How Thermoelectric Module Integration Enhances Automotive Energy Efficiency

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the conversion of temperature differences into electrical voltage. The subsequent discovery of the Peltier effect in 1834 established the foundation for modern thermoelectric applications. However, it wasn't until the mid-20th century that significant advancements in semiconductor materials enabled practical thermoelectric devices with improved efficiency.

The automotive industry's interest in thermoelectric technology began to accelerate in the 1990s, driven by increasing concerns about fuel efficiency and emissions reduction. Early applications focused primarily on seat heating and cooling systems, but research quickly expanded to waste heat recovery from exhaust systems. This evolution was marked by the development of more efficient thermoelectric materials with higher figure of merit (ZT) values, progressing from traditional bismuth telluride compounds to advanced skutterudites and half-Heusler alloys.

The past decade has witnessed remarkable progress in thermoelectric material science, with nanostructured materials and quantum well structures pushing theoretical efficiency limits. These advancements have been complemented by innovations in module design, thermal interface materials, and system integration approaches specifically tailored for automotive environments. The technology has evolved from simple proof-of-concept demonstrations to sophisticated systems capable of recovering meaningful amounts of energy from vehicle waste heat.

Current technological objectives in automotive thermoelectric integration focus on several key areas. Primary among these is improving conversion efficiency, with researchers targeting ZT values above 2.0 for commercially viable systems. Equally important is cost reduction through material innovations and manufacturing process optimization, as current high-performance thermoelectric materials often contain expensive or rare elements like tellurium.

Durability and reliability under automotive operating conditions represent another critical objective. Thermoelectric modules must withstand thermal cycling, vibration, and potential chemical exposure while maintaining performance over vehicle lifetimes exceeding 150,000 miles. System integration challenges are being addressed through objectives related to optimized heat exchangers, reduced thermal contact resistance, and intelligent power management electronics.

The overarching goal of these technological developments is to create thermoelectric systems capable of recovering 5-10% of waste heat energy in conventional vehicles, potentially improving fuel economy by 2-5%. In electric and hybrid vehicles, the objectives extend to thermal management of battery systems and cabin climate control with minimal impact on driving range. These advancements align with broader automotive industry trends toward electrification, sustainability, and energy efficiency.

The automotive industry's interest in thermoelectric technology began to accelerate in the 1990s, driven by increasing concerns about fuel efficiency and emissions reduction. Early applications focused primarily on seat heating and cooling systems, but research quickly expanded to waste heat recovery from exhaust systems. This evolution was marked by the development of more efficient thermoelectric materials with higher figure of merit (ZT) values, progressing from traditional bismuth telluride compounds to advanced skutterudites and half-Heusler alloys.

The past decade has witnessed remarkable progress in thermoelectric material science, with nanostructured materials and quantum well structures pushing theoretical efficiency limits. These advancements have been complemented by innovations in module design, thermal interface materials, and system integration approaches specifically tailored for automotive environments. The technology has evolved from simple proof-of-concept demonstrations to sophisticated systems capable of recovering meaningful amounts of energy from vehicle waste heat.

Current technological objectives in automotive thermoelectric integration focus on several key areas. Primary among these is improving conversion efficiency, with researchers targeting ZT values above 2.0 for commercially viable systems. Equally important is cost reduction through material innovations and manufacturing process optimization, as current high-performance thermoelectric materials often contain expensive or rare elements like tellurium.

Durability and reliability under automotive operating conditions represent another critical objective. Thermoelectric modules must withstand thermal cycling, vibration, and potential chemical exposure while maintaining performance over vehicle lifetimes exceeding 150,000 miles. System integration challenges are being addressed through objectives related to optimized heat exchangers, reduced thermal contact resistance, and intelligent power management electronics.

The overarching goal of these technological developments is to create thermoelectric systems capable of recovering 5-10% of waste heat energy in conventional vehicles, potentially improving fuel economy by 2-5%. In electric and hybrid vehicles, the objectives extend to thermal management of battery systems and cabin climate control with minimal impact on driving range. These advancements align with broader automotive industry trends toward electrification, sustainability, and energy efficiency.

Automotive Market Demand for Energy Recovery Systems

The global automotive industry is experiencing a significant shift towards energy efficiency and sustainability, creating a robust market demand for energy recovery systems. This demand is primarily driven by stringent emissions regulations worldwide, with the European Union's target to reduce CO2 emissions by 37.5% by 2030 and similar initiatives in North America and Asia. These regulatory pressures have compelled automotive manufacturers to explore innovative solutions for improving vehicle efficiency beyond traditional methods.

Thermoelectric waste heat recovery systems represent a promising technology segment within this market. According to recent market analyses, the global automotive waste heat recovery system market is projected to grow at a compound annual growth rate of 14.8% through 2028, reaching a market value of $7.5 billion. Thermoelectric modules specifically are gaining traction due to their solid-state operation and ability to directly convert waste heat into usable electricity.

Consumer preferences are also shifting dramatically toward fuel-efficient and environmentally friendly vehicles. A recent survey across major automotive markets revealed that over 65% of new vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions. This consumer sentiment has created a market pull effect, complementing the regulatory push for energy recovery technologies.

Fleet operators and commercial vehicle manufacturers demonstrate particularly strong interest in thermoelectric energy recovery systems due to their potential for significant operational cost savings. With fuel representing approximately 30% of operating costs for commercial fleets, even modest efficiency improvements translate to substantial financial benefits. Market research indicates that commercial vehicle segments may adopt these technologies at a faster rate than passenger vehicles due to the more favorable return on investment calculations.

The premium automotive segment has emerged as an early adopter market for thermoelectric modules, with luxury manufacturers integrating these systems to differentiate their offerings and meet efficiency targets without compromising performance. This trend is expected to cascade to mid-range vehicles as production scales and costs decrease.

Regional market analysis shows varying degrees of demand, with Europe leading in adoption due to stringent regulations, followed by North America and rapidly growing interest in China and Japan. The Chinese market is particularly noteworthy, as government initiatives promoting "new energy vehicles" have created favorable conditions for energy recovery technologies.

Overall, market indicators suggest that thermoelectric module integration in automotive applications is transitioning from a niche technology to a mainstream efficiency solution, with demand expected to accelerate as the technology matures and cost barriers are overcome.

Thermoelectric waste heat recovery systems represent a promising technology segment within this market. According to recent market analyses, the global automotive waste heat recovery system market is projected to grow at a compound annual growth rate of 14.8% through 2028, reaching a market value of $7.5 billion. Thermoelectric modules specifically are gaining traction due to their solid-state operation and ability to directly convert waste heat into usable electricity.

Consumer preferences are also shifting dramatically toward fuel-efficient and environmentally friendly vehicles. A recent survey across major automotive markets revealed that over 65% of new vehicle buyers consider fuel efficiency as a "very important" factor in their purchasing decisions. This consumer sentiment has created a market pull effect, complementing the regulatory push for energy recovery technologies.

Fleet operators and commercial vehicle manufacturers demonstrate particularly strong interest in thermoelectric energy recovery systems due to their potential for significant operational cost savings. With fuel representing approximately 30% of operating costs for commercial fleets, even modest efficiency improvements translate to substantial financial benefits. Market research indicates that commercial vehicle segments may adopt these technologies at a faster rate than passenger vehicles due to the more favorable return on investment calculations.

The premium automotive segment has emerged as an early adopter market for thermoelectric modules, with luxury manufacturers integrating these systems to differentiate their offerings and meet efficiency targets without compromising performance. This trend is expected to cascade to mid-range vehicles as production scales and costs decrease.

Regional market analysis shows varying degrees of demand, with Europe leading in adoption due to stringent regulations, followed by North America and rapidly growing interest in China and Japan. The Chinese market is particularly noteworthy, as government initiatives promoting "new energy vehicles" have created favorable conditions for energy recovery technologies.

Overall, market indicators suggest that thermoelectric module integration in automotive applications is transitioning from a niche technology to a mainstream efficiency solution, with demand expected to accelerate as the technology matures and cost barriers are overcome.

Global Thermoelectric Integration Challenges

The integration of thermoelectric modules in automotive applications faces significant challenges across multiple dimensions, impeding widespread adoption despite their potential benefits for energy efficiency. Technical integration challenges remain paramount, as automotive environments present extreme temperature fluctuations, constant vibration, and space constraints that test the durability and performance of thermoelectric systems. Current modules struggle to maintain optimal efficiency across the wide temperature ranges experienced in vehicles, from sub-zero conditions to engine compartments exceeding 100°C.

Manufacturing scalability presents another substantial hurdle. The production of high-quality thermoelectric materials with consistent properties at automotive volumes remains difficult, with bismuth telluride and other semiconductor materials requiring precise doping and processing. The complex assembly of modules with hundreds of thermoelectric couples demands automated manufacturing processes that have not yet reached maturity for automotive-grade reliability standards.

Cost effectiveness continues to be a significant barrier to widespread implementation. Current thermoelectric materials rely on relatively scarce elements like tellurium, making them expensive for mass-market vehicles. The cost-to-benefit ratio remains unfavorable compared to conventional technologies, with estimates suggesting thermoelectric systems need a 30-50% reduction in production costs to become commercially viable for mainstream automotive applications.

Regulatory and standardization issues further complicate global adoption. The absence of unified international standards for automotive thermoelectric systems creates uncertainty for manufacturers and suppliers. Different regions maintain varying requirements for thermal management systems, energy recovery devices, and electrical systems integration, creating a fragmented market that hinders economies of scale.

Supply chain vulnerabilities represent an emerging concern, with critical thermoelectric materials concentrated in specific geographic regions. Over 80% of tellurium production occurs in China, creating potential supply risks for global automotive manufacturers. Alternative material development faces its own challenges in performance, durability, and manufacturing readiness.

System integration complexity cannot be overlooked, as thermoelectric modules must interface with multiple vehicle systems including cooling circuits, electrical systems, and engine management. The additional weight and complexity introduced by thermoelectric systems must be carefully balanced against efficiency gains, particularly as the automotive industry transitions toward electrification where every gram of added weight impacts vehicle range.

Manufacturing scalability presents another substantial hurdle. The production of high-quality thermoelectric materials with consistent properties at automotive volumes remains difficult, with bismuth telluride and other semiconductor materials requiring precise doping and processing. The complex assembly of modules with hundreds of thermoelectric couples demands automated manufacturing processes that have not yet reached maturity for automotive-grade reliability standards.

Cost effectiveness continues to be a significant barrier to widespread implementation. Current thermoelectric materials rely on relatively scarce elements like tellurium, making them expensive for mass-market vehicles. The cost-to-benefit ratio remains unfavorable compared to conventional technologies, with estimates suggesting thermoelectric systems need a 30-50% reduction in production costs to become commercially viable for mainstream automotive applications.

Regulatory and standardization issues further complicate global adoption. The absence of unified international standards for automotive thermoelectric systems creates uncertainty for manufacturers and suppliers. Different regions maintain varying requirements for thermal management systems, energy recovery devices, and electrical systems integration, creating a fragmented market that hinders economies of scale.

Supply chain vulnerabilities represent an emerging concern, with critical thermoelectric materials concentrated in specific geographic regions. Over 80% of tellurium production occurs in China, creating potential supply risks for global automotive manufacturers. Alternative material development faces its own challenges in performance, durability, and manufacturing readiness.

System integration complexity cannot be overlooked, as thermoelectric modules must interface with multiple vehicle systems including cooling circuits, electrical systems, and engine management. The additional weight and complexity introduced by thermoelectric systems must be carefully balanced against efficiency gains, particularly as the automotive industry transitions toward electrification where every gram of added weight impacts vehicle range.

Current Thermoelectric Waste Heat Recovery Solutions

01 Material optimization for thermoelectric efficiency

Advanced materials can significantly improve the energy conversion efficiency of thermoelectric modules. These include nanostructured materials, semiconductor alloys, and composite materials that enhance the figure of merit (ZT) by optimizing electrical conductivity while reducing thermal conductivity. Such materials can effectively convert temperature differences into electrical energy with minimal energy loss, thereby increasing the overall efficiency of thermoelectric modules.- Material optimization for thermoelectric efficiency: Advanced materials play a crucial role in improving the energy efficiency of thermoelectric modules. By engineering materials with high Seebeck coefficients and low thermal conductivity, the conversion efficiency between thermal and electrical energy can be significantly enhanced. These optimizations include nanostructured materials, semiconductor alloys, and composite structures that can effectively increase the figure of merit (ZT) of thermoelectric devices, leading to higher power generation efficiency.

- Thermal management and heat transfer optimization: Effective thermal management is essential for maximizing thermoelectric module efficiency. This includes optimizing heat transfer between hot and cold sides, minimizing thermal resistance at interfaces, and implementing advanced heat dissipation techniques. Proper thermal design ensures maximum temperature differentials across the module, which directly impacts power generation capacity and overall system efficiency. Innovations in heat sink design, thermal interface materials, and heat spreading technologies contribute significantly to improved performance.

- Circuit design and power conditioning: Advanced electrical circuit designs and power conditioning systems are critical for optimizing the energy output of thermoelectric modules. This includes maximum power point tracking (MPPT) controllers, DC-DC converters with high efficiency, and intelligent load matching circuits. These systems ensure that thermoelectric generators operate at their optimal electrical conditions regardless of temperature fluctuations or load variations, maximizing energy harvesting efficiency and providing stable power output under dynamic operating conditions.

- Module architecture and assembly techniques: The physical design and assembly of thermoelectric modules significantly impact their energy efficiency. Innovations in module architecture include segmented leg designs, cascaded structures, and optimized geometric configurations that maximize power density. Advanced manufacturing and assembly techniques reduce contact resistance between elements and improve mechanical stability. These improvements in physical construction enhance thermal-to-electrical conversion efficiency while extending operational lifespan under thermal cycling conditions.

- System integration and application-specific optimization: Integrating thermoelectric modules into complete energy systems requires application-specific optimization to achieve maximum efficiency. This includes waste heat recovery systems, combined heat and power applications, and renewable energy hybrid systems. By tailoring the thermoelectric solution to specific operating conditions, temperature ranges, and power requirements, overall system efficiency can be significantly improved. This approach considers the entire energy conversion chain, from heat source characteristics to end-use power requirements.

02 Structural design improvements for thermoelectric modules

The physical configuration and structural design of thermoelectric modules play a crucial role in their energy efficiency. Innovations include optimized leg geometry, improved thermal interfaces, reduced contact resistance, and enhanced heat transfer mechanisms. Multi-stage cascaded structures and segmented leg designs can also help maximize performance across wider temperature gradients, leading to higher conversion efficiency in practical applications.Expand Specific Solutions03 Thermal management systems for efficiency enhancement

Effective thermal management is essential for maximizing thermoelectric module efficiency. This includes heat dissipation techniques, temperature gradient optimization, and thermal interface materials that minimize heat losses. Advanced cooling systems, heat exchangers, and thermal flow control mechanisms ensure optimal temperature differences across the module, preventing performance degradation and extending operational lifespan while maintaining high energy conversion efficiency.Expand Specific Solutions04 Electronic control and power conditioning systems

Sophisticated electronic control systems can significantly enhance thermoelectric module efficiency through dynamic load matching, maximum power point tracking, and intelligent temperature regulation. Power conditioning circuits optimize voltage and current output under varying conditions, while feedback control systems adjust operating parameters in real-time. These electronic enhancements ensure that thermoelectric modules operate at their optimal efficiency point regardless of changing external conditions.Expand Specific Solutions05 Testing and measurement methodologies for efficiency validation

Advanced testing and measurement techniques are crucial for accurately assessing and improving thermoelectric module efficiency. These include standardized performance metrics, precision measurement tools for thermal and electrical parameters, and simulation methodologies that predict real-world performance. Comprehensive characterization methods help identify efficiency bottlenecks and validate improvements, enabling the development of more efficient thermoelectric modules through data-driven optimization approaches.Expand Specific Solutions

Automotive OEMs and TEG Technology Providers

Thermoelectric module integration in automotive applications is currently in a growth phase, with the market expanding as automakers seek improved energy efficiency solutions. The global automotive thermoelectric market is projected to reach significant scale as fuel economy regulations tighten worldwide. Technology maturity varies across players, with established automotive suppliers like Continental, Valeo, and Bosch leading in commercial integration. BYD and Hyundai are advancing rapidly in electric vehicle applications, while specialized companies like Gentherm and Tegway focus on thermoelectric innovations. Research partnerships between manufacturers and institutions like Wuhan University of Technology are accelerating development. The technology is transitioning from premium vehicles (BMW, Kia) to broader market segments as costs decrease and efficiency improves, with particular momentum in electric vehicle thermal management systems.

Valeo Thermal Systems Japan Corp.

Technical Solution: Valeo has developed a comprehensive thermoelectric comfort system that integrates into vehicle HVAC architecture. Their approach utilizes distributed thermoelectric modules positioned at strategic points throughout the cabin to create personalized climate zones while reducing overall energy consumption. The system features rapid response thermoelectric elements that can achieve target temperatures significantly faster than conventional heating and cooling systems. Valeo's implementation includes specialized heat exchangers that optimize thermal transfer between thermoelectric modules and cabin airflow. Their technology incorporates smart zoning capabilities that focus heating or cooling only where passengers are seated, avoiding energy waste in unoccupied areas. Testing has demonstrated up to 30% reduction in HVAC energy consumption in electric vehicles, directly translating to extended driving range. The system also includes intelligent preconditioning capabilities that can optimize cabin temperatures while the vehicle is still connected to charging infrastructure, preserving battery capacity for driving range.

Strengths: Focused on passenger comfort while delivering significant efficiency improvements; modular design allows scalable implementation across vehicle segments; rapid temperature response improves user experience. Weaknesses: Requires significant redesign of traditional HVAC systems; higher component costs than conventional systems; performance benefits vary with ambient conditions.

BYD Co., Ltd.

Technical Solution: BYD has implemented an innovative thermoelectric battery conditioning system in their electric vehicle lineup. Their approach integrates thermoelectric modules directly into battery pack structures to maintain optimal cell temperatures across varying operating and environmental conditions. The system features bidirectional thermoelectric operation, allowing both heating and cooling of battery cells as needed. BYD's implementation includes a distributed network of thermoelectric modules with independent zone control to address thermal gradients within large battery packs. Their technology incorporates phase-change materials alongside thermoelectric elements to buffer temperature fluctuations and reduce peak power demands. The system achieves up to 20% improvement in cold-weather range by efficiently warming batteries to optimal operating temperatures using minimal energy. Additionally, their thermal management approach extends battery lifespan by maintaining cells within ideal temperature ranges, with testing showing up to 15% reduction in degradation rates over conventional liquid cooling systems.

Strengths: Direct integration with battery systems provides significant efficiency benefits for EVs; bidirectional capability addresses both heating and cooling needs; demonstrated range improvements in extreme temperatures. Weaknesses: Adds complexity to battery pack design; requires sophisticated control systems; higher initial manufacturing costs.

Key Patents in Automotive Thermoelectric Generation

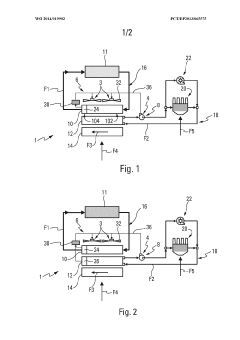

Assembly of a heat exchange module and at least one electrical component

PatentWO2014019902A1

Innovation

- Integration of thermoelectric devices within a heat exchange module to generate electrical energy from temperature gradients between fluids, autonomously powering electrical components such as fan motor units and pumps, thereby reducing reliance on alternators.

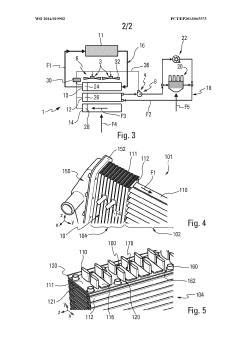

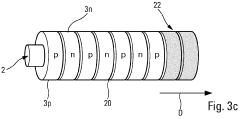

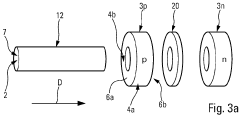

Thermoelectric module and device, particularly for generating an electric current in a motor vehicle

PatentWO2012163916A1

Innovation

- A thermoelectric module design with asymmetrical surface areas for the thermoelectric elements, where one face interacts with a fluid having a lower heat exchange coefficient (exhaust gases) and the other with a fluid having a higher coefficient, optimizing the thermal resistance ratio to enhance efficiency.

Cost-Benefit Analysis of TEG Implementation

The implementation of thermoelectric generators (TEGs) in automotive applications requires careful economic evaluation to determine viability. Initial investment costs for TEG systems remain relatively high, with current estimates ranging from $200-500 per unit depending on scale and specifications. This represents a significant cost factor when considering fleet-wide implementation, particularly for mass-market vehicle segments where price sensitivity is paramount.

Material costs constitute approximately 40-60% of total TEG expenses, with high-performance semiconductor materials like bismuth telluride commanding premium prices. Manufacturing complexity and assembly requirements further contribute to the cost structure, though economies of scale show promising potential for cost reduction of 15-25% at production volumes exceeding 100,000 units annually.

When analyzing return on investment, fuel efficiency improvements typically range from 2-5% in real-world driving conditions. For a vehicle consuming 500 gallons of fuel annually at $3.50 per gallon, this translates to potential savings of $35-87 per year. Consequently, the payback period for consumer applications currently extends to 3-7 years, depending on driving patterns and fuel prices.

Fleet operators with high-mileage vehicles experience more favorable economics, with potential payback periods reduced to 2-4 years. Commercial trucking applications, where annual fuel consumption may exceed 20,000 gallons, present particularly attractive economics with potential annual savings of $1,400-3,500 per vehicle.

Beyond direct fuel savings, secondary benefits include reduced emissions compliance costs, estimated at $50-150 per vehicle annually in regions with stringent environmental regulations. Additionally, the extended range capability provides marketing advantages and consumer appeal that, while difficult to quantify precisely, represent tangible value in competitive market segments.

Sensitivity analysis reveals that TEG economic viability improves significantly with rising fuel prices, with each $1.00 increase in fuel costs reducing payback periods by approximately 8-12 months. Similarly, technological improvements yielding 1% additional efficiency gain can reduce payback periods by 6-9 months, highlighting the importance of continued R&D investment.

Lifecycle cost analysis indicates that TEG systems typically maintain 85-90% of their initial performance over a 10-year vehicle lifespan, with minimal maintenance requirements compared to other energy recovery systems. This reliability factor positively influences the total cost of ownership calculations when compared with alternative technologies requiring more frequent service or replacement.

Material costs constitute approximately 40-60% of total TEG expenses, with high-performance semiconductor materials like bismuth telluride commanding premium prices. Manufacturing complexity and assembly requirements further contribute to the cost structure, though economies of scale show promising potential for cost reduction of 15-25% at production volumes exceeding 100,000 units annually.

When analyzing return on investment, fuel efficiency improvements typically range from 2-5% in real-world driving conditions. For a vehicle consuming 500 gallons of fuel annually at $3.50 per gallon, this translates to potential savings of $35-87 per year. Consequently, the payback period for consumer applications currently extends to 3-7 years, depending on driving patterns and fuel prices.

Fleet operators with high-mileage vehicles experience more favorable economics, with potential payback periods reduced to 2-4 years. Commercial trucking applications, where annual fuel consumption may exceed 20,000 gallons, present particularly attractive economics with potential annual savings of $1,400-3,500 per vehicle.

Beyond direct fuel savings, secondary benefits include reduced emissions compliance costs, estimated at $50-150 per vehicle annually in regions with stringent environmental regulations. Additionally, the extended range capability provides marketing advantages and consumer appeal that, while difficult to quantify precisely, represent tangible value in competitive market segments.

Sensitivity analysis reveals that TEG economic viability improves significantly with rising fuel prices, with each $1.00 increase in fuel costs reducing payback periods by approximately 8-12 months. Similarly, technological improvements yielding 1% additional efficiency gain can reduce payback periods by 6-9 months, highlighting the importance of continued R&D investment.

Lifecycle cost analysis indicates that TEG systems typically maintain 85-90% of their initial performance over a 10-year vehicle lifespan, with minimal maintenance requirements compared to other energy recovery systems. This reliability factor positively influences the total cost of ownership calculations when compared with alternative technologies requiring more frequent service or replacement.

Environmental Impact and Emissions Reduction Potential

The integration of thermoelectric modules in automotive systems presents significant environmental benefits that extend beyond mere energy efficiency improvements. By converting waste heat into usable electricity, these systems directly contribute to reducing the overall carbon footprint of vehicles through multiple pathways.

Thermoelectric waste heat recovery systems can potentially reduce CO2 emissions by 2-5% in conventional internal combustion engine vehicles. This reduction occurs primarily through decreased fuel consumption, as the electrical energy generated from waste heat reduces the alternator load, allowing the engine to operate more efficiently. For a typical passenger vehicle, this translates to approximately 4-10 grams of CO2 reduction per kilometer traveled.

In hybrid electric vehicles, the environmental benefits become even more pronounced. When thermoelectric generators are integrated with regenerative braking systems, the combined energy recovery can reduce emissions by up to 7-8% under optimal conditions. This synergistic effect maximizes the capture of energy that would otherwise be lost as waste.

Beyond carbon dioxide, thermoelectric systems also help reduce other harmful emissions including nitrogen oxides (NOx), particulate matter, and unburned hydrocarbons. This occurs because engines operating with reduced load tend to maintain more optimal combustion parameters, resulting in cleaner exhaust profiles. Studies indicate potential reductions of 3-6% in these secondary pollutants when thermoelectric systems are properly implemented.

From a lifecycle perspective, thermoelectric modules offer additional environmental advantages. Modern modules increasingly utilize environmentally friendly materials, moving away from rare earth elements and toxic compounds that characterized earlier generations. The manufacturing carbon debt of these systems is typically recovered within 1-2 years of vehicle operation through their emissions reduction capabilities.

When scaled to fleet level implementation, the environmental impact becomes substantial. If thermoelectric waste heat recovery were implemented across 50% of new vehicles globally, annual CO2 emissions could be reduced by approximately 35-70 million metric tons. This represents a meaningful contribution to transportation sector decarbonization efforts without requiring radical changes to existing vehicle architectures.

Furthermore, thermoelectric systems complement other green technologies in the automotive sector. They can enhance the range of electric vehicles by reducing auxiliary power demands, and they provide particular benefits in cold-weather conditions where traditional battery systems often struggle with efficiency. This complementary relationship strengthens the overall environmental case for their widespread adoption.

Thermoelectric waste heat recovery systems can potentially reduce CO2 emissions by 2-5% in conventional internal combustion engine vehicles. This reduction occurs primarily through decreased fuel consumption, as the electrical energy generated from waste heat reduces the alternator load, allowing the engine to operate more efficiently. For a typical passenger vehicle, this translates to approximately 4-10 grams of CO2 reduction per kilometer traveled.

In hybrid electric vehicles, the environmental benefits become even more pronounced. When thermoelectric generators are integrated with regenerative braking systems, the combined energy recovery can reduce emissions by up to 7-8% under optimal conditions. This synergistic effect maximizes the capture of energy that would otherwise be lost as waste.

Beyond carbon dioxide, thermoelectric systems also help reduce other harmful emissions including nitrogen oxides (NOx), particulate matter, and unburned hydrocarbons. This occurs because engines operating with reduced load tend to maintain more optimal combustion parameters, resulting in cleaner exhaust profiles. Studies indicate potential reductions of 3-6% in these secondary pollutants when thermoelectric systems are properly implemented.

From a lifecycle perspective, thermoelectric modules offer additional environmental advantages. Modern modules increasingly utilize environmentally friendly materials, moving away from rare earth elements and toxic compounds that characterized earlier generations. The manufacturing carbon debt of these systems is typically recovered within 1-2 years of vehicle operation through their emissions reduction capabilities.

When scaled to fleet level implementation, the environmental impact becomes substantial. If thermoelectric waste heat recovery were implemented across 50% of new vehicles globally, annual CO2 emissions could be reduced by approximately 35-70 million metric tons. This represents a meaningful contribution to transportation sector decarbonization efforts without requiring radical changes to existing vehicle architectures.

Furthermore, thermoelectric systems complement other green technologies in the automotive sector. They can enhance the range of electric vehicles by reducing auxiliary power demands, and they provide particular benefits in cold-weather conditions where traditional battery systems often struggle with efficiency. This complementary relationship strengthens the overall environmental case for their widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!