Design Strategies For High-Loading Sulfur Cathodes

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulfur Cathode Technology Background and Objectives

Lithium-sulfur (Li-S) batteries have emerged as promising candidates for next-generation energy storage systems due to their theoretical energy density of 2600 Wh/kg, which significantly exceeds that of conventional lithium-ion batteries (typically 150-200 Wh/kg). The development of sulfur cathodes can be traced back to the 1960s, but significant research momentum has only built up in the past two decades as the limitations of traditional lithium-ion technology became apparent. The evolution of sulfur cathode technology has been driven by the increasing demand for higher energy density storage solutions for applications ranging from portable electronics to electric vehicles and grid-scale storage.

The fundamental attraction of sulfur as a cathode material lies in its high theoretical capacity (1675 mAh/g), natural abundance, low cost, and environmental friendliness. These attributes align perfectly with the global push toward sustainable and economically viable energy solutions. However, the commercialization of Li-S batteries has been hindered by several intrinsic challenges, particularly when attempting to achieve high sulfur loading.

The technical evolution of sulfur cathodes has progressed through several distinct phases. Early research focused on understanding the basic electrochemistry and reaction mechanisms. This was followed by efforts to address the "shuttle effect" caused by soluble polysulfide intermediates, which leads to rapid capacity fading. Recent research has shifted toward developing high-loading sulfur cathodes to achieve practical energy densities that can compete with or surpass commercial lithium-ion batteries.

The primary technical objective in this field is to design sulfur cathodes with areal capacities exceeding 6 mAh/cm², which requires sulfur loadings above 6 mg/cm². This represents a critical threshold for commercial viability. Additionally, these high-loading cathodes must maintain stable cycling performance over hundreds of cycles while operating at practical current densities.

Current research trends are focusing on multifunctional electrode architectures that simultaneously address multiple challenges: accommodating volume expansion (up to 80% during cycling), enhancing electronic conductivity of insulating sulfur, trapping polysulfide intermediates, and facilitating ion transport within thick electrodes. Novel approaches include hierarchical carbon hosts, polar materials for chemical adsorption of polysulfides, and advanced binders and electrolyte systems.

The trajectory of sulfur cathode development is increasingly influenced by computational modeling and artificial intelligence, which are accelerating materials discovery and optimization. These tools are helping researchers understand complex reaction mechanisms and predict the performance of novel electrode designs before experimental validation, significantly reducing development time and costs.

The fundamental attraction of sulfur as a cathode material lies in its high theoretical capacity (1675 mAh/g), natural abundance, low cost, and environmental friendliness. These attributes align perfectly with the global push toward sustainable and economically viable energy solutions. However, the commercialization of Li-S batteries has been hindered by several intrinsic challenges, particularly when attempting to achieve high sulfur loading.

The technical evolution of sulfur cathodes has progressed through several distinct phases. Early research focused on understanding the basic electrochemistry and reaction mechanisms. This was followed by efforts to address the "shuttle effect" caused by soluble polysulfide intermediates, which leads to rapid capacity fading. Recent research has shifted toward developing high-loading sulfur cathodes to achieve practical energy densities that can compete with or surpass commercial lithium-ion batteries.

The primary technical objective in this field is to design sulfur cathodes with areal capacities exceeding 6 mAh/cm², which requires sulfur loadings above 6 mg/cm². This represents a critical threshold for commercial viability. Additionally, these high-loading cathodes must maintain stable cycling performance over hundreds of cycles while operating at practical current densities.

Current research trends are focusing on multifunctional electrode architectures that simultaneously address multiple challenges: accommodating volume expansion (up to 80% during cycling), enhancing electronic conductivity of insulating sulfur, trapping polysulfide intermediates, and facilitating ion transport within thick electrodes. Novel approaches include hierarchical carbon hosts, polar materials for chemical adsorption of polysulfides, and advanced binders and electrolyte systems.

The trajectory of sulfur cathode development is increasingly influenced by computational modeling and artificial intelligence, which are accelerating materials discovery and optimization. These tools are helping researchers understand complex reaction mechanisms and predict the performance of novel electrode designs before experimental validation, significantly reducing development time and costs.

Market Analysis for High-Energy Density Batteries

The high-energy density battery market is experiencing unprecedented growth, driven by the expanding electric vehicle (EV) sector, renewable energy storage systems, and portable electronics. Lithium-sulfur (Li-S) batteries featuring high-loading sulfur cathodes represent a promising next-generation technology with theoretical energy densities up to 2,600 Wh/kg, significantly surpassing current lithium-ion batteries (typically 250-300 Wh/kg).

Market projections indicate the global high-energy density battery market will reach $140 billion by 2030, with a compound annual growth rate of 18.7% from 2023 to 2030. Within this landscape, Li-S batteries are positioned to capture a growing segment, particularly as technological barriers related to sulfur cathode design are overcome.

Consumer demand for EVs with extended range capabilities is creating substantial pull for advanced battery technologies. Current market research shows 78% of potential EV buyers cite range anxiety as their primary concern, while 65% would pay premium prices for vehicles offering 500+ mile ranges. High-loading sulfur cathodes directly address this market need by potentially doubling or tripling energy density at reduced costs.

The aerospace and defense sectors represent another high-value market segment, where weight reduction is critical. These industries demonstrate willingness to adopt premium-priced battery technologies that offer substantial weight savings, creating early adoption opportunities for Li-S batteries with high-loading sulfur cathodes.

Cost analysis reveals significant economic advantages for sulfur-based cathodes. Raw sulfur costs approximately $0.15/kg compared to $15-20/kg for traditional cathode materials like nickel manganese cobalt (NMC). This 100x cost differential creates compelling economic incentives for commercialization, particularly as manufacturing scales.

Regional market analysis shows Asia-Pacific leading battery manufacturing capacity, with China controlling 75% of global lithium-ion production. However, recent policy shifts in North America and Europe, including the U.S. Inflation Reduction Act and European Battery Alliance initiatives, are creating new geographic opportunities for advanced battery technologies including high-loading sulfur cathodes.

Market barriers include consumer concerns about cycle life stability and safety perceptions. Survey data indicates 72% of industrial battery buyers prioritize proven cycle life over initial energy density advantages, suggesting early market entry strategies should target applications tolerating lower cycle requirements while technology matures.

Market projections indicate the global high-energy density battery market will reach $140 billion by 2030, with a compound annual growth rate of 18.7% from 2023 to 2030. Within this landscape, Li-S batteries are positioned to capture a growing segment, particularly as technological barriers related to sulfur cathode design are overcome.

Consumer demand for EVs with extended range capabilities is creating substantial pull for advanced battery technologies. Current market research shows 78% of potential EV buyers cite range anxiety as their primary concern, while 65% would pay premium prices for vehicles offering 500+ mile ranges. High-loading sulfur cathodes directly address this market need by potentially doubling or tripling energy density at reduced costs.

The aerospace and defense sectors represent another high-value market segment, where weight reduction is critical. These industries demonstrate willingness to adopt premium-priced battery technologies that offer substantial weight savings, creating early adoption opportunities for Li-S batteries with high-loading sulfur cathodes.

Cost analysis reveals significant economic advantages for sulfur-based cathodes. Raw sulfur costs approximately $0.15/kg compared to $15-20/kg for traditional cathode materials like nickel manganese cobalt (NMC). This 100x cost differential creates compelling economic incentives for commercialization, particularly as manufacturing scales.

Regional market analysis shows Asia-Pacific leading battery manufacturing capacity, with China controlling 75% of global lithium-ion production. However, recent policy shifts in North America and Europe, including the U.S. Inflation Reduction Act and European Battery Alliance initiatives, are creating new geographic opportunities for advanced battery technologies including high-loading sulfur cathodes.

Market barriers include consumer concerns about cycle life stability and safety perceptions. Survey data indicates 72% of industrial battery buyers prioritize proven cycle life over initial energy density advantages, suggesting early market entry strategies should target applications tolerating lower cycle requirements while technology matures.

Current Challenges in High-Loading Sulfur Cathode Development

Despite the promising theoretical energy density of lithium-sulfur batteries, significant challenges persist in developing high-loading sulfur cathodes for practical applications. The primary obstacle remains the low utilization efficiency of active sulfur material when increasing the areal loading beyond 2 mg/cm². As loading increases, the electrochemical performance deteriorates dramatically due to several interconnected issues.

The polysulfide shuttle effect becomes more pronounced at higher sulfur loadings, causing rapid capacity fading and reduced coulombic efficiency. These dissolved polysulfides migrate between electrodes, creating parasitic reactions that compromise long-term cycling stability. The severity of this issue scales with the amount of sulfur present, making it particularly problematic for high-loading designs.

Electrical conductivity presents another significant challenge. Sulfur's inherently insulating nature (5×10⁻³⁰ S/cm) creates substantial internal resistance in high-loading cathodes. This resistance leads to polarization effects that limit rate capability and reduce the accessible capacity, especially at practical current densities required for commercial applications.

Mass transport limitations become increasingly restrictive as sulfur loading increases. The thick electrode structures necessary for high loading impede efficient electrolyte penetration and lithium-ion diffusion. This creates concentration gradients within the electrode that result in uneven reaction distribution and underutilization of active material in the electrode's inner regions.

The volume expansion problem is exacerbated in high-loading configurations. During discharge, sulfur undergoes approximately 80% volumetric expansion when converting to Li₂S. In high-loading cathodes, this expansion creates mechanical stress that can disrupt the electrode architecture, leading to delamination, pulverization, and loss of electrical contact between active materials and current collectors.

Electrolyte management presents a complex challenge that intensifies with increased sulfur loading. High-loading cathodes require sufficient electrolyte for reaction kinetics, yet excess electrolyte exacerbates the polysulfide shuttle effect. The electrolyte-to-sulfur (E/S) ratio becomes a critical parameter, with current research struggling to achieve stable performance at commercially viable low E/S ratios below 3 μL/mg.

The combined effect of these challenges creates a technical barrier that has prevented lithium-sulfur batteries from achieving the energy densities necessary to compete with conventional lithium-ion technologies in practical applications. Addressing these interconnected issues requires innovative electrode design strategies that simultaneously tackle multiple failure mechanisms.

The polysulfide shuttle effect becomes more pronounced at higher sulfur loadings, causing rapid capacity fading and reduced coulombic efficiency. These dissolved polysulfides migrate between electrodes, creating parasitic reactions that compromise long-term cycling stability. The severity of this issue scales with the amount of sulfur present, making it particularly problematic for high-loading designs.

Electrical conductivity presents another significant challenge. Sulfur's inherently insulating nature (5×10⁻³⁰ S/cm) creates substantial internal resistance in high-loading cathodes. This resistance leads to polarization effects that limit rate capability and reduce the accessible capacity, especially at practical current densities required for commercial applications.

Mass transport limitations become increasingly restrictive as sulfur loading increases. The thick electrode structures necessary for high loading impede efficient electrolyte penetration and lithium-ion diffusion. This creates concentration gradients within the electrode that result in uneven reaction distribution and underutilization of active material in the electrode's inner regions.

The volume expansion problem is exacerbated in high-loading configurations. During discharge, sulfur undergoes approximately 80% volumetric expansion when converting to Li₂S. In high-loading cathodes, this expansion creates mechanical stress that can disrupt the electrode architecture, leading to delamination, pulverization, and loss of electrical contact between active materials and current collectors.

Electrolyte management presents a complex challenge that intensifies with increased sulfur loading. High-loading cathodes require sufficient electrolyte for reaction kinetics, yet excess electrolyte exacerbates the polysulfide shuttle effect. The electrolyte-to-sulfur (E/S) ratio becomes a critical parameter, with current research struggling to achieve stable performance at commercially viable low E/S ratios below 3 μL/mg.

The combined effect of these challenges creates a technical barrier that has prevented lithium-sulfur batteries from achieving the energy densities necessary to compete with conventional lithium-ion technologies in practical applications. Addressing these interconnected issues requires innovative electrode design strategies that simultaneously tackle multiple failure mechanisms.

Current Design Approaches for High-Loading Sulfur Cathodes

01 Composite structures for high-loading sulfur cathodes

Composite structures combining sulfur with conductive materials like carbon or polymers can enhance the performance of high-loading sulfur cathodes. These structures provide better electronic conductivity, accommodate volume changes during cycling, and mitigate polysulfide dissolution. The composites typically feature porous architectures that allow for higher sulfur loading while maintaining good electrochemical performance.- Conductive additives for high-loading sulfur cathodes: Conductive additives are incorporated into sulfur cathodes to enhance electronic conductivity and accommodate volume changes during cycling. Carbon-based materials such as carbon nanotubes, graphene, and conductive polymers create interconnected networks that maintain electrical contact throughout the electrode even at high sulfur loadings. These additives also help mitigate the shuttle effect by physically constraining polysulfides, resulting in improved cycling stability and rate capability for high-loading sulfur cathodes.

- Porous host structures for sulfur immobilization: Porous host structures are designed to accommodate high sulfur loading while providing physical confinement for polysulfides. Materials such as mesoporous carbon, metal-organic frameworks, and hierarchical porous structures offer large surface areas and pore volumes to host sulfur and its discharge products. These structures not only increase sulfur utilization but also mitigate polysulfide dissolution through physical entrapment and chemical bonding, enabling high areal capacity and improved cycling performance in lithium-sulfur batteries.

- Functional binders and interlayers for high-loading cathodes: Specialized binders and interlayers are developed to enhance the mechanical integrity and electrochemical performance of high-loading sulfur cathodes. Functional polymeric binders provide strong adhesion between active materials and current collectors while offering additional benefits such as polysulfide trapping capabilities. Interlayers positioned between the cathode and separator serve as physical barriers to block polysulfide migration while facilitating lithium ion transport, resulting in improved cycling stability and coulombic efficiency.

- Metal compound additives for polysulfide immobilization: Metal compounds such as metal oxides, sulfides, and nitrides are incorporated into sulfur cathodes to chemically interact with polysulfides and prevent their dissolution. These additives form strong chemical bonds with polysulfide species through polar-polar interactions or Lewis acid-base interactions. By effectively trapping polysulfides within the cathode structure, these metal compounds enable higher sulfur utilization and improved cycling stability, even at high sulfur loadings, addressing a key challenge in lithium-sulfur battery technology.

- Electrode architecture engineering for high mass loading: Advanced electrode architectures are designed to accommodate high sulfur loadings while maintaining efficient electron and ion transport. Techniques such as gradient structures, 3D current collectors, and controlled porosity distribution optimize the balance between sulfur content, electrolyte accessibility, and mechanical stability. These engineered structures facilitate uniform reaction distribution throughout thick electrodes, mitigate concentration polarization, and enhance rate capability, enabling high areal capacity without sacrificing power performance or cycle life.

02 Binders and interlayers for sulfur cathode stability

Specialized binders and interlayers are crucial for maintaining the structural integrity of high-loading sulfur cathodes. These components help to accommodate volume expansion during cycling, improve adhesion between active materials, and prevent electrode pulverization. Additionally, functional interlayers can act as physical barriers to trap polysulfides and prevent their migration to the anode, thereby enhancing cycling stability and coulombic efficiency.Expand Specific Solutions03 Electrolyte modifications for high-loading sulfur batteries

Tailored electrolyte formulations can significantly improve the performance of high-loading sulfur cathodes. These modifications include the use of additives that form protective films on electrodes, solvents that reduce polysulfide solubility, and salts that enhance ionic conductivity. Optimized electrolytes help to suppress the shuttle effect, improve sulfur utilization, and enhance the overall energy density of lithium-sulfur batteries.Expand Specific Solutions04 Nanostructured materials for sulfur immobilization

Nanostructured materials such as metal oxides, metal-organic frameworks, and functionalized carbon can effectively immobilize sulfur and trap polysulfides in high-loading cathodes. These materials provide strong chemical interactions with sulfur species, large surface areas for sulfur deposition, and conductive pathways for electron transfer. By incorporating these nanostructures, the cathodes can achieve higher sulfur loading while maintaining good cycle life and rate capability.Expand Specific Solutions05 Manufacturing techniques for high-loading sulfur cathodes

Advanced manufacturing techniques are essential for producing high-loading sulfur cathodes with uniform distribution of active materials and optimal electrode architecture. These techniques include specialized coating methods, controlled drying processes, and precise calendering procedures. Innovations in manufacturing enable the creation of thick electrodes with high sulfur content while maintaining good electrolyte penetration, mechanical stability, and electrochemical performance.Expand Specific Solutions

Key Industry Players in Sulfur Battery Research

The high-loading sulfur cathode market is currently in a growth phase, with increasing research activity across academic institutions and commercial entities. The market is projected to expand significantly as demand for higher energy density batteries rises, particularly in electric vehicle applications. Technologically, sulfur cathodes remain in the early-to-mid maturity stage, with key challenges including cycle stability and conductivity limitations. Leading companies like Sion Power and Theion GmbH are advancing commercial applications, while Sila Nanotechnologies and Corning are developing supporting materials. Academic institutions including MIT, Drexel University, and Shanghai Institute of Ceramics are contributing fundamental research breakthroughs. Toyota and other automotive manufacturers are increasingly investing in this technology to secure future battery supply chains for electric vehicles.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a revolutionary approach to high-loading sulfur cathodes through their "polysulfide-retaining" architecture. Their design utilizes a hierarchical carbon framework with precisely engineered pore sizes that physically confine polysulfides while maintaining excellent ionic and electronic conductivity. The MIT team has pioneered the use of metal-organic framework (MOF) derived carbon hosts that can achieve sulfur loadings exceeding 8 mg/cm² while maintaining high utilization rates[1]. Their strategy incorporates a gradient functional layer between the cathode and separator that acts as a selective barrier, allowing lithium ions to pass while blocking polysulfide migration. Additionally, MIT has developed novel electrolyte formulations containing fluorinated additives that form stable interfaces on both electrodes, significantly reducing capacity fade[2]. The cathode architecture features a bimodal pore distribution with mesopores (2-50 nm) for sulfur accommodation and micropores (<2 nm) for polysulfide adsorption. This design enables high sulfur utilization even at high loading conditions, addressing one of the key challenges in Li-S battery commercialization.

Strengths: Exceptional theoretical understanding of sulfur electrochemistry, innovative materials design approach, and potential for ultra-high energy density (>600 Wh/kg). Weaknesses: Complex synthesis procedures for specialized carbon hosts, challenges with scaling laboratory processes to industrial production, and higher material costs compared to conventional cathodes.

Sion Power Corp.

Technical Solution: Sion Power has developed a proprietary lithium-sulfur (Li-S) battery technology called "Licerion" that addresses high-loading sulfur cathodes through a multi-faceted approach. Their strategy employs a protected lithium anode (PLA) technology combined with high-capacity sulfur cathodes that can achieve energy densities exceeding 500 Wh/kg at the cell level[1]. The cathode design incorporates a carbon-sulfur composite structure where sulfur is embedded within a conductive carbon matrix to mitigate polysulfide dissolution. Additionally, Sion has implemented specialized electrolyte formulations containing lithium nitrate and other additives that form a stable solid electrolyte interphase (SEI) on the lithium anode while suppressing the shuttle effect[2]. Their cathode architecture features hierarchical porosity to accommodate sulfur volumetric expansion during cycling while maintaining electronic conductivity throughout the electrode.

Strengths: Industry-leading energy density (500+ Wh/kg), extended cycle life compared to typical Li-S batteries, and scalable manufacturing processes. Weaknesses: Higher production costs than conventional lithium-ion batteries, potential safety concerns with lithium metal anodes, and performance degradation at extreme temperatures.

Critical Patents and Innovations in Sulfur Cathode Design

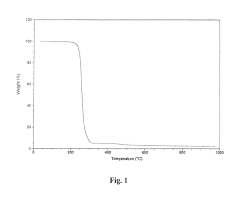

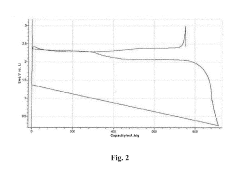

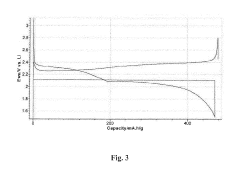

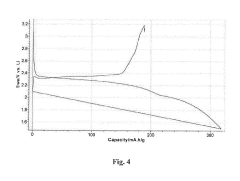

Formation of slurry for high loading sulfur cathodes

PatentActiveUS10312500B2

Innovation

- A high-density slurry comprising encapsulated chalcogen particles, carbon nanofibers, carbon black, carboxymethyl cellulose, styrene butadiene rubber, and water, with a sulfur content greater than 85 wt%, and a specific ratio of carbon nanofibers to carbon black, enhancing conductivity and sulfur loading while controlling polysulfide diffusion.

Material Supply Chain Considerations for Sulfur Batteries

The sulfur battery supply chain presents unique challenges and opportunities compared to conventional lithium-ion battery materials. Elemental sulfur, the primary cathode material, offers significant advantages from a supply chain perspective as it is abundantly available as a byproduct of petroleum refining and natural gas processing. Global annual production exceeds 70 million tons, with prices remaining relatively stable at approximately $150-200 per ton, making it substantially more cost-effective than traditional cathode materials like nickel, cobalt, and manganese compounds.

However, the development of high-loading sulfur cathodes introduces specific supply chain considerations. While raw sulfur is plentiful, specialized forms required for battery applications—such as purified sublimed sulfur or nanostructured sulfur composites—have more limited production capacity. Current global capacity for battery-grade sulfur processing remains under 10,000 tons annually, potentially creating bottlenecks as demand scales.

Carbon materials represent another critical component in the sulfur cathode supply chain. High-surface-area carbons such as carbon nanotubes, graphene, and mesoporous carbons are essential for creating conductive frameworks that enhance sulfur utilization and mitigate polysulfide shuttling. The production capacity for these specialized carbon materials is currently limited and concentrated in East Asia, particularly China, Japan, and South Korea, creating potential geopolitical vulnerabilities.

Electrolyte components for sulfur batteries also present supply chain challenges. Lithium salts (LiTFSI, LiFSI) and specialized additives like lithium nitrate are produced in limited quantities compared to conventional LiPF6. The fluorinated solvents often employed in sulfur battery electrolytes face production constraints and environmental concerns regarding their synthesis and disposal.

Regional distribution of sulfur battery material production capabilities shows significant imbalances. China currently dominates the production of most key components, while North America possesses abundant raw sulfur resources but limited processing infrastructure. Europe has invested in research capabilities but lacks large-scale manufacturing for specialized carbon materials and electrolytes.

Future supply chain resilience for high-loading sulfur cathodes will require strategic investments in diversified processing capabilities, particularly for specialized carbon materials and electrolyte components. Recycling infrastructure development remains in early stages but offers significant potential for reducing supply dependencies, as sulfur can be recovered at relatively high efficiency compared to transition metals in conventional batteries.

However, the development of high-loading sulfur cathodes introduces specific supply chain considerations. While raw sulfur is plentiful, specialized forms required for battery applications—such as purified sublimed sulfur or nanostructured sulfur composites—have more limited production capacity. Current global capacity for battery-grade sulfur processing remains under 10,000 tons annually, potentially creating bottlenecks as demand scales.

Carbon materials represent another critical component in the sulfur cathode supply chain. High-surface-area carbons such as carbon nanotubes, graphene, and mesoporous carbons are essential for creating conductive frameworks that enhance sulfur utilization and mitigate polysulfide shuttling. The production capacity for these specialized carbon materials is currently limited and concentrated in East Asia, particularly China, Japan, and South Korea, creating potential geopolitical vulnerabilities.

Electrolyte components for sulfur batteries also present supply chain challenges. Lithium salts (LiTFSI, LiFSI) and specialized additives like lithium nitrate are produced in limited quantities compared to conventional LiPF6. The fluorinated solvents often employed in sulfur battery electrolytes face production constraints and environmental concerns regarding their synthesis and disposal.

Regional distribution of sulfur battery material production capabilities shows significant imbalances. China currently dominates the production of most key components, while North America possesses abundant raw sulfur resources but limited processing infrastructure. Europe has invested in research capabilities but lacks large-scale manufacturing for specialized carbon materials and electrolytes.

Future supply chain resilience for high-loading sulfur cathodes will require strategic investments in diversified processing capabilities, particularly for specialized carbon materials and electrolyte components. Recycling infrastructure development remains in early stages but offers significant potential for reducing supply dependencies, as sulfur can be recovered at relatively high efficiency compared to transition metals in conventional batteries.

Environmental Impact and Sustainability Assessment

The environmental implications of high-loading sulfur cathodes extend far beyond their electrochemical performance, representing a critical dimension in their development trajectory. Lithium-sulfur (Li-S) batteries offer significant environmental advantages compared to conventional lithium-ion technologies, primarily due to sulfur's natural abundance, low toxicity, and sustainable sourcing options. Sulfur is often available as a byproduct from petroleum refining and other industrial processes, effectively transforming industrial waste into valuable battery materials.

When evaluating the life cycle assessment (LCA) of high-loading sulfur cathodes, the environmental footprint shows promising reductions in greenhouse gas emissions compared to traditional cathode materials. The energy-intensive mining operations associated with cobalt and nickel extraction are largely eliminated, resulting in substantially lower carbon emissions during the material acquisition phase. Studies indicate that Li-S batteries can potentially reduce production-phase carbon emissions by 60-80% compared to conventional lithium-ion batteries.

Water consumption metrics also favor sulfur cathodes, as their production requires significantly less water than mining operations for traditional cathode materials. This advantage becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities must consider their impact on local water resources.

The manufacturing processes for high-loading sulfur cathodes present both challenges and opportunities from an environmental perspective. Current methods often involve organic solvents that pose environmental concerns, necessitating the development of greener synthesis routes. Recent research has demonstrated promising water-based processing techniques that could substantially reduce the environmental impact of manufacturing while maintaining electrochemical performance.

End-of-life considerations reveal another environmental advantage of sulfur cathodes. The recycling potential for sulfur-based batteries exceeds that of conventional lithium-ion technologies, with simpler separation processes and higher material recovery rates. Preliminary recycling protocols have demonstrated sulfur recovery rates exceeding 90%, significantly reducing the need for virgin material extraction.

However, challenges remain in scaling environmentally friendly production methods for high-loading sulfur cathodes. The carbon hosts commonly used to improve sulfur utilization introduce additional environmental considerations, particularly when derived from fossil sources. Research into sustainable carbon sources, including biomass-derived carbons, represents a promising direction for further reducing the environmental footprint of these advanced battery systems.

When evaluating the life cycle assessment (LCA) of high-loading sulfur cathodes, the environmental footprint shows promising reductions in greenhouse gas emissions compared to traditional cathode materials. The energy-intensive mining operations associated with cobalt and nickel extraction are largely eliminated, resulting in substantially lower carbon emissions during the material acquisition phase. Studies indicate that Li-S batteries can potentially reduce production-phase carbon emissions by 60-80% compared to conventional lithium-ion batteries.

Water consumption metrics also favor sulfur cathodes, as their production requires significantly less water than mining operations for traditional cathode materials. This advantage becomes increasingly important in regions facing water scarcity challenges, where battery manufacturing facilities must consider their impact on local water resources.

The manufacturing processes for high-loading sulfur cathodes present both challenges and opportunities from an environmental perspective. Current methods often involve organic solvents that pose environmental concerns, necessitating the development of greener synthesis routes. Recent research has demonstrated promising water-based processing techniques that could substantially reduce the environmental impact of manufacturing while maintaining electrochemical performance.

End-of-life considerations reveal another environmental advantage of sulfur cathodes. The recycling potential for sulfur-based batteries exceeds that of conventional lithium-ion technologies, with simpler separation processes and higher material recovery rates. Preliminary recycling protocols have demonstrated sulfur recovery rates exceeding 90%, significantly reducing the need for virgin material extraction.

However, challenges remain in scaling environmentally friendly production methods for high-loading sulfur cathodes. The carbon hosts commonly used to improve sulfur utilization introduce additional environmental considerations, particularly when derived from fossil sources. Research into sustainable carbon sources, including biomass-derived carbons, represents a promising direction for further reducing the environmental footprint of these advanced battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!