Analyzing the Effects of Additives on Thermite Properties

JUN 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermite Additives Background and Objectives

Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has been a subject of scientific interest and practical application for over a century. The most common thermite reaction involves aluminum and iron oxide, producing intense heat and molten iron. This exothermic reaction has found uses in various fields, including welding, incendiary devices, and metal purification.

The evolution of thermite technology has been driven by the need for enhanced performance, safety, and controllability. Early applications focused on welding railroad tracks and repairing heavy machinery. As research progressed, the potential for thermite in military and industrial applications became apparent, leading to increased efforts to optimize its properties.

Recent years have seen a surge in research aimed at tailoring thermite properties through the use of additives. These additives can significantly alter the reaction kinetics, energy output, and overall performance of thermite mixtures. The primary objectives of this research are to enhance ignition sensitivity, increase reaction rate, improve energy density, and control the combustion process.

Additives can be broadly categorized into several groups: nano-scale particles, energetic materials, and inert diluents. Nano-scale additives, such as carbon nanotubes or nano-aluminum, can dramatically increase the reactive surface area, leading to faster ignition and more complete combustion. Energetic additives, like nitrocellulose or RDX, can boost the overall energy output of the thermite reaction. Inert diluents, such as silica or alumina, can be used to moderate the reaction rate and control the temperature profile.

The technological goals in this field include developing thermite compositions with precise and predictable burning characteristics, improving safety in handling and storage, and expanding the range of applications. Researchers are particularly interested in creating thermite mixtures that can be ignited at lower temperatures, burn more efficiently, and produce specific desired products.

Understanding the effects of additives on thermite properties is crucial for advancing this technology. It involves a multidisciplinary approach, combining principles from materials science, chemistry, and physics. The research aims to establish clear relationships between the type and quantity of additives and the resulting thermite properties, enabling the design of customized thermite compositions for specific applications.

As we delve deeper into this topic, we will explore the current state of research, the challenges faced, and the potential future directions in thermite technology. The insights gained from this investigation will contribute to the development of more efficient, safer, and versatile thermite-based systems, with implications for industries ranging from metallurgy to aerospace.

The evolution of thermite technology has been driven by the need for enhanced performance, safety, and controllability. Early applications focused on welding railroad tracks and repairing heavy machinery. As research progressed, the potential for thermite in military and industrial applications became apparent, leading to increased efforts to optimize its properties.

Recent years have seen a surge in research aimed at tailoring thermite properties through the use of additives. These additives can significantly alter the reaction kinetics, energy output, and overall performance of thermite mixtures. The primary objectives of this research are to enhance ignition sensitivity, increase reaction rate, improve energy density, and control the combustion process.

Additives can be broadly categorized into several groups: nano-scale particles, energetic materials, and inert diluents. Nano-scale additives, such as carbon nanotubes or nano-aluminum, can dramatically increase the reactive surface area, leading to faster ignition and more complete combustion. Energetic additives, like nitrocellulose or RDX, can boost the overall energy output of the thermite reaction. Inert diluents, such as silica or alumina, can be used to moderate the reaction rate and control the temperature profile.

The technological goals in this field include developing thermite compositions with precise and predictable burning characteristics, improving safety in handling and storage, and expanding the range of applications. Researchers are particularly interested in creating thermite mixtures that can be ignited at lower temperatures, burn more efficiently, and produce specific desired products.

Understanding the effects of additives on thermite properties is crucial for advancing this technology. It involves a multidisciplinary approach, combining principles from materials science, chemistry, and physics. The research aims to establish clear relationships between the type and quantity of additives and the resulting thermite properties, enabling the design of customized thermite compositions for specific applications.

As we delve deeper into this topic, we will explore the current state of research, the challenges faced, and the potential future directions in thermite technology. The insights gained from this investigation will contribute to the development of more efficient, safer, and versatile thermite-based systems, with implications for industries ranging from metallurgy to aerospace.

Market Analysis for Enhanced Thermite Applications

The market for enhanced thermite applications has been experiencing significant growth in recent years, driven by advancements in material science and increasing demand across various industries. Thermite, a pyrotechnic composition of metal powder fuel and metal oxide, has traditionally been used in welding and incendiary devices. However, the introduction of additives to modify thermite properties has opened up new market opportunities and applications.

In the defense sector, enhanced thermites are being explored for use in advanced incendiary weapons and reactive armor systems. The ability to tailor the burn rate, energy output, and ignition sensitivity of thermite compositions through additives has made them attractive for military applications. This has led to increased research and development investments from defense contractors and government agencies.

The aerospace industry has also shown growing interest in enhanced thermite applications. Additives that improve the stability and controllability of thermite reactions are being investigated for use in satellite deployment mechanisms and emergency destruction systems. The space exploration sector, in particular, is exploring thermite compositions with additives that can function reliably in extreme environments.

In the manufacturing sector, enhanced thermites are finding applications in metal purification processes and specialized welding techniques. Additives that increase the precision and efficiency of thermite reactions are driving adoption in high-value manufacturing operations, such as those in the automotive and electronics industries.

The mining and construction industries are exploring enhanced thermites for demolition and excavation applications. Additives that allow for more controlled and directed energy release are being developed to improve safety and efficiency in these sectors.

The global market for enhanced thermite applications is projected to grow steadily over the next five years. North America and Europe currently lead in terms of research and development, with Asia-Pacific expected to show the fastest growth due to increasing industrial and defense investments.

Key market drivers include the ongoing need for more efficient and controllable energetic materials, stringent safety regulations in industrial applications, and the push for miniaturization in electronics and aerospace components. However, challenges such as regulatory hurdles for new formulations and concerns over the environmental impact of certain additives may moderate growth in some sectors.

As the market evolves, collaborations between academic institutions, research laboratories, and industry players are expected to accelerate innovation in thermite additives. This collaborative approach is likely to yield new formulations that address specific industry needs while improving overall safety and performance characteristics.

In the defense sector, enhanced thermites are being explored for use in advanced incendiary weapons and reactive armor systems. The ability to tailor the burn rate, energy output, and ignition sensitivity of thermite compositions through additives has made them attractive for military applications. This has led to increased research and development investments from defense contractors and government agencies.

The aerospace industry has also shown growing interest in enhanced thermite applications. Additives that improve the stability and controllability of thermite reactions are being investigated for use in satellite deployment mechanisms and emergency destruction systems. The space exploration sector, in particular, is exploring thermite compositions with additives that can function reliably in extreme environments.

In the manufacturing sector, enhanced thermites are finding applications in metal purification processes and specialized welding techniques. Additives that increase the precision and efficiency of thermite reactions are driving adoption in high-value manufacturing operations, such as those in the automotive and electronics industries.

The mining and construction industries are exploring enhanced thermites for demolition and excavation applications. Additives that allow for more controlled and directed energy release are being developed to improve safety and efficiency in these sectors.

The global market for enhanced thermite applications is projected to grow steadily over the next five years. North America and Europe currently lead in terms of research and development, with Asia-Pacific expected to show the fastest growth due to increasing industrial and defense investments.

Key market drivers include the ongoing need for more efficient and controllable energetic materials, stringent safety regulations in industrial applications, and the push for miniaturization in electronics and aerospace components. However, challenges such as regulatory hurdles for new formulations and concerns over the environmental impact of certain additives may moderate growth in some sectors.

As the market evolves, collaborations between academic institutions, research laboratories, and industry players are expected to accelerate innovation in thermite additives. This collaborative approach is likely to yield new formulations that address specific industry needs while improving overall safety and performance characteristics.

Current Challenges in Thermite Additive Research

The field of thermite additive research faces several significant challenges that hinder progress and limit the potential applications of these energetic materials. One of the primary obstacles is the complex interplay between additives and the thermite reaction. Researchers struggle to fully understand and predict how various additives affect the ignition, propagation, and overall performance of thermite compositions.

A major challenge lies in achieving precise control over reaction rates and energy release. While additives can modify these parameters, fine-tuning them to meet specific application requirements remains difficult. This is particularly crucial in areas such as welding, metal purification, and pyrotechnics, where precise control of the thermite reaction is essential for optimal results.

Another significant hurdle is the development of additives that can enhance the stability and shelf life of thermite mixtures without compromising their reactivity. Many additives that improve performance may also increase sensitivity to accidental ignition, creating a delicate balance between safety and effectiveness. This challenge is especially relevant in the storage and transportation of thermite-based materials.

The environmental impact of thermite additives presents an additional concern. As regulations become more stringent, researchers must develop additives that not only enhance performance but also minimize harmful emissions and residues. This dual requirement complicates the selection and development of suitable additives, often leading to trade-offs between performance and environmental considerations.

Scalability and cost-effectiveness pose further challenges in thermite additive research. Many promising additives discovered in laboratory settings prove difficult or expensive to produce at industrial scales. This limitation restricts the practical application of novel thermite compositions, particularly in cost-sensitive industries.

Moreover, the characterization and testing of thermite mixtures with various additives remain complex and potentially hazardous. Developing standardized, safe, and accurate methods for evaluating the effects of additives on thermite properties is an ongoing challenge. This difficulty in assessment can slow down research progress and hinder the comparison of results across different studies.

Lastly, the multidisciplinary nature of thermite additive research presents its own set of challenges. Effective progress in this field requires collaboration between chemists, materials scientists, engineers, and safety experts. Coordinating these diverse perspectives and integrating their insights into cohesive research strategies can be challenging but is essential for overcoming the current limitations in thermite additive technology.

A major challenge lies in achieving precise control over reaction rates and energy release. While additives can modify these parameters, fine-tuning them to meet specific application requirements remains difficult. This is particularly crucial in areas such as welding, metal purification, and pyrotechnics, where precise control of the thermite reaction is essential for optimal results.

Another significant hurdle is the development of additives that can enhance the stability and shelf life of thermite mixtures without compromising their reactivity. Many additives that improve performance may also increase sensitivity to accidental ignition, creating a delicate balance between safety and effectiveness. This challenge is especially relevant in the storage and transportation of thermite-based materials.

The environmental impact of thermite additives presents an additional concern. As regulations become more stringent, researchers must develop additives that not only enhance performance but also minimize harmful emissions and residues. This dual requirement complicates the selection and development of suitable additives, often leading to trade-offs between performance and environmental considerations.

Scalability and cost-effectiveness pose further challenges in thermite additive research. Many promising additives discovered in laboratory settings prove difficult or expensive to produce at industrial scales. This limitation restricts the practical application of novel thermite compositions, particularly in cost-sensitive industries.

Moreover, the characterization and testing of thermite mixtures with various additives remain complex and potentially hazardous. Developing standardized, safe, and accurate methods for evaluating the effects of additives on thermite properties is an ongoing challenge. This difficulty in assessment can slow down research progress and hinder the comparison of results across different studies.

Lastly, the multidisciplinary nature of thermite additive research presents its own set of challenges. Effective progress in this field requires collaboration between chemists, materials scientists, engineers, and safety experts. Coordinating these diverse perspectives and integrating their insights into cohesive research strategies can be challenging but is essential for overcoming the current limitations in thermite additive technology.

Existing Thermite Additive Solutions

01 Composition and reactivity of thermite mixtures

Thermite mixtures typically consist of metal oxides and aluminum powder. The composition affects the reactivity and energy release of the thermite reaction. Various metal oxides can be used to tailor the properties of the thermite, such as reaction temperature, burn rate, and energy output. The particle size and distribution of the components also play a crucial role in determining the thermite's properties.- Composition and reactivity of thermite mixtures: Thermite mixtures typically consist of metal oxides and aluminum powder. The composition affects the reaction rate, heat generation, and overall performance. Various metal oxides can be used, including iron oxide, copper oxide, and others, to achieve different properties and applications.

- Ignition methods and control of thermite reactions: Different ignition methods can be employed to initiate thermite reactions, including electrical, chemical, and mechanical means. Controlling the ignition process and reaction rate is crucial for safety and desired outcomes in various applications, such as welding, incendiary devices, and metallurgical processes.

- Applications of thermite in oil and gas industry: Thermite reactions are utilized in the oil and gas industry for various purposes, including well perforating, cutting tools, and sealing operations. The high temperature and pressure generated by thermite reactions make it suitable for these applications, allowing for efficient and controlled operations in challenging environments.

- Safety considerations and handling of thermite materials: Due to the highly exothermic nature of thermite reactions, proper safety measures and handling procedures are essential. This includes storage, transportation, and usage guidelines to prevent accidental ignition and ensure safe operation. Specialized containers and equipment may be required for handling thermite materials.

- Modifications and enhancements to thermite properties: Research focuses on modifying thermite compositions to enhance specific properties such as reaction rate, energy output, or stability. This can involve adding catalysts, using nanoparticles, or incorporating other materials to tailor the thermite properties for specific applications or to improve overall performance.

02 Applications in welding and metal joining

Thermite reactions are utilized in welding and metal joining processes. The high temperatures generated by the exothermic reaction can be used to join railway tracks, pipes, and other large metal structures. The composition of the thermite mixture can be adjusted to suit specific welding applications, considering factors such as the metals being joined and the desired weld properties.Expand Specific Solutions03 Ignition methods and control

Various ignition methods are employed to initiate thermite reactions, including electrical, chemical, and mechanical means. The choice of ignition method can affect the reaction's onset and propagation. Control mechanisms are implemented to ensure safe and controlled ignition, especially in industrial applications. Ignition temperature and energy requirements vary depending on the thermite composition.Expand Specific Solutions04 Thermal and energetic properties

Thermite reactions are characterized by their high heat output and temperature generation. The thermal properties, such as heat capacity and thermal conductivity, influence the reaction dynamics. The energy density and release rate of thermite mixtures are important considerations for various applications. These properties can be modified by adjusting the composition and particle characteristics of the thermite components.Expand Specific Solutions05 Safety considerations and handling

Due to the highly exothermic nature of thermite reactions, proper safety measures are crucial. Handling and storage protocols are implemented to prevent accidental ignition. Protective equipment and specialized containment systems are used during thermite operations. Risk assessment and mitigation strategies are essential for the safe use of thermite in industrial and research settings.Expand Specific Solutions

Key Players in Thermite Additive Development

The competitive landscape for analyzing the effects of additives on thermite properties is in a growth phase, with increasing market size due to applications in various industries. The technology is moderately mature, with ongoing research to enhance performance and safety. Key players like Halliburton Energy Services, Lockheed Martin Corp., and Naval Research Laboratory are leading in industrial applications, while academic institutions such as Beijing Institute of Technology and Central South University are advancing fundamental research. Companies like BiSN Oil Tools Ltd. and 3M Innovative Properties Co. are focusing on specialized applications, indicating a diverse and competitive market with potential for further innovation and market expansion.

Halliburton Energy Services, Inc.

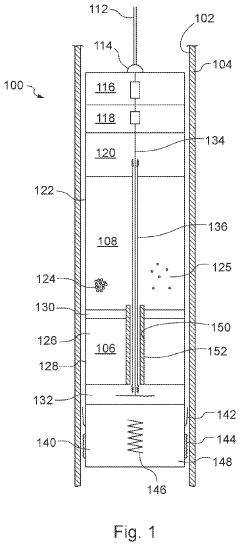

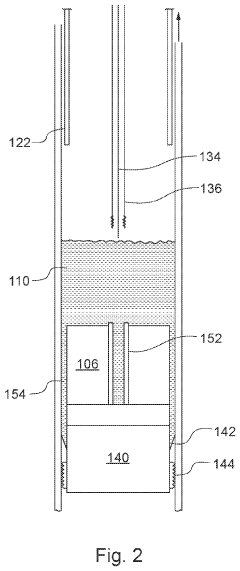

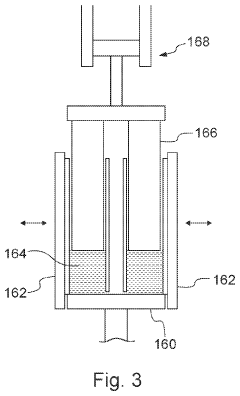

Technical Solution: Halliburton has developed advanced thermite-based technologies for well abandonment and intervention operations. Their system utilizes a controlled thermite reaction to create a high-temperature, high-pressure environment capable of melting and fusing downhole components. This technology allows for the creation of rock-to-rock barriers in oil and gas wells, effectively sealing off sections of the wellbore. The company has also incorporated additives to enhance the thermite reaction's efficiency and control its propagation rate, resulting in more precise and reliable well abandonment procedures.

Strengths: Highly effective for well abandonment, creates durable seals, reduces environmental risks. Weaknesses: High cost, potential safety concerns due to extreme temperatures.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced thermite-based propulsion systems for aerospace applications. Their research focuses on incorporating various additives to enhance the performance characteristics of thermite reactions. By carefully selecting and combining different metal oxides and reducing agents, they have created thermite mixtures with tailored burn rates, energy outputs, and reaction temperatures. These advancements have led to the development of more efficient and controllable solid-fuel propulsion systems for missiles and spacecraft. Additionally, Lockheed Martin has explored the use of nanoparticle additives to increase the reaction rate and energy density of thermite compositions.

Strengths: High energy density, customizable performance, suitable for aerospace applications. Weaknesses: Potential instability, complex manufacturing process.

Core Innovations in Thermite Modification

Downhole apparatus and method

PatentActiveUS20240011367A1

Innovation

- A downhole apparatus and method utilizing compressed thermite within a container, which reduces porosity and increases density, facilitating efficient heat transfer and reaction, and is combined with a low-melt-point alloy to form a solid plug, allowing for effective sealing without the need for binding agents and maintaining structural strength under pressure.

Pyrotechnic thermite composition

PatentInactiveUS7632365B1

Innovation

- A thermite formulation comprising a magnesium-aluminum alloy as fuel, copper oxide (CuO) and molybdenum oxide (MoO3) as oxidizers, with a binder material, optimized to provide excellent material perforation with low toxicity starting and reaction products, specifically using a ratio of about 39.8% CuO, 33% MoO3, 24.2% magnalium, and 3% binder by weight.

Safety Regulations for Thermite Handling

The handling of thermite requires strict adherence to safety regulations due to its highly reactive nature and potential hazards. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have established comprehensive guidelines for the safe use, storage, and disposal of thermite materials.

Personal protective equipment (PPE) is mandatory when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and respiratory protection. The specific type of PPE required may vary depending on the scale of the operation and the specific additives being used in the thermite mixture.

Storage regulations for thermite and its components are stringent. Thermite mixtures must be stored in cool, dry areas away from potential ignition sources. Separate storage is required for the fuel and oxidizer components to prevent accidental mixing. Containers must be clearly labeled and regularly inspected for any signs of degradation or contamination.

Transportation of thermite materials is subject to strict regulations under the Department of Transportation (DOT) guidelines. These materials are classified as hazardous and require special packaging, labeling, and documentation. Vehicles transporting thermite must be properly equipped and operators must receive specialized training.

Workplace safety protocols for thermite handling include designated work areas with proper ventilation, fire suppression systems, and emergency eyewash stations. Regular safety drills and training sessions are mandatory for all personnel involved in thermite operations. Standard operating procedures (SOPs) must be developed and strictly followed for each thermite-related process.

Disposal of thermite waste and byproducts must comply with environmental regulations. Unused thermite and contaminated materials must be treated as hazardous waste and disposed of through authorized facilities. Proper documentation and tracking of waste disposal are essential for regulatory compliance.

When analyzing the effects of additives on thermite properties, additional safety considerations come into play. Each additive must be evaluated for its potential impact on the reactivity, stability, and byproducts of the thermite reaction. Safety data sheets (SDS) for all additives must be readily available, and compatibility studies should be conducted before introducing new components to the mixture.

Regulatory compliance also extends to record-keeping and reporting. Detailed logs of thermite usage, storage conditions, and safety incidents must be maintained. Regular audits and inspections by regulatory agencies may be conducted to ensure compliance with safety standards.

Personal protective equipment (PPE) is mandatory when working with thermite. This includes fire-resistant clothing, heat-resistant gloves, safety goggles, and respiratory protection. The specific type of PPE required may vary depending on the scale of the operation and the specific additives being used in the thermite mixture.

Storage regulations for thermite and its components are stringent. Thermite mixtures must be stored in cool, dry areas away from potential ignition sources. Separate storage is required for the fuel and oxidizer components to prevent accidental mixing. Containers must be clearly labeled and regularly inspected for any signs of degradation or contamination.

Transportation of thermite materials is subject to strict regulations under the Department of Transportation (DOT) guidelines. These materials are classified as hazardous and require special packaging, labeling, and documentation. Vehicles transporting thermite must be properly equipped and operators must receive specialized training.

Workplace safety protocols for thermite handling include designated work areas with proper ventilation, fire suppression systems, and emergency eyewash stations. Regular safety drills and training sessions are mandatory for all personnel involved in thermite operations. Standard operating procedures (SOPs) must be developed and strictly followed for each thermite-related process.

Disposal of thermite waste and byproducts must comply with environmental regulations. Unused thermite and contaminated materials must be treated as hazardous waste and disposed of through authorized facilities. Proper documentation and tracking of waste disposal are essential for regulatory compliance.

When analyzing the effects of additives on thermite properties, additional safety considerations come into play. Each additive must be evaluated for its potential impact on the reactivity, stability, and byproducts of the thermite reaction. Safety data sheets (SDS) for all additives must be readily available, and compatibility studies should be conducted before introducing new components to the mixture.

Regulatory compliance also extends to record-keeping and reporting. Detailed logs of thermite usage, storage conditions, and safety incidents must be maintained. Regular audits and inspections by regulatory agencies may be conducted to ensure compliance with safety standards.

Environmental Impact of Thermite Additives

The environmental impact of thermite additives is a critical consideration in the development and application of thermite compositions. Thermite reactions, known for their high-temperature exothermic nature, can potentially release various byproducts into the environment. The addition of different substances to modify thermite properties may further complicate these environmental effects.

One of the primary environmental concerns associated with thermite additives is the release of particulate matter during combustion. Certain additives can alter the particle size distribution of the reaction products, potentially increasing the amount of fine particulates released into the air. These fine particles can contribute to air pollution and pose respiratory health risks to both humans and wildlife in the surrounding areas.

Gaseous emissions are another significant environmental factor influenced by thermite additives. Depending on the chemical composition of the additives, the thermite reaction may produce various gases, including carbon dioxide, nitrogen oxides, and volatile organic compounds. Some additives might catalyze the formation of more harmful gases or increase the overall volume of emissions, leading to potential air quality issues and contributing to greenhouse gas concentrations.

The persistence of reaction products in the environment is also affected by the choice of additives. Certain additives may result in the formation of more stable, long-lasting compounds that can accumulate in soil or water systems. This persistence can lead to long-term environmental contamination and potentially disrupt local ecosystems. Conversely, some additives might promote the formation of more readily degradable products, minimizing long-term environmental impact.

Water contamination is another crucial aspect to consider. Thermite reactions often produce metal oxides as byproducts, which can leach into groundwater or surface water systems. Additives may alter the solubility or mobility of these metal oxides, potentially increasing their spread in aquatic environments. This can lead to changes in water chemistry, affecting aquatic life and potentially contaminating drinking water sources.

The thermal effects of thermite reactions on the immediate environment should not be overlooked. Additives that increase the reaction temperature or duration may cause more severe localized heating of surrounding materials, potentially leading to secondary fires or damage to nearby vegetation and soil microorganisms. This can result in long-term changes to local ecosystems and soil fertility.

Lastly, the life cycle impact of thermite additives must be considered. The production, transportation, and disposal of these additives contribute to their overall environmental footprint. Some additives may require energy-intensive manufacturing processes or be derived from non-renewable resources, adding to their environmental cost. Additionally, unused or residual additives may pose disposal challenges, requiring special handling to prevent environmental contamination.

One of the primary environmental concerns associated with thermite additives is the release of particulate matter during combustion. Certain additives can alter the particle size distribution of the reaction products, potentially increasing the amount of fine particulates released into the air. These fine particles can contribute to air pollution and pose respiratory health risks to both humans and wildlife in the surrounding areas.

Gaseous emissions are another significant environmental factor influenced by thermite additives. Depending on the chemical composition of the additives, the thermite reaction may produce various gases, including carbon dioxide, nitrogen oxides, and volatile organic compounds. Some additives might catalyze the formation of more harmful gases or increase the overall volume of emissions, leading to potential air quality issues and contributing to greenhouse gas concentrations.

The persistence of reaction products in the environment is also affected by the choice of additives. Certain additives may result in the formation of more stable, long-lasting compounds that can accumulate in soil or water systems. This persistence can lead to long-term environmental contamination and potentially disrupt local ecosystems. Conversely, some additives might promote the formation of more readily degradable products, minimizing long-term environmental impact.

Water contamination is another crucial aspect to consider. Thermite reactions often produce metal oxides as byproducts, which can leach into groundwater or surface water systems. Additives may alter the solubility or mobility of these metal oxides, potentially increasing their spread in aquatic environments. This can lead to changes in water chemistry, affecting aquatic life and potentially contaminating drinking water sources.

The thermal effects of thermite reactions on the immediate environment should not be overlooked. Additives that increase the reaction temperature or duration may cause more severe localized heating of surrounding materials, potentially leading to secondary fires or damage to nearby vegetation and soil microorganisms. This can result in long-term changes to local ecosystems and soil fertility.

Lastly, the life cycle impact of thermite additives must be considered. The production, transportation, and disposal of these additives contribute to their overall environmental footprint. Some additives may require energy-intensive manufacturing processes or be derived from non-renewable resources, adding to their environmental cost. Additionally, unused or residual additives may pose disposal challenges, requiring special handling to prevent environmental contamination.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!