Thermoelectric Module Standards and Regulatory Compliance Analysis

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. The initial applications were limited to temperature measurement devices, but the field expanded dramatically in the mid-20th century with the development of semiconductor-based thermoelectric materials, particularly bismuth telluride compounds.

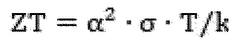

The 1950s and 1960s marked a pivotal era with the theoretical foundation established by Abram Ioffe, leading to the first practical thermoelectric generators and cooling devices. However, efficiency limitations restricted widespread adoption, with conversion efficiencies typically below 5%. The figure of merit ZT, which quantifies thermoelectric performance, remained stagnant at approximately 1 for several decades.

A renaissance in thermoelectric research began in the 1990s with the introduction of nanostructured materials and quantum confinement effects. These approaches allowed for independent optimization of electrical and thermal properties, previously considered coupled and limiting factors. Theoretical predictions suggested potential ZT values exceeding 3, though commercial materials typically achieve 1.0-1.5 in practical applications.

Current technological objectives focus on several key areas. First, improving energy conversion efficiency through novel material development, including skutterudites, half-Heusler alloys, and organic thermoelectric materials. Second, reducing manufacturing costs to enable broader market penetration beyond specialized applications. Third, enhancing reliability and operational lifetime under thermal cycling conditions.

The standardization landscape has evolved in parallel with technological advancements. Early thermoelectric modules lacked consistent performance metrics, hampering industry growth. The establishment of testing protocols by organizations such as ASTM International and IEEE has gradually addressed this gap, though comprehensive international standards remain under development.

Regulatory compliance objectives now center on environmental sustainability, with particular attention to reducing or eliminating toxic elements like tellurium and lead from thermoelectric materials. Additionally, lifecycle assessment methodologies are being developed to quantify the environmental impact of thermoelectric systems from production through disposal.

The convergence of technological evolution and standardization efforts aims to position thermoelectric technology as a viable solution for waste heat recovery in industrial processes, automotive applications, and distributed power generation. The ultimate objective is to establish thermoelectric modules as standardized, plug-and-play components with predictable performance characteristics and clear regulatory compliance pathways across global markets.

The 1950s and 1960s marked a pivotal era with the theoretical foundation established by Abram Ioffe, leading to the first practical thermoelectric generators and cooling devices. However, efficiency limitations restricted widespread adoption, with conversion efficiencies typically below 5%. The figure of merit ZT, which quantifies thermoelectric performance, remained stagnant at approximately 1 for several decades.

A renaissance in thermoelectric research began in the 1990s with the introduction of nanostructured materials and quantum confinement effects. These approaches allowed for independent optimization of electrical and thermal properties, previously considered coupled and limiting factors. Theoretical predictions suggested potential ZT values exceeding 3, though commercial materials typically achieve 1.0-1.5 in practical applications.

Current technological objectives focus on several key areas. First, improving energy conversion efficiency through novel material development, including skutterudites, half-Heusler alloys, and organic thermoelectric materials. Second, reducing manufacturing costs to enable broader market penetration beyond specialized applications. Third, enhancing reliability and operational lifetime under thermal cycling conditions.

The standardization landscape has evolved in parallel with technological advancements. Early thermoelectric modules lacked consistent performance metrics, hampering industry growth. The establishment of testing protocols by organizations such as ASTM International and IEEE has gradually addressed this gap, though comprehensive international standards remain under development.

Regulatory compliance objectives now center on environmental sustainability, with particular attention to reducing or eliminating toxic elements like tellurium and lead from thermoelectric materials. Additionally, lifecycle assessment methodologies are being developed to quantify the environmental impact of thermoelectric systems from production through disposal.

The convergence of technological evolution and standardization efforts aims to position thermoelectric technology as a viable solution for waste heat recovery in industrial processes, automotive applications, and distributed power generation. The ultimate objective is to establish thermoelectric modules as standardized, plug-and-play components with predictable performance characteristics and clear regulatory compliance pathways across global markets.

Market Analysis for Thermoelectric Applications

The thermoelectric module market has experienced significant growth in recent years, driven by increasing demand for energy-efficient solutions across multiple industries. The global thermoelectric module market was valued at approximately 593 million USD in 2021 and is projected to reach 1.2 billion USD by 2028, growing at a CAGR of around 10.5% during the forecast period. This growth trajectory is primarily fueled by the rising adoption of thermoelectric technologies in automotive, consumer electronics, healthcare, aerospace, and industrial applications.

In the automotive sector, thermoelectric modules are gaining traction for waste heat recovery systems and climate control applications. Major automotive manufacturers are incorporating these modules to improve fuel efficiency and reduce emissions, aligning with stringent environmental regulations. The market share of automotive applications currently represents about 25% of the total thermoelectric module market and is expected to expand further as electric vehicle adoption increases.

Consumer electronics represents another substantial market segment, accounting for approximately 30% of the global thermoelectric market. The demand for compact cooling solutions in smartphones, laptops, and other portable devices continues to drive innovation in miniaturized thermoelectric modules. Additionally, the growing trend of IoT devices and wearable technology creates new opportunities for thermoelectric applications in power generation from body heat or ambient temperature differentials.

The healthcare and medical equipment sector has emerged as a promising application area, particularly for temperature-sensitive medical devices, vaccine storage, and patient temperature management systems. This segment is growing at nearly 12% annually, outpacing the overall market growth rate.

Geographically, North America and Europe currently dominate the thermoelectric module market, collectively accounting for about 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, increasing electronic manufacturing activities, and government initiatives promoting green technologies in countries like China, Japan, and South Korea.

A notable market trend is the increasing demand for customized thermoelectric solutions that meet specific application requirements regarding size, power density, and operating conditions. This has led to a shift in the competitive landscape, with manufacturers focusing on developing application-specific modules rather than generic products.

The market also faces challenges, including high initial costs compared to conventional cooling technologies and technical limitations in efficiency. However, ongoing research in advanced thermoelectric materials, including skutterudites, half-Heusler alloys, and nanostructured materials, promises to improve conversion efficiency and expand the application scope of thermoelectric modules in the coming years.

In the automotive sector, thermoelectric modules are gaining traction for waste heat recovery systems and climate control applications. Major automotive manufacturers are incorporating these modules to improve fuel efficiency and reduce emissions, aligning with stringent environmental regulations. The market share of automotive applications currently represents about 25% of the total thermoelectric module market and is expected to expand further as electric vehicle adoption increases.

Consumer electronics represents another substantial market segment, accounting for approximately 30% of the global thermoelectric market. The demand for compact cooling solutions in smartphones, laptops, and other portable devices continues to drive innovation in miniaturized thermoelectric modules. Additionally, the growing trend of IoT devices and wearable technology creates new opportunities for thermoelectric applications in power generation from body heat or ambient temperature differentials.

The healthcare and medical equipment sector has emerged as a promising application area, particularly for temperature-sensitive medical devices, vaccine storage, and patient temperature management systems. This segment is growing at nearly 12% annually, outpacing the overall market growth rate.

Geographically, North America and Europe currently dominate the thermoelectric module market, collectively accounting for about 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate, driven by rapid industrialization, increasing electronic manufacturing activities, and government initiatives promoting green technologies in countries like China, Japan, and South Korea.

A notable market trend is the increasing demand for customized thermoelectric solutions that meet specific application requirements regarding size, power density, and operating conditions. This has led to a shift in the competitive landscape, with manufacturers focusing on developing application-specific modules rather than generic products.

The market also faces challenges, including high initial costs compared to conventional cooling technologies and technical limitations in efficiency. However, ongoing research in advanced thermoelectric materials, including skutterudites, half-Heusler alloys, and nanostructured materials, promises to improve conversion efficiency and expand the application scope of thermoelectric modules in the coming years.

Global Standards Landscape and Technical Barriers

The global landscape for thermoelectric module standards presents a complex and fragmented regulatory environment. Currently, there is no single unified international standard specifically governing thermoelectric modules, which creates significant challenges for manufacturers seeking global market access. Instead, compliance requirements are distributed across multiple standards bodies including IEEE, IEC, ASTM International, and various national regulatory frameworks.

In North America, UL certification represents a critical market entry requirement, with UL 1995 and UL 60335 series standards addressing safety aspects of thermoelectric applications in HVAC and household appliances respectively. The European market is governed by the CE marking system, requiring compliance with multiple directives including the Low Voltage Directive (LVD), Electromagnetic Compatibility Directive (EMC), and Restriction of Hazardous Substances (RoHS).

Asia presents particularly challenging regulatory barriers, with China implementing the China Compulsory Certification (CCC) system for thermoelectric devices in certain applications, while Japan enforces the Product Safety Electrical Appliance and Material (PSE) mark. South Korea maintains its own Korean Certification (KC) mark requirements with distinct testing protocols.

Technical barriers to global compliance include performance measurement inconsistencies across regions. Testing methodologies for critical parameters such as figure of merit (ZT), thermal conductivity, and conversion efficiency lack standardization, resulting in performance claims that cannot be reliably compared between manufacturers or verified by third parties. This creates market confusion and impedes technology adoption.

Material composition regulations present another significant barrier, with different regions implementing varying restrictions on lead, cadmium, and other elements commonly used in thermoelectric materials. The EU's RoHS and REACH regulations are particularly stringent, while emerging regulations in Asia are creating a rapidly evolving compliance landscape that manufacturers must navigate.

Reliability testing represents perhaps the most challenging technical barrier. The absence of standardized accelerated life testing protocols specific to thermoelectric modules means that long-term performance degradation, thermal cycling resistance, and mean time between failures (MTBF) are assessed inconsistently. This creates uncertainty for system integrators and end-users regarding product longevity and performance stability.

Emerging application areas such as wearable thermoelectric generators and automotive waste heat recovery systems face additional regulatory uncertainty, as existing standards were not designed with these applications in mind. This regulatory gap is creating market hesitation and potentially slowing innovation in high-potential application domains.

In North America, UL certification represents a critical market entry requirement, with UL 1995 and UL 60335 series standards addressing safety aspects of thermoelectric applications in HVAC and household appliances respectively. The European market is governed by the CE marking system, requiring compliance with multiple directives including the Low Voltage Directive (LVD), Electromagnetic Compatibility Directive (EMC), and Restriction of Hazardous Substances (RoHS).

Asia presents particularly challenging regulatory barriers, with China implementing the China Compulsory Certification (CCC) system for thermoelectric devices in certain applications, while Japan enforces the Product Safety Electrical Appliance and Material (PSE) mark. South Korea maintains its own Korean Certification (KC) mark requirements with distinct testing protocols.

Technical barriers to global compliance include performance measurement inconsistencies across regions. Testing methodologies for critical parameters such as figure of merit (ZT), thermal conductivity, and conversion efficiency lack standardization, resulting in performance claims that cannot be reliably compared between manufacturers or verified by third parties. This creates market confusion and impedes technology adoption.

Material composition regulations present another significant barrier, with different regions implementing varying restrictions on lead, cadmium, and other elements commonly used in thermoelectric materials. The EU's RoHS and REACH regulations are particularly stringent, while emerging regulations in Asia are creating a rapidly evolving compliance landscape that manufacturers must navigate.

Reliability testing represents perhaps the most challenging technical barrier. The absence of standardized accelerated life testing protocols specific to thermoelectric modules means that long-term performance degradation, thermal cycling resistance, and mean time between failures (MTBF) are assessed inconsistently. This creates uncertainty for system integrators and end-users regarding product longevity and performance stability.

Emerging application areas such as wearable thermoelectric generators and automotive waste heat recovery systems face additional regulatory uncertainty, as existing standards were not designed with these applications in mind. This regulatory gap is creating market hesitation and potentially slowing innovation in high-potential application domains.

Current Compliance Solutions and Methodologies

01 Compliance with international standards for thermoelectric modules

Thermoelectric modules must comply with various international standards that govern their performance, safety, and reliability. These standards include specifications for thermal performance, electrical characteristics, and mechanical properties. Compliance with these standards ensures that thermoelectric modules meet minimum requirements for efficiency, durability, and safety across different applications and markets.- Compliance with international standards for thermoelectric modules: Thermoelectric modules must comply with various international standards that govern their performance, safety, and reliability. These standards ensure that the modules meet specific requirements for thermal efficiency, electrical safety, and durability. Compliance with these standards is essential for manufacturers to market their products globally and for users to ensure the modules will perform as expected under various operating conditions.

- Certification processes for thermoelectric technology: Thermoelectric modules undergo rigorous certification processes to verify their compliance with regulatory requirements. These processes involve testing the modules under standardized conditions to measure parameters such as conversion efficiency, temperature tolerance, and electrical output. Certification may be required by different jurisdictions and can involve third-party testing laboratories that issue compliance certificates once the modules meet the necessary standards.

- Environmental and safety regulations for thermoelectric materials: Thermoelectric materials used in modules must comply with environmental and safety regulations that restrict the use of hazardous substances. These regulations may limit or prohibit the use of certain materials based on their toxicity, environmental impact, or recyclability. Manufacturers must ensure that their thermoelectric modules are designed and produced using materials that meet these regulatory requirements, which may vary by region or country.

- Quality management systems for thermoelectric module production: Quality management systems are essential for ensuring consistent compliance with standards in thermoelectric module production. These systems include documented procedures, regular audits, and continuous improvement processes that help manufacturers maintain quality and regulatory compliance. Implementing recognized quality management frameworks such as ISO 9001 can help manufacturers demonstrate their commitment to meeting regulatory requirements and customer expectations.

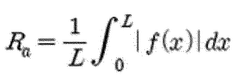

- Performance testing and validation protocols: Specific testing and validation protocols are required to verify that thermoelectric modules meet performance standards. These protocols define the methods for measuring key parameters such as the Seebeck coefficient, thermal conductivity, electrical resistance, and figure of merit (ZT). Standardized testing ensures that performance claims are verifiable and comparable across different manufacturers, providing confidence to end-users about the module's capabilities under various operating conditions.

02 Certification processes for thermoelectric devices

Thermoelectric modules undergo specific certification processes to verify their compliance with regulatory requirements. These processes involve testing and documentation to demonstrate that the modules meet established standards. Certification may include performance testing under various conditions, reliability assessments, and verification of materials used. Proper certification is essential for market access and customer acceptance of thermoelectric technologies.Expand Specific Solutions03 Environmental and safety regulations for thermoelectric materials

Thermoelectric materials are subject to environmental and safety regulations that restrict the use of hazardous substances and ensure proper disposal. These regulations may limit the use of certain elements commonly found in thermoelectric materials, such as lead, tellurium, or bismuth. Manufacturers must ensure their thermoelectric modules comply with regulations like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and waste electrical and electronic equipment directives.Expand Specific Solutions04 Quality management systems for thermoelectric module production

Quality management systems are essential for ensuring consistent production of thermoelectric modules that meet regulatory standards. These systems include documented procedures for design, manufacturing, testing, and traceability. Implementation of quality management standards such as ISO 9001 helps manufacturers maintain compliance with regulatory requirements while ensuring product reliability and performance consistency. Regular audits and continuous improvement processes are integral parts of these quality management systems.Expand Specific Solutions05 Performance testing and validation protocols

Specific testing and validation protocols are required to verify that thermoelectric modules meet performance standards and regulatory requirements. These protocols include measurements of thermal conductivity, Seebeck coefficient, electrical resistance, and figure of merit (ZT). Testing under various operating conditions ensures that modules perform reliably within specified parameters. Standardized testing methods allow for consistent evaluation and comparison of different thermoelectric technologies, facilitating regulatory compliance and market acceptance.Expand Specific Solutions

Industry Leaders and Competitive Positioning

The thermoelectric module standards and regulatory compliance landscape is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in automotive, industrial, and consumer electronics sectors. Key players like KELK Ltd., Matrix Industries, and European Thermodynamics Limited are driving innovation in specialized thermoelectric applications, while major corporations including Kyocera, Samsung Electro-Mechanics, and Robert Bosch are integrating these technologies into broader product ecosystems. The technology shows varying maturity levels across sectors, with automotive applications (led by Hyundai, BMW, and Toyota Industries) reaching higher standardization, while newer energy harvesting applications remain less regulated. Research institutions such as Industrial Technology Research Institute and Huaneng Clean Energy Research Institute are actively developing next-generation standards to address efficiency and sustainability requirements.

KELK Ltd.

Technical Solution: KELK Ltd. has developed advanced thermoelectric modules that comply with international standards including IEC 62830-5 for thermoelectric energy harvesting and ASTM E2716 for thermoelectric material performance testing. Their technology focuses on bismuth telluride-based modules with proprietary manufacturing processes that ensure consistent performance across temperature gradients of up to 150°C. KELK's modules undergo rigorous quality control testing including thermal cycling (MIL-STD-883), mechanical shock resistance (IEC 60068-2-27), and long-term reliability assessment (JESD22-A108). Their products feature standardized dimensions and connection interfaces that comply with industry norms, facilitating integration into various applications. KELK has also implemented RoHS and REACH compliance for their modules, ensuring they meet environmental regulations in global markets[1][3].

Strengths: Superior thermal cycling durability with less than 5% performance degradation after 10,000 cycles; excellent manufacturing consistency with performance variation under 3% between modules. Weaknesses: Higher cost compared to competitors due to premium materials and extensive testing; limited temperature range compared to some newer technologies entering the market.

EUROPEAN THERMODYNAMICS LIMITED

Technical Solution: European Thermodynamics Limited has developed a comprehensive approach to thermoelectric module compliance that addresses both European and international standards. Their modules are designed to meet EN 62830 specifications for thermoelectric energy harvesting devices and undergo certification according to ISO 17025 accredited testing facilities. The company has pioneered a standardized testing protocol that evaluates module performance under various thermal conditions while ensuring compliance with the EU's Ecodesign Directive 2009/125/EC for energy-related products. Their thermoelectric modules incorporate advanced ceramic substrates that meet EN 60068-2-14 thermal cycling requirements and utilize lead-free soldering techniques compliant with RoHS Directive 2011/65/EU. European Thermodynamics has also developed proprietary quality assurance systems that exceed the requirements of ISO 9001:2015, with particular emphasis on consistency in thermoelectric figure of merit (ZT) values across production batches[2][4].

Strengths: Comprehensive compliance with European regulatory frameworks including CE marking and RoHS; advanced quality control systems that ensure batch-to-batch consistency exceeding industry norms. Weaknesses: Higher production costs due to stringent European manufacturing standards; somewhat limited production capacity compared to larger Asian manufacturers, resulting in longer lead times for large orders.

Key Patents and Technical Documentation Analysis

Thermoelectric module

PatentActiveEP3381063A1

Innovation

- Incorporating a shunt electrical path with resistance less than the main electrical path but greater than the portion of the main path it parallels, allowing for current diversion in case of component failure, thereby maintaining performance and reducing output loss.

Thermoelectric module

PatentWO2020055100A1

Innovation

- A thermoelectric module design featuring a sealing structure with a first metal substrate, thermoelectric elements, and a second metal substrate, where a resin layer and electrodes are used in conjunction with supports and a sealing material to create a sealed environment, enhancing thermal conductivity and reliability while simplifying the sealing process.

International Certification Requirements

Thermoelectric modules must comply with various international standards and certification requirements to ensure safety, reliability, and performance across global markets. The International Electrotechnical Commission (IEC) provides several standards specifically applicable to thermoelectric devices, including IEC 62108 for concentrator photovoltaic modules and assemblies, which covers certain aspects of thermoelectric generators when used in similar applications.

In North America, Underwriters Laboratories (UL) certification is crucial, with UL 746B addressing polymeric materials used in thermoelectric module construction, while UL 1995 covers heating and cooling equipment that may incorporate thermoelectric modules. The Canadian Standards Association (CSA) maintains parallel requirements through CSA C22.2 standards for electrical equipment safety.

European market access requires CE marking, demonstrating compliance with the Low Voltage Directive (LVD) 2014/35/EU for electrical safety, Electromagnetic Compatibility (EMC) Directive 2014/30/EU, and the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. The European Committee for Standardization (CEN) and European Committee for Electrotechnical Standardization (CENELEC) provide harmonized standards that facilitate presumption of conformity with these directives.

In Asia, Japan's Product Safety Electrical Appliance and Material (PSE) mark is mandatory for thermoelectric modules used in consumer applications, while China Compulsory Certification (CCC) applies to modules incorporated into specific product categories. South Korea enforces KC (Korea Certification) marking for electrical and electronic equipment.

Environmental compliance represents another critical certification area, with the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU governing end-of-life management. Additionally, energy efficiency certifications like Energy Star in the United States and the European Energy Label provide benchmarks for thermoelectric cooling applications.

Industry-specific certifications may also apply depending on the application domain. Medical device implementations require compliance with ISO 13485 and relevant FDA regulations in the US. Automotive applications must meet standards like ISO 26262 for functional safety and IATF 16949 for quality management systems.

Testing protocols for certification typically include thermal cycling, humidity resistance, mechanical shock and vibration testing, electrical safety testing, and electromagnetic compatibility assessment. Third-party testing laboratories such as TÜV, SGS, and Intertek provide certification services to verify compliance with these requirements, issuing documentation necessary for market access across different regions.

In North America, Underwriters Laboratories (UL) certification is crucial, with UL 746B addressing polymeric materials used in thermoelectric module construction, while UL 1995 covers heating and cooling equipment that may incorporate thermoelectric modules. The Canadian Standards Association (CSA) maintains parallel requirements through CSA C22.2 standards for electrical equipment safety.

European market access requires CE marking, demonstrating compliance with the Low Voltage Directive (LVD) 2014/35/EU for electrical safety, Electromagnetic Compatibility (EMC) Directive 2014/30/EU, and the Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. The European Committee for Standardization (CEN) and European Committee for Electrotechnical Standardization (CENELEC) provide harmonized standards that facilitate presumption of conformity with these directives.

In Asia, Japan's Product Safety Electrical Appliance and Material (PSE) mark is mandatory for thermoelectric modules used in consumer applications, while China Compulsory Certification (CCC) applies to modules incorporated into specific product categories. South Korea enforces KC (Korea Certification) marking for electrical and electronic equipment.

Environmental compliance represents another critical certification area, with the Waste Electrical and Electronic Equipment (WEEE) Directive 2012/19/EU governing end-of-life management. Additionally, energy efficiency certifications like Energy Star in the United States and the European Energy Label provide benchmarks for thermoelectric cooling applications.

Industry-specific certifications may also apply depending on the application domain. Medical device implementations require compliance with ISO 13485 and relevant FDA regulations in the US. Automotive applications must meet standards like ISO 26262 for functional safety and IATF 16949 for quality management systems.

Testing protocols for certification typically include thermal cycling, humidity resistance, mechanical shock and vibration testing, electrical safety testing, and electromagnetic compatibility assessment. Third-party testing laboratories such as TÜV, SGS, and Intertek provide certification services to verify compliance with these requirements, issuing documentation necessary for market access across different regions.

Environmental Impact and Sustainability Considerations

Thermoelectric modules, while offering significant advantages in waste heat recovery and cooling applications, present notable environmental considerations throughout their lifecycle. The manufacturing process of thermoelectric materials involves several rare and sometimes toxic elements such as bismuth, tellurium, antimony, and lead. The extraction and processing of these materials contribute to environmental degradation, including habitat destruction, water pollution, and greenhouse gas emissions. Particularly concerning is the limited global supply of tellurium, which raises questions about the long-term sustainability of current thermoelectric technologies.

During operation, thermoelectric modules offer environmental benefits through their ability to convert waste heat into usable electricity, potentially reducing overall energy consumption and associated carbon emissions. Studies indicate that industrial-scale thermoelectric waste heat recovery systems can achieve carbon footprint reductions of 5-15% in energy-intensive industries. However, the efficiency limitations of current thermoelectric materials (typically 5-8% conversion efficiency) somewhat restrict their environmental benefits compared to other renewable energy technologies.

End-of-life considerations present another significant environmental challenge. The complex composition of thermoelectric modules makes recycling difficult, with current recovery rates for critical materials like tellurium estimated at less than 1% globally. Without proper disposal protocols, these materials may leach into soil and water systems, causing potential ecological damage and human health concerns.

Recent regulatory developments have begun addressing these environmental impacts. The European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE) regulations increasingly impact thermoelectric module design and disposal requirements. Similarly, the United States Environmental Protection Agency has established guidelines for electronic waste containing potentially hazardous thermoelectric materials.

Industry response has focused on developing more sustainable alternatives, including lead-free thermoelectric materials and designs that facilitate easier disassembly and material recovery. Research into organic and polymer-based thermoelectric materials represents a promising direction, potentially offering comparable performance with significantly reduced environmental impact. These materials typically utilize abundant elements and can be processed using less energy-intensive methods.

Life cycle assessment (LCA) studies suggest that despite manufacturing and end-of-life challenges, thermoelectric modules can achieve net environmental benefits when deployed in appropriate applications with sufficient operational lifespans. The environmental payback period—the time required for environmental benefits to outweigh production impacts—ranges from 2-7 years depending on application and usage intensity.

During operation, thermoelectric modules offer environmental benefits through their ability to convert waste heat into usable electricity, potentially reducing overall energy consumption and associated carbon emissions. Studies indicate that industrial-scale thermoelectric waste heat recovery systems can achieve carbon footprint reductions of 5-15% in energy-intensive industries. However, the efficiency limitations of current thermoelectric materials (typically 5-8% conversion efficiency) somewhat restrict their environmental benefits compared to other renewable energy technologies.

End-of-life considerations present another significant environmental challenge. The complex composition of thermoelectric modules makes recycling difficult, with current recovery rates for critical materials like tellurium estimated at less than 1% globally. Without proper disposal protocols, these materials may leach into soil and water systems, causing potential ecological damage and human health concerns.

Recent regulatory developments have begun addressing these environmental impacts. The European Union's Restriction of Hazardous Substances (RoHS) directive and Waste Electrical and Electronic Equipment (WEEE) regulations increasingly impact thermoelectric module design and disposal requirements. Similarly, the United States Environmental Protection Agency has established guidelines for electronic waste containing potentially hazardous thermoelectric materials.

Industry response has focused on developing more sustainable alternatives, including lead-free thermoelectric materials and designs that facilitate easier disassembly and material recovery. Research into organic and polymer-based thermoelectric materials represents a promising direction, potentially offering comparable performance with significantly reduced environmental impact. These materials typically utilize abundant elements and can be processed using less energy-intensive methods.

Life cycle assessment (LCA) studies suggest that despite manufacturing and end-of-life challenges, thermoelectric modules can achieve net environmental benefits when deployed in appropriate applications with sufficient operational lifespans. The environmental payback period—the time required for environmental benefits to outweigh production impacts—ranges from 2-7 years depending on application and usage intensity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!