Benchmarking Li-S Cells Under Realistic Duty Cycles

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Technology Background and Objectives

Lithium-sulfur (Li-S) batteries have emerged as a promising next-generation energy storage technology, attracting significant attention from both academia and industry over the past two decades. The fundamental chemistry of Li-S batteries was first explored in the 1960s, but substantial research momentum only began building in the early 2000s when the demand for higher energy density batteries became critical for various applications.

The core advantage of Li-S technology lies in its theoretical energy density of approximately 2600 Wh/kg, which significantly surpasses the theoretical limits of conventional lithium-ion batteries (typically 350-400 Wh/kg). This exceptional energy density potential stems from sulfur's ability to host multiple lithium ions per atom and its natural abundance as a low-cost material.

Despite these promising characteristics, the evolution of Li-S battery technology has been hindered by several persistent challenges. These include the insulating nature of sulfur, the shuttle effect caused by soluble polysulfide intermediates, and substantial volume changes during cycling. These issues have historically resulted in rapid capacity fading, low Coulombic efficiency, and limited cycle life.

Recent technological advancements have focused on addressing these fundamental challenges through innovative materials engineering approaches. Notable progress has been made in developing specialized carbon hosts, functional separators, and electrolyte additives that collectively mitigate the shuttle effect and enhance overall performance.

The current technological trajectory aims to bridge the gap between laboratory demonstrations and practical applications. While early research concentrated primarily on achieving high specific capacity, recent efforts have shifted toward balancing multiple performance metrics including cycle life, rate capability, and sulfur loading to meet real-world requirements.

The primary objective of benchmarking Li-S cells under realistic duty cycles is to evaluate their performance under conditions that accurately reflect actual usage scenarios. This approach represents a critical shift from idealized laboratory testing protocols toward application-oriented evaluation frameworks that can better predict real-world performance.

This benchmarking effort seeks to establish standardized testing methodologies that account for variable discharge rates, intermittent usage patterns, and environmental factors that significantly impact battery performance. By subjecting Li-S cells to these realistic operational conditions, researchers can identify specific failure mechanisms and performance limitations that may not be apparent under conventional testing regimes.

The ultimate goal is to accelerate the technological maturation of Li-S batteries by providing actionable insights that guide further research and development efforts. This approach aims to expedite the transition of Li-S technology from laboratory curiosity to commercial viability across multiple application domains including electric vehicles, aerospace, and grid storage systems.

The core advantage of Li-S technology lies in its theoretical energy density of approximately 2600 Wh/kg, which significantly surpasses the theoretical limits of conventional lithium-ion batteries (typically 350-400 Wh/kg). This exceptional energy density potential stems from sulfur's ability to host multiple lithium ions per atom and its natural abundance as a low-cost material.

Despite these promising characteristics, the evolution of Li-S battery technology has been hindered by several persistent challenges. These include the insulating nature of sulfur, the shuttle effect caused by soluble polysulfide intermediates, and substantial volume changes during cycling. These issues have historically resulted in rapid capacity fading, low Coulombic efficiency, and limited cycle life.

Recent technological advancements have focused on addressing these fundamental challenges through innovative materials engineering approaches. Notable progress has been made in developing specialized carbon hosts, functional separators, and electrolyte additives that collectively mitigate the shuttle effect and enhance overall performance.

The current technological trajectory aims to bridge the gap between laboratory demonstrations and practical applications. While early research concentrated primarily on achieving high specific capacity, recent efforts have shifted toward balancing multiple performance metrics including cycle life, rate capability, and sulfur loading to meet real-world requirements.

The primary objective of benchmarking Li-S cells under realistic duty cycles is to evaluate their performance under conditions that accurately reflect actual usage scenarios. This approach represents a critical shift from idealized laboratory testing protocols toward application-oriented evaluation frameworks that can better predict real-world performance.

This benchmarking effort seeks to establish standardized testing methodologies that account for variable discharge rates, intermittent usage patterns, and environmental factors that significantly impact battery performance. By subjecting Li-S cells to these realistic operational conditions, researchers can identify specific failure mechanisms and performance limitations that may not be apparent under conventional testing regimes.

The ultimate goal is to accelerate the technological maturation of Li-S batteries by providing actionable insights that guide further research and development efforts. This approach aims to expedite the transition of Li-S technology from laboratory curiosity to commercial viability across multiple application domains including electric vehicles, aerospace, and grid storage systems.

Market Analysis for Li-S Battery Applications

The lithium-sulfur (Li-S) battery market is experiencing significant growth potential due to the technology's promising energy density advantages over conventional lithium-ion batteries. Current market projections indicate that the global Li-S battery market could reach $2.1 billion by 2030, with a compound annual growth rate of approximately 35% from 2023 to 2030. This rapid growth trajectory is primarily driven by increasing demand for high-energy-density storage solutions across multiple sectors.

Aviation and aerospace applications represent the most immediate and high-value market opportunity for Li-S technology. These sectors prioritize energy density over cycle life, making them ideal early adopters. The drone market particularly stands out, with commercial and military UAV manufacturers actively seeking lightweight power solutions that can extend flight times beyond current limitations. Military applications alone could constitute 25% of the initial Li-S battery market.

Electric vehicles represent another substantial market segment, though with more stringent requirements. While the automotive sector demands both high energy density and extended cycle life, certain premium EV manufacturers are exploring Li-S technology for range-extended models where the weight advantages could offset current cycle life limitations. Market analysis suggests that by 2028, up to 5% of premium electric vehicles could incorporate Li-S cells in hybrid battery systems.

Consumer electronics manufacturers are also showing interest in Li-S technology, particularly for applications where device thinness and weight are critical selling points. Wearable technology and portable computing devices could benefit significantly from the volumetric advantages of Li-S cells, potentially creating a market segment worth $350 million by 2027.

Grid storage presents a longer-term opportunity, contingent upon significant improvements in cycle life and cost reduction. While current Li-S technology is not competitive in this space, research into specialized formulations for stationary applications is ongoing, with potential market entry expected post-2030.

Regional market analysis indicates that Asia-Pacific will likely dominate Li-S manufacturing, with China, South Korea, and Japan leading production capacity development. However, significant R&D investments in North America and Europe suggest a more distributed value chain than current lithium-ion technologies.

Market barriers include competition from solid-state lithium batteries, sodium-ion technologies, and continued improvements in conventional lithium-ion chemistry. Cost remains a significant factor, with current Li-S production costs approximately 30% higher than equivalent lithium-ion cells, though this gap is expected to narrow as manufacturing scales.

Aviation and aerospace applications represent the most immediate and high-value market opportunity for Li-S technology. These sectors prioritize energy density over cycle life, making them ideal early adopters. The drone market particularly stands out, with commercial and military UAV manufacturers actively seeking lightweight power solutions that can extend flight times beyond current limitations. Military applications alone could constitute 25% of the initial Li-S battery market.

Electric vehicles represent another substantial market segment, though with more stringent requirements. While the automotive sector demands both high energy density and extended cycle life, certain premium EV manufacturers are exploring Li-S technology for range-extended models where the weight advantages could offset current cycle life limitations. Market analysis suggests that by 2028, up to 5% of premium electric vehicles could incorporate Li-S cells in hybrid battery systems.

Consumer electronics manufacturers are also showing interest in Li-S technology, particularly for applications where device thinness and weight are critical selling points. Wearable technology and portable computing devices could benefit significantly from the volumetric advantages of Li-S cells, potentially creating a market segment worth $350 million by 2027.

Grid storage presents a longer-term opportunity, contingent upon significant improvements in cycle life and cost reduction. While current Li-S technology is not competitive in this space, research into specialized formulations for stationary applications is ongoing, with potential market entry expected post-2030.

Regional market analysis indicates that Asia-Pacific will likely dominate Li-S manufacturing, with China, South Korea, and Japan leading production capacity development. However, significant R&D investments in North America and Europe suggest a more distributed value chain than current lithium-ion technologies.

Market barriers include competition from solid-state lithium batteries, sodium-ion technologies, and continued improvements in conventional lithium-ion chemistry. Cost remains a significant factor, with current Li-S production costs approximately 30% higher than equivalent lithium-ion cells, though this gap is expected to narrow as manufacturing scales.

Current Challenges in Li-S Cell Performance Evaluation

Despite significant advancements in lithium-sulfur (Li-S) battery technology, standardized performance evaluation remains a critical challenge in the field. Current testing protocols predominantly employ constant current (CC) charging and discharging methods, which fail to represent real-world usage scenarios. This disconnect between laboratory testing and actual application conditions creates significant barriers to accurate performance assessment and meaningful comparison between different Li-S cell designs.

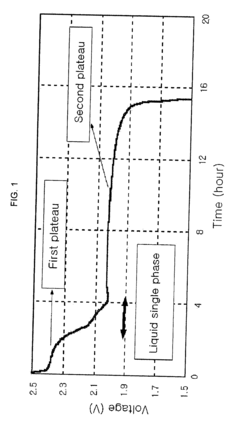

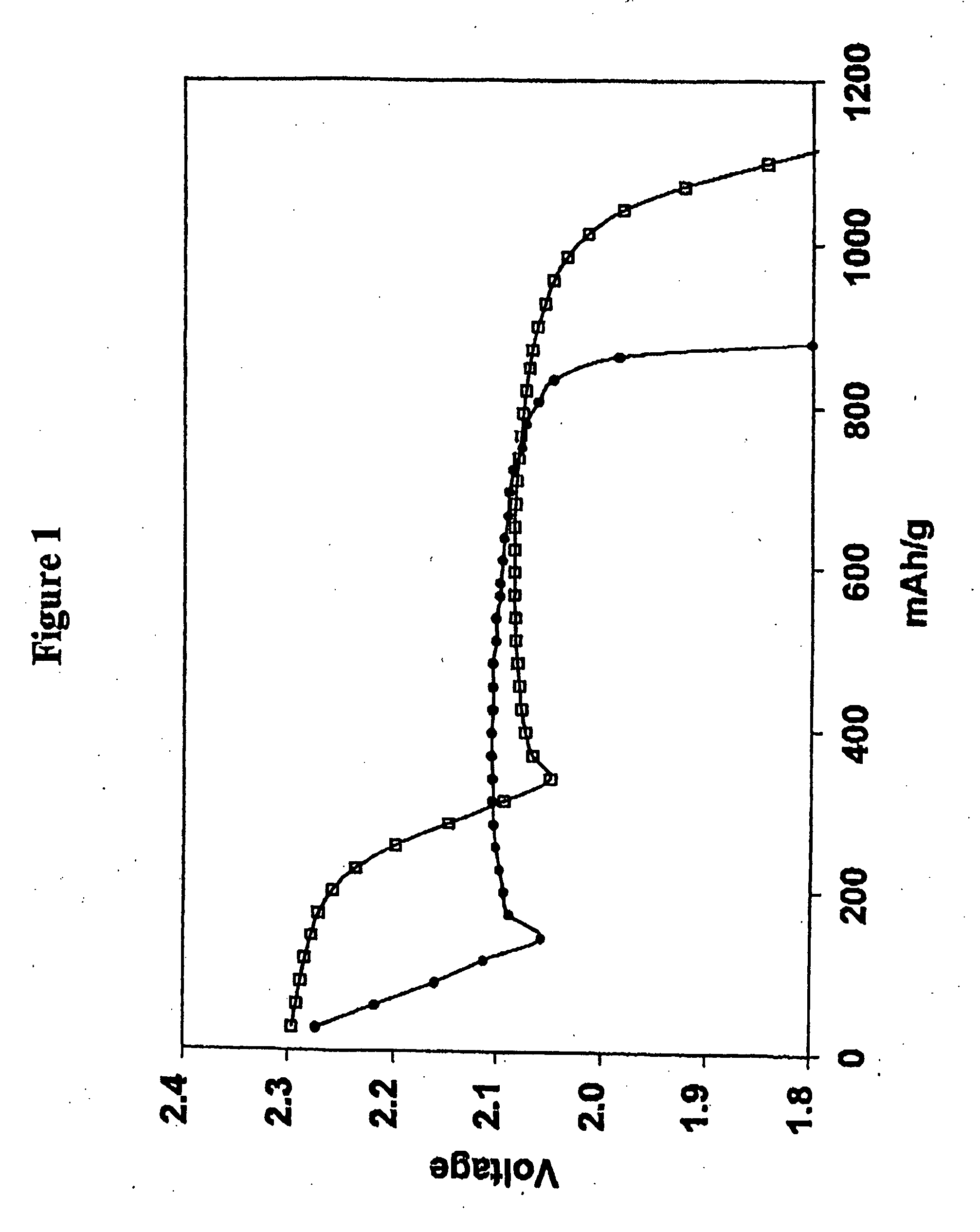

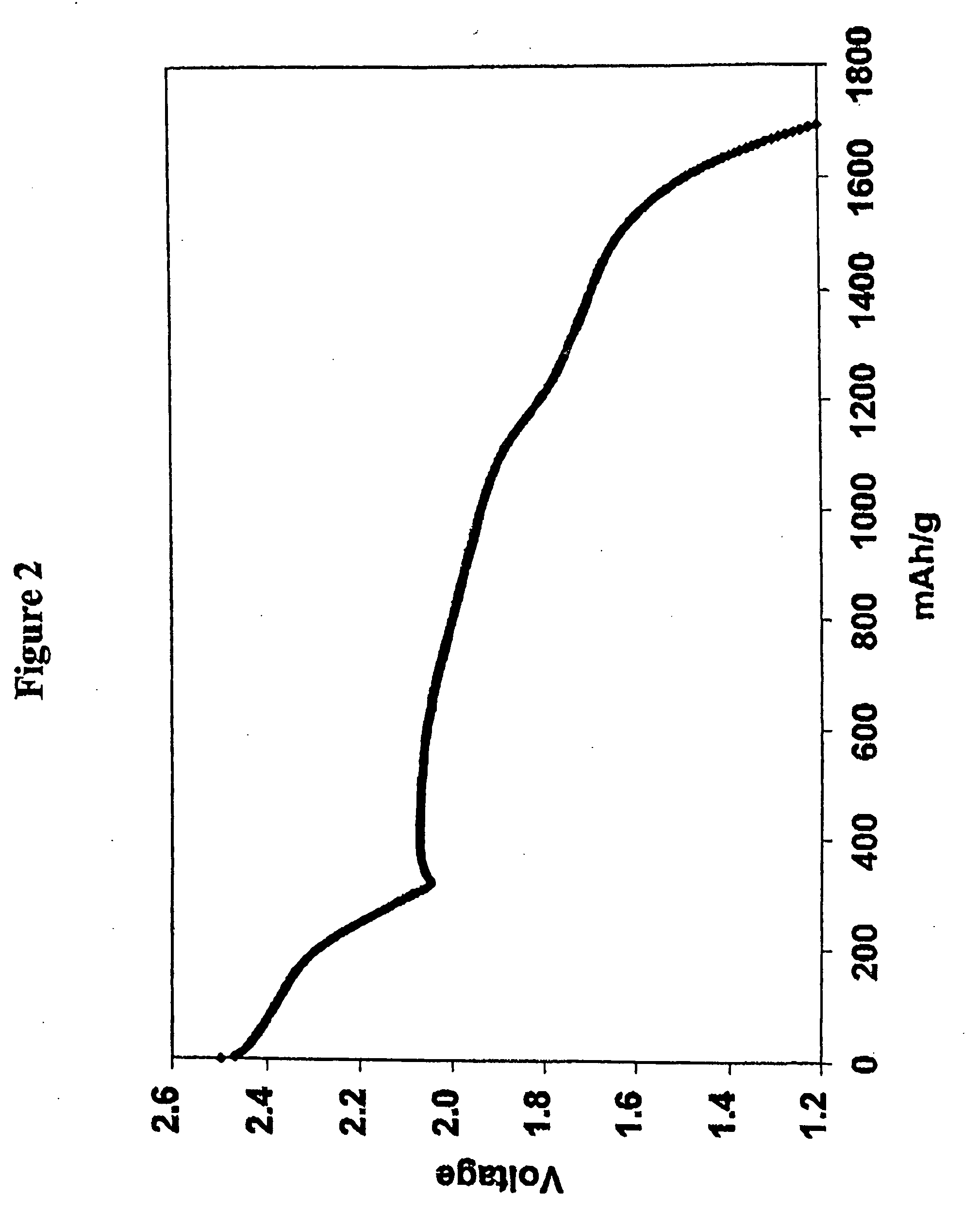

The unique electrochemical characteristics of Li-S cells, particularly their complex discharge profile with two distinct voltage plateaus, make them especially sensitive to dynamic load conditions. Unlike lithium-ion batteries, Li-S cells exhibit substantial capacity variations depending on discharge rates, rest periods, and temperature fluctuations. These sensitivities are inadequately captured by conventional testing methodologies, leading to overly optimistic performance projections that rarely translate to real-world applications.

Another significant challenge is the lack of industry-wide standardized testing protocols specifically designed for Li-S technology. While established protocols exist for lithium-ion batteries, direct application of these standards to Li-S cells yields misleading results due to fundamental differences in chemistry and behavior. This absence of standardization impedes meaningful cross-comparison between research efforts and hinders industrial adoption.

The polysulfide shuttle effect, a characteristic phenomenon in Li-S cells, presents additional evaluation complexities. This effect causes capacity fading and efficiency losses that manifest differently under dynamic versus static load conditions. Current evaluation methods often underestimate the impact of this phenomenon in practical applications, leading to discrepancies between reported and actual cycle life.

Temperature sensitivity represents another underaddressed factor in current evaluation practices. Li-S cells exhibit significantly different behavior across temperature ranges, with particular challenges at low temperatures where reaction kinetics slow dramatically. Most laboratory testing occurs under controlled room temperature conditions, failing to account for performance variations in real-world temperature fluctuations.

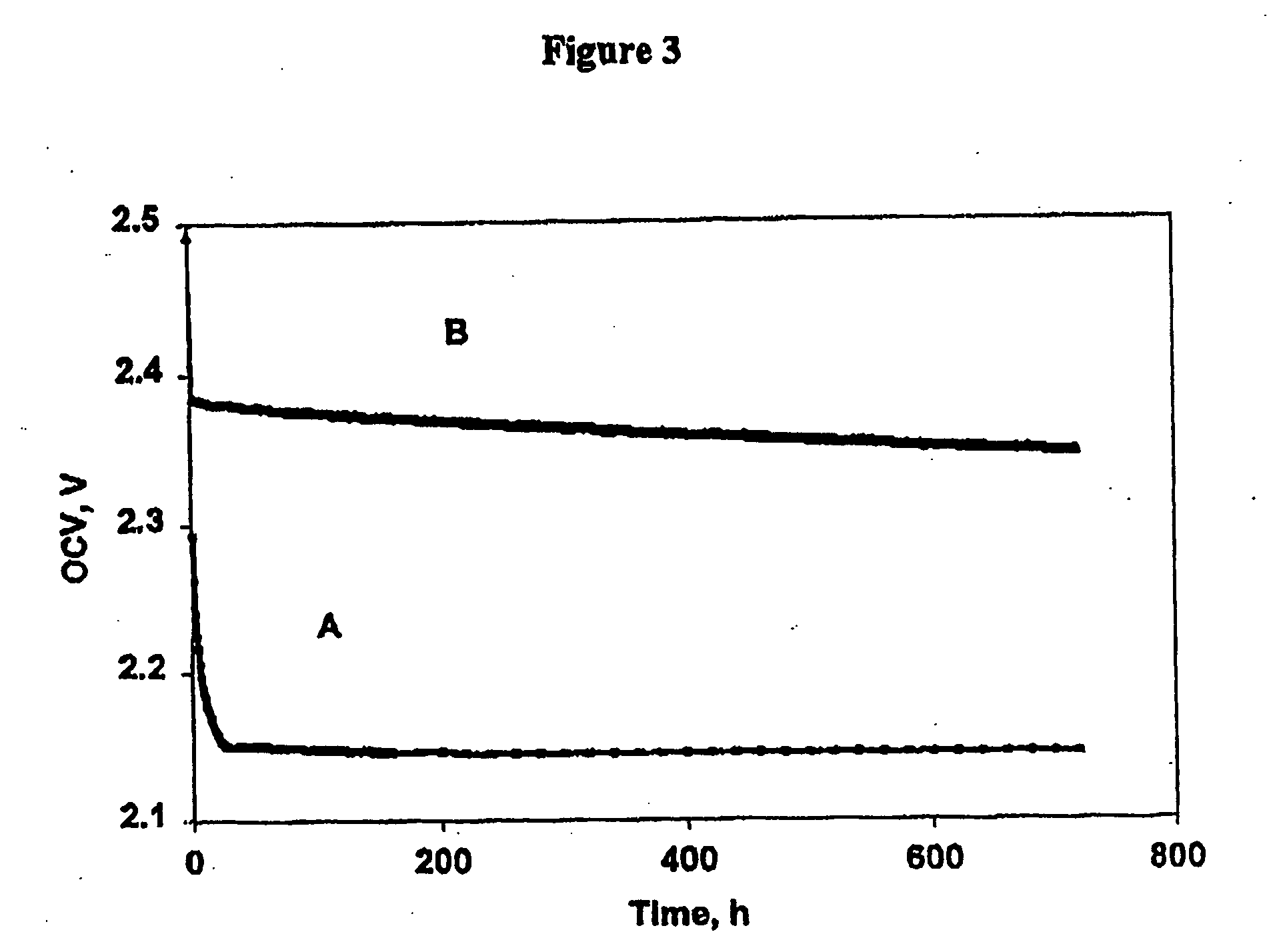

Self-discharge characteristics of Li-S cells also remain poorly characterized by current evaluation methods. The spontaneous reduction of higher-order polysulfides during rest periods leads to capacity loss that varies significantly with state of charge and temperature. This behavior is particularly relevant for applications with intermittent usage patterns but is rarely incorporated into standardized testing protocols.

The development of realistic duty cycles that accurately represent target applications remains perhaps the most pressing challenge. Different applications—from electric vehicles to grid storage—impose vastly different demand patterns on batteries, necessitating application-specific testing protocols that few research facilities currently implement.

The unique electrochemical characteristics of Li-S cells, particularly their complex discharge profile with two distinct voltage plateaus, make them especially sensitive to dynamic load conditions. Unlike lithium-ion batteries, Li-S cells exhibit substantial capacity variations depending on discharge rates, rest periods, and temperature fluctuations. These sensitivities are inadequately captured by conventional testing methodologies, leading to overly optimistic performance projections that rarely translate to real-world applications.

Another significant challenge is the lack of industry-wide standardized testing protocols specifically designed for Li-S technology. While established protocols exist for lithium-ion batteries, direct application of these standards to Li-S cells yields misleading results due to fundamental differences in chemistry and behavior. This absence of standardization impedes meaningful cross-comparison between research efforts and hinders industrial adoption.

The polysulfide shuttle effect, a characteristic phenomenon in Li-S cells, presents additional evaluation complexities. This effect causes capacity fading and efficiency losses that manifest differently under dynamic versus static load conditions. Current evaluation methods often underestimate the impact of this phenomenon in practical applications, leading to discrepancies between reported and actual cycle life.

Temperature sensitivity represents another underaddressed factor in current evaluation practices. Li-S cells exhibit significantly different behavior across temperature ranges, with particular challenges at low temperatures where reaction kinetics slow dramatically. Most laboratory testing occurs under controlled room temperature conditions, failing to account for performance variations in real-world temperature fluctuations.

Self-discharge characteristics of Li-S cells also remain poorly characterized by current evaluation methods. The spontaneous reduction of higher-order polysulfides during rest periods leads to capacity loss that varies significantly with state of charge and temperature. This behavior is particularly relevant for applications with intermittent usage patterns but is rarely incorporated into standardized testing protocols.

The development of realistic duty cycles that accurately represent target applications remains perhaps the most pressing challenge. Different applications—from electric vehicles to grid storage—impose vastly different demand patterns on batteries, necessitating application-specific testing protocols that few research facilities currently implement.

Benchmarking Methodologies for Li-S Cells

01 Electrode materials for improved Li-S cell performance

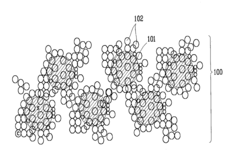

Various electrode materials can significantly enhance the performance of lithium-sulfur cells. These include carbon-based materials with optimized pore structures, conductive polymers, and metal oxides that can effectively trap polysulfides and improve electron transport. The incorporation of these materials helps address key challenges in Li-S cells such as the shuttle effect and low conductivity of sulfur, resulting in higher capacity retention and improved cycle life.- Electrode materials for improved Li-S cell performance: Various electrode materials can significantly enhance the performance of lithium-sulfur cells. These include specialized carbon-based materials, conductive polymers, and metal oxides that can effectively host sulfur and mitigate polysulfide shuttling. The incorporation of these materials can lead to higher capacity retention, improved cycling stability, and enhanced rate capability, which are critical performance metrics for Li-S cells.

- Electrolyte formulations for Li-S battery performance: Electrolyte composition plays a crucial role in the performance of lithium-sulfur batteries. Advanced electrolyte formulations incorporating additives, ionic liquids, or solid-state electrolytes can suppress polysulfide dissolution, enhance lithium ion conductivity, and improve the interfacial stability between electrodes and electrolyte. These formulations contribute to higher coulombic efficiency, extended cycle life, and better overall performance benchmarks for Li-S cells.

- Cell design and architecture optimization: The physical design and architecture of lithium-sulfur cells significantly impact their performance metrics. Innovations in cell configuration, separator design, current collector structures, and packaging can address challenges such as volume expansion during cycling, internal resistance, and thermal management. Optimized cell designs can lead to improved energy density, power capability, and operational safety of Li-S batteries.

- Performance testing and benchmarking methodologies: Standardized testing protocols and benchmarking methodologies are essential for accurately evaluating and comparing the performance of lithium-sulfur cells. These include specific testing conditions for cycle life assessment, rate capability tests, temperature performance evaluation, and self-discharge measurements. Advanced analytical techniques and diagnostic tools help in understanding degradation mechanisms and identifying performance bottlenecks in Li-S technology.

- Novel sulfur host materials and composites: Innovative sulfur host materials and composite structures can dramatically improve the performance of lithium-sulfur batteries. These include hierarchical porous structures, core-shell architectures, and functional composites that can effectively trap polysulfides, accommodate volume changes, and facilitate electron/ion transport. Such materials enable higher sulfur loading, improved utilization efficiency, and enhanced electrochemical performance, pushing the benchmarks for Li-S cell technology.

02 Electrolyte formulations for Li-S battery performance

Specialized electrolyte formulations play a crucial role in lithium-sulfur cell performance. These formulations often include additives that suppress polysulfide dissolution, form stable solid electrolyte interphases, and enhance ionic conductivity. Electrolytes with optimized salt concentrations, solvent mixtures, and functional additives can significantly improve the cycling stability, coulombic efficiency, and overall performance metrics of Li-S cells.Expand Specific Solutions03 Novel cell architectures and configurations

Innovative cell designs and architectures can substantially improve lithium-sulfur battery performance. These include advanced separator designs, interlayers between electrodes, and three-dimensional cell configurations that optimize sulfur utilization and minimize polysulfide shuttling. Such architectural innovations help address fundamental challenges in Li-S technology while improving energy density, power capability, and operational stability under various conditions.Expand Specific Solutions04 Performance evaluation methods and benchmarking protocols

Standardized testing protocols and evaluation methods are essential for accurate benchmarking of lithium-sulfur cells. These include specific cycling procedures, rate capability tests, temperature performance evaluations, and long-term stability assessments. Consistent benchmarking approaches enable meaningful comparisons between different Li-S cell technologies and help identify the most promising directions for further development and optimization.Expand Specific Solutions05 Sulfur host materials and composite structures

Advanced sulfur host materials and composite structures can dramatically improve the performance metrics of Li-S cells. These include hierarchical porous materials, yolk-shell structures, and core-shell composites that effectively encapsulate sulfur while providing sufficient space for volume expansion during cycling. Such host structures enhance sulfur utilization, improve electronic conductivity, and mitigate polysulfide dissolution, leading to superior capacity retention and cycle life.Expand Specific Solutions

Key Industry Players in Li-S Battery Development

Lithium-Sulfur (Li-S) battery technology is currently in the early commercialization phase, with a global market projected to reach $1.4 billion by 2028. The competitive landscape features established players like Robert Bosch GmbH and Samsung SDI alongside specialized innovators such as Sion Power and Lyten, who are pioneering Li-S cell development. Technical maturity varies significantly across companies, with Sion Power leading through its Licerion technology (500 Wh/kg), while BASF, Honeycomb Battery, and Blue Current focus on addressing key challenges like sulfur shuttling and cathode degradation. Academic institutions including Monash University and Beihang University contribute fundamental research, while automotive manufacturers like GM are exploring Li-S for EV applications, indicating growing industry confidence in realistic duty cycle performance.

Sion Power Corp.

Technical Solution: Sion Power has developed advanced lithium-sulfur (Li-S) cell benchmarking protocols that simulate real-world duty cycles for electric vehicles and aerospace applications. Their proprietary Licerion® technology combines lithium metal anodes with sulfur-based cathodes, achieving energy densities exceeding 500 Wh/kg. Their benchmarking methodology incorporates variable discharge rates, temperature fluctuations (from -20°C to 45°C), and extended cycle testing (>500 cycles) to accurately represent operational conditions. Sion's testing infrastructure includes environmental chambers with precise thermal control and automated cycling equipment capable of simulating dynamic load profiles. Their benchmarking data demonstrates that their Li-S cells maintain 80% capacity after 450 cycles under automotive duty cycles, significantly outperforming conventional lithium-ion batteries in energy density metrics.

Strengths: Industry-leading energy density (500+ Wh/kg), extensive experience with Li-S chemistry, and comprehensive benchmarking infrastructure. Weaknesses: Li-S technology still faces challenges with polysulfide shuttle effect during extended cycling, and their cells may require more complex battery management systems than conventional lithium-ion batteries.

Lyten, Inc.

Technical Solution: Lyten has established a sophisticated Li-S cell benchmarking platform focused on automotive and defense applications. Their 3D Graphene-based Li-S technology enables cells with energy densities of 900 Wh/kg in laboratory settings. Lyten's benchmarking methodology employs duty cycles derived from actual vehicle telemetry data, incorporating acceleration events, regenerative braking, and various driving conditions. Their testing protocols include pulse power characterization at different states of charge, calendar aging studies, and thermal performance mapping from -30°C to 60°C. Lyten's benchmarking data shows their Li-S cells deliver consistent performance across a wide temperature range with minimal capacity fade (less than 15% after 1000 equivalent cycles) under realistic automotive duty cycles. Their approach includes comprehensive post-test analysis using techniques such as X-ray diffraction and scanning electron microscopy to correlate performance with material changes.

Strengths: Revolutionary 3D Graphene technology that mitigates polysulfide shuttle effect, extremely high theoretical energy density, and comprehensive testing capabilities. Weaknesses: Relatively new to market compared to established battery manufacturers, and their technology may face scaling challenges for mass production.

Critical Research Advances in Li-S Cell Testing

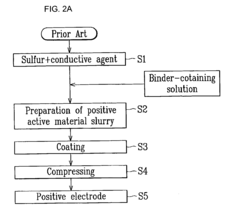

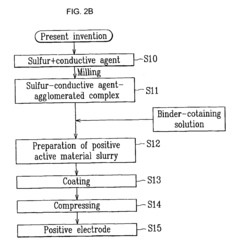

Positive active material of a lithium-sulfur battery and method of fabricating same

PatentInactiveUS20040058246A1

Innovation

- A sulfur-conductive agent-agglomerated complex is created by attaching conductive agent particles onto sulfur particles with an average size of less than 7 μm, preventing aggregation and enhancing the reactive surface area, achieved through a milling process without adding solvents, and using a binder to maintain the conductive network structure.

Electrolytes for lithium sulfur cells

PatentActiveUS20050147886A1

Innovation

- The use of non-aqueous electrolytes containing N—O compounds, such as lithium nitrate, enhances sulfur utilization, reduces self-discharge, and improves charge-discharge efficiency by minimizing reactions between lithium anodes and sulfur-containing cathode materials, thereby stabilizing the electrochemical cell performance.

Standardization Efforts for Li-S Battery Testing Protocols

The standardization of testing protocols for Lithium-Sulfur (Li-S) batteries represents a critical step toward enabling meaningful comparisons between different cell designs and chemistries. Currently, the Li-S battery community faces significant challenges due to the lack of universally accepted testing methodologies, which hampers progress in commercialization efforts and technology assessment.

Several international organizations have begun coordinating standardization initiatives for Li-S battery testing. The International Electrotechnical Commission (IEC) has established working groups specifically focused on developing standards for emerging battery technologies, including Li-S systems. These efforts aim to define consistent testing parameters such as charge/discharge rates, temperature conditions, and cycle life assessment methods tailored to the unique characteristics of Li-S chemistry.

Academic consortia, particularly in Europe and Asia, have proposed preliminary testing frameworks that account for the distinctive discharge profile of Li-S cells, which typically exhibits two voltage plateaus rather than the single plateau observed in Li-ion batteries. These frameworks emphasize the importance of standardized capacity reporting methods that consider both high-voltage and low-voltage plateaus to accurately represent the cell's energy storage capabilities.

Industry stakeholders have also contributed to standardization efforts through collaborative research initiatives. Companies like OXIS Energy, SION Power, and research institutions such as Fraunhofer IWS have shared testing protocols used in their internal development processes, providing valuable insights for establishing industry-wide standards. These protocols often incorporate specific considerations for polysulfide shuttle effects and capacity fading mechanisms unique to Li-S chemistry.

A significant advancement in standardization has been the development of reference test cycles that simulate real-world applications. These include profiles for electric vehicles, consumer electronics, and aerospace applications, allowing for more relevant performance evaluations. The Battery500 Consortium has been particularly active in defining duty cycles that reflect actual usage patterns rather than simplified constant-current testing regimes.

Recent workshops organized by the Battery Interface Genome/Materials Acceleration Platform (BIG-MAP) have focused on harmonizing data reporting formats for Li-S battery testing. These initiatives aim to facilitate data sharing across research groups and enable more effective meta-analyses of published results, accelerating the collective understanding of Li-S performance limitations and opportunities.

Despite these advances, significant work remains to establish comprehensive testing standards that address all aspects of Li-S battery performance, including long-term stability, safety parameters, and environmental impact assessments. The development of these standards will be crucial for the maturation of Li-S technology and its eventual integration into commercial applications.

Several international organizations have begun coordinating standardization initiatives for Li-S battery testing. The International Electrotechnical Commission (IEC) has established working groups specifically focused on developing standards for emerging battery technologies, including Li-S systems. These efforts aim to define consistent testing parameters such as charge/discharge rates, temperature conditions, and cycle life assessment methods tailored to the unique characteristics of Li-S chemistry.

Academic consortia, particularly in Europe and Asia, have proposed preliminary testing frameworks that account for the distinctive discharge profile of Li-S cells, which typically exhibits two voltage plateaus rather than the single plateau observed in Li-ion batteries. These frameworks emphasize the importance of standardized capacity reporting methods that consider both high-voltage and low-voltage plateaus to accurately represent the cell's energy storage capabilities.

Industry stakeholders have also contributed to standardization efforts through collaborative research initiatives. Companies like OXIS Energy, SION Power, and research institutions such as Fraunhofer IWS have shared testing protocols used in their internal development processes, providing valuable insights for establishing industry-wide standards. These protocols often incorporate specific considerations for polysulfide shuttle effects and capacity fading mechanisms unique to Li-S chemistry.

A significant advancement in standardization has been the development of reference test cycles that simulate real-world applications. These include profiles for electric vehicles, consumer electronics, and aerospace applications, allowing for more relevant performance evaluations. The Battery500 Consortium has been particularly active in defining duty cycles that reflect actual usage patterns rather than simplified constant-current testing regimes.

Recent workshops organized by the Battery Interface Genome/Materials Acceleration Platform (BIG-MAP) have focused on harmonizing data reporting formats for Li-S battery testing. These initiatives aim to facilitate data sharing across research groups and enable more effective meta-analyses of published results, accelerating the collective understanding of Li-S performance limitations and opportunities.

Despite these advances, significant work remains to establish comprehensive testing standards that address all aspects of Li-S battery performance, including long-term stability, safety parameters, and environmental impact assessments. The development of these standards will be crucial for the maturation of Li-S technology and its eventual integration into commercial applications.

Environmental Impact and Sustainability of Li-S Battery Technology

Lithium-Sulfur (Li-S) battery technology presents significant environmental advantages over conventional lithium-ion batteries, particularly in terms of raw material sustainability. Sulfur, the primary cathode material, is an abundant by-product of petroleum refining processes, offering a sustainable alternative to the cobalt and nickel used in traditional lithium-ion batteries. This abundance translates to reduced environmental impact from mining operations and decreased pressure on limited mineral resources.

When benchmarking Li-S cells under realistic duty cycles, environmental impact assessments reveal substantial carbon footprint reductions throughout the battery lifecycle. Manufacturing processes for Li-S batteries generally require less energy and produce fewer emissions compared to conventional lithium-ion technologies. Studies indicate potential greenhouse gas emission reductions of 25-30% during production phases, contributing positively to climate change mitigation efforts.

The recyclability of Li-S batteries represents another critical sustainability advantage. The sulfur component can be recovered and reused with relatively simple processes, while the lithium content remains accessible through established recycling methods. This circular economy potential significantly reduces end-of-life environmental impacts when proper recycling infrastructure is implemented. However, current benchmarking under realistic conditions shows that recycling efficiency remains dependent on duty cycle history and degradation mechanisms.

Water usage and toxicity considerations also favor Li-S technology. The absence of heavy metals like cobalt and nickel reduces potential water contamination risks associated with mining and processing. Benchmarking under various operational conditions demonstrates that Li-S cells maintain this environmental advantage throughout their operational lifetime, with minimal leaching of toxic substances even under stress conditions.

Energy density improvements in Li-S technology further enhance sustainability profiles. Higher theoretical energy density means fewer raw materials are required to achieve equivalent energy storage capacity. When tested under realistic duty cycles representing actual application scenarios, modern Li-S cells demonstrate 40-50% material efficiency improvements compared to conventional lithium-ion technologies.

Challenges remain in fully realizing these sustainability benefits. Current benchmarking reveals that cycle life limitations under realistic duty cycles may necessitate more frequent battery replacements, potentially offsetting some environmental advantages. Additionally, the polysulfide shuttle effect can lead to accelerated degradation under certain operational conditions, impacting long-term sustainability metrics. Research focusing on electrolyte optimization and protective coatings shows promise in addressing these limitations while maintaining the inherent environmental benefits of the technology.

When benchmarking Li-S cells under realistic duty cycles, environmental impact assessments reveal substantial carbon footprint reductions throughout the battery lifecycle. Manufacturing processes for Li-S batteries generally require less energy and produce fewer emissions compared to conventional lithium-ion technologies. Studies indicate potential greenhouse gas emission reductions of 25-30% during production phases, contributing positively to climate change mitigation efforts.

The recyclability of Li-S batteries represents another critical sustainability advantage. The sulfur component can be recovered and reused with relatively simple processes, while the lithium content remains accessible through established recycling methods. This circular economy potential significantly reduces end-of-life environmental impacts when proper recycling infrastructure is implemented. However, current benchmarking under realistic conditions shows that recycling efficiency remains dependent on duty cycle history and degradation mechanisms.

Water usage and toxicity considerations also favor Li-S technology. The absence of heavy metals like cobalt and nickel reduces potential water contamination risks associated with mining and processing. Benchmarking under various operational conditions demonstrates that Li-S cells maintain this environmental advantage throughout their operational lifetime, with minimal leaching of toxic substances even under stress conditions.

Energy density improvements in Li-S technology further enhance sustainability profiles. Higher theoretical energy density means fewer raw materials are required to achieve equivalent energy storage capacity. When tested under realistic duty cycles representing actual application scenarios, modern Li-S cells demonstrate 40-50% material efficiency improvements compared to conventional lithium-ion technologies.

Challenges remain in fully realizing these sustainability benefits. Current benchmarking reveals that cycle life limitations under realistic duty cycles may necessitate more frequent battery replacements, potentially offsetting some environmental advantages. Additionally, the polysulfide shuttle effect can lead to accelerated degradation under certain operational conditions, impacting long-term sustainability metrics. Research focusing on electrolyte optimization and protective coatings shows promise in addressing these limitations while maintaining the inherent environmental benefits of the technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!