How Thermoelectric Module Design Affects Energy Conversion Efficiency

SEP 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Evolution and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century when Thomas Johann Seebeck first observed the phenomenon of direct conversion between temperature differences and electric voltage. This fundamental principle, known as the Seebeck effect, laid the groundwork for modern thermoelectric devices. The subsequent discovery of the Peltier effect in 1834 further expanded the potential applications by demonstrating that applying an electric current could create a temperature difference.

The mid-20th century marked a pivotal era for thermoelectric technology with the development of semiconductor-based thermoelectric materials, which significantly improved conversion efficiency compared to metal-based predecessors. During the 1950s and 1960s, bismuth telluride (Bi₂Te₃) emerged as a breakthrough material, establishing itself as the industry standard for near-room-temperature applications that continues to dominate commercial thermoelectric modules today.

Recent decades have witnessed an acceleration in thermoelectric research, driven by growing energy concerns and environmental awareness. The field has expanded from simple bulk materials to include complex nanostructured materials, quantum dot superlattices, and skutterudites, all designed to enhance the figure of merit (ZT) - the key parameter determining thermoelectric efficiency. This evolution reflects the persistent pursuit of higher energy conversion rates while addressing limitations in traditional designs.

The primary objective in thermoelectric module design is maximizing the ZT value, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity of the materials used. Contemporary research aims to achieve ZT values exceeding 2.0, compared to traditional materials that typically reach only 1.0-1.5. This improvement would make thermoelectric generators competitive with conventional power generation methods for certain applications.

Another critical objective is developing cost-effective manufacturing processes that can scale thermoelectric technology for widespread commercial adoption. Current high-performance thermoelectric materials often contain rare or toxic elements, presenting challenges for mass production and environmental sustainability. Research efforts are increasingly focused on earth-abundant, environmentally friendly alternatives that maintain comparable efficiency.

The technology trajectory is moving toward multifunctional thermoelectric systems that can simultaneously harvest waste heat and provide cooling functions. Integration with other renewable energy technologies represents another frontier, with hybrid systems combining thermoelectric generators with photovoltaics or thermal solar collectors showing promising results in laboratory settings.

As global energy demands continue to rise alongside concerns about carbon emissions, thermoelectric technology stands at a crucial juncture. The field's evolution is increasingly guided by the dual imperatives of enhancing energy conversion efficiency while developing sustainable, scalable solutions that can contribute meaningfully to the global energy landscape.

The mid-20th century marked a pivotal era for thermoelectric technology with the development of semiconductor-based thermoelectric materials, which significantly improved conversion efficiency compared to metal-based predecessors. During the 1950s and 1960s, bismuth telluride (Bi₂Te₃) emerged as a breakthrough material, establishing itself as the industry standard for near-room-temperature applications that continues to dominate commercial thermoelectric modules today.

Recent decades have witnessed an acceleration in thermoelectric research, driven by growing energy concerns and environmental awareness. The field has expanded from simple bulk materials to include complex nanostructured materials, quantum dot superlattices, and skutterudites, all designed to enhance the figure of merit (ZT) - the key parameter determining thermoelectric efficiency. This evolution reflects the persistent pursuit of higher energy conversion rates while addressing limitations in traditional designs.

The primary objective in thermoelectric module design is maximizing the ZT value, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity of the materials used. Contemporary research aims to achieve ZT values exceeding 2.0, compared to traditional materials that typically reach only 1.0-1.5. This improvement would make thermoelectric generators competitive with conventional power generation methods for certain applications.

Another critical objective is developing cost-effective manufacturing processes that can scale thermoelectric technology for widespread commercial adoption. Current high-performance thermoelectric materials often contain rare or toxic elements, presenting challenges for mass production and environmental sustainability. Research efforts are increasingly focused on earth-abundant, environmentally friendly alternatives that maintain comparable efficiency.

The technology trajectory is moving toward multifunctional thermoelectric systems that can simultaneously harvest waste heat and provide cooling functions. Integration with other renewable energy technologies represents another frontier, with hybrid systems combining thermoelectric generators with photovoltaics or thermal solar collectors showing promising results in laboratory settings.

As global energy demands continue to rise alongside concerns about carbon emissions, thermoelectric technology stands at a crucial juncture. The field's evolution is increasingly guided by the dual imperatives of enhancing energy conversion efficiency while developing sustainable, scalable solutions that can contribute meaningfully to the global energy landscape.

Market Analysis for Thermoelectric Energy Conversion

The global thermoelectric energy conversion market is experiencing significant growth, driven by increasing demand for waste heat recovery systems and energy-efficient solutions across various industries. Currently valued at approximately $626 million in 2023, the market is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 13.8%. This growth trajectory is supported by rising energy costs, stringent environmental regulations, and the push for sustainable energy solutions.

The automotive sector remains the largest application segment, accounting for roughly 35% of the total market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs focused on thermoelectric technology integration.

Industrial waste heat recovery represents another substantial market segment with approximately 28% market share. Industries such as steel, glass, cement, and chemical processing generate significant amounts of waste heat that can be harvested using thermoelectric modules. The potential for energy savings in these sectors is substantial, with some implementations demonstrating payback periods of 2-3 years.

Consumer electronics and wearable technology constitute an emerging application area, growing at nearly 18% annually. Thermoelectric cooling for electronic components and small-scale power generation for IoT devices are driving adoption in this segment. The miniaturization of thermoelectric modules has enabled their integration into smartphones, smartwatches, and other portable devices.

Geographically, North America leads the market with approximately 32% share, followed closely by Asia-Pacific at 30% and Europe at 27%. However, the Asia-Pacific region is expected to witness the highest growth rate of 15.2% through 2028, primarily due to rapid industrialization in China and India, coupled with government initiatives promoting energy efficiency.

The market is characterized by a high degree of fragmentation, with numerous small to medium-sized enterprises specializing in specific applications or technologies. Key market players include Ferrotec, Laird Thermal Systems, II-VI Marlow, Kelk Ltd, and Gentherm, collectively holding about 45% of the global market share. Strategic partnerships between module manufacturers and end-users are becoming increasingly common to develop customized solutions for specific applications.

Customer demand is increasingly focused on modules with higher conversion efficiency, longer operational lifetimes, and improved cost-effectiveness. The current price-performance ratio remains a significant barrier to wider adoption, with typical costs ranging from $5-15 per watt of generating capacity, depending on application requirements and production volume.

The automotive sector remains the largest application segment, accounting for roughly 35% of the total market share. Thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 3-5% in conventional vehicles. Major automotive manufacturers including BMW, Ford, and Toyota have active research programs focused on thermoelectric technology integration.

Industrial waste heat recovery represents another substantial market segment with approximately 28% market share. Industries such as steel, glass, cement, and chemical processing generate significant amounts of waste heat that can be harvested using thermoelectric modules. The potential for energy savings in these sectors is substantial, with some implementations demonstrating payback periods of 2-3 years.

Consumer electronics and wearable technology constitute an emerging application area, growing at nearly 18% annually. Thermoelectric cooling for electronic components and small-scale power generation for IoT devices are driving adoption in this segment. The miniaturization of thermoelectric modules has enabled their integration into smartphones, smartwatches, and other portable devices.

Geographically, North America leads the market with approximately 32% share, followed closely by Asia-Pacific at 30% and Europe at 27%. However, the Asia-Pacific region is expected to witness the highest growth rate of 15.2% through 2028, primarily due to rapid industrialization in China and India, coupled with government initiatives promoting energy efficiency.

The market is characterized by a high degree of fragmentation, with numerous small to medium-sized enterprises specializing in specific applications or technologies. Key market players include Ferrotec, Laird Thermal Systems, II-VI Marlow, Kelk Ltd, and Gentherm, collectively holding about 45% of the global market share. Strategic partnerships between module manufacturers and end-users are becoming increasingly common to develop customized solutions for specific applications.

Customer demand is increasingly focused on modules with higher conversion efficiency, longer operational lifetimes, and improved cost-effectiveness. The current price-performance ratio remains a significant barrier to wider adoption, with typical costs ranging from $5-15 per watt of generating capacity, depending on application requirements and production volume.

Current Challenges in Thermoelectric Module Design

Despite significant advancements in thermoelectric technology, several critical challenges continue to impede the optimization of thermoelectric module (TEM) design for maximum energy conversion efficiency. The fundamental limitation remains the inherent trade-off between thermal conductivity and electrical conductivity in thermoelectric materials. As attempts are made to increase electrical conductivity to reduce resistive losses, thermal conductivity typically increases proportionally, which diminishes the temperature gradient necessary for efficient thermoelectric conversion.

Contact resistance at material interfaces presents another substantial challenge, accounting for up to 30% of efficiency losses in some module designs. The thermal and electrical contact resistances at junctions between different materials create bottlenecks for both heat flow and charge carrier transport, significantly reducing overall module performance. Current manufacturing techniques struggle to create consistently low-resistance interfaces at scale.

Thermal management issues also plague contemporary TEM designs. The ability to maintain optimal temperature gradients across the module while effectively dissipating excess heat represents a complex engineering challenge. Inadequate heat sinking or thermal spreading can lead to localized hotspots that reduce efficiency and potentially damage module components through thermal stress or accelerated degradation mechanisms.

Mechanical stability concerns further complicate TEM design optimization. The repeated thermal cycling that modules experience in real-world applications induces mechanical stresses due to coefficient of thermal expansion mismatches between different materials. These stresses can lead to microcracking, delamination, and eventual failure of the module structure, significantly reducing operational lifespan and reliability.

Manufacturing scalability remains problematic for advanced TEM designs. While laboratory prototypes have demonstrated impressive efficiency improvements using novel materials and structures, translating these designs to mass production while maintaining performance and cost-effectiveness presents significant challenges. Current manufacturing processes often involve trade-offs between precision, throughput, and cost that limit commercial viability.

Material degradation under operating conditions constitutes another critical challenge. Many high-performance thermoelectric materials exhibit performance deterioration over time due to oxidation, sublimation, or compositional changes at elevated temperatures. This degradation is particularly problematic in waste heat recovery applications where high temperatures are common and long-term stability is essential.

Geometric optimization of module architecture presents multidimensional challenges involving leg geometry, packing density, and current path optimization. While computational models suggest theoretical improvements through complex geometries, practical manufacturing constraints often limit implementation of these optimized designs. The gap between theoretical models and manufacturable designs represents a significant barrier to efficiency improvements.

Contact resistance at material interfaces presents another substantial challenge, accounting for up to 30% of efficiency losses in some module designs. The thermal and electrical contact resistances at junctions between different materials create bottlenecks for both heat flow and charge carrier transport, significantly reducing overall module performance. Current manufacturing techniques struggle to create consistently low-resistance interfaces at scale.

Thermal management issues also plague contemporary TEM designs. The ability to maintain optimal temperature gradients across the module while effectively dissipating excess heat represents a complex engineering challenge. Inadequate heat sinking or thermal spreading can lead to localized hotspots that reduce efficiency and potentially damage module components through thermal stress or accelerated degradation mechanisms.

Mechanical stability concerns further complicate TEM design optimization. The repeated thermal cycling that modules experience in real-world applications induces mechanical stresses due to coefficient of thermal expansion mismatches between different materials. These stresses can lead to microcracking, delamination, and eventual failure of the module structure, significantly reducing operational lifespan and reliability.

Manufacturing scalability remains problematic for advanced TEM designs. While laboratory prototypes have demonstrated impressive efficiency improvements using novel materials and structures, translating these designs to mass production while maintaining performance and cost-effectiveness presents significant challenges. Current manufacturing processes often involve trade-offs between precision, throughput, and cost that limit commercial viability.

Material degradation under operating conditions constitutes another critical challenge. Many high-performance thermoelectric materials exhibit performance deterioration over time due to oxidation, sublimation, or compositional changes at elevated temperatures. This degradation is particularly problematic in waste heat recovery applications where high temperatures are common and long-term stability is essential.

Geometric optimization of module architecture presents multidimensional challenges involving leg geometry, packing density, and current path optimization. While computational models suggest theoretical improvements through complex geometries, practical manufacturing constraints often limit implementation of these optimized designs. The gap between theoretical models and manufacturable designs represents a significant barrier to efficiency improvements.

State-of-the-Art Module Design Approaches

01 Material composition for improved thermoelectric efficiency

Specific material compositions can significantly enhance the energy conversion efficiency of thermoelectric modules. These include advanced semiconductor materials, nanostructured materials, and composite materials that exhibit improved Seebeck coefficients and reduced thermal conductivity. By optimizing the material composition, the figure of merit (ZT) can be increased, leading to higher energy conversion efficiency in thermoelectric modules.- Material composition for improved thermoelectric efficiency: Specific material compositions can significantly enhance the energy conversion efficiency of thermoelectric modules. These include advanced semiconductor materials, nanostructured materials, and composite materials that exhibit improved Seebeck coefficient, reduced thermal conductivity, and enhanced electrical conductivity. The optimization of these material properties leads to higher figure of merit (ZT) values, directly correlating with increased energy conversion efficiency in thermoelectric modules.

- Structural design optimization of thermoelectric modules: The structural design of thermoelectric modules plays a crucial role in maximizing energy conversion efficiency. This includes optimizing the geometry of thermoelectric elements, improving thermal interfaces between components, and developing novel module architectures. Advanced designs focus on reducing thermal resistance, minimizing electrical contact resistance, and enhancing heat flow management, all contributing to improved overall system efficiency.

- Temperature gradient management techniques: Effective management of temperature gradients across thermoelectric modules is essential for maximizing energy conversion efficiency. This involves techniques for maintaining optimal hot and cold side temperatures, implementing heat concentration methods, and utilizing thermal isolation strategies. By optimizing the temperature differential and heat flow across the module, the Carnot efficiency can be approached more closely, resulting in higher electrical power output for a given heat input.

- Integration of nanotechnology in thermoelectric systems: Nanotechnology offers significant advantages for improving thermoelectric module efficiency. Nanoscale structures such as quantum dots, nanowires, and superlattices can enhance phonon scattering while maintaining good electrical conductivity. These nanostructured materials create quantum confinement effects that favorably modify electronic properties, leading to enhanced Seebeck coefficients and reduced thermal conductivity, which are critical factors for achieving higher ZT values and improved energy conversion efficiency.

- Advanced manufacturing and fabrication techniques: Novel manufacturing and fabrication methods significantly impact the energy conversion efficiency of thermoelectric modules. These include precision deposition techniques, advanced sintering processes, and innovative assembly methods that reduce interfacial thermal resistance. Manufacturing innovations focus on creating more uniform material properties, better electrical connections, and improved thermal interfaces, all contributing to enhanced module performance and higher energy conversion efficiency in real-world applications.

02 Structural design optimization of thermoelectric modules

The structural design of thermoelectric modules plays a crucial role in determining their energy conversion efficiency. This includes optimizing the geometry of thermoelectric elements, improving thermal interfaces, and enhancing electrical contacts. Advanced designs such as segmented or cascaded structures can help maximize the temperature gradient across the module, thereby increasing the overall energy conversion efficiency.Expand Specific Solutions03 Heat management techniques for efficiency enhancement

Effective heat management is essential for maximizing the energy conversion efficiency of thermoelectric modules. This involves optimizing heat flow paths, minimizing thermal resistance at interfaces, and implementing advanced heat dissipation methods. By maintaining optimal temperature gradients across the thermoelectric elements, these techniques help to increase the power output and overall efficiency of the modules.Expand Specific Solutions04 Manufacturing processes for high-efficiency modules

Advanced manufacturing processes can significantly impact the energy conversion efficiency of thermoelectric modules. These include precision deposition techniques, novel sintering methods, and improved electrical contact formation. By enhancing material uniformity, reducing defects, and optimizing interfaces between different materials, these manufacturing processes contribute to higher performance and more efficient thermoelectric energy conversion.Expand Specific Solutions05 System-level integration for maximizing conversion efficiency

System-level integration approaches focus on optimizing the overall performance of thermoelectric modules within larger energy systems. This includes developing intelligent control systems, implementing power conditioning circuits, and designing complementary thermal management systems. By considering the thermoelectric module as part of a complete energy system, these approaches can maximize the practical energy conversion efficiency in real-world applications.Expand Specific Solutions

Leading Companies in Thermoelectric Industry

The thermoelectric module design market is currently in a growth phase, with increasing focus on energy conversion efficiency improvements. The global market is projected to reach significant scale as waste heat recovery applications expand across automotive, industrial, and consumer electronics sectors. Technologically, the field shows varying maturity levels, with companies like LG Innotek, Murata Manufacturing, and Toshiba leading with advanced material science approaches. Industrial Technology Research Institute and O-Flexx Technologies are pioneering novel module architectures, while automotive giants Toyota, BMW, and Hyundai are integrating thermoelectric solutions into vehicle systems. Japanese corporations dominate the competitive landscape, leveraging their semiconductor and materials expertise to overcome the efficiency limitations that have historically constrained widespread thermoelectric adoption.

Industrial Technology Research Institute

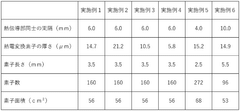

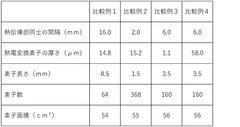

Technical Solution: Industrial Technology Research Institute (ITRI) has developed advanced thermoelectric module designs focusing on nanostructured materials and innovative junction configurations. Their approach incorporates skutterudite-based materials with nano-inclusions that effectively scatter phonons while maintaining electron transport, significantly reducing thermal conductivity. ITRI's modules feature segmented leg designs that optimize performance across temperature gradients by using different materials for hot and cold sides. They've pioneered flexible thermoelectric modules using screen printing techniques for conformal applications, achieving ZT values exceeding 1.5 in laboratory settings. Their proprietary contact technology reduces interfacial resistance between thermoelectric elements and electrodes, minimizing parasitic losses that typically degrade conversion efficiency.

Strengths: Superior material engineering with nano-inclusions provides excellent phonon scattering; flexible module designs enable applications on curved surfaces; strong expertise in contact resistance minimization. Weaknesses: Higher manufacturing complexity increases production costs; some advanced materials have limited temperature stability; scaling to mass production remains challenging.

Toshiba Corp.

Technical Solution: Toshiba has developed proprietary bismuth-telluride based thermoelectric modules with unique structural designs that maximize the Seebeck effect while minimizing thermal conductivity. Their approach focuses on precise control of element geometry and junction density to optimize power output per unit area. Toshiba's modules feature specialized ceramic substrates with customized metallization patterns that reduce thermal stress during temperature cycling, enhancing long-term reliability. Their manufacturing process incorporates automated precision assembly techniques that ensure consistent contact resistance across all thermoelectric couples. Toshiba has achieved conversion efficiencies approaching 9-10% in their latest generation modules through careful optimization of leg height-to-area ratios and minimization of parasitic heat losses through innovative insulation techniques and edge sealing methods.

Strengths: Exceptional manufacturing precision ensures consistent performance across production batches; advanced ceramic substrates provide superior thermal cycling durability; excellent system integration capabilities with other power electronics. Weaknesses: Relatively high cost compared to conventional cooling solutions; limited flexibility in form factor; performance degrades significantly at very high temperature differentials.

Key Patents in Thermoelectric Efficiency Enhancement

Thermoelectric conversion module

PatentWO2019181683A1

Innovation

- The module design features a plurality of thermoelectric conversion elements arranged side by side with fluid passage holes, increasing the heat transfer coefficient and interface area, allowing for efficient heat transfer between the thermal fluid and the thermoelectric conversion elements, thereby enhancing energy conversion efficiency.

Thermoelectric conversion module and manufacturing method therefor

PatentWO2023058523A1

Innovation

- A thermoelectric conversion module design with p-type and n-type elements of specific thickness ranges (3 μm to 30 μm) and strategically placed heat conductive parts, along with a manufacturing method involving carbon nanotubes, conductive resin, and a dopant solution, to optimize temperature difference and element density for enhanced output.

Material Science Advancements for Thermoelectric Applications

Recent advancements in material science have revolutionized the field of thermoelectric applications, significantly impacting energy conversion efficiency in thermoelectric modules. The development of novel materials with enhanced thermoelectric properties has been a primary focus for researchers worldwide, aiming to overcome the traditional limitations of thermoelectric technology.

Nanostructured materials represent one of the most promising breakthroughs in this domain. By manipulating material structures at the nanoscale, scientists have successfully reduced thermal conductivity while maintaining electrical conductivity, thereby increasing the ZT value (figure of merit) that directly correlates with conversion efficiency. Specifically, quantum dot superlattices and nanowire arrays have demonstrated remarkable improvements, with some laboratory prototypes achieving ZT values exceeding 2.0, compared to conventional materials that typically range between 0.8 and 1.0.

Skutterudites and clathrates have emerged as another category of advanced materials with intrinsic "rattling" structures that scatter phonons effectively. These materials feature cage-like frameworks where guest atoms can vibrate independently, disrupting heat flow without significantly affecting electron transport. This phonon-glass electron-crystal (PGEC) behavior makes them exceptionally suitable for mid-temperature range applications (200-600°C).

Half-Heusler compounds have gained attention for their thermal stability and mechanical robustness, making them particularly valuable for high-temperature industrial applications. Recent doping and band engineering techniques have enhanced their thermoelectric performance, with some compositions reaching ZT values of approximately 1.5 at temperatures above 400°C.

Organic thermoelectric materials represent a paradigm shift in the field, offering flexibility, low toxicity, and cost-effective manufacturing processes. While their efficiency currently lags behind inorganic counterparts, their potential for large-area applications and integration with wearable technology presents unique advantages. Recent polymer-based composites have shown promising ZT values approaching 0.4 at room temperature.

Hybrid materials combining different material classes have demonstrated synergistic effects that overcome the limitations of individual components. For instance, organic-inorganic hybrids leverage the flexibility and processability of organic materials with the superior thermoelectric properties of inorganic components. Similarly, nanocomposites incorporating carbon nanotubes or graphene into traditional thermoelectric materials have shown enhanced electrical conductivity without proportional increases in thermal conductivity.

The integration of these advanced materials into practical thermoelectric modules requires sophisticated manufacturing techniques, including precision deposition methods, interface engineering, and novel contact materials to minimize parasitic losses. As material science continues to evolve, the prospect of achieving ZT values above 3.0 becomes increasingly realistic, potentially transforming thermoelectric technology from niche applications to mainstream energy solutions.

Nanostructured materials represent one of the most promising breakthroughs in this domain. By manipulating material structures at the nanoscale, scientists have successfully reduced thermal conductivity while maintaining electrical conductivity, thereby increasing the ZT value (figure of merit) that directly correlates with conversion efficiency. Specifically, quantum dot superlattices and nanowire arrays have demonstrated remarkable improvements, with some laboratory prototypes achieving ZT values exceeding 2.0, compared to conventional materials that typically range between 0.8 and 1.0.

Skutterudites and clathrates have emerged as another category of advanced materials with intrinsic "rattling" structures that scatter phonons effectively. These materials feature cage-like frameworks where guest atoms can vibrate independently, disrupting heat flow without significantly affecting electron transport. This phonon-glass electron-crystal (PGEC) behavior makes them exceptionally suitable for mid-temperature range applications (200-600°C).

Half-Heusler compounds have gained attention for their thermal stability and mechanical robustness, making them particularly valuable for high-temperature industrial applications. Recent doping and band engineering techniques have enhanced their thermoelectric performance, with some compositions reaching ZT values of approximately 1.5 at temperatures above 400°C.

Organic thermoelectric materials represent a paradigm shift in the field, offering flexibility, low toxicity, and cost-effective manufacturing processes. While their efficiency currently lags behind inorganic counterparts, their potential for large-area applications and integration with wearable technology presents unique advantages. Recent polymer-based composites have shown promising ZT values approaching 0.4 at room temperature.

Hybrid materials combining different material classes have demonstrated synergistic effects that overcome the limitations of individual components. For instance, organic-inorganic hybrids leverage the flexibility and processability of organic materials with the superior thermoelectric properties of inorganic components. Similarly, nanocomposites incorporating carbon nanotubes or graphene into traditional thermoelectric materials have shown enhanced electrical conductivity without proportional increases in thermal conductivity.

The integration of these advanced materials into practical thermoelectric modules requires sophisticated manufacturing techniques, including precision deposition methods, interface engineering, and novel contact materials to minimize parasitic losses. As material science continues to evolve, the prospect of achieving ZT values above 3.0 becomes increasingly realistic, potentially transforming thermoelectric technology from niche applications to mainstream energy solutions.

Environmental Impact and Sustainability Considerations

The environmental implications of thermoelectric module design extend far beyond mere energy conversion efficiency metrics. Thermoelectric technology offers significant sustainability advantages through waste heat recovery systems that capture otherwise lost thermal energy and convert it into usable electricity. This process directly contributes to reducing overall energy consumption and associated greenhouse gas emissions across various industrial applications, transportation systems, and power generation facilities.

Material selection represents a critical environmental consideration in thermoelectric module design. Traditional high-performance thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, raising concerns about resource scarcity and end-of-life disposal. Recent research has focused on developing alternative materials with reduced environmental impact, including silicon-germanium alloys, skutterudites, and organic thermoelectric compounds derived from abundant, non-toxic elements.

The manufacturing processes for thermoelectric modules also present notable environmental challenges. Conventional fabrication techniques typically involve energy-intensive processes including high-temperature sintering, vacuum deposition, and precision machining. These processes contribute to the embodied energy and carbon footprint of thermoelectric devices. Emerging manufacturing approaches such as additive manufacturing, solution-based processing, and low-temperature synthesis methods offer promising pathways to reduce environmental impact while potentially improving device performance through enhanced structural control.

Life cycle assessment (LCA) studies of thermoelectric systems reveal complex sustainability trade-offs. While operational benefits from waste heat recovery are substantial, the environmental burden of material extraction, processing, and device manufacturing must be carefully balanced against lifetime energy generation. Research indicates that thermoelectric systems typically require 1-3 years of operation to achieve net positive environmental impact, depending on application conditions and system design parameters.

The durability and reliability of thermoelectric modules significantly influence their sustainability profile. Designs that maximize operational lifespan through improved thermal cycling resistance, reduced mechanical stress, and enhanced protection against environmental degradation deliver superior environmental returns on investment. Advanced encapsulation techniques, stress-compensating structural elements, and self-healing material interfaces represent promising approaches to extend service life while maintaining performance.

End-of-life considerations are increasingly important as thermoelectric applications expand. Designing modules with recyclability in mind—through separable components, recoverable materials, and reduced use of permanent adhesives—can significantly improve their overall environmental footprint. Several manufacturers have begun implementing design-for-disassembly principles and establishing take-back programs to recover valuable materials from decommissioned thermoelectric systems.

Material selection represents a critical environmental consideration in thermoelectric module design. Traditional high-performance thermoelectric materials often contain toxic or rare elements such as tellurium, bismuth, and lead, raising concerns about resource scarcity and end-of-life disposal. Recent research has focused on developing alternative materials with reduced environmental impact, including silicon-germanium alloys, skutterudites, and organic thermoelectric compounds derived from abundant, non-toxic elements.

The manufacturing processes for thermoelectric modules also present notable environmental challenges. Conventional fabrication techniques typically involve energy-intensive processes including high-temperature sintering, vacuum deposition, and precision machining. These processes contribute to the embodied energy and carbon footprint of thermoelectric devices. Emerging manufacturing approaches such as additive manufacturing, solution-based processing, and low-temperature synthesis methods offer promising pathways to reduce environmental impact while potentially improving device performance through enhanced structural control.

Life cycle assessment (LCA) studies of thermoelectric systems reveal complex sustainability trade-offs. While operational benefits from waste heat recovery are substantial, the environmental burden of material extraction, processing, and device manufacturing must be carefully balanced against lifetime energy generation. Research indicates that thermoelectric systems typically require 1-3 years of operation to achieve net positive environmental impact, depending on application conditions and system design parameters.

The durability and reliability of thermoelectric modules significantly influence their sustainability profile. Designs that maximize operational lifespan through improved thermal cycling resistance, reduced mechanical stress, and enhanced protection against environmental degradation deliver superior environmental returns on investment. Advanced encapsulation techniques, stress-compensating structural elements, and self-healing material interfaces represent promising approaches to extend service life while maintaining performance.

End-of-life considerations are increasingly important as thermoelectric applications expand. Designing modules with recyclability in mind—through separable components, recoverable materials, and reduced use of permanent adhesives—can significantly improve their overall environmental footprint. Several manufacturers have begun implementing design-for-disassembly principles and establishing take-back programs to recover valuable materials from decommissioned thermoelectric systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!