Why Thermoelectric Module Improves Waste Heat Recovery Efficiency

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Waste heat recovery represents a significant opportunity in the global pursuit of energy efficiency and sustainability. Approximately 20-50% of industrial energy consumption is lost as waste heat, presenting both an environmental challenge and an economic opportunity. Thermoelectric modules, which directly convert temperature differences into electrical energy through the Seebeck effect, have emerged as a promising technology for capturing this otherwise wasted energy resource.

The evolution of thermoelectric technology dates back to the early 19th century with Thomas Johann Seebeck's discovery of the thermoelectric effect in 1821. However, practical applications remained limited until the mid-20th century when semiconductor materials revolutionized the field. The technology gained prominence in specialized applications such as space exploration, where radioisotope thermoelectric generators (RTGs) have powered deep space missions since the 1960s.

Recent technological advancements have significantly improved thermoelectric materials' figure of merit (ZT), a dimensionless parameter indicating conversion efficiency. Traditional thermoelectric materials typically achieved ZT values below 1, but modern nanostructured materials and advanced composites have demonstrated ZT values exceeding 2, marking substantial progress toward commercial viability in broader applications.

The primary objective of thermoelectric waste heat recovery research is to develop cost-effective, efficient, and durable systems capable of converting low to medium-grade waste heat (80-500°C) into usable electricity. This involves enhancing three key aspects: improving thermoelectric material performance, optimizing system design for maximum heat transfer, and reducing manufacturing costs to achieve competitive levelized cost of electricity.

Current technological trends indicate growing interest in flexible thermoelectric generators for wearable applications, hybrid systems combining thermoelectric with other waste heat recovery technologies, and integration with Internet of Things (IoT) platforms for smart energy management. The development of non-toxic, earth-abundant thermoelectric materials represents another significant trend addressing sustainability concerns associated with traditional materials containing tellurium, bismuth, and lead.

The expected technical outcomes include achieving system conversion efficiencies of 10-15% (compared to current 5-8%), reducing production costs below $1/W, extending operational lifespans beyond 100,000 hours, and developing plug-and-play solutions adaptable to various industrial waste heat sources. These advancements would position thermoelectric technology as a viable component in the global energy efficiency portfolio, contributing to carbon emission reduction targets while offering economic benefits through energy recovery.

The evolution of thermoelectric technology dates back to the early 19th century with Thomas Johann Seebeck's discovery of the thermoelectric effect in 1821. However, practical applications remained limited until the mid-20th century when semiconductor materials revolutionized the field. The technology gained prominence in specialized applications such as space exploration, where radioisotope thermoelectric generators (RTGs) have powered deep space missions since the 1960s.

Recent technological advancements have significantly improved thermoelectric materials' figure of merit (ZT), a dimensionless parameter indicating conversion efficiency. Traditional thermoelectric materials typically achieved ZT values below 1, but modern nanostructured materials and advanced composites have demonstrated ZT values exceeding 2, marking substantial progress toward commercial viability in broader applications.

The primary objective of thermoelectric waste heat recovery research is to develop cost-effective, efficient, and durable systems capable of converting low to medium-grade waste heat (80-500°C) into usable electricity. This involves enhancing three key aspects: improving thermoelectric material performance, optimizing system design for maximum heat transfer, and reducing manufacturing costs to achieve competitive levelized cost of electricity.

Current technological trends indicate growing interest in flexible thermoelectric generators for wearable applications, hybrid systems combining thermoelectric with other waste heat recovery technologies, and integration with Internet of Things (IoT) platforms for smart energy management. The development of non-toxic, earth-abundant thermoelectric materials represents another significant trend addressing sustainability concerns associated with traditional materials containing tellurium, bismuth, and lead.

The expected technical outcomes include achieving system conversion efficiencies of 10-15% (compared to current 5-8%), reducing production costs below $1/W, extending operational lifespans beyond 100,000 hours, and developing plug-and-play solutions adaptable to various industrial waste heat sources. These advancements would position thermoelectric technology as a viable component in the global energy efficiency portfolio, contributing to carbon emission reduction targets while offering economic benefits through energy recovery.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery market is experiencing significant growth, valued at approximately $54 billion in 2020 and projected to reach $80 billion by 2026, with a compound annual growth rate of 8.8%. This growth is primarily driven by increasing industrial energy costs, stringent environmental regulations, and the global push toward sustainable energy practices. Industries such as manufacturing, power generation, oil and gas, and chemical processing represent the largest market segments, collectively accounting for over 65% of the total market share.

Thermoelectric modules represent a growing segment within this market, currently valued at around $600 million and expected to grow at 9.5% annually through 2028. While this represents a relatively small portion of the overall waste heat recovery market, thermoelectric technology is gaining traction due to its unique advantages in specific applications where traditional methods are impractical.

Geographically, Asia-Pacific dominates the waste heat recovery market with approximately 40% market share, led by China, Japan, and South Korea's industrial sectors. North America and Europe follow with 25% and 22% respectively, with particularly strong growth in Germany, France, and the United States. These regions have implemented favorable policies promoting energy efficiency and carbon reduction, creating conducive environments for waste heat recovery technologies.

The competitive landscape features both established players and innovative startups. Traditional waste heat recovery is dominated by companies like Siemens, GE, Mitsubishi Heavy Industries, and ABB, which primarily focus on large-scale heat exchangers, steam generators, and organic Rankine cycle systems. In the thermoelectric module space, companies like Ferrotec, Laird Thermal Systems, II-VI Marlow, and Komatsu are leading innovation and market penetration.

Customer segments vary significantly based on application requirements. Large industrial facilities typically prioritize high-capacity systems with proven reliability and reasonable payback periods of 2-5 years. Meanwhile, automotive applications focus on compact, durable solutions that can withstand vibration and temperature fluctuations. The emerging distributed energy sector seeks modular, scalable solutions that can be deployed in various settings.

Market barriers include high initial capital costs, with payback periods sometimes extending beyond acceptable thresholds for certain industries. Technical challenges related to efficiency limitations and integration complexity also hinder wider adoption. Additionally, lack of awareness and technical expertise among potential end-users remains a significant obstacle, particularly in developing markets where energy efficiency initiatives are still maturing.

Thermoelectric modules represent a growing segment within this market, currently valued at around $600 million and expected to grow at 9.5% annually through 2028. While this represents a relatively small portion of the overall waste heat recovery market, thermoelectric technology is gaining traction due to its unique advantages in specific applications where traditional methods are impractical.

Geographically, Asia-Pacific dominates the waste heat recovery market with approximately 40% market share, led by China, Japan, and South Korea's industrial sectors. North America and Europe follow with 25% and 22% respectively, with particularly strong growth in Germany, France, and the United States. These regions have implemented favorable policies promoting energy efficiency and carbon reduction, creating conducive environments for waste heat recovery technologies.

The competitive landscape features both established players and innovative startups. Traditional waste heat recovery is dominated by companies like Siemens, GE, Mitsubishi Heavy Industries, and ABB, which primarily focus on large-scale heat exchangers, steam generators, and organic Rankine cycle systems. In the thermoelectric module space, companies like Ferrotec, Laird Thermal Systems, II-VI Marlow, and Komatsu are leading innovation and market penetration.

Customer segments vary significantly based on application requirements. Large industrial facilities typically prioritize high-capacity systems with proven reliability and reasonable payback periods of 2-5 years. Meanwhile, automotive applications focus on compact, durable solutions that can withstand vibration and temperature fluctuations. The emerging distributed energy sector seeks modular, scalable solutions that can be deployed in various settings.

Market barriers include high initial capital costs, with payback periods sometimes extending beyond acceptable thresholds for certain industries. Technical challenges related to efficiency limitations and integration complexity also hinder wider adoption. Additionally, lack of awareness and technical expertise among potential end-users remains a significant obstacle, particularly in developing markets where energy efficiency initiatives are still maturing.

Current Thermoelectric Module Technology Landscape

The thermoelectric module (TEM) market has experienced significant growth in recent years, driven by increasing focus on energy efficiency and waste heat recovery across multiple industries. Current commercial TEMs predominantly utilize bismuth telluride (Bi2Te3) semiconductor materials, which offer optimal performance at low to moderate temperatures (up to 250°C). These modules typically achieve conversion efficiencies between 5-8% under ideal conditions, with the highest performing laboratory prototypes reaching approximately 10-12%.

For higher temperature applications (250-600°C), lead telluride (PbTe) and silicon-germanium (SiGe) based modules have gained traction, though their commercial deployment remains more limited than Bi2Te3 systems. Recent advancements in skutterudite and half-Heusler alloys have shown promising results for mid-to-high temperature waste heat recovery, with several manufacturers beginning small-scale production of these advanced modules.

The global TEM manufacturing landscape is dominated by companies in North America, Europe, and East Asia. Major players include Ferrotec, Laird Thermal Systems, Marlow Industries, Kelk Ltd, and II-VI Incorporated, who collectively control approximately 60% of the global market share. China has emerged as a significant manufacturing hub, particularly for lower-cost, standard-performance modules, while specialized high-performance modules remain concentrated among manufacturers in Japan, Germany, and the United States.

From a design perspective, current TEMs typically employ a flat-plate configuration with thermoelectric elements sandwiched between ceramic substrates. Advanced designs incorporating segmented legs (using different materials optimized for specific temperature ranges) and cascaded architectures (stacking multiple modules) have demonstrated improved performance in laboratory settings but face manufacturing challenges for mass production.

The integration of TEMs into waste heat recovery systems has evolved significantly, with manufacturers now offering complete subsystems including heat exchangers, thermal interface materials, and power conditioning electronics. This system-level approach has improved overall efficiency and reliability while reducing implementation complexity for end-users.

Fabrication technologies have also advanced, with manufacturers increasingly adopting automated assembly processes, precision deposition techniques, and improved electrical interconnection methods. These manufacturing improvements have resulted in more consistent performance, enhanced durability, and gradual cost reductions, though TEMs remain relatively expensive compared to alternative energy conversion technologies on a cost-per-watt basis.

Despite these advancements, current TEM technology still faces fundamental limitations in conversion efficiency due to inherent material constraints, creating significant opportunities for further innovation in both materials science and system design to improve waste heat recovery performance.

For higher temperature applications (250-600°C), lead telluride (PbTe) and silicon-germanium (SiGe) based modules have gained traction, though their commercial deployment remains more limited than Bi2Te3 systems. Recent advancements in skutterudite and half-Heusler alloys have shown promising results for mid-to-high temperature waste heat recovery, with several manufacturers beginning small-scale production of these advanced modules.

The global TEM manufacturing landscape is dominated by companies in North America, Europe, and East Asia. Major players include Ferrotec, Laird Thermal Systems, Marlow Industries, Kelk Ltd, and II-VI Incorporated, who collectively control approximately 60% of the global market share. China has emerged as a significant manufacturing hub, particularly for lower-cost, standard-performance modules, while specialized high-performance modules remain concentrated among manufacturers in Japan, Germany, and the United States.

From a design perspective, current TEMs typically employ a flat-plate configuration with thermoelectric elements sandwiched between ceramic substrates. Advanced designs incorporating segmented legs (using different materials optimized for specific temperature ranges) and cascaded architectures (stacking multiple modules) have demonstrated improved performance in laboratory settings but face manufacturing challenges for mass production.

The integration of TEMs into waste heat recovery systems has evolved significantly, with manufacturers now offering complete subsystems including heat exchangers, thermal interface materials, and power conditioning electronics. This system-level approach has improved overall efficiency and reliability while reducing implementation complexity for end-users.

Fabrication technologies have also advanced, with manufacturers increasingly adopting automated assembly processes, precision deposition techniques, and improved electrical interconnection methods. These manufacturing improvements have resulted in more consistent performance, enhanced durability, and gradual cost reductions, though TEMs remain relatively expensive compared to alternative energy conversion technologies on a cost-per-watt basis.

Despite these advancements, current TEM technology still faces fundamental limitations in conversion efficiency due to inherent material constraints, creating significant opportunities for further innovation in both materials science and system design to improve waste heat recovery performance.

Existing Thermoelectric Module Efficiency Solutions

01 Thermoelectric module design optimization

Optimizing the design of thermoelectric modules can significantly improve waste heat recovery efficiency. This includes modifications to the module structure, geometry, and arrangement of thermoelectric elements. Advanced designs incorporate improved heat transfer interfaces, optimized leg geometries, and better electrical connections to minimize thermal resistance and maximize power output from waste heat sources.- Thermoelectric module design optimization: Optimizing the design of thermoelectric modules can significantly improve waste heat recovery efficiency. This includes modifications to the module structure, geometry, and arrangement of thermoelectric elements. Advanced designs incorporate improved heat transfer surfaces, optimal element spacing, and specialized configurations that maximize the temperature differential across the module. These design optimizations help to convert a greater percentage of waste heat into usable electrical energy.

- Material selection and composition for thermoelectric elements: The selection of appropriate thermoelectric materials and their composition plays a crucial role in determining waste heat recovery efficiency. High-performance thermoelectric materials with superior figure of merit (ZT) values can significantly enhance conversion efficiency. This includes advanced semiconductor materials, nanostructured composites, and materials with low thermal conductivity but high electrical conductivity. Doping and alloying techniques are also employed to optimize the thermoelectric properties of these materials.

- Heat exchanger integration and thermal management: Effective integration of heat exchangers and thermal management systems with thermoelectric modules can substantially improve waste heat recovery efficiency. This involves designing efficient heat collection systems, optimizing heat flux distribution, and minimizing thermal resistance at interfaces. Advanced cooling techniques for the cold side of the module and enhanced heat capture methods for the hot side ensure maximum temperature differential is maintained across the thermoelectric elements, thereby increasing power generation efficiency.

- System-level integration and application-specific designs: Tailoring thermoelectric waste heat recovery systems to specific applications and integrating them effectively within larger systems can optimize overall efficiency. This includes customized solutions for automotive exhaust systems, industrial processes, power plants, and residential applications. System-level considerations such as placement of modules, flow dynamics, operational temperature ranges, and load matching are critical for maximizing energy recovery. Hybrid systems that combine thermoelectric generators with other waste heat recovery technologies can also provide enhanced efficiency.

- Control systems and power conditioning: Advanced control systems and power conditioning technologies can significantly improve the operational efficiency of thermoelectric waste heat recovery systems. This includes maximum power point tracking (MPPT) algorithms, dynamic load matching circuits, and intelligent control strategies that adapt to changing thermal conditions. Power conditioning circuits optimize the electrical output from thermoelectric modules, ensuring efficient energy transfer to storage systems or electrical loads. Monitoring systems that provide real-time performance data enable continuous optimization of system parameters.

02 Material selection and composition for thermoelectric elements

The selection of thermoelectric materials with high figure of merit (ZT) is crucial for improving waste heat recovery efficiency. Advanced materials such as skutterudites, half-Heusler alloys, and nanostructured semiconductors can significantly enhance the conversion of thermal energy to electrical energy. Doping and compositional modifications of these materials can further optimize their thermoelectric properties for specific temperature ranges encountered in waste heat recovery applications.Expand Specific Solutions03 Heat exchanger integration and thermal management

Effective integration of heat exchangers with thermoelectric modules is essential for maximizing waste heat recovery efficiency. This includes designing heat sinks, heat pipes, and thermal interfaces that efficiently capture and transfer waste heat to the thermoelectric modules. Advanced thermal management systems can maintain optimal temperature gradients across the modules, ensuring maximum power generation while preventing thermal degradation of the thermoelectric materials.Expand Specific Solutions04 System-level integration and control strategies

Comprehensive system integration approaches that incorporate thermoelectric modules into existing industrial or automotive systems can significantly improve overall waste heat recovery efficiency. This includes intelligent control systems that dynamically adjust operating parameters based on heat source conditions, load requirements, and environmental factors. Advanced power conditioning circuits and maximum power point tracking algorithms ensure optimal electrical output from the thermoelectric modules under varying conditions.Expand Specific Solutions05 Hybrid and cascaded thermoelectric systems

Hybrid systems that combine thermoelectric modules with other waste heat recovery technologies can achieve higher overall efficiency. Cascaded thermoelectric systems with multiple stages operating at different temperature ranges can harvest energy from a broader spectrum of waste heat sources. These approaches allow for more comprehensive waste heat utilization and can significantly increase the total energy recovered from industrial processes, vehicle exhaust systems, or power generation facilities.Expand Specific Solutions

Leading Companies in Thermoelectric Waste Heat Recovery

The thermoelectric waste heat recovery technology market is currently in a growth phase, with increasing adoption across automotive and industrial sectors. The global market size is projected to expand significantly due to rising energy efficiency demands and environmental regulations. Technologically, the field shows varying maturity levels, with established players like Toyota, Hyundai, and Kia leading automotive applications, while companies such as Valeo Thermal Systems and LG Innotek drive innovation in component development. Research institutions including Fraunhofer-Gesellschaft and Industrial Technology Research Institute are advancing fundamental technologies. Specialized firms like Thermogentech and Alternative Energy Innovations are developing next-generation solutions, while industrial giants such as Caterpillar and Hitachi Powdered Metals are integrating these systems into heavy machinery applications, demonstrating the technology's cross-sector potential.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric waste heat recovery systems specifically for hybrid and conventional vehicles. Their technology utilizes bismuth telluride-based thermoelectric modules strategically positioned in the exhaust system to capture thermal energy that would otherwise be lost. Toyota's approach includes a dual-stage heat exchanger design that maximizes temperature differential across the thermoelectric elements, achieving conversion efficiencies of up to 4-5% in real-world driving conditions. Their system incorporates specialized heat transfer interfaces with thermal expansion compensation mechanisms to maintain optimal contact between hot exhaust gases and thermoelectric materials. Toyota has demonstrated that their thermoelectric generators can recover approximately 3-5% of engine waste heat, translating to a 2-3% improvement in overall fuel economy in their test vehicles. The company has also developed proprietary manufacturing techniques to reduce the cost of thermoelectric modules while maintaining performance and durability under the harsh conditions of automotive exhaust systems.

Strengths: Toyota's system demonstrates excellent durability in automotive applications with proven performance in real-world conditions. Their manufacturing scale provides cost advantages for commercialization. Weaknesses: The technology still faces efficiency limitations compared to other waste heat recovery methods, and requires significant integration engineering for each vehicle platform.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered an innovative thermoelectric waste heat recovery system that integrates directly with their vehicle exhaust systems. Their technology employs segmented thermoelectric materials with varying compositions optimized for different temperature ranges within the exhaust flow path. This approach allows for maximum energy harvesting across the wide temperature gradients present in automotive exhaust systems (from 100°C to over 600°C). Hyundai's system features a cascaded module design where multiple thermoelectric generators are arranged in series and parallel configurations to optimize power output under varying driving conditions. Their latest generation modules utilize skutterudite-based materials for high-temperature sections and bismuth-telluride compounds for lower temperature regions, achieving a system-level conversion efficiency approaching 5%. Hyundai has also developed specialized power conditioning electronics that can effectively manage the variable output from thermoelectric generators and integrate it with the vehicle's electrical system. Testing on production vehicles has demonstrated fuel economy improvements of 3-4% under highway driving conditions.

Strengths: Hyundai's segmented material approach effectively addresses the wide temperature ranges in exhaust systems, maximizing energy capture. Their system shows excellent integration with existing vehicle electrical architectures. Weaknesses: The complex material system increases manufacturing complexity and cost, while the technology still faces challenges with long-term reliability under thermal cycling conditions.

Key Innovations in Thermoelectric Materials Science

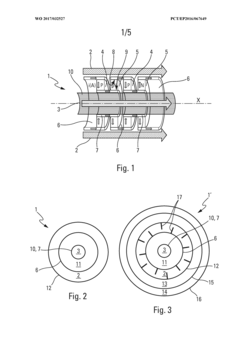

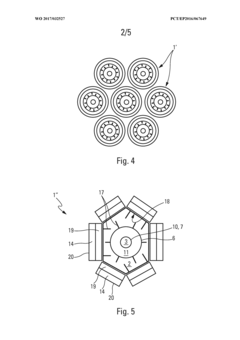

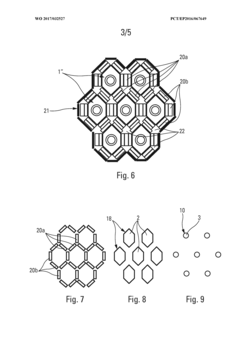

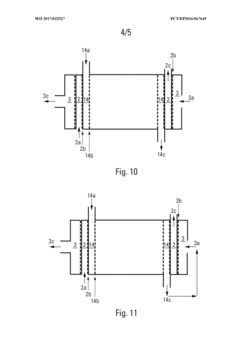

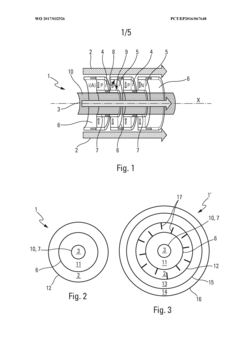

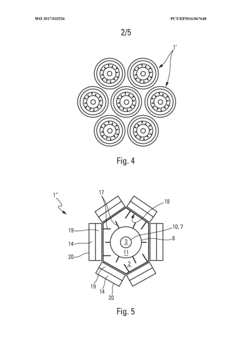

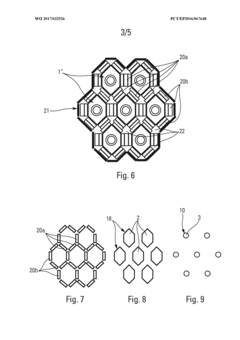

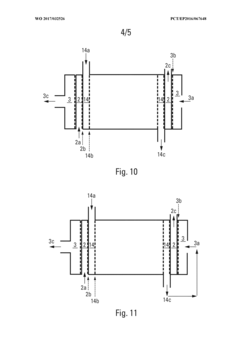

Thermoelectric module for a thermoelectric generator and device

PatentWO2017032527A1

Innovation

- A thermoelectric module design featuring a central cylindrical assembly with multiple peripheral parallelepiped assemblies arranged discontinuously around it, enhancing heat exchange surfaces by combining both geometries and incorporating fins to disturb hot fluid flow, thereby optimizing energy recovery from the hot fluid.

Thermoelectric module for a thermoelectric generator

PatentWO2017032526A1

Innovation

- A thermoelectric module design featuring a central cylindrical thermoelectric assembly with a peripheral assembly of parallel cylindrical shape, where the hot fluid circulates both outside and inside the modules, enhancing heat exchange by using fins to disturb the fluid flow and increasing the heat transfer surface area, and the modules are electrically connected in parallel to maximize energy recovery.

Environmental Impact and Sustainability Benefits

Thermoelectric modules represent a significant advancement in sustainable energy practices by enabling the recovery of waste heat that would otherwise be lost to the environment. The environmental impact of implementing thermoelectric waste heat recovery systems extends far beyond simple energy efficiency improvements, contributing substantially to global sustainability goals.

The reduction of greenhouse gas emissions stands as one of the most critical environmental benefits of thermoelectric waste heat recovery. By converting waste heat into usable electricity, these systems decrease the demand for primary energy generation, directly reducing carbon dioxide, methane, and other harmful emissions associated with conventional power production. Industrial facilities implementing thermoelectric modules can potentially reduce their carbon footprint by 5-15%, depending on the scale and efficiency of the recovery system.

Resource conservation represents another significant sustainability advantage. Thermoelectric waste heat recovery effectively increases the energy yield from existing fuel inputs without requiring additional resource extraction. This "energy recycling" approach aligns perfectly with circular economy principles, maximizing utility from resources already in the industrial cycle and reducing pressure on natural resource reserves.

The decentralized nature of thermoelectric waste heat recovery systems also contributes to grid resilience and energy security. By generating electricity at the point of consumption, these systems reduce transmission losses and decrease vulnerability to centralized power disruptions. This distributed generation model supports sustainable community development and enhances energy independence for industrial facilities.

Water conservation benefits emerge as an often-overlooked sustainability advantage. Unlike many conventional power generation methods that require substantial water resources for cooling, thermoelectric waste heat recovery systems operate without additional water consumption. In water-stressed regions, this characteristic provides a dual environmental benefit of energy recovery and water conservation.

From a lifecycle perspective, thermoelectric modules demonstrate favorable sustainability metrics. Modern modules increasingly utilize abundant, non-toxic materials and feature long operational lifespans with minimal maintenance requirements. The embodied energy of manufacturing thermoelectric systems is typically recovered within 1-3 years of operation, after which the systems provide net positive environmental returns.

When integrated into comprehensive industrial sustainability strategies, thermoelectric waste heat recovery creates synergistic benefits with other green technologies. For example, recovered electricity can power electrolytic hydrogen production, efficient LED lighting systems, or electric vehicle charging infrastructure, multiplying the environmental benefits across different sustainability domains.

The reduction of greenhouse gas emissions stands as one of the most critical environmental benefits of thermoelectric waste heat recovery. By converting waste heat into usable electricity, these systems decrease the demand for primary energy generation, directly reducing carbon dioxide, methane, and other harmful emissions associated with conventional power production. Industrial facilities implementing thermoelectric modules can potentially reduce their carbon footprint by 5-15%, depending on the scale and efficiency of the recovery system.

Resource conservation represents another significant sustainability advantage. Thermoelectric waste heat recovery effectively increases the energy yield from existing fuel inputs without requiring additional resource extraction. This "energy recycling" approach aligns perfectly with circular economy principles, maximizing utility from resources already in the industrial cycle and reducing pressure on natural resource reserves.

The decentralized nature of thermoelectric waste heat recovery systems also contributes to grid resilience and energy security. By generating electricity at the point of consumption, these systems reduce transmission losses and decrease vulnerability to centralized power disruptions. This distributed generation model supports sustainable community development and enhances energy independence for industrial facilities.

Water conservation benefits emerge as an often-overlooked sustainability advantage. Unlike many conventional power generation methods that require substantial water resources for cooling, thermoelectric waste heat recovery systems operate without additional water consumption. In water-stressed regions, this characteristic provides a dual environmental benefit of energy recovery and water conservation.

From a lifecycle perspective, thermoelectric modules demonstrate favorable sustainability metrics. Modern modules increasingly utilize abundant, non-toxic materials and feature long operational lifespans with minimal maintenance requirements. The embodied energy of manufacturing thermoelectric systems is typically recovered within 1-3 years of operation, after which the systems provide net positive environmental returns.

When integrated into comprehensive industrial sustainability strategies, thermoelectric waste heat recovery creates synergistic benefits with other green technologies. For example, recovered electricity can power electrolytic hydrogen production, efficient LED lighting systems, or electric vehicle charging infrastructure, multiplying the environmental benefits across different sustainability domains.

Cost-Benefit Analysis of Implementation

The implementation of thermoelectric modules for waste heat recovery requires careful cost-benefit analysis to determine economic viability across different applications. Initial capital expenditure represents a significant consideration, with high-quality thermoelectric modules typically costing between $5-15 per watt of generation capacity. This investment must be evaluated against the projected energy savings over the system's operational lifetime, which typically ranges from 15-20 years with minimal maintenance requirements.

Installation costs vary considerably depending on application complexity, with industrial implementations generally requiring more substantial infrastructure modifications than smaller-scale applications. For large industrial waste heat recovery systems, installation can represent 40-60% of total project costs, while integration into existing thermal management systems may reduce this proportion significantly.

Operational expenses remain relatively low compared to alternative waste heat recovery technologies. Thermoelectric modules contain no moving parts, eliminating maintenance costs associated with mechanical wear. The primary operational consideration involves periodic inspection and cleaning to maintain optimal thermal contact surfaces, typically requiring minimal technical expertise.

Return on investment calculations demonstrate significant variation across industries. In high-temperature manufacturing processes where waste heat exceeds 400°C, ROI periods of 3-5 years are achievable. Conversely, lower-temperature applications (100-200°C) may require 7-10 years to reach breakeven, depending on energy costs and utilization patterns.

Energy price sensitivity analysis reveals that regions with higher electricity costs (>$0.15/kWh) demonstrate substantially improved economic feasibility. For example, implementation in European manufacturing facilities with average electricity costs of €0.18/kWh shows 30-40% faster payback periods compared to regions with lower energy costs.

Regulatory incentives significantly impact financial calculations. Carbon pricing mechanisms, renewable energy credits, and industrial efficiency subsidies can reduce effective payback periods by 15-30% in applicable jurisdictions. The increasing global trend toward carbon pricing mechanisms suggests improving economic viability in coming years.

Non-monetary benefits must also factor into comprehensive analysis. These include reduced carbon footprint (typically 0.4-0.7 kg CO₂ reduction per kWh recovered), improved corporate sustainability metrics, and potential marketing advantages in environmentally conscious markets. Additionally, thermoelectric implementation can contribute to regulatory compliance regarding emissions and energy efficiency standards, potentially avoiding future compliance costs.

Installation costs vary considerably depending on application complexity, with industrial implementations generally requiring more substantial infrastructure modifications than smaller-scale applications. For large industrial waste heat recovery systems, installation can represent 40-60% of total project costs, while integration into existing thermal management systems may reduce this proportion significantly.

Operational expenses remain relatively low compared to alternative waste heat recovery technologies. Thermoelectric modules contain no moving parts, eliminating maintenance costs associated with mechanical wear. The primary operational consideration involves periodic inspection and cleaning to maintain optimal thermal contact surfaces, typically requiring minimal technical expertise.

Return on investment calculations demonstrate significant variation across industries. In high-temperature manufacturing processes where waste heat exceeds 400°C, ROI periods of 3-5 years are achievable. Conversely, lower-temperature applications (100-200°C) may require 7-10 years to reach breakeven, depending on energy costs and utilization patterns.

Energy price sensitivity analysis reveals that regions with higher electricity costs (>$0.15/kWh) demonstrate substantially improved economic feasibility. For example, implementation in European manufacturing facilities with average electricity costs of €0.18/kWh shows 30-40% faster payback periods compared to regions with lower energy costs.

Regulatory incentives significantly impact financial calculations. Carbon pricing mechanisms, renewable energy credits, and industrial efficiency subsidies can reduce effective payback periods by 15-30% in applicable jurisdictions. The increasing global trend toward carbon pricing mechanisms suggests improving economic viability in coming years.

Non-monetary benefits must also factor into comprehensive analysis. These include reduced carbon footprint (typically 0.4-0.7 kg CO₂ reduction per kWh recovered), improved corporate sustainability metrics, and potential marketing advantages in environmentally conscious markets. Additionally, thermoelectric implementation can contribute to regulatory compliance regarding emissions and energy efficiency standards, potentially avoiding future compliance costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!