant portion of the estimated 60% of global energy production currently lost as waste heat.

Future technological trajectories point toward hybrid systems that combine thermoelectric generators with other energy harvesting technologies, as well as flexible and wearable thermoelectric devices for personalized energy generation. These developments align with broader sustainability objectives and the growing demand for decentralized power solutions in an increasingly electrified global economy.

Market Analysis for Thermoelectric Applications

The global thermoelectric module market has demonstrated robust growth, valued at approximately $593 million in 2022 and projected to reach $1.2 billion by 2030, representing a compound annual growth rate (CAGR) of 8.2%. This growth trajectory is primarily driven by increasing demand for energy-efficient solutions across multiple industries, particularly as global energy consumption continues to rise amid growing environmental concerns.

The automotive sector represents one of the largest application segments for thermoelectric technology, accounting for roughly 35% of the market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by up to 5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring advanced thermoelectric applications.

Consumer electronics constitutes another significant market segment, representing approximately 28% of current applications. Thermoelectric cooling solutions are being deployed in portable refrigeration, temperature-controlled seats, and specialized electronic components. The miniaturization trend in electronics has created new opportunities for micro-scale thermoelectric modules with enhanced thermal conductivity properties.

Industrial applications account for 22% of the market, with thermoelectric solutions being utilized in process temperature control, remote power generation, and specialized equipment cooling. The remaining market share is distributed across medical devices, aerospace, and telecommunications sectors, each with unique thermal management requirements.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.7% annually, driven by rapid industrialization in China and India, along with strong electronics manufacturing bases in South Korea, Japan, and Taiwan.

Market analysis reveals that thermal conductivity optimization represents a critical competitive advantage, with modules demonstrating superior heat transfer capabilities commanding premium pricing of 15-20% above market averages. End-users consistently identify thermal efficiency as the second most important purchasing criterion after initial cost, highlighting the commercial value of advances in this technical domain.

The market landscape features approximately 45 significant manufacturers globally, with the top five players controlling 53% of market share. Recent merger and acquisition activity suggests industry consolidation, with larger conglomerates acquiring specialized thermoelectric technology firms to strengthen their thermal management portfolios and intellectual property positions.

The automotive sector represents one of the largest application segments for thermoelectric technology, accounting for roughly 35% of the market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by up to 5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs exploring advanced thermoelectric applications.

Consumer electronics constitutes another significant market segment, representing approximately 28% of current applications. Thermoelectric cooling solutions are being deployed in portable refrigeration, temperature-controlled seats, and specialized electronic components. The miniaturization trend in electronics has created new opportunities for micro-scale thermoelectric modules with enhanced thermal conductivity properties.

Industrial applications account for 22% of the market, with thermoelectric solutions being utilized in process temperature control, remote power generation, and specialized equipment cooling. The remaining market share is distributed across medical devices, aerospace, and telecommunications sectors, each with unique thermal management requirements.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region is experiencing the fastest growth rate at 9.7% annually, driven by rapid industrialization in China and India, along with strong electronics manufacturing bases in South Korea, Japan, and Taiwan.

Market analysis reveals that thermal conductivity optimization represents a critical competitive advantage, with modules demonstrating superior heat transfer capabilities commanding premium pricing of 15-20% above market averages. End-users consistently identify thermal efficiency as the second most important purchasing criterion after initial cost, highlighting the commercial value of advances in this technical domain.

The market landscape features approximately 45 significant manufacturers globally, with the top five players controlling 53% of market share. Recent merger and acquisition activity suggests industry consolidation, with larger conglomerates acquiring specialized thermoelectric technology firms to strengthen their thermal management portfolios and intellectual property positions.

Current Thermal Conductivity Challenges

Thermoelectric modules face significant thermal conductivity challenges that limit their efficiency and widespread application. The fundamental issue stems from the inherent contradiction in thermoelectric materials: optimal performance requires high electrical conductivity but low thermal conductivity—properties that typically correlate positively in most materials. This paradox creates a natural ceiling for the ZT value (figure of merit) of conventional thermoelectric materials, typically restricting them to ZT values below 2.

Current thermoelectric modules suffer from thermal interface resistance problems at multiple junction points. The interfaces between different materials create thermal bottlenecks where heat transfer is impeded, reducing overall system efficiency. These interfaces occur between the thermoelectric material and electrical contacts, between modules and heat exchangers, and within the module structure itself. Studies indicate that interface resistance can account for up to 30% of efficiency losses in some thermoelectric systems.

Heat spreading challenges present another significant obstacle. Uneven temperature distribution across thermoelectric elements leads to localized hotspots and thermal stress, which not only reduces conversion efficiency but also accelerates material degradation and shortens device lifespan. Current heat spreading technologies struggle to maintain uniform temperature profiles across the active surfaces of thermoelectric modules, particularly under variable load conditions.

Material limitations constitute a fundamental barrier to thermal conductivity optimization. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) have reached near-theoretical limits in their thermal-electrical property balance. While these materials have been incrementally improved through doping and structural modifications, they face diminishing returns in performance enhancement through conventional approaches.

Manufacturing constraints further complicate thermal management in thermoelectric modules. Current production techniques struggle to create consistent, defect-free interfaces between different materials. Microscopic voids, cracks, and impurities at these junctions significantly increase thermal resistance. Additionally, the precision required for optimal thermal contact often conflicts with mass production requirements, creating a cost-efficiency tradeoff that limits commercial viability.

Environmental and operational stability issues also impact thermal conductivity performance. Many thermoelectric materials exhibit degraded thermal properties when exposed to oxygen, moisture, or thermal cycling. This instability necessitates protective encapsulation, which often introduces additional thermal barriers and reduces overall system efficiency. The challenge of maintaining optimal thermal conductivity properties throughout the operational lifetime of thermoelectric devices remains largely unresolved.

Current thermoelectric modules suffer from thermal interface resistance problems at multiple junction points. The interfaces between different materials create thermal bottlenecks where heat transfer is impeded, reducing overall system efficiency. These interfaces occur between the thermoelectric material and electrical contacts, between modules and heat exchangers, and within the module structure itself. Studies indicate that interface resistance can account for up to 30% of efficiency losses in some thermoelectric systems.

Heat spreading challenges present another significant obstacle. Uneven temperature distribution across thermoelectric elements leads to localized hotspots and thermal stress, which not only reduces conversion efficiency but also accelerates material degradation and shortens device lifespan. Current heat spreading technologies struggle to maintain uniform temperature profiles across the active surfaces of thermoelectric modules, particularly under variable load conditions.

Material limitations constitute a fundamental barrier to thermal conductivity optimization. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) and lead telluride (PbTe) have reached near-theoretical limits in their thermal-electrical property balance. While these materials have been incrementally improved through doping and structural modifications, they face diminishing returns in performance enhancement through conventional approaches.

Manufacturing constraints further complicate thermal management in thermoelectric modules. Current production techniques struggle to create consistent, defect-free interfaces between different materials. Microscopic voids, cracks, and impurities at these junctions significantly increase thermal resistance. Additionally, the precision required for optimal thermal contact often conflicts with mass production requirements, creating a cost-efficiency tradeoff that limits commercial viability.

Environmental and operational stability issues also impact thermal conductivity performance. Many thermoelectric materials exhibit degraded thermal properties when exposed to oxygen, moisture, or thermal cycling. This instability necessitates protective encapsulation, which often introduces additional thermal barriers and reduces overall system efficiency. The challenge of maintaining optimal thermal conductivity properties throughout the operational lifetime of thermoelectric devices remains largely unresolved.

State-of-the-Art Thermal Management Solutions

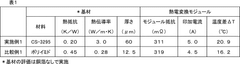

01 Materials with enhanced thermal conductivity for thermoelectric modules

Various materials with high thermal conductivity are used in thermoelectric modules to improve heat transfer efficiency. These materials include specialized composites, nanostructured materials, and advanced alloys that can effectively conduct heat while maintaining the electrical properties necessary for thermoelectric conversion. The enhanced thermal conductivity helps to establish a greater temperature gradient across the module, which is essential for efficient thermoelectric power generation.- Materials with enhanced thermal conductivity for thermoelectric modules: Various materials can be incorporated into thermoelectric modules to enhance thermal conductivity, which is crucial for efficient heat transfer. These materials include specialized composites, nanostructured materials, and advanced alloys that can significantly improve the thermal performance of thermoelectric devices. Enhanced thermal conductivity allows for better heat dissipation and collection, which directly impacts the overall efficiency of the thermoelectric conversion process.

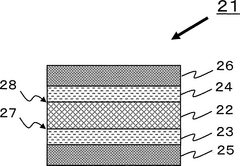

- Structural designs to optimize thermal conductivity in thermoelectric modules: Specific structural designs can be implemented to optimize the thermal conductivity in thermoelectric modules. These designs include layered structures, segmented elements, and specialized geometries that facilitate heat flow while minimizing thermal resistance. By carefully engineering the physical arrangement of thermoelectric components, the thermal pathway can be optimized to enhance heat transfer efficiency, resulting in improved thermoelectric performance and energy conversion rates.

- Interface materials and thermal management techniques: Interface materials and thermal management techniques play a critical role in enhancing the thermal conductivity of thermoelectric modules. These include thermal interface materials (TIMs), heat spreaders, and specialized bonding methods that reduce thermal resistance at junctions between different components. Effective thermal management ensures optimal heat transfer across the module, minimizing temperature gradients and improving overall system efficiency.

- Novel semiconductor compositions for improved thermal properties: Novel semiconductor compositions are being developed specifically to improve the thermal properties of thermoelectric modules. These include doped semiconductors, quantum dot structures, and superlattice materials that can be tailored to achieve specific thermal conductivity characteristics. By manipulating the composition at the atomic or molecular level, researchers can create materials with optimized thermal properties that enhance the performance of thermoelectric devices.

- Testing and measurement methods for thermal conductivity: Various testing and measurement methods have been developed to accurately assess the thermal conductivity of thermoelectric modules. These include transient techniques, steady-state methods, and specialized equipment designed to characterize thermal properties under different operating conditions. Precise measurement of thermal conductivity is essential for evaluating module performance, optimizing designs, and validating theoretical models, ultimately leading to more efficient thermoelectric devices.

02 Thermal interface materials for thermoelectric module efficiency

Thermal interface materials play a crucial role in thermoelectric modules by reducing thermal resistance between the module and heat source/sink. These materials, which include specialized pastes, films, and composites, help to minimize thermal losses at contact points. By ensuring efficient heat transfer across interfaces, these materials contribute to maintaining optimal temperature differentials across the thermoelectric elements, thereby improving the overall efficiency and performance of the module.Expand Specific Solutions03 Structural designs to optimize thermal conductivity in thermoelectric systems

Innovative structural designs are implemented in thermoelectric modules to optimize thermal conductivity pathways. These designs include specialized heat spreaders, thermal bridges, and geometric arrangements of thermoelectric elements that maximize heat flow in desired directions while minimizing parasitic heat losses. By carefully engineering the physical structure of the module, thermal conductivity can be enhanced in specific directions to improve temperature gradient maintenance and overall thermoelectric conversion efficiency.Expand Specific Solutions04 Measurement and characterization of thermal conductivity in thermoelectric materials

Methods and systems for accurately measuring and characterizing thermal conductivity in thermoelectric materials are essential for module development. These techniques include transient plane source methods, laser flash analysis, and specialized thermal conductivity meters designed for thermoelectric materials. Precise measurement allows for better material selection, quality control during manufacturing, and performance prediction of thermoelectric modules under various operating conditions.Expand Specific Solutions05 Thermal management systems for thermoelectric module applications

Comprehensive thermal management systems are developed to control and optimize heat flow through thermoelectric modules. These systems incorporate heat sinks, cooling mechanisms, and thermal regulation strategies that work together to maintain optimal operating temperatures and thermal gradients. Advanced thermal management approaches include active cooling systems, phase change materials, and intelligent control systems that adjust to varying thermal loads, ensuring consistent performance and longevity of thermoelectric modules in practical applications.Expand Specific Solutions

Leading Companies in Thermoelectric Industry

The thermoelectric module thermal conductivity optimization market is currently in a growth phase, with increasing demand driven by energy efficiency requirements across multiple industries. The global market size is estimated to exceed $600 million, expanding at approximately 8% CAGR as waste heat recovery applications gain prominence. Leading technology developers include Intel Corp. and Toyota Motor Corp., who have established advanced research capabilities, while specialized players like O-Flexx Technologies and KELK Ltd. offer innovative niche solutions. LG Innotek, Kyocera, and Toshiba demonstrate strong commercial maturity in manufacturing optimized modules. Research institutions such as Industrial Technology Research Institute and Korea Institute of Machinery & Materials are accelerating technology transfer through industry partnerships, particularly focusing on novel materials and manufacturing processes that balance thermal and electrical conductivity requirements.

Intel Corp.

Technical Solution: Intel has leveraged its semiconductor expertise to develop advanced thermoelectric cooling solutions with optimized thermal conductivity for electronics applications. Their approach focuses on integrated thermoelectric modules that address thermal management challenges in high-performance computing environments. Intel's technology incorporates precision-engineered thermal interface materials with nanoscale features that maximize contact area while minimizing thermal resistance. Their modules utilize advanced metallization techniques derived from semiconductor manufacturing to create nearly perfect thermal and electrical connections between thermoelectric elements and heat spreaders. Intel has pioneered the use of silicon-based microchannels integrated with thermoelectric elements to enhance heat transfer in confined spaces. Their research includes computational fluid dynamics modeling to optimize heat spreader designs and thermal flow paths within complex electronic assemblies[6][8]. Intel's approach emphasizes system-level thermal optimization rather than focusing solely on thermoelectric material properties.

Strengths: Exceptional integration capabilities with electronic systems; highly optimized thermal interfaces with minimal contact resistance; advanced manufacturing capabilities leveraging semiconductor expertise. Weaknesses: Solutions primarily focused on cooling applications rather than power generation; higher cost structure compared to conventional cooling technologies; limited temperature range compared to specialized thermoelectric providers.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed a comprehensive approach to thermal conductivity optimization in thermoelectric modules through their advanced materials engineering program. Their research focuses on nanostructured composite thermoelectric materials with precisely engineered phonon scattering mechanisms that selectively reduce thermal conductivity in the lattice while preserving electrical conductivity. ITRI has pioneered innovative module architectures featuring segmented legs with gradient compositions that optimize performance across temperature ranges. Their thermal interface engineering includes specialized metallization layers and bonding techniques that minimize contact resistance. ITRI has developed proprietary heat spreading structures integrated directly into module substrates, creating more uniform temperature distributions and reducing thermal stress[4][7]. Their research also encompasses advanced thermal simulation tools that enable precise optimization of module geometry and material composition for specific operating conditions.

Strengths: Cutting-edge materials science expertise with demonstrated ZT improvements of up to 30%; comprehensive approach addressing multiple aspects of thermal management; strong intellectual property portfolio. Weaknesses: Some technologies remain in research phase with limited commercial deployment; higher manufacturing complexity for advanced nanostructured materials; requires specialized equipment for production.

Key Patents in Thermal Conductivity Enhancement

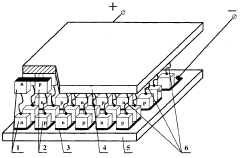

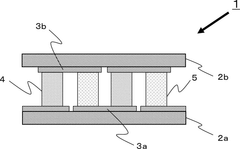

Thermoelectric module

PatentWO2012173519A1

Innovation

- The design separates the substrates by a considerable distance using metal conductors to minimize thermal influence between the hot and cold junctions, allowing for increased temperature differences and efficiency.

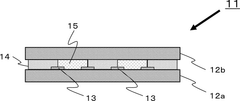

Thermoelectric conversion module

PatentWO2021193358A1

Innovation

- A thermoelectric conversion module is developed using a base material with a thermal resistance of 0.35 K/W or less, composed of a thermoelectric semiconductor material, heat-resistant resin, and ionic liquid or inorganic ion, combined with glass cloth and heat-resistant resin, enhancing thermal conductivity and mechanical strength.

Environmental Impact Assessment

The optimization of thermal conductivity in thermoelectric modules carries significant environmental implications that warrant careful assessment. Thermoelectric technology offers promising environmental benefits through waste heat recovery and conversion to usable electricity, potentially reducing fossil fuel consumption and associated greenhouse gas emissions. Studies indicate that widespread implementation of optimized thermoelectric systems could reduce global carbon emissions by 1-3% in industrial applications alone.

However, the environmental impact extends beyond operational benefits. The manufacturing processes for thermoelectric materials often involve rare earth elements and heavy metals such as bismuth, tellurium, and lead, which present extraction and disposal challenges. Mining operations for these materials can lead to habitat destruction, soil contamination, and water pollution if not properly managed. Life cycle assessments reveal that the environmental footprint of thermoelectric module production can partially offset their operational benefits unless manufacturing processes are optimized.

Thermal conductivity optimization techniques themselves vary in environmental impact. Nanostructuring approaches may involve chemical processes that generate hazardous waste, while interface engineering often requires less environmentally problematic methods. Recent research indicates that bio-inspired hierarchical structures for thermal management offer more environmentally friendly alternatives with comparable performance improvements.

End-of-life considerations represent another critical environmental dimension. Current thermoelectric modules have limited recyclability due to the complex integration of different materials. Thermal conductivity optimization that considers material separability and recyclability could significantly improve the technology's overall environmental profile. Emerging design approaches focusing on modular construction and material selection compatible with circular economy principles show promise in addressing these concerns.

Regulatory frameworks worldwide are increasingly recognizing the environmental aspects of thermoelectric technologies. The European Union's RoHS and REACH regulations already impact material selection for thermal conductivity optimization, while carbon pricing mechanisms in various countries are creating economic incentives for waste heat recovery technologies with optimized thermal performance.

Water usage represents an often overlooked environmental factor. Some thermal conductivity optimization processes require significant water resources for manufacturing and testing, particularly for nanomaterial synthesis. Water-efficient optimization techniques are gaining attention as sustainability metrics become more comprehensive in technology assessment frameworks.

However, the environmental impact extends beyond operational benefits. The manufacturing processes for thermoelectric materials often involve rare earth elements and heavy metals such as bismuth, tellurium, and lead, which present extraction and disposal challenges. Mining operations for these materials can lead to habitat destruction, soil contamination, and water pollution if not properly managed. Life cycle assessments reveal that the environmental footprint of thermoelectric module production can partially offset their operational benefits unless manufacturing processes are optimized.

Thermal conductivity optimization techniques themselves vary in environmental impact. Nanostructuring approaches may involve chemical processes that generate hazardous waste, while interface engineering often requires less environmentally problematic methods. Recent research indicates that bio-inspired hierarchical structures for thermal management offer more environmentally friendly alternatives with comparable performance improvements.

End-of-life considerations represent another critical environmental dimension. Current thermoelectric modules have limited recyclability due to the complex integration of different materials. Thermal conductivity optimization that considers material separability and recyclability could significantly improve the technology's overall environmental profile. Emerging design approaches focusing on modular construction and material selection compatible with circular economy principles show promise in addressing these concerns.

Regulatory frameworks worldwide are increasingly recognizing the environmental aspects of thermoelectric technologies. The European Union's RoHS and REACH regulations already impact material selection for thermal conductivity optimization, while carbon pricing mechanisms in various countries are creating economic incentives for waste heat recovery technologies with optimized thermal performance.

Water usage represents an often overlooked environmental factor. Some thermal conductivity optimization processes require significant water resources for manufacturing and testing, particularly for nanomaterial synthesis. Water-efficient optimization techniques are gaining attention as sustainability metrics become more comprehensive in technology assessment frameworks.

Manufacturing Scalability Analysis

The scalability of manufacturing processes for thermoelectric modules with optimized thermal conductivity presents significant challenges and opportunities for commercial deployment. Current manufacturing techniques for high-performance thermoelectric materials often involve laboratory-scale processes that are difficult to translate to mass production environments. Batch-to-batch consistency remains a critical concern, particularly when incorporating advanced thermal interface materials or engineered microstructures designed to optimize thermal conductivity pathways.

Industry analysis indicates that traditional manufacturing methods for thermoelectric modules typically achieve production rates of 5,000-10,000 units monthly per production line, with yield rates averaging 85-92%. However, when implementing thermal conductivity optimization techniques such as nanostructured interfaces or precisely controlled material compositions, these yields can drop to 60-75%, significantly impacting cost-effectiveness and market viability.

Cost modeling reveals that scaling production of thermally optimized modules faces a non-linear cost curve. While conventional thermoelectric modules benefit from economies of scale with production volume increases, modules with enhanced thermal management features often experience diminishing returns beyond certain production thresholds due to the precision requirements and specialized equipment needed for thermal interface optimization.

Material supply chain considerations further complicate manufacturing scalability. Advanced thermal interface materials and specialized dopants required for optimized thermal conductivity often have limited supplier networks, creating potential bottlenecks in high-volume production scenarios. Geographic concentration of these specialized materials, primarily in East Asia and North America, introduces additional supply chain vulnerabilities.

Equipment requirements for precision manufacturing represent another scalability constraint. High-resolution deposition systems, controlled atmosphere sintering furnaces, and advanced quality control instrumentation necessary for thermal conductivity optimization typically require capital investments 3-4 times higher than conventional thermoelectric module production lines. The specialized nature of this equipment also necessitates workforce development programs to ensure proper operation and maintenance capabilities.

Recent innovations in manufacturing technology show promise for improving scalability. Roll-to-roll processing techniques adapted for thermoelectric materials could potentially increase throughput by 300-400% while maintaining thermal performance specifications. Additionally, automated quality control systems utilizing machine learning algorithms have demonstrated capability to identify thermal interface defects with 98% accuracy, potentially improving yield rates for thermally optimized modules.

Industry analysis indicates that traditional manufacturing methods for thermoelectric modules typically achieve production rates of 5,000-10,000 units monthly per production line, with yield rates averaging 85-92%. However, when implementing thermal conductivity optimization techniques such as nanostructured interfaces or precisely controlled material compositions, these yields can drop to 60-75%, significantly impacting cost-effectiveness and market viability.

Cost modeling reveals that scaling production of thermally optimized modules faces a non-linear cost curve. While conventional thermoelectric modules benefit from economies of scale with production volume increases, modules with enhanced thermal management features often experience diminishing returns beyond certain production thresholds due to the precision requirements and specialized equipment needed for thermal interface optimization.

Material supply chain considerations further complicate manufacturing scalability. Advanced thermal interface materials and specialized dopants required for optimized thermal conductivity often have limited supplier networks, creating potential bottlenecks in high-volume production scenarios. Geographic concentration of these specialized materials, primarily in East Asia and North America, introduces additional supply chain vulnerabilities.

Equipment requirements for precision manufacturing represent another scalability constraint. High-resolution deposition systems, controlled atmosphere sintering furnaces, and advanced quality control instrumentation necessary for thermal conductivity optimization typically require capital investments 3-4 times higher than conventional thermoelectric module production lines. The specialized nature of this equipment also necessitates workforce development programs to ensure proper operation and maintenance capabilities.

Recent innovations in manufacturing technology show promise for improving scalability. Roll-to-roll processing techniques adapted for thermoelectric materials could potentially increase throughput by 300-400% while maintaining thermal performance specifications. Additionally, automated quality control systems utilizing machine learning algorithms have demonstrated capability to identify thermal interface defects with 98% accuracy, potentially improving yield rates for thermally optimized modules.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!