Comparison of Thermoelectric Module vs Conventional Heat Engines

SEP 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Technology Background and Objectives

Thermoelectric technology represents a fascinating intersection of physics, materials science, and energy conversion principles that has evolved significantly over the past two centuries. The phenomenon was first discovered in 1821 by Thomas Johann Seebeck, who observed that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This Seebeck effect became the foundation for thermoelectric generators (TEGs), which directly convert heat into electricity without moving parts.

The subsequent discovery of the Peltier effect in 1834 by Jean Charles Athanase Peltier demonstrated the inverse process—applying an electric current to create a temperature difference. These complementary phenomena established the theoretical framework for thermoelectric technology that continues to guide development today.

Throughout the 20th century, thermoelectric technology remained primarily in specialized applications due to efficiency limitations. However, the energy crises of the 1970s sparked renewed interest in alternative energy technologies, including thermoelectric systems. The development of semiconductor materials in the latter half of the century further accelerated progress in this field.

Modern thermoelectric modules represent a significant departure from conventional heat engines like steam turbines or internal combustion engines. While traditional heat engines rely on mechanical processes to convert thermal energy into work, thermoelectric modules perform this conversion directly through solid-state physics, offering unique advantages in reliability and simplicity, albeit typically at lower efficiency rates.

The current technological trajectory aims to overcome the historical efficiency limitations of thermoelectric systems. Research is increasingly focused on nanostructured materials, quantum well structures, and novel semiconductor compounds that can enhance the figure of merit (ZT)—the key parameter determining thermoelectric efficiency. Recent breakthroughs have pushed ZT values from historically below 1 to above 2 in laboratory settings.

The primary objectives in thermoelectric technology development include achieving higher conversion efficiencies comparable to conventional heat engines, reducing manufacturing costs to enable broader commercial viability, and expanding application scenarios beyond current niche uses. Researchers are particularly interested in exploiting low-grade waste heat recovery from industrial processes, automotive exhaust systems, and even body heat for powering small electronic devices.

As global emphasis on sustainable energy solutions intensifies, thermoelectric technology stands at a critical juncture. The field aims to position itself as a complementary technology to conventional heat engines in certain applications, particularly where reliability, silence, scalability, and maintenance-free operation outweigh pure efficiency considerations.

The subsequent discovery of the Peltier effect in 1834 by Jean Charles Athanase Peltier demonstrated the inverse process—applying an electric current to create a temperature difference. These complementary phenomena established the theoretical framework for thermoelectric technology that continues to guide development today.

Throughout the 20th century, thermoelectric technology remained primarily in specialized applications due to efficiency limitations. However, the energy crises of the 1970s sparked renewed interest in alternative energy technologies, including thermoelectric systems. The development of semiconductor materials in the latter half of the century further accelerated progress in this field.

Modern thermoelectric modules represent a significant departure from conventional heat engines like steam turbines or internal combustion engines. While traditional heat engines rely on mechanical processes to convert thermal energy into work, thermoelectric modules perform this conversion directly through solid-state physics, offering unique advantages in reliability and simplicity, albeit typically at lower efficiency rates.

The current technological trajectory aims to overcome the historical efficiency limitations of thermoelectric systems. Research is increasingly focused on nanostructured materials, quantum well structures, and novel semiconductor compounds that can enhance the figure of merit (ZT)—the key parameter determining thermoelectric efficiency. Recent breakthroughs have pushed ZT values from historically below 1 to above 2 in laboratory settings.

The primary objectives in thermoelectric technology development include achieving higher conversion efficiencies comparable to conventional heat engines, reducing manufacturing costs to enable broader commercial viability, and expanding application scenarios beyond current niche uses. Researchers are particularly interested in exploiting low-grade waste heat recovery from industrial processes, automotive exhaust systems, and even body heat for powering small electronic devices.

As global emphasis on sustainable energy solutions intensifies, thermoelectric technology stands at a critical juncture. The field aims to position itself as a complementary technology to conventional heat engines in certain applications, particularly where reliability, silence, scalability, and maintenance-free operation outweigh pure efficiency considerations.

Market Analysis for Thermoelectric Applications

The global thermoelectric module market has demonstrated significant growth potential, valued at approximately $593 million in 2022 and projected to reach $1.3 billion by 2030, representing a compound annual growth rate (CAGR) of 10.3%. This growth trajectory is primarily driven by increasing demand for energy-efficient solutions across various industries, particularly in waste heat recovery applications.

When comparing market applications of thermoelectric modules versus conventional heat engines, several distinct market segments emerge. The automotive sector represents the largest application area, where thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 2-5%. Major automotive manufacturers including BMW, Ford, and Toyota have active development programs in this space.

Industrial waste heat recovery presents another substantial market opportunity, with global industrial processes wasting approximately 20-50% of consumed energy as heat. Thermoelectric solutions offer advantages in scenarios where conventional heat engines are impractical due to size constraints or intermittent heat sources. The market for industrial TEG applications is growing at 12.7% annually, outpacing conventional heat recovery systems.

Consumer electronics and refrigeration applications form a rapidly expanding market segment, with thermoelectric cooling modules being deployed in portable coolers, wine cabinets, and electronic device cooling. This segment is expected to grow at 14.2% annually through 2030, driven by increasing consumer preference for noise-free, compact cooling solutions.

Aerospace and defense applications represent a premium market segment where thermoelectric technology's reliability and lack of moving parts provide critical advantages over conventional systems. This sector values the long operational life and maintenance-free characteristics of thermoelectric solutions, despite higher initial costs.

Regional market analysis reveals North America currently leads with 35% market share, followed by Europe (28%) and Asia-Pacific (27%). However, the Asia-Pacific region is experiencing the fastest growth rate at 13.5% annually, driven by rapid industrialization in China and India, and increasing adoption of energy efficiency technologies.

Market barriers for thermoelectric modules compared to conventional heat engines include higher cost-per-watt metrics, with thermoelectric solutions typically costing 3-5 times more per watt of capacity than conventional alternatives. However, this gap is narrowing as manufacturing scales and material innovations progress, with cost reductions of approximately 8% annually over the past five years.

When comparing market applications of thermoelectric modules versus conventional heat engines, several distinct market segments emerge. The automotive sector represents the largest application area, where thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to convert waste heat into usable electricity, improving fuel efficiency by 2-5%. Major automotive manufacturers including BMW, Ford, and Toyota have active development programs in this space.

Industrial waste heat recovery presents another substantial market opportunity, with global industrial processes wasting approximately 20-50% of consumed energy as heat. Thermoelectric solutions offer advantages in scenarios where conventional heat engines are impractical due to size constraints or intermittent heat sources. The market for industrial TEG applications is growing at 12.7% annually, outpacing conventional heat recovery systems.

Consumer electronics and refrigeration applications form a rapidly expanding market segment, with thermoelectric cooling modules being deployed in portable coolers, wine cabinets, and electronic device cooling. This segment is expected to grow at 14.2% annually through 2030, driven by increasing consumer preference for noise-free, compact cooling solutions.

Aerospace and defense applications represent a premium market segment where thermoelectric technology's reliability and lack of moving parts provide critical advantages over conventional systems. This sector values the long operational life and maintenance-free characteristics of thermoelectric solutions, despite higher initial costs.

Regional market analysis reveals North America currently leads with 35% market share, followed by Europe (28%) and Asia-Pacific (27%). However, the Asia-Pacific region is experiencing the fastest growth rate at 13.5% annually, driven by rapid industrialization in China and India, and increasing adoption of energy efficiency technologies.

Market barriers for thermoelectric modules compared to conventional heat engines include higher cost-per-watt metrics, with thermoelectric solutions typically costing 3-5 times more per watt of capacity than conventional alternatives. However, this gap is narrowing as manufacturing scales and material innovations progress, with cost reductions of approximately 8% annually over the past five years.

Current Status and Technical Challenges

Thermoelectric modules and conventional heat engines represent two distinct approaches to energy conversion, each with its own technological maturity and challenges. Currently, conventional heat engines dominate the market due to their established technology and higher efficiency at large scales. These systems, including internal combustion engines, steam turbines, and gas turbines, typically achieve conversion efficiencies of 30-40% in practical applications, with some combined cycle systems reaching up to 60% efficiency.

In contrast, thermoelectric modules exhibit significantly lower conversion efficiencies, typically ranging from 5-8% in commercial applications. This efficiency gap represents the primary technical challenge for thermoelectric technology. The theoretical maximum efficiency of thermoelectric devices is limited by their figure of merit (ZT), with current best-performing materials achieving ZT values around 1-2, which translates to maximum theoretical efficiencies of approximately 15-20% under ideal conditions.

Material constraints pose significant challenges for thermoelectric technology advancement. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about scalability, cost, and environmental impact. Additionally, these materials must simultaneously possess contradictory properties: high electrical conductivity coupled with low thermal conductivity, a combination that defies conventional material physics.

Thermal management represents another critical challenge for both technologies but manifests differently. Conventional heat engines require complex cooling systems to manage waste heat, adding to system complexity and maintenance requirements. Thermoelectric modules face challenges in maintaining optimal temperature gradients across the device while minimizing thermal losses, particularly at interface boundaries between different materials.

Geographically, research and development in thermoelectric technology is concentrated in North America, East Asia (particularly Japan, China, and South Korea), and Europe. The United States leads in fundamental research through institutions like NASA and Department of Energy laboratories, while Japan and Germany focus on automotive applications. China has emerged as a significant player in both research and manufacturing of thermoelectric materials.

Conventional heat engine technology, being mature, sees more distributed development globally but with significant innovations coming from traditional automotive and energy technology centers in Germany, Japan, the United States, and increasingly China. These regions continue to refine conventional technologies through incremental improvements in materials, design, and control systems.

Scale represents a divergent challenge between the technologies. Conventional heat engines benefit from economies of scale and typically become more efficient as they grow larger, making them ideal for centralized power generation. Thermoelectric modules, conversely, maintain relatively consistent efficiency across scales, potentially offering advantages for distributed, small-scale, and waste heat recovery applications where conventional engines become impractical.

In contrast, thermoelectric modules exhibit significantly lower conversion efficiencies, typically ranging from 5-8% in commercial applications. This efficiency gap represents the primary technical challenge for thermoelectric technology. The theoretical maximum efficiency of thermoelectric devices is limited by their figure of merit (ZT), with current best-performing materials achieving ZT values around 1-2, which translates to maximum theoretical efficiencies of approximately 15-20% under ideal conditions.

Material constraints pose significant challenges for thermoelectric technology advancement. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about scalability, cost, and environmental impact. Additionally, these materials must simultaneously possess contradictory properties: high electrical conductivity coupled with low thermal conductivity, a combination that defies conventional material physics.

Thermal management represents another critical challenge for both technologies but manifests differently. Conventional heat engines require complex cooling systems to manage waste heat, adding to system complexity and maintenance requirements. Thermoelectric modules face challenges in maintaining optimal temperature gradients across the device while minimizing thermal losses, particularly at interface boundaries between different materials.

Geographically, research and development in thermoelectric technology is concentrated in North America, East Asia (particularly Japan, China, and South Korea), and Europe. The United States leads in fundamental research through institutions like NASA and Department of Energy laboratories, while Japan and Germany focus on automotive applications. China has emerged as a significant player in both research and manufacturing of thermoelectric materials.

Conventional heat engine technology, being mature, sees more distributed development globally but with significant innovations coming from traditional automotive and energy technology centers in Germany, Japan, the United States, and increasingly China. These regions continue to refine conventional technologies through incremental improvements in materials, design, and control systems.

Scale represents a divergent challenge between the technologies. Conventional heat engines benefit from economies of scale and typically become more efficient as they grow larger, making them ideal for centralized power generation. Thermoelectric modules, conversely, maintain relatively consistent efficiency across scales, potentially offering advantages for distributed, small-scale, and waste heat recovery applications where conventional engines become impractical.

Current Technical Solutions Comparison

01 Thermoelectric module efficiency enhancement techniques

Various techniques can be employed to enhance the efficiency of thermoelectric modules for power generation. These include optimizing the thermoelectric materials, improving the module structure, and enhancing heat transfer mechanisms. Advanced semiconductor materials with high figure of merit (ZT) values can significantly increase conversion efficiency. Additionally, structural improvements such as segmented or cascaded designs help maximize performance across temperature gradients.- Thermoelectric module efficiency enhancement techniques: Various techniques can be employed to enhance the efficiency of thermoelectric modules for power generation. These include optimizing the thermoelectric materials, improving the module structure, and enhancing heat transfer mechanisms. Advanced semiconductor materials with high figure of merit (ZT) values can significantly increase conversion efficiency. Additionally, structural improvements such as segmented or cascaded designs help maximize the temperature gradient across the module, resulting in higher power output.

- Hybrid systems combining thermoelectric modules with conventional heat engines: Hybrid power generation systems that integrate thermoelectric modules with conventional heat engines can achieve higher overall efficiency. By recovering waste heat from conventional engines such as internal combustion engines or gas turbines, thermoelectric generators can produce additional electricity without requiring extra fuel. This synergistic approach allows for better utilization of thermal energy and increases the total power output of the system while reducing fuel consumption and emissions.

- Temperature gradient optimization for thermoelectric power generation: Maintaining and optimizing temperature gradients is crucial for maximizing the efficiency of thermoelectric power generation. Various heat management techniques, including advanced heat exchangers, thermal interface materials, and cooling systems, can be implemented to create and sustain larger temperature differences across thermoelectric modules. Innovative designs that focus on thermal concentration and isolation help to minimize heat losses and improve the overall conversion efficiency of the system.

- Novel thermoelectric materials and nanostructures for improved performance: Research on novel thermoelectric materials and nanostructures has led to significant improvements in power generation efficiency. Materials with complex crystal structures, nanocomposites, and quantum well structures can reduce thermal conductivity while maintaining good electrical conductivity, thereby increasing the figure of merit. Skutterudites, half-Heusler alloys, and bismuth telluride-based materials with nanoscale features have shown promising results in enhancing thermoelectric performance beyond conventional limits.

- Waste heat recovery systems using thermoelectric generators: Thermoelectric generators can be effectively used in waste heat recovery systems across various industrial applications. These systems capture thermal energy that would otherwise be lost from industrial processes, vehicle exhausts, or power plants, and convert it into useful electricity. The implementation of such recovery systems not only improves overall energy efficiency but also reduces environmental impact by decreasing the carbon footprint associated with power generation.

02 Hybrid systems combining thermoelectric modules with conventional heat engines

Hybrid power generation systems that integrate thermoelectric modules with conventional heat engines can achieve higher overall efficiency by utilizing waste heat recovery. These systems capture thermal energy that would otherwise be lost in traditional heat engines and convert it into additional electrical power. The complementary operation allows for improved total system efficiency, especially in applications where size and weight constraints are not critical factors.Expand Specific Solutions03 Temperature gradient optimization for thermoelectric power generation

Maximizing the temperature difference across thermoelectric modules is crucial for improving power generation efficiency. Various heat concentration techniques, thermal management systems, and heat exchanger designs can be implemented to maintain optimal temperature gradients. Innovations in heat sink design, thermal interface materials, and heat pipe technologies help to establish and maintain the temperature differential required for efficient thermoelectric conversion.Expand Specific Solutions04 Novel thermoelectric materials and nanostructures for improved performance

Advanced thermoelectric materials and nanostructured designs offer significant improvements in conversion efficiency. These include skutterudites, half-Heusler alloys, clathrates, and various nanocomposites that exhibit enhanced thermoelectric properties. Quantum confinement effects in nanostructured materials can reduce thermal conductivity while maintaining electrical conductivity, thereby increasing the figure of merit and overall efficiency of thermoelectric power generation systems.Expand Specific Solutions05 Waste heat recovery applications and system integration

Thermoelectric modules can be effectively integrated into various systems for waste heat recovery applications. These include industrial processes, automotive exhaust systems, and residential heating systems. The integration requires careful consideration of heat source characteristics, module placement, and electrical output management. Properly designed waste heat recovery systems can significantly improve overall energy efficiency by converting otherwise wasted thermal energy into useful electrical power.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The thermoelectric module market is currently in a growth phase, with increasing adoption across automotive, industrial, and consumer electronics sectors. Compared to conventional heat engines, thermoelectric technology offers advantages in waste heat recovery applications despite lower efficiency. The global market is projected to reach approximately $1 billion by 2026, driven by automotive applications. Major automotive players like BMW, Hyundai, Kia, and GM are investing in thermoelectric solutions for vehicle efficiency improvements. Component manufacturers such as Gentherm, Webasto, and Valeo lead in commercialization, while research institutions like Industrial Technology Research Institute and University of Florida continue advancing the technology. Asian manufacturers including Samsung, LG, and Toshiba are expanding their presence, leveraging their electronics expertise to develop more efficient thermoelectric solutions.

Toshiba Corp.

Technical Solution: Toshiba has pioneered advanced thermoelectric module technology through their "TOSMOTEC" (Toshiba Module Technology) platform, which utilizes bismuth-telluride semiconductor materials with proprietary doping techniques to achieve higher ZT values. Their modules operate on the Seebeck effect, directly converting temperature differentials into electrical energy without moving parts. Toshiba's latest generation modules achieve conversion efficiencies of up to 7.2% at temperature differentials of 300°C, representing significant improvement over earlier designs. The company has developed specialized manufacturing techniques that reduce thermal and electrical contact resistance between module components, a critical factor in overall system efficiency. Toshiba's modules feature a cascaded design that optimizes performance across different temperature ranges, allowing for effective operation in variable conditions. Unlike conventional heat engines that require regular maintenance of moving components, Toshiba's solid-state thermoelectric modules offer maintenance-free operation with projected lifespans exceeding 100,000 hours of continuous use.

Strengths: Completely silent operation with no vibration; extremely reliable with no moving parts to wear out; compact form factor allows integration into space-constrained applications; instant response to temperature changes. Weaknesses: Lower conversion efficiency compared to Rankine cycle engines; higher initial cost per watt of capacity; performance degrades significantly if optimal temperature differential cannot be maintained; requires effective heat sinking to maintain performance.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a comprehensive thermoelectric generation system that leverages temperature differentials in industrial and automotive applications. Their proprietary modules utilize advanced skutterudite materials that demonstrate improved performance at higher operating temperatures (400-600°C), achieving ZT values approaching 1.5 in laboratory conditions. Mitsubishi's system architecture incorporates specialized heat exchangers and thermal interface materials that minimize thermal resistance between heat sources and thermoelectric elements. Unlike conventional heat engines that convert heat to mechanical energy before generating electricity, Mitsubishi's thermoelectric modules directly convert thermal energy to electrical energy in a single step. Their automotive waste heat recovery systems can generate 200-450W of continuous power from exhaust heat, reducing alternator load and improving fuel efficiency by 2-4%. Mitsubishi has also developed specialized power conditioning electronics that optimize the variable output from thermoelectric modules across different operating conditions, ensuring stable power delivery to vehicle electrical systems.

Strengths: Highly scalable technology that can be deployed in various sizes from milliwatts to kilowatts; no working fluids required, eliminating leakage concerns; can operate in any orientation without performance impact; capable of harvesting low-grade waste heat that conventional systems cannot utilize. Weaknesses: Higher cost per watt than conventional generators; lower power density requiring more space for equivalent power output; efficiency drops significantly as temperature differential decreases; requires careful thermal management to prevent material degradation.

Core Technologies and Patent Analysis

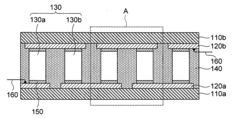

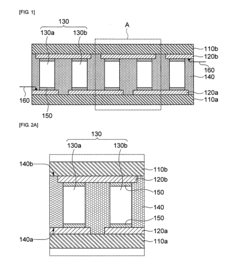

Thermoelectric module and method for fabricating the same

PatentInactiveUS20120049314A1

Innovation

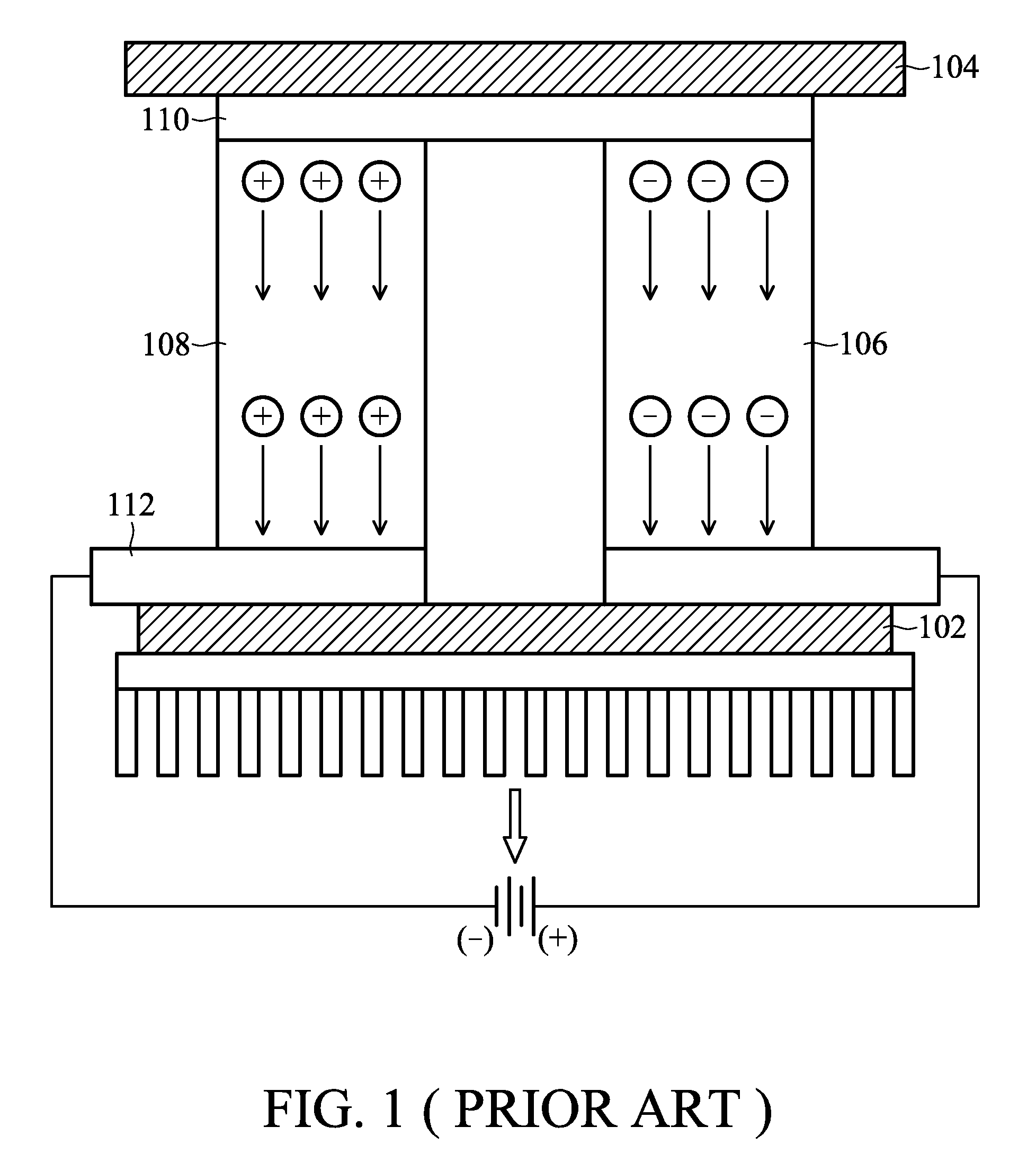

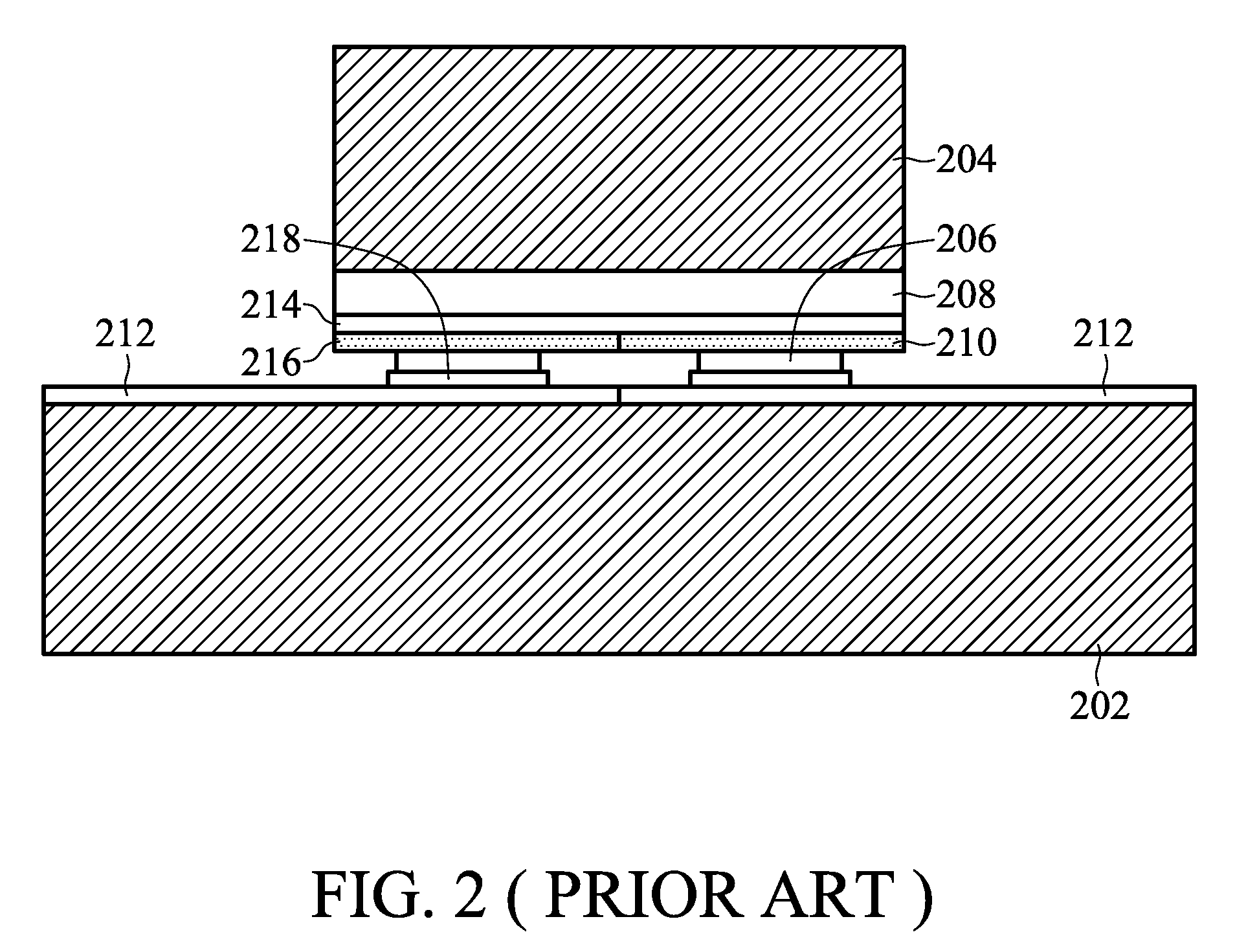

- A thermoelectric module design that includes a first and second substrate with a thermoelectric device inserted between them, where an elastic member is filled between the substrates to ensure a complete junction, and embossing or unevenness is applied to the elastic member surfaces for enhanced adhesion, using materials like ABS, PMMA, or Teflon, and optionally ceramic powder, with thermal grease added for improved thermal conductivity.

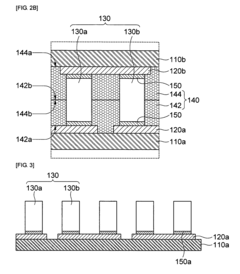

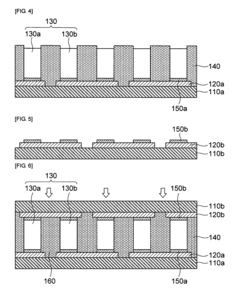

Thermoelectric module device with thin film elements and fabrication thereof

PatentActiveUS8269098B2

Innovation

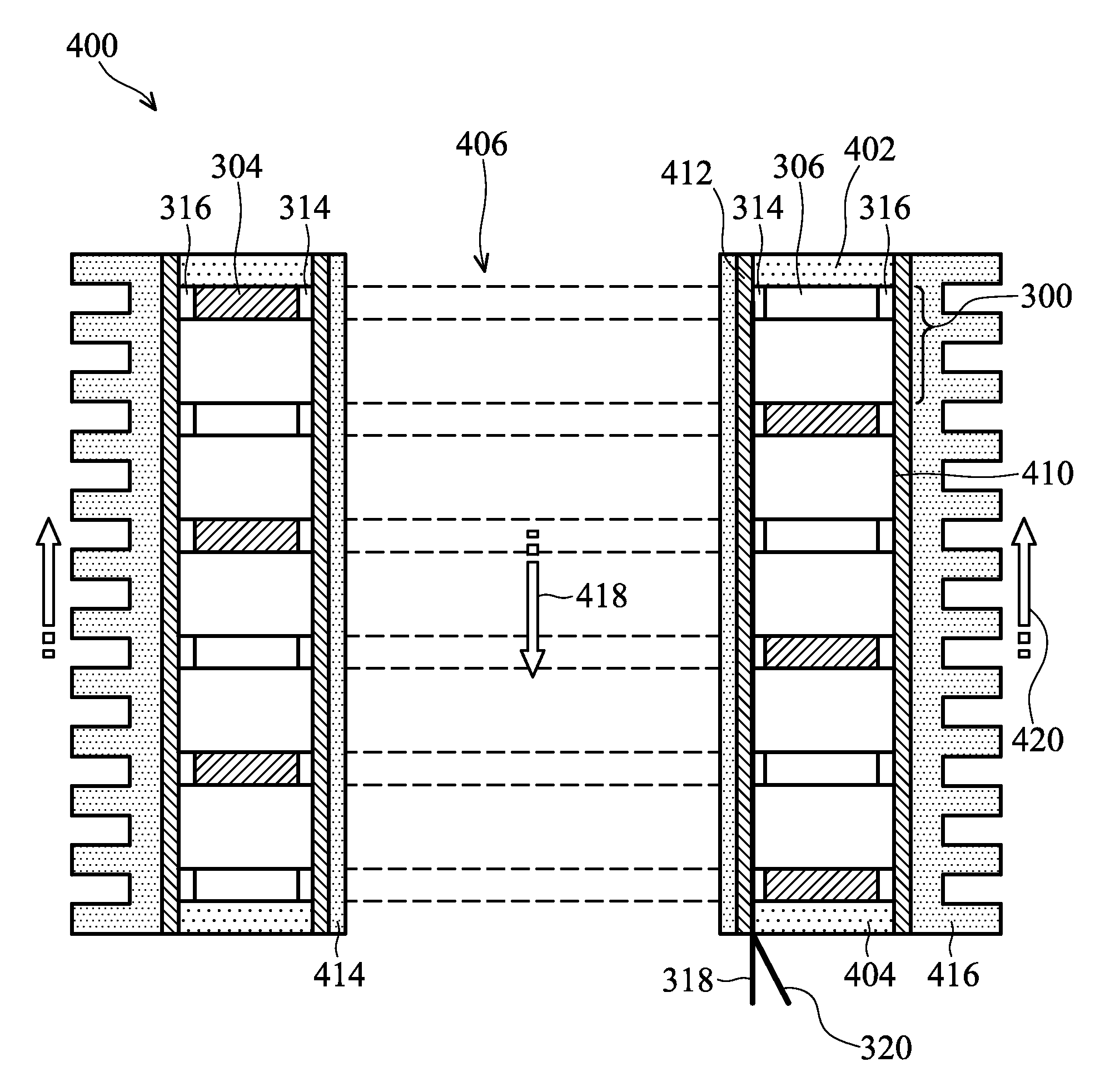

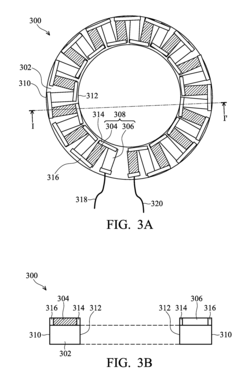

- A thermoelectric module device with a pillar structure comprising stacked ring-shaped thin film thermoelectric elements, where an insulating and thermal conducting layer covers the inner and outer sidewalls, and a cooling or heating source is placed within or outside the hollow region, allowing for a greater distance between heat sources to minimize reflective heat transfer and enhance efficiency.

Energy Efficiency and Performance Metrics

When evaluating thermoelectric modules against conventional heat engines, energy efficiency and performance metrics serve as critical benchmarks for technological comparison. Thermoelectric modules typically operate at efficiency levels between 5-8% under optimal conditions, significantly lower than mature conventional heat engines which can achieve 30-40% efficiency in automotive applications and up to 60% in large-scale combined cycle power plants.

The primary efficiency metric for thermoelectric devices is the figure of merit ZT, which combines the Seebeck coefficient, electrical conductivity, and thermal conductivity. Current commercial thermoelectric materials achieve ZT values around 1-2, with laboratory prototypes reaching up to 2.5. Higher ZT values directly correlate with improved conversion efficiency, though material scientists face significant challenges in simultaneously optimizing these competing properties.

Power density represents another crucial performance indicator, where conventional heat engines generally outperform thermoelectric modules by an order of magnitude. While modern combustion engines can deliver 1-10 kW/kg, thermoelectric generators typically provide only 0.1-0.5 kW/kg. This substantial difference limits thermoelectric applications primarily to specialized niches rather than mainstream power generation.

Temperature operating range and response characteristics create distinct performance profiles for both technologies. Thermoelectric modules function across broad temperature differentials (50-600°C) with instantaneous response times, whereas heat engines require specific operating temperatures and warm-up periods. This grants thermoelectric technology advantages in applications requiring rapid power availability or operation in fluctuating thermal environments.

Scalability metrics reveal inverse relationships between the technologies. Conventional heat engines demonstrate increasing efficiency with size, making them optimal for centralized power generation. Conversely, thermoelectric modules maintain relatively consistent efficiency regardless of scale, offering advantages in distributed and miniaturized applications where conventional engines become impractical.

Lifecycle performance assessment shows thermoelectric modules maintaining stable efficiency over operational lifespans exceeding 100,000 hours with minimal maintenance, contrasting with heat engines that experience efficiency degradation requiring regular maintenance interventions. This reliability factor significantly impacts total cost of ownership calculations despite the initial efficiency disadvantage of thermoelectric technology.

The primary efficiency metric for thermoelectric devices is the figure of merit ZT, which combines the Seebeck coefficient, electrical conductivity, and thermal conductivity. Current commercial thermoelectric materials achieve ZT values around 1-2, with laboratory prototypes reaching up to 2.5. Higher ZT values directly correlate with improved conversion efficiency, though material scientists face significant challenges in simultaneously optimizing these competing properties.

Power density represents another crucial performance indicator, where conventional heat engines generally outperform thermoelectric modules by an order of magnitude. While modern combustion engines can deliver 1-10 kW/kg, thermoelectric generators typically provide only 0.1-0.5 kW/kg. This substantial difference limits thermoelectric applications primarily to specialized niches rather than mainstream power generation.

Temperature operating range and response characteristics create distinct performance profiles for both technologies. Thermoelectric modules function across broad temperature differentials (50-600°C) with instantaneous response times, whereas heat engines require specific operating temperatures and warm-up periods. This grants thermoelectric technology advantages in applications requiring rapid power availability or operation in fluctuating thermal environments.

Scalability metrics reveal inverse relationships between the technologies. Conventional heat engines demonstrate increasing efficiency with size, making them optimal for centralized power generation. Conversely, thermoelectric modules maintain relatively consistent efficiency regardless of scale, offering advantages in distributed and miniaturized applications where conventional engines become impractical.

Lifecycle performance assessment shows thermoelectric modules maintaining stable efficiency over operational lifespans exceeding 100,000 hours with minimal maintenance, contrasting with heat engines that experience efficiency degradation requiring regular maintenance interventions. This reliability factor significantly impacts total cost of ownership calculations despite the initial efficiency disadvantage of thermoelectric technology.

Environmental Impact and Sustainability Considerations

The environmental impact of energy conversion technologies has become increasingly critical in our transition toward sustainable development. Thermoelectric modules and conventional heat engines represent two distinct approaches to energy conversion with significantly different environmental footprints throughout their lifecycle.

Thermoelectric modules offer notable environmental advantages through their zero-emission operation. Unlike combustion-based heat engines, thermoelectric devices produce no direct pollutants during energy conversion, eliminating concerns about particulate matter, nitrogen oxides, or carbon monoxide emissions. This characteristic makes them particularly valuable for indoor applications and environmentally sensitive areas where air quality is paramount.

From a lifecycle perspective, thermoelectric modules contain semiconductor materials that may include tellurium, bismuth, and antimony. While these elements present potential environmental concerns during extraction and disposal phases, the modules' exceptional longevity—often exceeding 100,000 hours of operation—distributes this impact over a significantly longer timeframe compared to conventional engines requiring frequent maintenance and part replacement.

Conventional heat engines, particularly internal combustion engines, continue to face scrutiny for their substantial environmental footprint. Despite efficiency improvements, these systems inherently produce greenhouse gases and air pollutants during operation. The complex mechanical systems also require regular maintenance involving lubricants, coolants, and replacement parts, creating additional waste streams throughout their operational life.

Water consumption represents another critical environmental consideration. Traditional heat engines typically require substantial cooling systems that consume significant water resources, whereas thermoelectric modules operate with minimal or no water requirements. This distinction becomes increasingly important in water-stressed regions where resource conservation is essential.

Manufacturing energy intensity differs significantly between these technologies. Conventional engines require energy-intensive metal casting, precision machining, and assembly processes. Thermoelectric module production involves semiconductor fabrication techniques that, while precise, generally consume less energy per unit of lifetime energy conversion capacity.

End-of-life considerations also favor thermoelectric technology. The solid-state nature of thermoelectric modules facilitates more straightforward recycling processes for recovering valuable semiconductor materials. Conventional engines present more complex disassembly challenges with numerous material types requiring separation.

Carbon footprint analysis across full lifecycles reveals that thermoelectric modules typically achieve carbon payback faster than conventional systems when utilized in appropriate applications, particularly in waste heat recovery scenarios where they generate electricity from otherwise discarded thermal energy.

Thermoelectric modules offer notable environmental advantages through their zero-emission operation. Unlike combustion-based heat engines, thermoelectric devices produce no direct pollutants during energy conversion, eliminating concerns about particulate matter, nitrogen oxides, or carbon monoxide emissions. This characteristic makes them particularly valuable for indoor applications and environmentally sensitive areas where air quality is paramount.

From a lifecycle perspective, thermoelectric modules contain semiconductor materials that may include tellurium, bismuth, and antimony. While these elements present potential environmental concerns during extraction and disposal phases, the modules' exceptional longevity—often exceeding 100,000 hours of operation—distributes this impact over a significantly longer timeframe compared to conventional engines requiring frequent maintenance and part replacement.

Conventional heat engines, particularly internal combustion engines, continue to face scrutiny for their substantial environmental footprint. Despite efficiency improvements, these systems inherently produce greenhouse gases and air pollutants during operation. The complex mechanical systems also require regular maintenance involving lubricants, coolants, and replacement parts, creating additional waste streams throughout their operational life.

Water consumption represents another critical environmental consideration. Traditional heat engines typically require substantial cooling systems that consume significant water resources, whereas thermoelectric modules operate with minimal or no water requirements. This distinction becomes increasingly important in water-stressed regions where resource conservation is essential.

Manufacturing energy intensity differs significantly between these technologies. Conventional engines require energy-intensive metal casting, precision machining, and assembly processes. Thermoelectric module production involves semiconductor fabrication techniques that, while precise, generally consume less energy per unit of lifetime energy conversion capacity.

End-of-life considerations also favor thermoelectric technology. The solid-state nature of thermoelectric modules facilitates more straightforward recycling processes for recovering valuable semiconductor materials. Conventional engines present more complex disassembly challenges with numerous material types requiring separation.

Carbon footprint analysis across full lifecycles reveals that thermoelectric modules typically achieve carbon payback faster than conventional systems when utilized in appropriate applications, particularly in waste heat recovery scenarios where they generate electricity from otherwise discarded thermal energy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!