Analyzing V8 Engine Patents: Innovations and Impacts

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine has undergone significant evolution since its inception in the early 20th century. This iconic engine configuration has been a cornerstone of automotive engineering, continuously adapting to meet changing performance demands, efficiency requirements, and environmental regulations.

In the early stages of V8 development, the focus was primarily on increasing power output and reliability. The 1930s and 1940s saw the introduction of overhead valve designs, which improved engine breathing and allowed for higher compression ratios. This period also marked the beginning of V8 engines' widespread adoption in American automobiles, setting the stage for their dominance in the following decades.

The 1950s and 1960s witnessed a horsepower race, with manufacturers pushing the limits of V8 performance. This era saw the introduction of high-performance variants like the Chrysler Hemi and Chevrolet's small-block V8, which became legendary for their power and versatility. Concurrently, advancements in metallurgy and manufacturing processes allowed for lighter, more durable engine components.

The 1970s brought a paradigm shift in V8 development due to the oil crisis and stricter emissions regulations. Engineers focused on improving fuel efficiency and reducing emissions, leading to the introduction of electronic fuel injection systems and catalytic converters. This period also saw the downsizing of V8 engines and the exploration of alternative configurations to meet new regulatory challenges.

In the 1980s and 1990s, computer-aided design and manufacturing techniques revolutionized V8 engine development. These technologies enabled more precise engineering, resulting in engines with improved power-to-weight ratios and better fuel economy. The introduction of overhead cam designs and variable valve timing systems further enhanced performance and efficiency.

The turn of the millennium marked a new era for V8 engines, characterized by the integration of advanced materials and technologies. Aluminum block construction became more prevalent, significantly reducing engine weight. Direct fuel injection, turbocharging, and cylinder deactivation technologies were widely adopted to meet increasingly stringent fuel economy and emissions standards while maintaining performance.

Recent years have seen a focus on hybridization and electrification of V8 powertrains. Many manufacturers are now combining V8 engines with electric motors to create high-performance hybrid systems that offer both power and improved efficiency. This trend represents the latest stage in V8 evolution, as the automotive industry transitions towards more sustainable propulsion technologies.

Throughout its evolution, the V8 engine has consistently adapted to changing market demands and regulatory landscapes. Its enduring popularity is a testament to its versatility and the continuous innovation efforts of automotive engineers. As we move into an era of increased electrification, the role of V8 engines is evolving, but their legacy of performance and engineering excellence continues to influence automotive design and technology.

In the early stages of V8 development, the focus was primarily on increasing power output and reliability. The 1930s and 1940s saw the introduction of overhead valve designs, which improved engine breathing and allowed for higher compression ratios. This period also marked the beginning of V8 engines' widespread adoption in American automobiles, setting the stage for their dominance in the following decades.

The 1950s and 1960s witnessed a horsepower race, with manufacturers pushing the limits of V8 performance. This era saw the introduction of high-performance variants like the Chrysler Hemi and Chevrolet's small-block V8, which became legendary for their power and versatility. Concurrently, advancements in metallurgy and manufacturing processes allowed for lighter, more durable engine components.

The 1970s brought a paradigm shift in V8 development due to the oil crisis and stricter emissions regulations. Engineers focused on improving fuel efficiency and reducing emissions, leading to the introduction of electronic fuel injection systems and catalytic converters. This period also saw the downsizing of V8 engines and the exploration of alternative configurations to meet new regulatory challenges.

In the 1980s and 1990s, computer-aided design and manufacturing techniques revolutionized V8 engine development. These technologies enabled more precise engineering, resulting in engines with improved power-to-weight ratios and better fuel economy. The introduction of overhead cam designs and variable valve timing systems further enhanced performance and efficiency.

The turn of the millennium marked a new era for V8 engines, characterized by the integration of advanced materials and technologies. Aluminum block construction became more prevalent, significantly reducing engine weight. Direct fuel injection, turbocharging, and cylinder deactivation technologies were widely adopted to meet increasingly stringent fuel economy and emissions standards while maintaining performance.

Recent years have seen a focus on hybridization and electrification of V8 powertrains. Many manufacturers are now combining V8 engines with electric motors to create high-performance hybrid systems that offer both power and improved efficiency. This trend represents the latest stage in V8 evolution, as the automotive industry transitions towards more sustainable propulsion technologies.

Throughout its evolution, the V8 engine has consistently adapted to changing market demands and regulatory landscapes. Its enduring popularity is a testament to its versatility and the continuous innovation efforts of automotive engineers. As we move into an era of increased electrification, the role of V8 engines is evolving, but their legacy of performance and engineering excellence continues to influence automotive design and technology.

Market Demand Analysis

The market demand for V8 engine technology has been steadily growing, driven by the automotive industry's pursuit of higher performance and efficiency. V8 engines are particularly popular in luxury vehicles, sports cars, and high-performance SUVs, where power and prestige are key selling points. The global V8 engine market is expected to expand significantly in the coming years, with a compound annual growth rate (CAGR) projected to be in the mid-single digits.

One of the primary factors fueling this demand is the continuous innovation in V8 engine design, which has led to improved fuel efficiency and reduced emissions without compromising on power output. This has allowed V8 engines to remain relevant in an era of increasingly stringent environmental regulations. Manufacturers are investing heavily in research and development to create more advanced V8 engines that can meet these regulatory requirements while still delivering the performance that consumers expect.

The luxury car segment has been a major driver of V8 engine demand. Brands like Mercedes-Benz, BMW, and Audi continue to offer V8 options in their high-end models, catering to customers who prioritize performance and prestige. In the sports car market, V8 engines remain a staple, with iconic models from manufacturers such as Ferrari, Porsche, and Chevrolet relying on V8 power to deliver exhilarating driving experiences.

The truck and SUV market has also contributed significantly to the demand for V8 engines. In North America, where large pickup trucks are particularly popular, V8 engines are often preferred for their towing capacity and durability. As the trend towards larger vehicles continues globally, the demand for powerful V8 engines in SUVs is expected to grow, especially in emerging markets where luxury SUVs are gaining traction.

However, the market for V8 engines is not without challenges. The shift towards electrification and stricter emissions standards in many countries has put pressure on manufacturers to develop alternative powertrains. This has led to increased investment in hybrid and electric technologies, which could potentially impact the long-term demand for traditional V8 engines.

Despite these challenges, there remains a strong niche market for V8 engines, particularly in high-performance and luxury applications. Manufacturers are responding by developing more advanced V8 engines that incorporate technologies such as cylinder deactivation, turbocharging, and mild hybrid systems to improve efficiency while maintaining the characteristic power and sound that V8 enthusiasts crave.

In conclusion, while the overall automotive market is evolving, the demand for V8 engines continues to be robust in specific segments. The future of V8 technology will likely involve a balance between traditional performance characteristics and innovative solutions to meet environmental and regulatory requirements.

One of the primary factors fueling this demand is the continuous innovation in V8 engine design, which has led to improved fuel efficiency and reduced emissions without compromising on power output. This has allowed V8 engines to remain relevant in an era of increasingly stringent environmental regulations. Manufacturers are investing heavily in research and development to create more advanced V8 engines that can meet these regulatory requirements while still delivering the performance that consumers expect.

The luxury car segment has been a major driver of V8 engine demand. Brands like Mercedes-Benz, BMW, and Audi continue to offer V8 options in their high-end models, catering to customers who prioritize performance and prestige. In the sports car market, V8 engines remain a staple, with iconic models from manufacturers such as Ferrari, Porsche, and Chevrolet relying on V8 power to deliver exhilarating driving experiences.

The truck and SUV market has also contributed significantly to the demand for V8 engines. In North America, where large pickup trucks are particularly popular, V8 engines are often preferred for their towing capacity and durability. As the trend towards larger vehicles continues globally, the demand for powerful V8 engines in SUVs is expected to grow, especially in emerging markets where luxury SUVs are gaining traction.

However, the market for V8 engines is not without challenges. The shift towards electrification and stricter emissions standards in many countries has put pressure on manufacturers to develop alternative powertrains. This has led to increased investment in hybrid and electric technologies, which could potentially impact the long-term demand for traditional V8 engines.

Despite these challenges, there remains a strong niche market for V8 engines, particularly in high-performance and luxury applications. Manufacturers are responding by developing more advanced V8 engines that incorporate technologies such as cylinder deactivation, turbocharging, and mild hybrid systems to improve efficiency while maintaining the characteristic power and sound that V8 enthusiasts crave.

In conclusion, while the overall automotive market is evolving, the demand for V8 engines continues to be robust in specific segments. The future of V8 technology will likely involve a balance between traditional performance characteristics and innovative solutions to meet environmental and regulatory requirements.

Technical Challenges

The V8 engine, developed by Google, has revolutionized JavaScript execution in web browsers. However, as with any cutting-edge technology, it faces several technical challenges that require ongoing innovation and research.

One of the primary challenges is optimizing performance across diverse hardware architectures. As the V8 engine is used in various environments, from high-end desktop computers to resource-constrained mobile devices, ensuring consistent and efficient performance across all platforms remains a significant hurdle. This challenge is compounded by the rapid evolution of hardware technologies, requiring constant adaptation of the engine's optimization strategies.

Memory management presents another critical challenge for the V8 engine. JavaScript's dynamic nature and the increasing complexity of web applications demand sophisticated garbage collection mechanisms. Balancing efficient memory usage with minimal performance impact during garbage collection cycles continues to be an area of intense focus and development.

The V8 engine also grapples with the challenge of optimizing just-in-time (JIT) compilation. While JIT compilation significantly enhances JavaScript execution speed, it introduces complexities in terms of compilation overhead and code optimization. Striking the right balance between compilation time and runtime performance, especially for large and complex applications, remains an ongoing challenge.

Security is another paramount concern for the V8 engine. As a core component of web browsers, it is a prime target for malicious actors. Ensuring robust security measures while maintaining high performance is a delicate balancing act that requires continuous vigilance and innovation.

The ever-evolving JavaScript language specification also poses challenges for the V8 engine. Implementing new language features and ensuring backward compatibility with existing code bases demands significant engineering efforts. This challenge is further complicated by the need to maintain performance parity or improvements with each new feature addition.

Lastly, the V8 engine faces the challenge of reducing power consumption, particularly on mobile devices. Optimizing the engine to be more energy-efficient without compromising performance is crucial for enhancing battery life and user experience on portable devices.

These technical challenges drive ongoing research and development efforts in the V8 engine, spurring innovations that continue to push the boundaries of JavaScript performance and capabilities.

One of the primary challenges is optimizing performance across diverse hardware architectures. As the V8 engine is used in various environments, from high-end desktop computers to resource-constrained mobile devices, ensuring consistent and efficient performance across all platforms remains a significant hurdle. This challenge is compounded by the rapid evolution of hardware technologies, requiring constant adaptation of the engine's optimization strategies.

Memory management presents another critical challenge for the V8 engine. JavaScript's dynamic nature and the increasing complexity of web applications demand sophisticated garbage collection mechanisms. Balancing efficient memory usage with minimal performance impact during garbage collection cycles continues to be an area of intense focus and development.

The V8 engine also grapples with the challenge of optimizing just-in-time (JIT) compilation. While JIT compilation significantly enhances JavaScript execution speed, it introduces complexities in terms of compilation overhead and code optimization. Striking the right balance between compilation time and runtime performance, especially for large and complex applications, remains an ongoing challenge.

Security is another paramount concern for the V8 engine. As a core component of web browsers, it is a prime target for malicious actors. Ensuring robust security measures while maintaining high performance is a delicate balancing act that requires continuous vigilance and innovation.

The ever-evolving JavaScript language specification also poses challenges for the V8 engine. Implementing new language features and ensuring backward compatibility with existing code bases demands significant engineering efforts. This challenge is further complicated by the need to maintain performance parity or improvements with each new feature addition.

Lastly, the V8 engine faces the challenge of reducing power consumption, particularly on mobile devices. Optimizing the engine to be more energy-efficient without compromising performance is crucial for enhancing battery life and user experience on portable devices.

These technical challenges drive ongoing research and development efforts in the V8 engine, spurring innovations that continue to push the boundaries of JavaScript performance and capabilities.

Current V8 Solutions

01 Improved V8 engine design and performance

Innovations in V8 engine design focus on enhancing overall performance, efficiency, and power output. These improvements may include modifications to cylinder configuration, combustion chamber design, and valve timing systems. Advanced materials and manufacturing techniques are employed to reduce weight and increase durability.- Improved V8 engine design and performance: Innovations in V8 engine design focus on enhancing overall performance, efficiency, and power output. These advancements include optimized cylinder configurations, improved combustion processes, and advanced materials for engine components. Such innovations aim to increase horsepower, reduce fuel consumption, and minimize emissions while maintaining the characteristic V8 engine sound and feel.

- V8 engine control systems and diagnostics: Advancements in V8 engine control systems involve sophisticated electronic management and diagnostic capabilities. These innovations include real-time monitoring of engine parameters, adaptive control algorithms, and predictive maintenance features. Such systems optimize engine performance, detect potential issues early, and facilitate efficient troubleshooting and maintenance procedures.

- Fuel efficiency and emissions reduction in V8 engines: Innovations aimed at improving fuel efficiency and reducing emissions in V8 engines include advanced fuel injection systems, variable valve timing, cylinder deactivation technologies, and integration of hybrid or electric assist systems. These advancements help V8 engines meet stringent environmental regulations while maintaining high performance characteristics.

- V8 engine manufacturing and assembly techniques: Advancements in V8 engine manufacturing and assembly processes focus on improving production efficiency, quality control, and customization capabilities. These innovations include automated assembly lines, precision machining techniques, and modular design approaches that allow for easier maintenance and upgrades.

- V8 engine integration with vehicle systems: Innovations in integrating V8 engines with other vehicle systems aim to enhance overall vehicle performance and user experience. These advancements include improved engine mounting systems for reduced vibration, integration with advanced transmission technologies, and compatibility with vehicle-wide electronic control systems for optimized performance and efficiency.

02 Fuel efficiency and emissions reduction

Developments in V8 engine technology aim to improve fuel efficiency and reduce emissions. This includes innovations in fuel injection systems, exhaust gas recirculation, and advanced combustion control strategies. Integration of hybrid or electric components may also be incorporated to further enhance efficiency and meet stringent environmental regulations.Expand Specific Solutions03 Engine management and control systems

Advancements in electronic control units (ECUs) and engine management systems for V8 engines. These innovations focus on optimizing engine performance, fuel consumption, and emissions through real-time monitoring and adjustment of various engine parameters. Integration of artificial intelligence and machine learning algorithms may be employed for predictive maintenance and performance optimization.Expand Specific Solutions04 Cooling and lubrication system improvements

Innovations in cooling and lubrication systems for V8 engines to enhance thermal management and reduce friction. This may include advanced coolant formulations, improved oil circulation systems, and novel heat exchanger designs. These improvements contribute to increased engine longevity and overall performance.Expand Specific Solutions05 Manufacturing and assembly processes

Advancements in manufacturing techniques and assembly processes for V8 engines. These innovations may include improved casting methods, precision machining techniques, and automated assembly systems. The focus is on enhancing production efficiency, reducing costs, and improving overall engine quality and consistency.Expand Specific Solutions

Key Industry Players

The V8 engine patent landscape reflects a mature technology with ongoing innovation in a competitive automotive industry. Major players like Toyota, BMW, Nissan, and Ford are actively developing improvements to enhance performance, efficiency, and emissions control. The market for V8 engines remains significant, particularly in high-performance vehicles and heavy-duty applications, despite a shift towards electrification. Technological advancements focus on integrating hybrid systems, optimizing combustion processes, and incorporating advanced materials. While traditional automakers dominate, specialized engineering firms and research institutions contribute to the evolving V8 technology, indicating a collaborative ecosystem driving continuous refinement and adaptation to changing regulatory and market demands.

Toyota Motor Corp.

Technical Solution: Toyota has made significant advancements in V8 engine technology, focusing on improving fuel efficiency and reducing emissions. Their D-4S (Direct injection 4-stroke gasoline engine Superior version) system combines both direct and port fuel injection, optimizing fuel delivery based on driving conditions[1]. This technology has been implemented in their 5.7-liter V8 engines, resulting in improved combustion efficiency and power output. Toyota has also developed a variable valve timing system specifically for V8 engines, which allows for better control of engine breathing and combustion processes[2]. Additionally, they have explored the use of lightweight materials and advanced manufacturing techniques to reduce the overall weight of their V8 engines, contributing to improved vehicle performance and fuel economy[3].

Strengths: Improved fuel efficiency, reduced emissions, and optimized power output. Weaknesses: Complexity of the dual injection system may lead to higher maintenance costs and potential reliability issues in the long term.

Ford Global Technologies LLC

Technical Solution: Ford has been at the forefront of V8 engine innovation, particularly with their EcoBoost technology. While primarily known for smaller engines, Ford has applied EcoBoost principles to their V8 lineup, resulting in the development of a twin-turbocharged 3.5-liter V6 that rivals traditional V8 performance[4]. For their V8 engines, Ford has focused on cylinder deactivation technology, allowing the engine to run on four cylinders during light load conditions, significantly improving fuel economy[5]. They have also patented advanced cooling systems for V8 engines, addressing thermal management challenges in high-performance applications[6]. Ford's plasma transferred wire arc (PTWA) coating technology has been applied to cylinder bores in V8 engines, reducing friction and improving durability[7].

Strengths: Innovative technologies like EcoBoost and cylinder deactivation improve efficiency without sacrificing performance. Weaknesses: The complexity of these systems may increase production costs and potential points of failure.

Core V8 Innovations

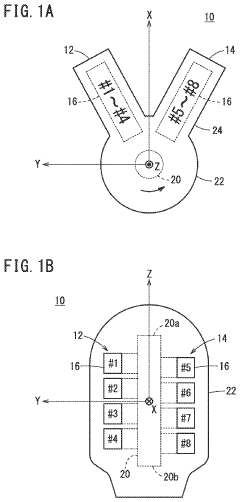

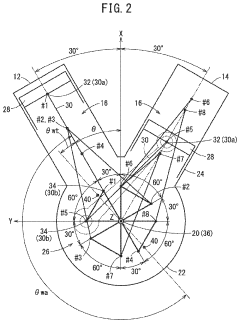

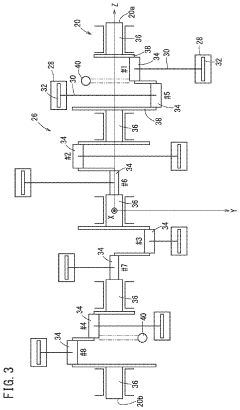

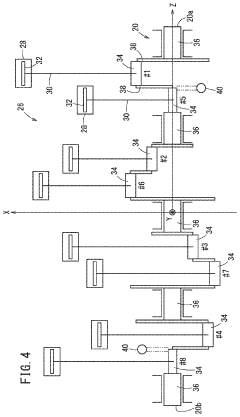

V8 engine

PatentActiveUS11821359B2

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized parts by optimizing the arrangement of crank pins and connecting rods.

Engine with intake valves operated by camshaft

PatentInactiveEP1943411A1

Innovation

- The engine operates intake valves by a camshaft that adjusts its rotational speed during closing operations by starting the opening of another intake valve, ensuring each intake valve closes at a more advanced crank angle relative to its rotational speed, thus compensating for decreased rotational speed and maintaining uniform intake air quantity across cylinders.

Environmental Impact

The environmental impact of V8 engine patents and innovations is a critical aspect to consider in the automotive industry's ongoing efforts to reduce carbon emissions and improve sustainability. V8 engines, known for their power and performance, have traditionally been associated with higher fuel consumption and emissions compared to smaller engine configurations. However, recent patent innovations in V8 engine technology have aimed to address these environmental concerns while maintaining the engine's desirable characteristics.

One significant area of innovation focuses on improving fuel efficiency through advanced combustion techniques. Patents related to direct fuel injection, variable valve timing, and cylinder deactivation have contributed to reducing fuel consumption in V8 engines. These technologies allow for more precise control over the combustion process, optimizing fuel usage and reducing waste. As a result, modern V8 engines can achieve better fuel economy ratings than their predecessors, mitigating their environmental impact.

Emissions reduction has been another key target for V8 engine patents. Innovations in exhaust gas recirculation (EGR) systems and catalytic converter designs have led to significant reductions in harmful emissions such as nitrogen oxides (NOx) and particulate matter. Some patents have explored the integration of hybrid technologies with V8 engines, combining electric motors with the internal combustion engine to further reduce emissions during city driving and low-speed operations.

The development of lightweight materials and advanced manufacturing techniques has also played a role in improving the environmental performance of V8 engines. Patents related to the use of aluminum alloys, carbon fiber components, and 3D-printed parts have contributed to reducing the overall weight of V8 engines and the vehicles they power. This weight reduction translates to improved fuel efficiency and lower emissions over the vehicle's lifecycle.

Furthermore, patents focusing on thermal management and waste heat recovery systems have emerged as promising avenues for enhancing V8 engine efficiency. These innovations aim to capture and utilize the heat energy typically lost through the exhaust system, converting it into useful power or using it to warm up the engine more quickly, thereby reducing cold-start emissions.

While these patent innovations have undoubtedly improved the environmental performance of V8 engines, it is important to note that the automotive industry's shift towards electrification poses challenges to the long-term viability of V8 engines in many markets. However, the technologies developed through these patents may find applications in other engine configurations or contribute to the development of more efficient powertrains in the future, extending their environmental benefits beyond V8 engines themselves.

One significant area of innovation focuses on improving fuel efficiency through advanced combustion techniques. Patents related to direct fuel injection, variable valve timing, and cylinder deactivation have contributed to reducing fuel consumption in V8 engines. These technologies allow for more precise control over the combustion process, optimizing fuel usage and reducing waste. As a result, modern V8 engines can achieve better fuel economy ratings than their predecessors, mitigating their environmental impact.

Emissions reduction has been another key target for V8 engine patents. Innovations in exhaust gas recirculation (EGR) systems and catalytic converter designs have led to significant reductions in harmful emissions such as nitrogen oxides (NOx) and particulate matter. Some patents have explored the integration of hybrid technologies with V8 engines, combining electric motors with the internal combustion engine to further reduce emissions during city driving and low-speed operations.

The development of lightweight materials and advanced manufacturing techniques has also played a role in improving the environmental performance of V8 engines. Patents related to the use of aluminum alloys, carbon fiber components, and 3D-printed parts have contributed to reducing the overall weight of V8 engines and the vehicles they power. This weight reduction translates to improved fuel efficiency and lower emissions over the vehicle's lifecycle.

Furthermore, patents focusing on thermal management and waste heat recovery systems have emerged as promising avenues for enhancing V8 engine efficiency. These innovations aim to capture and utilize the heat energy typically lost through the exhaust system, converting it into useful power or using it to warm up the engine more quickly, thereby reducing cold-start emissions.

While these patent innovations have undoubtedly improved the environmental performance of V8 engines, it is important to note that the automotive industry's shift towards electrification poses challenges to the long-term viability of V8 engines in many markets. However, the technologies developed through these patents may find applications in other engine configurations or contribute to the development of more efficient powertrains in the future, extending their environmental benefits beyond V8 engines themselves.

Regulatory Landscape

The regulatory landscape surrounding V8 engine patents is complex and multifaceted, involving various national and international legal frameworks. Patent laws and regulations play a crucial role in protecting intellectual property rights and fostering innovation in the automotive industry. In the context of V8 engine technology, regulatory bodies such as the United States Patent and Trademark Office (USPTO) and the European Patent Office (EPO) are key players in granting and enforcing patent rights.

These regulatory bodies have established specific guidelines and criteria for patentability, including novelty, non-obviousness, and industrial applicability. For V8 engine innovations, meeting these criteria often requires demonstrating significant improvements in performance, efficiency, or emissions reduction. The increasing focus on environmental regulations has also impacted the patent landscape, with many jurisdictions implementing stricter emissions standards that drive innovation in engine technology.

International agreements, such as the Patent Cooperation Treaty (PCT), facilitate the process of obtaining patent protection across multiple countries. This is particularly relevant for V8 engine patents, as automotive manufacturers often seek global protection for their innovations. However, the interpretation and enforcement of patent rights can vary significantly between jurisdictions, creating challenges for companies operating in multiple markets.

The regulatory landscape also encompasses antitrust and competition laws, which can impact the licensing and use of patented V8 engine technologies. In some cases, regulatory bodies may intervene to ensure fair competition and prevent monopolistic practices, particularly when essential patents are involved. This has led to the development of concepts such as FRAND (Fair, Reasonable, and Non-Discriminatory) licensing terms for standard-essential patents in the automotive industry.

Recent years have seen an increased focus on sustainability and environmental protection in regulatory frameworks. This has resulted in more stringent emissions standards and fuel efficiency requirements, driving innovation in V8 engine technology. Patents related to improvements in fuel injection systems, exhaust gas recirculation, and advanced materials for engine components have become increasingly valuable in this regulatory environment.

The regulatory landscape also includes provisions for patent challenges and litigation. Inter partes reviews and post-grant proceedings provide mechanisms for challenging the validity of granted patents, which can significantly impact the value and enforceability of V8 engine patents. Additionally, the rise of non-practicing entities (NPEs) or "patent trolls" has led to increased scrutiny of patent quality and efforts to reform patent laws to prevent abusive litigation practices.

These regulatory bodies have established specific guidelines and criteria for patentability, including novelty, non-obviousness, and industrial applicability. For V8 engine innovations, meeting these criteria often requires demonstrating significant improvements in performance, efficiency, or emissions reduction. The increasing focus on environmental regulations has also impacted the patent landscape, with many jurisdictions implementing stricter emissions standards that drive innovation in engine technology.

International agreements, such as the Patent Cooperation Treaty (PCT), facilitate the process of obtaining patent protection across multiple countries. This is particularly relevant for V8 engine patents, as automotive manufacturers often seek global protection for their innovations. However, the interpretation and enforcement of patent rights can vary significantly between jurisdictions, creating challenges for companies operating in multiple markets.

The regulatory landscape also encompasses antitrust and competition laws, which can impact the licensing and use of patented V8 engine technologies. In some cases, regulatory bodies may intervene to ensure fair competition and prevent monopolistic practices, particularly when essential patents are involved. This has led to the development of concepts such as FRAND (Fair, Reasonable, and Non-Discriminatory) licensing terms for standard-essential patents in the automotive industry.

Recent years have seen an increased focus on sustainability and environmental protection in regulatory frameworks. This has resulted in more stringent emissions standards and fuel efficiency requirements, driving innovation in V8 engine technology. Patents related to improvements in fuel injection systems, exhaust gas recirculation, and advanced materials for engine components have become increasingly valuable in this regulatory environment.

The regulatory landscape also includes provisions for patent challenges and litigation. Inter partes reviews and post-grant proceedings provide mechanisms for challenging the validity of granted patents, which can significantly impact the value and enforceability of V8 engine patents. Additionally, the rise of non-practicing entities (NPEs) or "patent trolls" has led to increased scrutiny of patent quality and efforts to reform patent laws to prevent abusive litigation practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!