Anode-Free Lithium-Sulfur Concepts: Feasibility And Roadmap

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Li-S Battery Background and Objectives

Lithium-sulfur (Li-S) batteries have emerged as a promising next-generation energy storage technology due to their theoretical energy density of 2600 Wh/kg, which far exceeds that of conventional lithium-ion batteries (typically 250-300 Wh/kg). The development of Li-S battery technology can be traced back to the 1960s, but significant progress has been made in the past decade with the advancement of materials science and nanotechnology.

Traditional Li-S batteries face several challenges, including the shuttle effect of polysulfides, volume expansion of sulfur cathodes, and dendrite formation on lithium metal anodes. These issues have limited their practical application despite their theoretical advantages. The concept of anode-free Li-S batteries represents a revolutionary approach to address these limitations while further increasing energy density and reducing costs.

Anode-free Li-S battery designs eliminate the pre-loaded lithium metal anode, instead relying on in-situ plating of lithium ions onto a current collector during the initial charging process. This configuration offers several advantages: increased energy density by removing the weight and volume of the anode, reduced manufacturing costs, and enhanced safety by eliminating the highly reactive lithium metal during production and storage.

The evolution of this technology has been driven by the growing demand for high-energy-density batteries in electric vehicles, portable electronics, and grid-scale energy storage. Market projections indicate that the global electric vehicle battery market will reach $84 billion by 2025, creating significant opportunities for advanced battery technologies like anode-free Li-S systems.

The primary technical objectives for anode-free Li-S battery development include achieving stable cycling performance (>500 cycles), high Coulombic efficiency (>99.5%), practical energy densities exceeding 400 Wh/kg, and cost reduction to below $100/kWh. These targets align with the U.S. Department of Energy's goals for next-generation battery systems and the requirements for commercial viability in automotive applications.

Current research is focused on developing novel electrolytes that enable uniform lithium deposition, designing advanced current collectors with optimized surface properties, and creating effective strategies to mitigate polysulfide shuttling. The integration of these components into a functional anode-free Li-S system represents a significant technical challenge that requires interdisciplinary collaboration.

The successful development of anode-free Li-S technology could potentially disrupt the energy storage landscape by offering a sustainable alternative to conventional lithium-ion batteries with higher energy density, lower cost, and reduced environmental impact. This aligns with global efforts to transition to renewable energy sources and reduce carbon emissions through electrification of transportation and other sectors.

Traditional Li-S batteries face several challenges, including the shuttle effect of polysulfides, volume expansion of sulfur cathodes, and dendrite formation on lithium metal anodes. These issues have limited their practical application despite their theoretical advantages. The concept of anode-free Li-S batteries represents a revolutionary approach to address these limitations while further increasing energy density and reducing costs.

Anode-free Li-S battery designs eliminate the pre-loaded lithium metal anode, instead relying on in-situ plating of lithium ions onto a current collector during the initial charging process. This configuration offers several advantages: increased energy density by removing the weight and volume of the anode, reduced manufacturing costs, and enhanced safety by eliminating the highly reactive lithium metal during production and storage.

The evolution of this technology has been driven by the growing demand for high-energy-density batteries in electric vehicles, portable electronics, and grid-scale energy storage. Market projections indicate that the global electric vehicle battery market will reach $84 billion by 2025, creating significant opportunities for advanced battery technologies like anode-free Li-S systems.

The primary technical objectives for anode-free Li-S battery development include achieving stable cycling performance (>500 cycles), high Coulombic efficiency (>99.5%), practical energy densities exceeding 400 Wh/kg, and cost reduction to below $100/kWh. These targets align with the U.S. Department of Energy's goals for next-generation battery systems and the requirements for commercial viability in automotive applications.

Current research is focused on developing novel electrolytes that enable uniform lithium deposition, designing advanced current collectors with optimized surface properties, and creating effective strategies to mitigate polysulfide shuttling. The integration of these components into a functional anode-free Li-S system represents a significant technical challenge that requires interdisciplinary collaboration.

The successful development of anode-free Li-S technology could potentially disrupt the energy storage landscape by offering a sustainable alternative to conventional lithium-ion batteries with higher energy density, lower cost, and reduced environmental impact. This aligns with global efforts to transition to renewable energy sources and reduce carbon emissions through electrification of transportation and other sectors.

Market Demand Analysis for Next-Generation Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. Current projections indicate the energy storage market will reach $546 billion by 2035, with a compound annual growth rate of approximately 20% between 2023 and 2035. Within this expanding landscape, next-generation battery technologies, particularly lithium-sulfur (Li-S) batteries, are positioned to capture significant market share due to their theoretical advantages over conventional lithium-ion batteries.

Anode-free lithium-sulfur battery concepts represent a particularly promising segment within this market. The demand for these advanced energy storage solutions is being fueled by several converging factors. First, the electric vehicle (EV) market continues its rapid expansion, with global EV sales projected to increase from 10.5 million units in 2022 to over 45 million by 2030. These vehicles require batteries with higher energy density, longer lifespan, and improved safety profiles – precisely the advantages that anode-free Li-S technology promises to deliver.

The aerospace and defense sectors present another significant market opportunity. With theoretical energy densities up to 2,600 Wh/kg (compared to 250-300 Wh/kg for current lithium-ion batteries), anode-free Li-S batteries could revolutionize electric aviation and satellite power systems. Major aerospace companies have already begun investing in Li-S research partnerships, signaling strong industry interest.

Consumer electronics manufacturers are also closely monitoring developments in this field, as the demand for longer-lasting portable devices continues to grow. Market research indicates that battery performance remains a top consumer pain point, with 73% of smartphone users citing battery life as a critical purchasing factor.

Grid-scale energy storage represents perhaps the largest potential market for advanced battery technologies. As renewable energy generation increases globally, the need for efficient, high-capacity storage solutions becomes more acute. The intermittent nature of solar and wind power necessitates storage systems that can efficiently capture excess energy during peak production periods and discharge it during high demand. Anode-free Li-S systems, with their potential for lower cost per kWh and reduced environmental impact, could address this growing market need.

From a regional perspective, Asia-Pacific currently leads battery technology development and manufacturing, but significant research initiatives in North America and Europe indicate a global race to commercialize next-generation energy storage solutions. Government policies supporting clean energy transition further amplify market demand, with many countries implementing regulatory frameworks and financial incentives that favor advanced battery technologies.

Anode-free lithium-sulfur battery concepts represent a particularly promising segment within this market. The demand for these advanced energy storage solutions is being fueled by several converging factors. First, the electric vehicle (EV) market continues its rapid expansion, with global EV sales projected to increase from 10.5 million units in 2022 to over 45 million by 2030. These vehicles require batteries with higher energy density, longer lifespan, and improved safety profiles – precisely the advantages that anode-free Li-S technology promises to deliver.

The aerospace and defense sectors present another significant market opportunity. With theoretical energy densities up to 2,600 Wh/kg (compared to 250-300 Wh/kg for current lithium-ion batteries), anode-free Li-S batteries could revolutionize electric aviation and satellite power systems. Major aerospace companies have already begun investing in Li-S research partnerships, signaling strong industry interest.

Consumer electronics manufacturers are also closely monitoring developments in this field, as the demand for longer-lasting portable devices continues to grow. Market research indicates that battery performance remains a top consumer pain point, with 73% of smartphone users citing battery life as a critical purchasing factor.

Grid-scale energy storage represents perhaps the largest potential market for advanced battery technologies. As renewable energy generation increases globally, the need for efficient, high-capacity storage solutions becomes more acute. The intermittent nature of solar and wind power necessitates storage systems that can efficiently capture excess energy during peak production periods and discharge it during high demand. Anode-free Li-S systems, with their potential for lower cost per kWh and reduced environmental impact, could address this growing market need.

From a regional perspective, Asia-Pacific currently leads battery technology development and manufacturing, but significant research initiatives in North America and Europe indicate a global race to commercialize next-generation energy storage solutions. Government policies supporting clean energy transition further amplify market demand, with many countries implementing regulatory frameworks and financial incentives that favor advanced battery technologies.

Technical Challenges and Global Research Status

Anode-free lithium-sulfur (Li-S) batteries face significant technical challenges despite their theoretical advantages of high energy density and cost-effectiveness. The primary obstacle remains the "shuttle effect," where soluble polysulfide intermediates migrate between electrodes during cycling, causing rapid capacity fading and shortened battery life. This phenomenon is particularly pronounced in anode-free configurations where no pre-lithiated anode exists to compensate for lithium loss.

Another critical challenge is the formation and stability of the solid electrolyte interphase (SEI) on the lithium metal surface. Without proper protection, lithium tends to form dendrites during cycling, leading to safety hazards and eventual short-circuiting. In anode-free designs, this challenge is magnified as lithium must be efficiently plated and stripped with each cycle.

The volumetric expansion of sulfur during lithiation (approximately 80%) creates mechanical stress within the cathode structure, leading to pulverization and loss of electrical contact. This issue becomes more pronounced over extended cycling, resulting in capacity degradation that has proven difficult to mitigate in practical applications.

Electrolyte stability presents another significant hurdle. Most electrolytes that facilitate lithium-ion transport also dissolve polysulfides, creating a fundamental contradiction in requirements. Developing electrolytes that simultaneously suppress the shuttle effect while maintaining high ionic conductivity remains an active research challenge.

Globally, research efforts are concentrated in several key regions. China leads in publication volume, with significant contributions from institutions like the Chinese Academy of Sciences and Tsinghua University focusing on novel cathode architectures and electrolyte formulations. North American research, particularly from Stanford University and Pacific Northwest National Laboratory, emphasizes fundamental understanding of reaction mechanisms and advanced characterization techniques.

European research centers, including institutions in Germany and the UK, have made notable progress in computational modeling of Li-S systems and development of specialized separators. South Korean and Japanese efforts have concentrated on industrial scalability and integration with existing manufacturing processes.

Recent breakthroughs include the development of functional interlayers that physically restrict polysulfide migration, single-atom catalysts that promote complete conversion reactions, and artificial SEI formulations that stabilize the lithium-electrolyte interface. Despite these advances, commercial viability of anode-free Li-S batteries remains distant, with most prototypes demonstrating fewer than 100 stable cycles under practical conditions.

Another critical challenge is the formation and stability of the solid electrolyte interphase (SEI) on the lithium metal surface. Without proper protection, lithium tends to form dendrites during cycling, leading to safety hazards and eventual short-circuiting. In anode-free designs, this challenge is magnified as lithium must be efficiently plated and stripped with each cycle.

The volumetric expansion of sulfur during lithiation (approximately 80%) creates mechanical stress within the cathode structure, leading to pulverization and loss of electrical contact. This issue becomes more pronounced over extended cycling, resulting in capacity degradation that has proven difficult to mitigate in practical applications.

Electrolyte stability presents another significant hurdle. Most electrolytes that facilitate lithium-ion transport also dissolve polysulfides, creating a fundamental contradiction in requirements. Developing electrolytes that simultaneously suppress the shuttle effect while maintaining high ionic conductivity remains an active research challenge.

Globally, research efforts are concentrated in several key regions. China leads in publication volume, with significant contributions from institutions like the Chinese Academy of Sciences and Tsinghua University focusing on novel cathode architectures and electrolyte formulations. North American research, particularly from Stanford University and Pacific Northwest National Laboratory, emphasizes fundamental understanding of reaction mechanisms and advanced characterization techniques.

European research centers, including institutions in Germany and the UK, have made notable progress in computational modeling of Li-S systems and development of specialized separators. South Korean and Japanese efforts have concentrated on industrial scalability and integration with existing manufacturing processes.

Recent breakthroughs include the development of functional interlayers that physically restrict polysulfide migration, single-atom catalysts that promote complete conversion reactions, and artificial SEI formulations that stabilize the lithium-electrolyte interface. Despite these advances, commercial viability of anode-free Li-S batteries remains distant, with most prototypes demonstrating fewer than 100 stable cycles under practical conditions.

Current Anode-Free Li-S Battery Design Approaches

01 Design of anode-free lithium-sulfur battery structures

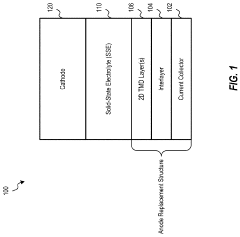

Anode-free lithium-sulfur batteries can be designed with specific structural configurations to enhance performance. These designs typically involve a cathode containing sulfur, a separator, and a current collector that allows lithium deposition during charging. The absence of a pre-loaded lithium anode reduces weight and increases energy density. Various architectural approaches include using specialized current collectors, protective layers, and optimized cell configurations to facilitate efficient lithium plating and stripping.- Anode-free lithium-sulfur battery design principles: Anode-free lithium-sulfur batteries represent a novel battery architecture that eliminates the traditional lithium metal anode during assembly. Instead, lithium ions are plated onto a current collector during the first charge cycle, forming an in-situ lithium anode. This design significantly increases energy density by reducing battery weight and volume while addressing safety concerns associated with traditional lithium metal anodes. The feasibility of this approach depends on optimizing the current collector material and structure to ensure uniform lithium deposition.

- Electrolyte formulations for anode-free lithium-sulfur batteries: Specialized electrolyte formulations are critical for the feasibility of anode-free lithium-sulfur batteries. These electrolytes must facilitate efficient lithium ion transport while suppressing the shuttle effect of polysulfides. Additives such as lithium nitrate and fluorinated compounds help form stable solid electrolyte interphases on the in-situ formed lithium anode. Dual-salt electrolytes and high-concentration electrolytes have shown promise in improving coulombic efficiency and cycle life by promoting uniform lithium deposition and minimizing side reactions with the sulfur cathode.

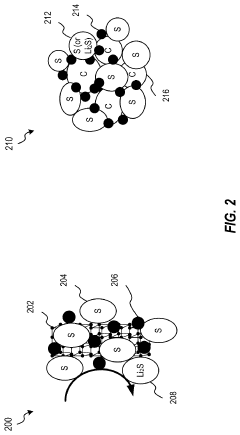

- Cathode materials and structures for sulfur utilization: Advanced cathode materials and structures are essential for maximizing sulfur utilization in anode-free lithium-sulfur batteries. Porous carbon hosts with tailored pore structures can physically confine sulfur and polysulfides while providing conductive pathways for electrons. Functionalized carbon materials with polar groups can chemically bind polysulfides, reducing their dissolution. Composite cathodes incorporating metal oxides or sulfides as catalysts can accelerate the conversion reactions of polysulfides, improving rate capability and cycling stability of these battery systems.

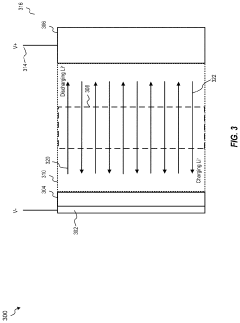

- Protective interfaces and interlayers: Protective interfaces and interlayers play a crucial role in the feasibility of anode-free lithium-sulfur batteries. These components are designed to prevent direct contact between the in-situ formed lithium anode and the sulfur cathode, mitigating the shuttle effect. Functional separators with selective permeability allow lithium ion transport while blocking polysulfide migration. Artificial solid electrolyte interphase layers applied to current collectors can guide uniform lithium deposition and prevent dendrite formation, significantly improving cycling stability and safety of these battery systems.

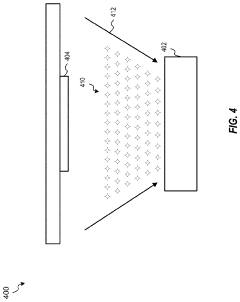

- Cell design and manufacturing considerations: Practical implementation of anode-free lithium-sulfur batteries requires careful cell design and manufacturing considerations. Pressure regulation within the cell is critical to maintain intimate contact between components as volume changes occur during cycling. Advanced manufacturing techniques such as dry electrode processing can reduce environmental impact and cost while improving electrode quality. Stacking and packaging configurations must accommodate the volume expansion of sulfur during discharge while maintaining mechanical stability. These engineering aspects are essential for translating the theoretical advantages of anode-free lithium-sulfur batteries into commercially viable energy storage solutions.

02 Electrolyte formulations for anode-free lithium-sulfur batteries

Specialized electrolyte formulations are crucial for the feasibility of anode-free lithium-sulfur batteries. These electrolytes must facilitate uniform lithium deposition, suppress dendrite formation, and mitigate the shuttle effect of polysulfides. Formulations may include lithium salts, solvents, and additives specifically designed to create stable solid electrolyte interphases. Functional additives can help control lithium nucleation and growth while preventing side reactions that would otherwise lead to capacity fade and safety issues.Expand Specific Solutions03 Cathode materials and modifications for sulfur utilization

Advanced cathode materials and modifications are essential for maximizing sulfur utilization in anode-free configurations. These include carbon-based hosts with hierarchical porosity, conductive polymers, and metal oxide additives that can trap polysulfides and enhance electronic conductivity. Surface modifications of cathode materials can improve the adsorption of polysulfides and facilitate their conversion. These approaches address the insulating nature of sulfur and its discharge products while accommodating the volume changes during cycling.Expand Specific Solutions04 Interface engineering for stable lithium deposition

Interface engineering is critical for achieving stable lithium deposition in anode-free lithium-sulfur batteries. This involves creating artificial interfaces or protective layers on current collectors to guide uniform lithium nucleation and growth. Approaches include surface modification of current collectors with lithiophilic materials, application of artificial solid electrolyte interphases, and introduction of three-dimensional host structures. These strategies help prevent dendrite formation and improve cycling stability by controlling the lithium deposition process.Expand Specific Solutions05 Performance evaluation and practical feasibility assessment

Comprehensive performance evaluation is necessary to assess the practical feasibility of anode-free lithium-sulfur batteries. This includes analysis of energy density, power capability, cycle life, and safety characteristics under various operating conditions. Testing protocols may involve different charge-discharge rates, temperature ranges, and extended cycling to identify failure mechanisms. Economic and manufacturing considerations are also evaluated to determine commercial viability, including cost analysis, scalability of production processes, and compatibility with existing battery manufacturing infrastructure.Expand Specific Solutions

Key Industry Players and Research Institutions

Anode-Free Lithium-Sulfur battery technology is currently in the early development stage, with market growth projected as energy storage demands increase. The technology offers theoretical advantages in energy density but faces significant commercialization challenges. Key players include established battery manufacturers (LG Energy Solution, Samsung SDI) investing in R&D alongside specialized startups like Lyten and SES Holdings focusing on innovative approaches. Academic institutions (MIT, Xiamen University, Beihang University) are driving fundamental research, while materials companies (Johnson Matthey, XG Sciences) develop enabling components. Industry collaboration between battery manufacturers, materials suppliers, and research institutions is accelerating development, though commercial viability remains 3-5 years away pending solutions to stability and manufacturing challenges.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an innovative approach to anode-free lithium-sulfur battery technology focusing on advanced separator and electrolyte designs. Their system employs a copper current collector that serves as the anode substrate, eliminating the need for pre-lithiated anodes. During initial charging, lithium ions from the sulfur cathode plate onto this copper substrate, forming an in-situ lithium layer. LG's proprietary electrolyte formulation includes lithium salt additives and fluorinated solvents that form a stable solid electrolyte interphase (SEI) on the in-situ formed lithium, significantly reducing dendrite formation. Additionally, they've engineered functional separators with lithium-ion conductive ceramic coatings that further suppress polysulfide shuttling while maintaining high ionic conductivity, addressing one of the major challenges in lithium-sulfur chemistry.

Strengths: Eliminates costly and complex anode manufacturing; potentially higher energy density than conventional lithium-ion batteries; leverages existing manufacturing infrastructure. Weaknesses: Still faces challenges with cycle life stability; dendrite formation remains a concern despite mitigation strategies; electrolyte optimization continues to be necessary for commercial viability.

Lyten, Inc.

Technical Solution: Lyten has developed a proprietary 3D Graphene platform specifically for anode-free lithium-sulfur batteries. Their approach involves creating a three-dimensional graphene structure that serves as a host for sulfur cathodes while eliminating the need for traditional lithium metal anodes. The company's technology uses a lithium-free anode current collector where lithium ions plate during the initial charge cycle, forming an in-situ lithium layer. This design addresses the key challenges of lithium-sulfur chemistry by effectively containing polysulfide shuttling through their 3D Graphene matrix, which provides conductive pathways and physical barriers to trap sulfur species. Lyten claims their batteries can achieve energy densities exceeding 900 Wh/kg, significantly higher than conventional lithium-ion batteries, while maintaining stability over hundreds of cycles.

Strengths: Superior energy density (>900 Wh/kg) compared to conventional lithium-ion; lightweight design ideal for aerospace and defense applications; uses abundant, low-cost sulfur. Weaknesses: Still working to improve cycle life for commercial applications; requires specialized manufacturing processes; temperature sensitivity may limit some applications.

Critical Patents and Scientific Breakthroughs

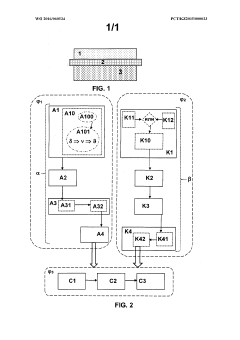

Anode-less lithium-sulfur (li-s) battery with lithium metal-free current

PatentInactiveUS20220223868A1

Innovation

- Implementing a lithium metal-free current collector coated with two-dimensional (2D) transition metal dichalcogenide (TMD) materials, such as MoS2, to prevent dendrite growth and enhance ion transport, combined with a solid-state electrolyte and a carbon matrix structure to trap polysulfides, thereby improving energy density and cycle life.

Lithium metal-free silicon/sulphur battery

PatentWO2016060534A2

Innovation

- A lithium metal-free rechargeable silicon/sulfur battery design featuring a prelithiated silicon/polyacrylonitrile composite anode and a sulfur/polyacrylonitrile composite cathode, with optimized silicon and sulfur mass content, electrical conductivity, and fixation using conductive polymers and carbon-based materials, and an organic electrolyte to enhance performance.

Material Supply Chain Considerations

The supply chain for anode-free lithium-sulfur batteries presents both significant opportunities and challenges for commercial implementation. Sulfur represents an abundant, low-cost material with global reserves estimated at over 5 billion tons, primarily as a byproduct of petroleum refining and natural gas processing. This abundance contrasts sharply with traditional lithium-ion battery materials like cobalt and nickel, which face supply constraints and geopolitical complications.

However, the lithium component remains a critical consideration. While lithium reserves are substantial globally, production capacity is concentrated in a limited number of regions, particularly the "Lithium Triangle" of Chile, Argentina, and Bolivia, which holds approximately 75% of the world's lithium brine resources. Australia also maintains significant hard-rock lithium mining operations. This geographic concentration creates potential supply vulnerabilities that must be addressed through diversification strategies.

The manufacturing infrastructure for anode-free lithium-sulfur batteries requires substantial modification compared to conventional lithium-ion production lines. Current battery manufacturing facilities would need significant retooling to accommodate the different electrode compositions and assembly processes. This transition represents a major capital investment hurdle but also an opportunity for countries seeking to establish new manufacturing capabilities without competing directly with entrenched lithium-ion production ecosystems.

Material purity requirements present another supply chain consideration. While sulfur is abundant, battery-grade sulfur requires additional processing to remove impurities that could compromise electrochemical performance. Similarly, the electrolyte components for lithium-sulfur batteries differ substantially from conventional systems, often requiring specialized additives to mitigate polysulfide shuttling effects.

The recyclability of lithium-sulfur batteries offers a potential advantage in supply chain sustainability. The theoretical simplicity of the sulfur cathode could enable more straightforward recycling processes compared to the complex mixed-metal oxides in conventional lithium-ion batteries. However, commercial-scale recycling infrastructure for these systems remains underdeveloped and requires further investment.

Scaling production presents perhaps the most immediate supply chain challenge. Current pilot-scale manufacturing of lithium-sulfur cells cannot meet the potential demand if the technology achieves widespread adoption in electric vehicles or grid storage applications. Establishing robust supply networks for specialized components like sulfur-carbon composite materials and lithium metal protection layers will be essential for commercial viability.

However, the lithium component remains a critical consideration. While lithium reserves are substantial globally, production capacity is concentrated in a limited number of regions, particularly the "Lithium Triangle" of Chile, Argentina, and Bolivia, which holds approximately 75% of the world's lithium brine resources. Australia also maintains significant hard-rock lithium mining operations. This geographic concentration creates potential supply vulnerabilities that must be addressed through diversification strategies.

The manufacturing infrastructure for anode-free lithium-sulfur batteries requires substantial modification compared to conventional lithium-ion production lines. Current battery manufacturing facilities would need significant retooling to accommodate the different electrode compositions and assembly processes. This transition represents a major capital investment hurdle but also an opportunity for countries seeking to establish new manufacturing capabilities without competing directly with entrenched lithium-ion production ecosystems.

Material purity requirements present another supply chain consideration. While sulfur is abundant, battery-grade sulfur requires additional processing to remove impurities that could compromise electrochemical performance. Similarly, the electrolyte components for lithium-sulfur batteries differ substantially from conventional systems, often requiring specialized additives to mitigate polysulfide shuttling effects.

The recyclability of lithium-sulfur batteries offers a potential advantage in supply chain sustainability. The theoretical simplicity of the sulfur cathode could enable more straightforward recycling processes compared to the complex mixed-metal oxides in conventional lithium-ion batteries. However, commercial-scale recycling infrastructure for these systems remains underdeveloped and requires further investment.

Scaling production presents perhaps the most immediate supply chain challenge. Current pilot-scale manufacturing of lithium-sulfur cells cannot meet the potential demand if the technology achieves widespread adoption in electric vehicles or grid storage applications. Establishing robust supply networks for specialized components like sulfur-carbon composite materials and lithium metal protection layers will be essential for commercial viability.

Safety and Scalability Assessment

The safety and scalability of anode-free lithium-sulfur (Li-S) battery concepts present significant challenges that must be addressed before widespread commercial adoption. Current safety concerns primarily revolve around lithium dendrite formation, which can lead to internal short circuits and thermal runaway events. Without a traditional anode structure to regulate lithium deposition, anode-free designs face heightened risks of uneven lithium plating during charging cycles, potentially compromising cell integrity and safety.

Thermal management represents another critical safety consideration. Li-S cells generally exhibit higher heat generation during operation compared to conventional lithium-ion batteries, particularly during high-rate charging and discharging. This thermal behavior necessitates advanced cooling systems and thermal management strategies to maintain safe operating temperatures and prevent thermal propagation between cells in larger battery packs.

From a scalability perspective, anode-free Li-S concepts face several manufacturing hurdles. The absence of a pre-lithiated anode requires precise control of electrolyte composition and volume to facilitate proper lithium deposition during initial charging. Current production techniques struggle to achieve the necessary uniformity across large-format cells, resulting in performance variations that impede mass production capabilities.

Material supply chains present additional scalability challenges. While sulfur offers advantages as an abundant and low-cost cathode material, the specialized electrolytes and separators required for anode-free Li-S systems often incorporate rare or expensive components. The lithium metal supply chain itself faces constraints, with concerns about long-term availability and price volatility as demand increases across the battery sector.

Production equipment compatibility represents another obstacle to scalability. Existing battery manufacturing lines designed for lithium-ion technologies require significant modifications to accommodate the unique assembly requirements of anode-free Li-S cells. The handling of reactive lithium-containing components demands specialized equipment and controlled environments, increasing capital investment requirements for mass production.

Regulatory frameworks for safety certification also impact scalability timelines. Current battery safety standards were largely developed for lithium-ion chemistries and may not adequately address the unique failure modes of anode-free Li-S systems. Establishing appropriate testing protocols and safety standards will require extensive validation testing and regulatory engagement, potentially delaying commercial scale-up efforts.

Thermal management represents another critical safety consideration. Li-S cells generally exhibit higher heat generation during operation compared to conventional lithium-ion batteries, particularly during high-rate charging and discharging. This thermal behavior necessitates advanced cooling systems and thermal management strategies to maintain safe operating temperatures and prevent thermal propagation between cells in larger battery packs.

From a scalability perspective, anode-free Li-S concepts face several manufacturing hurdles. The absence of a pre-lithiated anode requires precise control of electrolyte composition and volume to facilitate proper lithium deposition during initial charging. Current production techniques struggle to achieve the necessary uniformity across large-format cells, resulting in performance variations that impede mass production capabilities.

Material supply chains present additional scalability challenges. While sulfur offers advantages as an abundant and low-cost cathode material, the specialized electrolytes and separators required for anode-free Li-S systems often incorporate rare or expensive components. The lithium metal supply chain itself faces constraints, with concerns about long-term availability and price volatility as demand increases across the battery sector.

Production equipment compatibility represents another obstacle to scalability. Existing battery manufacturing lines designed for lithium-ion technologies require significant modifications to accommodate the unique assembly requirements of anode-free Li-S cells. The handling of reactive lithium-containing components demands specialized equipment and controlled environments, increasing capital investment requirements for mass production.

Regulatory frameworks for safety certification also impact scalability timelines. Current battery safety standards were largely developed for lithium-ion chemistries and may not adequately address the unique failure modes of anode-free Li-S systems. Establishing appropriate testing protocols and safety standards will require extensive validation testing and regulatory engagement, potentially delaying commercial scale-up efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!