Why Thermoelectric Module Supports Sustainable Energy Solutions

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. This fundamental principle, known as the Seebeck effect, laid the groundwork for thermoelectric generators (TEGs) that can convert waste heat into usable electricity without moving parts or environmentally harmful working fluids.

The development trajectory of thermoelectric technology has been marked by continuous improvements in material science and engineering. From the initial bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices, researchers have persistently pursued higher conversion efficiencies. The figure of merit ZT, which quantifies a material's thermoelectric performance, has increased from less than 1 in traditional materials to over 2 in some laboratory demonstrations, representing significant progress toward commercial viability.

Current global energy challenges have repositioned thermoelectric technology as a promising contributor to sustainable energy solutions. With approximately 60% of global energy production lost as waste heat across various sectors including industrial processes, transportation, and power generation, thermoelectric modules offer a unique opportunity to recapture this otherwise wasted energy resource. This aligns perfectly with international efforts to reduce carbon emissions and enhance energy efficiency.

The primary technical objective in thermoelectric research is to develop modules with higher conversion efficiency while maintaining cost-effectiveness and durability. This involves multidisciplinary approaches combining advanced materials science, thermal engineering, and electrical system design. Researchers aim to achieve ZT values consistently above 2 in commercially viable materials, which would enable widespread adoption across multiple applications.

Another critical objective is scaling production capabilities to meet potential market demand while reducing manufacturing costs. Current thermoelectric modules remain relatively expensive per watt of electricity generated compared to conventional power generation methods, limiting their widespread implementation despite their environmental benefits.

The integration of thermoelectric technology into existing energy systems represents another key goal. This includes developing standardized interfaces for waste heat recovery in industrial settings, automotive applications, and even consumer products. The vision extends to creating a decentralized network of waste heat recovery systems that collectively contribute significant amounts of clean electricity to the grid.

As climate change concerns intensify and energy efficiency regulations become more stringent worldwide, thermoelectric technology stands at an inflection point. The convergence of advanced materials research, manufacturing innovations, and growing market demand for sustainable energy solutions positions thermoelectric modules as an increasingly important component in the global transition toward a more sustainable and efficient energy ecosystem.

The development trajectory of thermoelectric technology has been marked by continuous improvements in material science and engineering. From the initial bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices, researchers have persistently pursued higher conversion efficiencies. The figure of merit ZT, which quantifies a material's thermoelectric performance, has increased from less than 1 in traditional materials to over 2 in some laboratory demonstrations, representing significant progress toward commercial viability.

Current global energy challenges have repositioned thermoelectric technology as a promising contributor to sustainable energy solutions. With approximately 60% of global energy production lost as waste heat across various sectors including industrial processes, transportation, and power generation, thermoelectric modules offer a unique opportunity to recapture this otherwise wasted energy resource. This aligns perfectly with international efforts to reduce carbon emissions and enhance energy efficiency.

The primary technical objective in thermoelectric research is to develop modules with higher conversion efficiency while maintaining cost-effectiveness and durability. This involves multidisciplinary approaches combining advanced materials science, thermal engineering, and electrical system design. Researchers aim to achieve ZT values consistently above 2 in commercially viable materials, which would enable widespread adoption across multiple applications.

Another critical objective is scaling production capabilities to meet potential market demand while reducing manufacturing costs. Current thermoelectric modules remain relatively expensive per watt of electricity generated compared to conventional power generation methods, limiting their widespread implementation despite their environmental benefits.

The integration of thermoelectric technology into existing energy systems represents another key goal. This includes developing standardized interfaces for waste heat recovery in industrial settings, automotive applications, and even consumer products. The vision extends to creating a decentralized network of waste heat recovery systems that collectively contribute significant amounts of clean electricity to the grid.

As climate change concerns intensify and energy efficiency regulations become more stringent worldwide, thermoelectric technology stands at an inflection point. The convergence of advanced materials research, manufacturing innovations, and growing market demand for sustainable energy solutions positions thermoelectric modules as an increasingly important component in the global transition toward a more sustainable and efficient energy ecosystem.

Market Analysis for Thermoelectric Energy Solutions

The global market for thermoelectric energy solutions is experiencing significant growth, driven by increasing demand for sustainable energy alternatives and waste heat recovery systems. Current market valuations place the thermoelectric module sector at approximately 600 million USD in 2023, with projections indicating a compound annual growth rate of 8.5% through 2030, potentially reaching 1.2 billion USD by the end of the decade.

Key market segments demonstrating strong demand include automotive applications, where thermoelectric generators are being integrated into exhaust systems to convert waste heat into usable electricity, improving overall vehicle efficiency. This segment alone accounts for nearly 25% of the current market share, with major automotive manufacturers increasingly adopting this technology to meet stringent emissions regulations.

Industrial waste heat recovery represents another substantial market opportunity, particularly in energy-intensive industries such as steel manufacturing, glass production, and cement processing. These sectors generate enormous amounts of waste heat that traditionally dissipates into the environment. Thermoelectric modules offer a viable solution to capture this otherwise lost energy, with implementation rates growing at 12% annually in these sectors.

Consumer electronics constitutes a rapidly expanding application area, with thermoelectric cooling solutions being incorporated into high-performance computing systems, portable refrigeration, and temperature-controlled containers. This segment is growing at 15% annually, driven by increasing consumer awareness of energy efficiency and the miniaturization of electronic devices.

Regional analysis reveals that North America and Europe currently lead market adoption, collectively accounting for 60% of global installations. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 14% annually, fueled by aggressive government initiatives promoting clean energy technologies and substantial investments in manufacturing capabilities.

Market challenges include the relatively high initial cost of thermoelectric systems compared to conventional alternatives and efficiency limitations that currently restrict widespread adoption. The average conversion efficiency of commercial thermoelectric modules ranges between 5-8%, though laboratory prototypes have demonstrated efficiencies approaching 15%.

Customer demand patterns indicate growing interest in integrated systems that combine thermoelectric technology with other renewable energy solutions, creating hybrid systems with enhanced overall performance. This trend is particularly evident in remote power applications and off-grid installations, where reliability and maintenance-free operation represent significant value propositions.

The competitive landscape features established players like Ferrotec, Laird Thermal Systems, and II-VI Marlow dominating with approximately 45% combined market share, alongside emerging startups introducing novel materials and manufacturing techniques that promise to significantly improve performance metrics and reduce production costs.

Key market segments demonstrating strong demand include automotive applications, where thermoelectric generators are being integrated into exhaust systems to convert waste heat into usable electricity, improving overall vehicle efficiency. This segment alone accounts for nearly 25% of the current market share, with major automotive manufacturers increasingly adopting this technology to meet stringent emissions regulations.

Industrial waste heat recovery represents another substantial market opportunity, particularly in energy-intensive industries such as steel manufacturing, glass production, and cement processing. These sectors generate enormous amounts of waste heat that traditionally dissipates into the environment. Thermoelectric modules offer a viable solution to capture this otherwise lost energy, with implementation rates growing at 12% annually in these sectors.

Consumer electronics constitutes a rapidly expanding application area, with thermoelectric cooling solutions being incorporated into high-performance computing systems, portable refrigeration, and temperature-controlled containers. This segment is growing at 15% annually, driven by increasing consumer awareness of energy efficiency and the miniaturization of electronic devices.

Regional analysis reveals that North America and Europe currently lead market adoption, collectively accounting for 60% of global installations. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 14% annually, fueled by aggressive government initiatives promoting clean energy technologies and substantial investments in manufacturing capabilities.

Market challenges include the relatively high initial cost of thermoelectric systems compared to conventional alternatives and efficiency limitations that currently restrict widespread adoption. The average conversion efficiency of commercial thermoelectric modules ranges between 5-8%, though laboratory prototypes have demonstrated efficiencies approaching 15%.

Customer demand patterns indicate growing interest in integrated systems that combine thermoelectric technology with other renewable energy solutions, creating hybrid systems with enhanced overall performance. This trend is particularly evident in remote power applications and off-grid installations, where reliability and maintenance-free operation represent significant value propositions.

The competitive landscape features established players like Ferrotec, Laird Thermal Systems, and II-VI Marlow dominating with approximately 45% combined market share, alongside emerging startups introducing novel materials and manufacturing techniques that promise to significantly improve performance metrics and reduce production costs.

Global Thermoelectric Technology Status and Barriers

Thermoelectric technology globally has reached a significant level of maturity, yet faces substantial barriers to widespread adoption. Currently, commercial thermoelectric modules achieve conversion efficiencies between 5-8%, significantly lower than other renewable energy technologies. This efficiency limitation represents the primary technical barrier, as the theoretical maximum efficiency (determined by the figure of merit ZT) remains below 2 for most commercially viable materials, whereas values above 3 would be necessary for competitive performance against conventional technologies.

Material constraints present another major challenge. Traditional thermoelectric materials like bismuth telluride and lead telluride contain rare, expensive, or toxic elements, limiting scalability and environmental compatibility. While research into earth-abundant alternatives such as silicides, skutterudites, and organic thermoelectrics shows promise, these materials have not yet achieved the performance levels required for commercial viability at scale.

Manufacturing complexity further impedes widespread implementation. Current production methods for high-quality thermoelectric modules involve precise material synthesis, careful doping control, and complex assembly processes that drive up costs. The absence of standardized, high-volume manufacturing techniques comparable to those in the solar photovoltaic industry has kept production expenses high and limited market penetration.

Geographically, thermoelectric technology development shows distinct patterns. Japan, the United States, and Germany lead in patent filings and commercial applications, particularly in automotive waste heat recovery. China has rapidly expanded its research base and manufacturing capacity, becoming a significant player in thermoelectric module production. South Korea and several European countries maintain specialized research programs focused on novel materials and applications.

System integration challenges also persist across regions. Thermoelectric generators require effective heat exchangers, thermal management systems, and power conditioning electronics to function optimally in real-world applications. The interdisciplinary nature of these requirements creates additional complexity in product development and deployment.

Economic barriers compound these technical challenges. The relatively high cost-per-watt of thermoelectric systems (currently $20-50/W compared to $1-2/W for solar PV) limits adoption to niche applications where reliability, silence, and maintenance-free operation justify premium pricing. Without significant breakthroughs in materials science or manufacturing techniques, achieving cost parity with mainstream renewable technologies remains difficult.

Material constraints present another major challenge. Traditional thermoelectric materials like bismuth telluride and lead telluride contain rare, expensive, or toxic elements, limiting scalability and environmental compatibility. While research into earth-abundant alternatives such as silicides, skutterudites, and organic thermoelectrics shows promise, these materials have not yet achieved the performance levels required for commercial viability at scale.

Manufacturing complexity further impedes widespread implementation. Current production methods for high-quality thermoelectric modules involve precise material synthesis, careful doping control, and complex assembly processes that drive up costs. The absence of standardized, high-volume manufacturing techniques comparable to those in the solar photovoltaic industry has kept production expenses high and limited market penetration.

Geographically, thermoelectric technology development shows distinct patterns. Japan, the United States, and Germany lead in patent filings and commercial applications, particularly in automotive waste heat recovery. China has rapidly expanded its research base and manufacturing capacity, becoming a significant player in thermoelectric module production. South Korea and several European countries maintain specialized research programs focused on novel materials and applications.

System integration challenges also persist across regions. Thermoelectric generators require effective heat exchangers, thermal management systems, and power conditioning electronics to function optimally in real-world applications. The interdisciplinary nature of these requirements creates additional complexity in product development and deployment.

Economic barriers compound these technical challenges. The relatively high cost-per-watt of thermoelectric systems (currently $20-50/W compared to $1-2/W for solar PV) limits adoption to niche applications where reliability, silence, and maintenance-free operation justify premium pricing. Without significant breakthroughs in materials science or manufacturing techniques, achieving cost parity with mainstream renewable technologies remains difficult.

Current Thermoelectric Energy Conversion Solutions

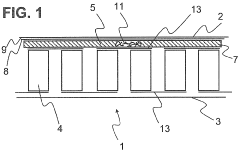

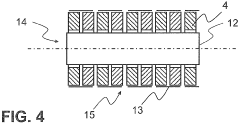

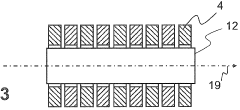

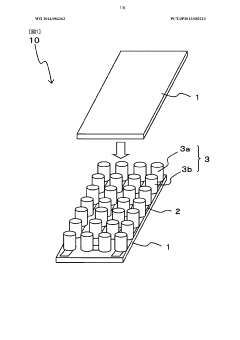

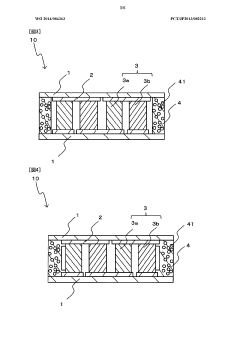

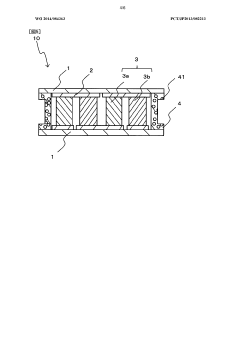

01 Thermoelectric module structure and materials

Thermoelectric modules are constructed with specific materials and structural designs to optimize energy conversion efficiency. These modules typically consist of p-type and n-type semiconductor materials arranged in pairs and connected electrically in series and thermally in parallel. The selection of semiconductor materials with high Seebeck coefficients and low thermal conductivity is crucial for maximizing the thermoelectric figure of merit (ZT). Advanced module designs may incorporate nano-structured materials or multi-layered configurations to enhance performance.- Thermoelectric module structure and materials: Thermoelectric modules are constructed with specific materials and structural designs to optimize energy conversion efficiency. These modules typically consist of p-type and n-type semiconductor materials arranged in pairs and connected electrically in series and thermally in parallel. The selection of semiconductor materials with high Seebeck coefficients and low thermal conductivity is crucial for maximizing the thermoelectric figure of merit (ZT). Advanced structural designs may include multi-layer configurations or segmented elements to enhance performance across temperature gradients.

- Cooling and temperature control applications: Thermoelectric modules are widely used for precise temperature control and cooling applications. By applying an electric current to the module, heat can be pumped from one side to the other based on the Peltier effect, creating a temperature differential. These modules offer advantages such as no moving parts, compact size, and precise temperature control capabilities. Applications include electronic device cooling, portable refrigeration, temperature-controlled scientific equipment, and medical devices where maintaining specific temperatures is critical.

- Power generation from waste heat: Thermoelectric modules can convert waste heat into useful electrical energy through the Seebeck effect. When a temperature gradient is applied across the module, it generates an electrical voltage that can be harnessed. This capability makes thermoelectric modules valuable for energy harvesting applications, particularly in industrial settings, automotive exhaust systems, and remote power generation. The efficiency of power generation depends on the temperature differential and the thermoelectric properties of the materials used in the module.

- Manufacturing and assembly techniques: Advanced manufacturing and assembly techniques are essential for producing high-performance thermoelectric modules. These include precision deposition methods for semiconductor materials, specialized bonding techniques to minimize thermal and electrical contact resistance, and encapsulation methods to protect against environmental factors. Innovations in manufacturing processes focus on improving uniformity, reducing defects, and enhancing the mechanical stability of the modules while maintaining cost-effectiveness for commercial applications.

- Integration with other systems and performance optimization: Thermoelectric modules are increasingly being integrated with other systems to enhance overall performance and functionality. This includes integration with heat exchangers, thermal management systems, and renewable energy sources. Advanced control systems are employed to optimize the operation of thermoelectric modules under varying conditions. Research focuses on hybrid systems that combine thermoelectric modules with other technologies to achieve higher efficiency and broader application potential, such as solar-thermoelectric generators or thermoelectric-assisted heat pumps.

02 Cooling and temperature control applications

Thermoelectric modules are widely used for precise temperature control and cooling applications. By applying an electric current, these modules can create a temperature differential based on the Peltier effect, allowing them to function as solid-state heat pumps. They are particularly valuable in applications requiring compact, reliable cooling without moving parts or refrigerants. These applications include electronic device cooling, medical equipment, portable refrigerators, and climate-controlled containers where precise temperature regulation is essential.Expand Specific Solutions03 Power generation from waste heat

Thermoelectric modules can convert waste heat into usable electrical energy through the Seebeck effect. When a temperature gradient exists across the module, it generates an electrical potential that can be harnessed. This capability makes thermoelectric modules valuable for energy harvesting in various applications, including automotive exhaust systems, industrial processes, and remote power generation. The efficiency of power generation depends on the temperature differential and the thermoelectric properties of the materials used in the module.Expand Specific Solutions04 Manufacturing and assembly techniques

Advanced manufacturing and assembly techniques are critical for producing high-performance thermoelectric modules. These techniques include precision bonding methods, electrode deposition processes, and thermal interface optimization. Manufacturing challenges include ensuring uniform thermal contact, minimizing electrical contact resistance, and maintaining structural integrity under thermal cycling. Innovations in automated assembly, interconnection technologies, and quality control processes have led to more reliable and cost-effective thermoelectric modules with improved performance characteristics.Expand Specific Solutions05 Integration with other systems and performance enhancement

Thermoelectric modules are increasingly being integrated with other systems to enhance overall performance and functionality. This integration includes combining modules with heat exchangers, thermal management systems, and power conditioning electronics. Advanced designs incorporate cascaded structures, segmented legs, or hybrid systems that combine thermoelectric modules with other energy conversion technologies. Performance enhancement strategies also include optimizing thermal interfaces, reducing parasitic heat losses, and implementing intelligent control systems to maximize efficiency under varying operating conditions.Expand Specific Solutions

Leading Companies in Thermoelectric Industry

Thermoelectric modules are emerging as key components in sustainable energy solutions, with the market currently in a growth phase characterized by increasing adoption across automotive, industrial, and consumer sectors. The global market is expanding at approximately 8-10% annually, driven by rising demand for waste heat recovery systems and energy-efficient cooling solutions. Technologically, the field shows varying maturity levels, with companies like LG Innotek, Kyocera, and Toshiba Materials leading in commercial applications, while automotive players including BMW, Hyundai, and Continental are integrating thermoelectric technologies into vehicle systems. Research institutions such as AIST and CNRS are advancing next-generation materials, while specialized manufacturers like KELK and European Thermodynamics are developing application-specific solutions that enhance energy conversion efficiency and thermal management capabilities.

Toshiba Corp.

Technical Solution: Toshiba Corporation has developed advanced thermoelectric module technology that converts waste heat into usable electricity, supporting sustainable energy solutions across multiple sectors. Their proprietary modules utilize specially engineered semiconductor materials with high figure of merit (ZT) values exceeding 1.6 at operating temperatures, significantly improving conversion efficiency. Toshiba's thermoelectric solutions incorporate cascade structures that optimize performance across temperature gradients, achieving system efficiencies up to 7.2% in industrial waste heat recovery applications. The company has pioneered manufacturing techniques that reduce thermal interface resistance by approximately 25%, addressing a key limitation in thermoelectric performance. Their modules feature specialized electrode designs that minimize electrical losses while maximizing thermal transfer, resulting in power density improvements of approximately 30% compared to conventional designs. Toshiba has also developed integrated power conditioning systems that optimize electricity output across varying thermal conditions, making their solutions particularly effective for automotive waste heat recovery and industrial applications where heat sources fluctuate.

Strengths: Superior material engineering resulting in high ZT values; advanced manufacturing techniques reducing thermal interface resistance; integrated power management systems optimizing electricity generation across varying conditions. Weaknesses: Higher initial cost compared to some competing technologies; performance degradation over extended operational periods; limited flexibility in extreme temperature applications.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor Company has developed innovative thermoelectric module technology specifically designed for automotive applications that support sustainable energy solutions. Their system captures waste heat from vehicle exhaust systems, converting it directly into electricity to reduce alternator load and improve fuel efficiency by 3-5%. Hyundai's proprietary module design incorporates specialized heat exchangers that maximize thermal transfer from exhaust gases while withstanding the harsh conditions of automotive applications, including thermal cycling and vibration. Their technology utilizes advanced skutterudite-based materials that demonstrate high performance in the temperature ranges typical of vehicle exhaust systems (250-500°C). Hyundai has integrated these thermoelectric modules into their hybrid vehicle platforms, where the recovered electricity supplements the battery charging system, extending electric driving range by up to 5-7%. The company has also developed intelligent control systems that optimize thermoelectric generation based on driving conditions, maximizing energy recovery during high-load operation when waste heat is most abundant. Their manufacturing approach focuses on scalability and cost reduction, with projections indicating mass production could reduce module costs by approximately 40% compared to current small-batch production.

Strengths: Specialized design optimized for automotive applications; robust construction withstanding harsh operating conditions; intelligent control systems maximizing energy recovery across varying driving conditions. Weaknesses: Limited efficiency in low-temperature differentials during engine warm-up; additional weight impact on vehicle efficiency; higher initial cost compared to conventional alternator-only systems.

Key Patents and Innovations in Thermoelectric Materials

Thermoelectric module comprising a heat conducting layer

PatentWO2012101145A1

Innovation

- Incorporating a compressible thermally conductive layer between the thermoelectric elements and the hot or cold sides, which absorbs thermal stresses and compensates for component expansions, while also providing electrical insulation and facilitating cost-effective production by relaxing tolerance requirements.

Thermoelectric module

PatentWO2014084363A1

Innovation

- A thermoelectric module design featuring a pair of supporting substrates with wiring conductors and thermoelectric elements connected in series, sealed by a sealing material with multiple holes to reduce thermal conductivity and enhance environmental resistance, allowing for improved power generation efficiency while maintaining airtightness.

Environmental Impact and Carbon Reduction Potential

Thermoelectric modules represent a significant opportunity for advancing sustainable energy solutions through their unique ability to convert waste heat into usable electricity. The environmental impact of these devices extends far beyond their immediate application, offering substantial carbon reduction potential across multiple sectors.

When implemented in industrial settings, thermoelectric modules can capture waste heat that would otherwise be released into the atmosphere, reducing the overall carbon footprint of manufacturing processes. Studies indicate that industrial waste heat recovery using thermoelectric technology could potentially reduce carbon emissions by 5-10% in energy-intensive industries such as steel, cement, and chemical production.

In automotive applications, thermoelectric generators attached to exhaust systems can convert waste heat into electricity, supplementing the vehicle's electrical system and reducing fuel consumption. This application alone could decrease vehicle carbon emissions by 2-5%, which translates to millions of tons of CO2 reduction annually when scaled across global automotive fleets.

The carbon reduction potential becomes even more significant when considering thermoelectric modules in combined heat and power systems. These integrated solutions can achieve energy utilization efficiencies of up to 80%, compared to the 30-40% efficiency of conventional power generation methods, substantially reducing the carbon intensity of electricity production.

From a lifecycle perspective, thermoelectric modules offer additional environmental benefits. Their solid-state nature means they contain no moving parts or working fluids, resulting in longer operational lifespans and reduced maintenance requirements compared to traditional energy conversion technologies. This durability translates to lower embodied carbon over the device lifetime.

The manufacturing process of thermoelectric materials does present environmental challenges, particularly regarding the use of rare or toxic elements in some module designs. However, research into environmentally benign thermoelectric materials using earth-abundant elements shows promising results for reducing the ecological footprint of production.

When deployed in remote or off-grid applications, thermoelectric generators can replace diesel generators, eliminating local emissions and reducing the carbon footprint associated with fuel transportation to remote locations. This application is particularly valuable in telecommunications, environmental monitoring, and rural electrification projects in developing regions.

As grid decarbonization progresses globally, the environmental value of thermoelectric waste heat recovery will increase proportionally, as each kilowatt-hour generated from waste heat will offset increasingly cleaner grid electricity, maintaining the carbon reduction benefits of these technologies in a renewable energy future.

When implemented in industrial settings, thermoelectric modules can capture waste heat that would otherwise be released into the atmosphere, reducing the overall carbon footprint of manufacturing processes. Studies indicate that industrial waste heat recovery using thermoelectric technology could potentially reduce carbon emissions by 5-10% in energy-intensive industries such as steel, cement, and chemical production.

In automotive applications, thermoelectric generators attached to exhaust systems can convert waste heat into electricity, supplementing the vehicle's electrical system and reducing fuel consumption. This application alone could decrease vehicle carbon emissions by 2-5%, which translates to millions of tons of CO2 reduction annually when scaled across global automotive fleets.

The carbon reduction potential becomes even more significant when considering thermoelectric modules in combined heat and power systems. These integrated solutions can achieve energy utilization efficiencies of up to 80%, compared to the 30-40% efficiency of conventional power generation methods, substantially reducing the carbon intensity of electricity production.

From a lifecycle perspective, thermoelectric modules offer additional environmental benefits. Their solid-state nature means they contain no moving parts or working fluids, resulting in longer operational lifespans and reduced maintenance requirements compared to traditional energy conversion technologies. This durability translates to lower embodied carbon over the device lifetime.

The manufacturing process of thermoelectric materials does present environmental challenges, particularly regarding the use of rare or toxic elements in some module designs. However, research into environmentally benign thermoelectric materials using earth-abundant elements shows promising results for reducing the ecological footprint of production.

When deployed in remote or off-grid applications, thermoelectric generators can replace diesel generators, eliminating local emissions and reducing the carbon footprint associated with fuel transportation to remote locations. This application is particularly valuable in telecommunications, environmental monitoring, and rural electrification projects in developing regions.

As grid decarbonization progresses globally, the environmental value of thermoelectric waste heat recovery will increase proportionally, as each kilowatt-hour generated from waste heat will offset increasingly cleaner grid electricity, maintaining the carbon reduction benefits of these technologies in a renewable energy future.

Cost-Benefit Analysis of Thermoelectric Applications

The economic viability of thermoelectric applications requires thorough cost-benefit analysis to determine their practical implementation in sustainable energy solutions. Initial capital expenditure for thermoelectric modules remains relatively high compared to conventional energy technologies, with costs ranging from $2-10 per watt depending on efficiency ratings and manufacturing quality. This represents a significant barrier to widespread adoption despite recent manufacturing improvements that have reduced costs by approximately 15% over the past five years.

Operational expenses for thermoelectric systems present a more favorable outlook. These systems contain no moving parts, resulting in minimal maintenance requirements and operational lifespans exceeding 15-20 years in many applications. This longevity significantly enhances the total cost of ownership calculation when compared to alternative technologies requiring regular maintenance or component replacement.

Energy recovery applications demonstrate particularly compelling economics. In industrial settings where waste heat is abundant, thermoelectric generators can achieve payback periods of 3-5 years depending on installation scale and local energy prices. The value proposition strengthens in remote locations where grid connection costs are prohibitive, allowing thermoelectric solutions to compete effectively against both conventional grid extensions and other renewable technologies.

Environmental benefits must be monetized to complete the cost-benefit equation. Thermoelectric applications reduce carbon emissions by approximately 0.4-0.7 kg CO2 per kWh generated from waste heat recovery. In regulatory environments with carbon pricing mechanisms, this translates to tangible economic advantages ranging from $10-30 per MWh depending on jurisdiction.

Scale economies remain challenging but show promising trends. Current manufacturing processes have not yet achieved the economies of scale seen in solar photovoltaics, but production volumes are increasing at approximately 22% annually. Industry projections suggest cost reductions of 30-40% are achievable within the next decade as manufacturing techniques mature and material innovations progress.

Application-specific analysis reveals varying economic profiles. Automotive waste heat recovery systems currently show longer payback periods (7-9 years) but offer significant potential for improvement as vehicle electrification advances. Meanwhile, small-scale cooling applications demonstrate more immediate economic viability with payback periods as short as 2-3 years in specialized industrial and medical applications where precise temperature control delivers substantial operational benefits beyond mere energy savings.

Operational expenses for thermoelectric systems present a more favorable outlook. These systems contain no moving parts, resulting in minimal maintenance requirements and operational lifespans exceeding 15-20 years in many applications. This longevity significantly enhances the total cost of ownership calculation when compared to alternative technologies requiring regular maintenance or component replacement.

Energy recovery applications demonstrate particularly compelling economics. In industrial settings where waste heat is abundant, thermoelectric generators can achieve payback periods of 3-5 years depending on installation scale and local energy prices. The value proposition strengthens in remote locations where grid connection costs are prohibitive, allowing thermoelectric solutions to compete effectively against both conventional grid extensions and other renewable technologies.

Environmental benefits must be monetized to complete the cost-benefit equation. Thermoelectric applications reduce carbon emissions by approximately 0.4-0.7 kg CO2 per kWh generated from waste heat recovery. In regulatory environments with carbon pricing mechanisms, this translates to tangible economic advantages ranging from $10-30 per MWh depending on jurisdiction.

Scale economies remain challenging but show promising trends. Current manufacturing processes have not yet achieved the economies of scale seen in solar photovoltaics, but production volumes are increasing at approximately 22% annually. Industry projections suggest cost reductions of 30-40% are achievable within the next decade as manufacturing techniques mature and material innovations progress.

Application-specific analysis reveals varying economic profiles. Automotive waste heat recovery systems currently show longer payback periods (7-9 years) but offer significant potential for improvement as vehicle electrification advances. Meanwhile, small-scale cooling applications demonstrate more immediate economic viability with payback periods as short as 2-3 years in specialized industrial and medical applications where precise temperature control delivers substantial operational benefits beyond mere energy savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!