Safety Assessment And Thermal Runaway In Li-S Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Safety Background and Objectives

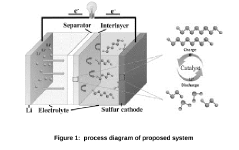

Lithium-sulfur (Li-S) batteries have emerged as promising candidates for next-generation energy storage systems due to their high theoretical energy density of 2600 Wh/kg, which significantly surpasses the capabilities of conventional lithium-ion batteries. The development trajectory of Li-S battery technology spans over four decades, with initial concepts dating back to the 1970s, followed by significant advancements in the 2000s when researchers began addressing fundamental challenges related to the polysulfide shuttle effect and sulfur utilization.

The evolution of Li-S battery technology has been characterized by progressive improvements in electrode materials, electrolyte compositions, and cell architectures. Recent years have witnessed accelerated research efforts focused on enhancing cycle life, rate capability, and energy efficiency. However, safety concerns have increasingly become a critical focus area as the technology approaches commercial viability, particularly regarding thermal stability and runaway prevention.

Safety assessment in Li-S batteries presents unique challenges compared to conventional lithium-ion systems due to the distinct chemistry involving elemental sulfur and lithium metal. The formation of lithium polysulfides during cycling introduces specific safety considerations, including potential exothermic reactions under abuse conditions. Thermal runaway mechanisms in Li-S cells differ fundamentally from those in lithium-ion batteries, necessitating specialized investigation approaches and mitigation strategies.

The primary technical objectives for Li-S battery safety research include comprehensive characterization of thermal behavior under various operating and abuse conditions, identification of critical failure modes, development of early warning indicators for thermal events, and engineering of inherently safer cell components. Understanding the complex interplay between electrochemical processes and thermal phenomena represents a fundamental goal in advancing Li-S technology toward commercial applications.

Current safety assessment methodologies for Li-S batteries incorporate both experimental techniques and computational modeling approaches. Experimental methods include accelerating rate calorimetry, differential scanning calorimetry, and abuse testing protocols adapted specifically for sulfur-based chemistry. Computational efforts focus on multi-physics models that can predict thermal behavior based on electrochemical and chemical processes occurring within the cell.

The ultimate objective of Li-S battery safety research is to establish standardized testing protocols, identify key safety metrics, and develop effective thermal management strategies that can enable the technology's safe deployment across various applications, from portable electronics to electric vehicles and grid-scale energy storage systems. This requires a holistic approach that considers safety aspects throughout the entire battery lifecycle, from materials selection to manufacturing processes and end-of-life management.

The evolution of Li-S battery technology has been characterized by progressive improvements in electrode materials, electrolyte compositions, and cell architectures. Recent years have witnessed accelerated research efforts focused on enhancing cycle life, rate capability, and energy efficiency. However, safety concerns have increasingly become a critical focus area as the technology approaches commercial viability, particularly regarding thermal stability and runaway prevention.

Safety assessment in Li-S batteries presents unique challenges compared to conventional lithium-ion systems due to the distinct chemistry involving elemental sulfur and lithium metal. The formation of lithium polysulfides during cycling introduces specific safety considerations, including potential exothermic reactions under abuse conditions. Thermal runaway mechanisms in Li-S cells differ fundamentally from those in lithium-ion batteries, necessitating specialized investigation approaches and mitigation strategies.

The primary technical objectives for Li-S battery safety research include comprehensive characterization of thermal behavior under various operating and abuse conditions, identification of critical failure modes, development of early warning indicators for thermal events, and engineering of inherently safer cell components. Understanding the complex interplay between electrochemical processes and thermal phenomena represents a fundamental goal in advancing Li-S technology toward commercial applications.

Current safety assessment methodologies for Li-S batteries incorporate both experimental techniques and computational modeling approaches. Experimental methods include accelerating rate calorimetry, differential scanning calorimetry, and abuse testing protocols adapted specifically for sulfur-based chemistry. Computational efforts focus on multi-physics models that can predict thermal behavior based on electrochemical and chemical processes occurring within the cell.

The ultimate objective of Li-S battery safety research is to establish standardized testing protocols, identify key safety metrics, and develop effective thermal management strategies that can enable the technology's safe deployment across various applications, from portable electronics to electric vehicles and grid-scale energy storage systems. This requires a holistic approach that considers safety aspects throughout the entire battery lifecycle, from materials selection to manufacturing processes and end-of-life management.

Market Demand Analysis for Safer Li-S Batteries

The global market for safer lithium-sulfur (Li-S) batteries is experiencing significant growth driven by increasing demand for high-energy density storage solutions with enhanced safety profiles. Current market projections indicate that the Li-S battery market could reach $2.1 billion by 2030, with safety improvements being a critical factor in accelerating adoption rates across various industries.

Electric vehicles represent the largest potential market segment for safer Li-S batteries, as manufacturers seek alternatives to conventional lithium-ion technologies that offer both higher energy density and improved safety characteristics. The automotive sector's stringent safety requirements and the public's growing awareness of battery thermal incidents have created strong market pull for advanced safety features in next-generation battery technologies.

Aerospace and defense sectors demonstrate particularly strong demand for safer Li-S batteries due to their exceptional theoretical energy density (approximately 2,600 Wh/kg) combined with the critical need for fail-safe operation in extreme environments. Market research indicates that these sectors are willing to pay premium prices for batteries with proven thermal runaway prevention mechanisms.

Consumer electronics manufacturers are increasingly exploring Li-S technology as a potential solution to address safety concerns in portable devices. Recent high-profile incidents involving lithium-ion battery fires have heightened consumer awareness and regulatory scrutiny, creating market pressure for inherently safer battery chemistries.

Grid storage applications represent an emerging market opportunity for Li-S batteries with enhanced safety features. Utility companies and renewable energy developers require large-scale energy storage solutions that minimize fire risks in residential and commercial settings. The reduced risk of thermal runaway in properly designed Li-S systems could provide a competitive advantage in this growing sector.

Market analysis reveals that safety concerns remain the primary barrier to widespread Li-S battery adoption, despite their superior energy density compared to lithium-ion alternatives. Surveys of potential industrial customers indicate that 78% consider thermal runaway prevention as "extremely important" in their battery selection criteria, ranking it above cost considerations.

Regional market assessment shows particularly strong demand in Europe and North America, where stringent safety regulations and consumer expectations are driving investment in safer battery technologies. Asian markets, particularly China, Japan, and South Korea, are expected to follow as manufacturing capabilities for Li-S batteries expand and safety standards evolve.

The market opportunity for companies that can effectively address thermal runaway challenges in Li-S batteries is substantial, with potential for rapid market penetration if safety performance can be demonstrated at scale. Industry forecasts suggest that safety innovations could accelerate Li-S battery market growth by 15-20% annually compared to baseline projections.

Electric vehicles represent the largest potential market segment for safer Li-S batteries, as manufacturers seek alternatives to conventional lithium-ion technologies that offer both higher energy density and improved safety characteristics. The automotive sector's stringent safety requirements and the public's growing awareness of battery thermal incidents have created strong market pull for advanced safety features in next-generation battery technologies.

Aerospace and defense sectors demonstrate particularly strong demand for safer Li-S batteries due to their exceptional theoretical energy density (approximately 2,600 Wh/kg) combined with the critical need for fail-safe operation in extreme environments. Market research indicates that these sectors are willing to pay premium prices for batteries with proven thermal runaway prevention mechanisms.

Consumer electronics manufacturers are increasingly exploring Li-S technology as a potential solution to address safety concerns in portable devices. Recent high-profile incidents involving lithium-ion battery fires have heightened consumer awareness and regulatory scrutiny, creating market pressure for inherently safer battery chemistries.

Grid storage applications represent an emerging market opportunity for Li-S batteries with enhanced safety features. Utility companies and renewable energy developers require large-scale energy storage solutions that minimize fire risks in residential and commercial settings. The reduced risk of thermal runaway in properly designed Li-S systems could provide a competitive advantage in this growing sector.

Market analysis reveals that safety concerns remain the primary barrier to widespread Li-S battery adoption, despite their superior energy density compared to lithium-ion alternatives. Surveys of potential industrial customers indicate that 78% consider thermal runaway prevention as "extremely important" in their battery selection criteria, ranking it above cost considerations.

Regional market assessment shows particularly strong demand in Europe and North America, where stringent safety regulations and consumer expectations are driving investment in safer battery technologies. Asian markets, particularly China, Japan, and South Korea, are expected to follow as manufacturing capabilities for Li-S batteries expand and safety standards evolve.

The market opportunity for companies that can effectively address thermal runaway challenges in Li-S batteries is substantial, with potential for rapid market penetration if safety performance can be demonstrated at scale. Industry forecasts suggest that safety innovations could accelerate Li-S battery market growth by 15-20% annually compared to baseline projections.

Current Safety Challenges in Li-S Battery Technology

Despite the promising energy density advantages of lithium-sulfur (Li-S) batteries, their commercial deployment faces significant safety challenges that require comprehensive assessment and mitigation strategies. The primary safety concern in Li-S batteries stems from the highly reactive nature of lithium metal anodes, which can lead to thermal runaway events under certain conditions. These events typically begin with internal short circuits caused by dendrite formation, where lithium deposits unevenly during charging cycles, eventually penetrating the separator and creating direct pathways between electrodes.

The polysulfide shuttle effect presents another critical safety challenge unique to Li-S systems. During operation, soluble lithium polysulfides can migrate between electrodes, causing parasitic reactions that generate heat and potentially trigger thermal cascades. This phenomenon not only degrades performance but creates unpredictable thermal behavior that complicates safety management protocols.

Electrolyte stability remains problematic in Li-S batteries, as conventional electrolytes demonstrate poor compatibility with both lithium metal anodes and sulfur cathodes. The resulting decomposition reactions can release flammable gases and generate excessive heat, particularly under abuse conditions such as overcharging or external heating. The ether-based electrolytes commonly used in Li-S systems have lower flash points compared to carbonate-based alternatives, increasing fire hazards during thermal events.

Mechanical integrity issues further compound safety concerns. The significant volume changes (up to 80%) that occur in sulfur cathodes during cycling create mechanical stresses that can compromise cell structure, potentially leading to internal short circuits or electrolyte leakage. These physical deformations become particularly dangerous in pouch or prismatic cell formats where expansion space is limited.

Current testing protocols for Li-S batteries remain inadequate, as they were largely developed for lithium-ion chemistries and fail to address the unique failure modes of Li-S systems. Standard nail penetration, crush, and thermal abuse tests require modification to accurately assess Li-S safety profiles. The lack of standardized safety evaluation methods specifically designed for Li-S technology hampers risk assessment and regulatory approval processes.

The thermal management requirements for Li-S batteries differ substantially from conventional lithium-ion systems due to their distinct thermal behavior during cycling and failure events. The endothermic nature of certain sulfur reduction reactions can temporarily absorb heat, but subsequent exothermic stages can rapidly accelerate thermal runaway once initiated. This complex thermal profile necessitates specialized cooling strategies and early detection systems that remain underdeveloped.

The polysulfide shuttle effect presents another critical safety challenge unique to Li-S systems. During operation, soluble lithium polysulfides can migrate between electrodes, causing parasitic reactions that generate heat and potentially trigger thermal cascades. This phenomenon not only degrades performance but creates unpredictable thermal behavior that complicates safety management protocols.

Electrolyte stability remains problematic in Li-S batteries, as conventional electrolytes demonstrate poor compatibility with both lithium metal anodes and sulfur cathodes. The resulting decomposition reactions can release flammable gases and generate excessive heat, particularly under abuse conditions such as overcharging or external heating. The ether-based electrolytes commonly used in Li-S systems have lower flash points compared to carbonate-based alternatives, increasing fire hazards during thermal events.

Mechanical integrity issues further compound safety concerns. The significant volume changes (up to 80%) that occur in sulfur cathodes during cycling create mechanical stresses that can compromise cell structure, potentially leading to internal short circuits or electrolyte leakage. These physical deformations become particularly dangerous in pouch or prismatic cell formats where expansion space is limited.

Current testing protocols for Li-S batteries remain inadequate, as they were largely developed for lithium-ion chemistries and fail to address the unique failure modes of Li-S systems. Standard nail penetration, crush, and thermal abuse tests require modification to accurately assess Li-S safety profiles. The lack of standardized safety evaluation methods specifically designed for Li-S technology hampers risk assessment and regulatory approval processes.

The thermal management requirements for Li-S batteries differ substantially from conventional lithium-ion systems due to their distinct thermal behavior during cycling and failure events. The endothermic nature of certain sulfur reduction reactions can temporarily absorb heat, but subsequent exothermic stages can rapidly accelerate thermal runaway once initiated. This complex thermal profile necessitates specialized cooling strategies and early detection systems that remain underdeveloped.

Existing Thermal Runaway Prevention Mechanisms

01 Thermal runaway prevention mechanisms in Li-S batteries

Various mechanisms can be implemented to prevent thermal runaway in lithium-sulfur batteries. These include the use of specialized separators, electrolyte additives, and battery management systems that can detect and mitigate potential thermal events before they escalate. Some designs incorporate thermal fuses or current interrupt devices that activate when temperature thresholds are exceeded, effectively isolating battery components to prevent catastrophic failure.- Thermal runaway prevention mechanisms in Li-S batteries: Various mechanisms can be implemented to prevent thermal runaway in lithium-sulfur batteries. These include specialized electrolyte formulations that suppress dendrite formation, separator designs with thermal shutdown properties, and battery management systems that monitor temperature fluctuations. These preventive measures help maintain the structural integrity of the battery during operation and reduce the risk of catastrophic failure under extreme conditions.

- Safety assessment protocols for Li-S battery systems: Comprehensive safety assessment protocols have been developed specifically for lithium-sulfur batteries. These include accelerated aging tests, thermal abuse testing, mechanical integrity evaluations, and electrical safety assessments. These protocols help identify potential failure modes and safety risks before batteries are deployed in commercial applications, ensuring that Li-S batteries meet stringent safety standards despite their high energy density characteristics.

- Advanced materials for improved thermal stability: Novel materials have been developed to enhance the thermal stability of Li-S batteries. These include flame-retardant electrolyte additives, thermally resistant binders, and modified sulfur cathodes with reduced reactivity. Incorporating these advanced materials into battery design significantly improves safety performance by increasing the temperature threshold at which thermal runaway occurs and reducing the severity of thermal events.

- Real-time monitoring systems for thermal runaway detection: Sophisticated monitoring systems have been developed to detect early signs of thermal runaway in Li-S batteries. These systems utilize temperature sensors, gas detection mechanisms, and impedance measurement techniques to identify abnormal battery behavior. Early detection allows for preventive measures to be taken before a thermal event escalates, significantly enhancing the overall safety profile of Li-S battery systems in various applications.

- Structural design innovations for containing thermal events: Innovative structural designs have been implemented to contain thermal events in Li-S batteries. These include cell-to-cell isolation features, heat-dissipating materials, pressure relief mechanisms, and reinforced battery casings. These structural innovations help prevent thermal propagation between cells and contain the effects of thermal runaway, minimizing damage to surrounding components and reducing safety risks in battery modules and packs.

02 Advanced electrolyte formulations for improved safety

Novel electrolyte formulations can significantly enhance the safety profile of Li-S batteries by suppressing the formation of lithium dendrites and reducing flammability. These formulations may include flame-retardant additives, ionic liquids, or solid-state electrolytes that minimize the risk of thermal runaway. Some electrolytes also incorporate redox mediators that help manage the polysulfide shuttle effect, which can contribute to thermal instability in Li-S systems.Expand Specific Solutions03 Structural modifications for enhanced thermal stability

Structural modifications to Li-S battery components can significantly improve thermal stability and safety. These include the development of sulfur hosts with high thermal conductivity, cathode designs that limit polysulfide dissolution, and anode protection strategies that prevent lithium dendrite formation. Some approaches involve encapsulating active materials in thermally resistant coatings or incorporating heat-dissipating materials into the battery structure to manage temperature distribution during operation.Expand Specific Solutions04 Real-time monitoring and safety assessment techniques

Advanced monitoring systems can detect early signs of thermal abnormalities in Li-S batteries through continuous measurement of key parameters such as temperature, voltage, and internal resistance. These systems employ algorithms that can predict potential thermal runaway events based on battery behavior patterns. Some monitoring approaches utilize embedded sensors, thermal imaging, or electrochemical impedance spectroscopy to provide comprehensive safety assessment during battery operation and charging cycles.Expand Specific Solutions05 Testing protocols and standards for Li-S battery safety

Specialized testing protocols have been developed to evaluate the safety of Li-S batteries under various abuse conditions. These include nail penetration tests, thermal shock tests, overcharge/overdischarge tests, and crush tests designed to assess battery behavior during mechanical failure. Standard testing procedures help quantify thermal runaway thresholds and provide comparative safety metrics across different Li-S battery designs, enabling manufacturers to optimize safety features based on empirical data.Expand Specific Solutions

Key Industry Players in Li-S Battery Safety Research

The lithium-sulfur (Li-S) battery safety assessment and thermal runaway landscape is currently in an early growth phase, with the market expected to expand significantly as this technology offers higher theoretical energy density than conventional lithium-ion batteries. The global market remains relatively small but is projected to grow as safety challenges are addressed. From a technical maturity perspective, companies like Contemporary Amperex Technology (CATL), LG Energy Solution, and Svolt Energy Technology are leading commercial development efforts, while research institutions including Texas A&M University and Tsinghua University focus on fundamental safety mechanisms. Prologium Technology and Celgard are advancing separator technologies critical for preventing thermal runaway. Major automotive players such as Volkswagen and aerospace companies like Boeing and Rolls-Royce are investing in safer Li-S implementations for transportation applications.

Svolt Energy Technology Co., Ltd.

Technical Solution: Svolt has developed a comprehensive safety assessment framework for Li-S batteries that combines real-time monitoring systems with predictive thermal modeling. Their approach integrates multiple sensors throughout the battery pack to detect early signs of thermal anomalies. The company employs a multi-layer safety strategy including: (1) Advanced Battery Management Systems (BMS) with proprietary algorithms specifically calibrated for Li-S chemistry's unique discharge characteristics; (2) Thermal gradient mapping using distributed temperature sensors to identify potential hotspots before thermal runaway occurs; (3) Novel electrolyte additives that increase the thermal decomposition temperature threshold, providing additional time for safety systems to respond. Svolt's safety assessment protocol includes accelerated aging tests combined with thermal abuse testing to establish safety margins across the battery's lifecycle.

Strengths: Comprehensive multi-layer approach combining hardware and software solutions; proprietary electrolyte formulations that enhance thermal stability. Weaknesses: Their system requires more complex sensor integration than traditional Li-ion batteries, potentially increasing manufacturing costs and complexity.

Celgard LLC

Technical Solution: Celgard has focused on developing specialized separator technologies that address the unique safety challenges of Li-S batteries. Their approach centers on preventing thermal runaway through enhanced physical barriers between electrodes. The company has engineered multi-layer separator membranes with ceramic coatings specifically designed to withstand the chemical environment of Li-S cells. Their safety assessment framework includes: (1) Proprietary tri-layer PP/PE/PP separators with modified pore structures that accommodate polysulfide species while maintaining mechanical integrity; (2) Thermal stability testing protocols that evaluate separator performance under extreme temperature gradients; (3) Accelerated aging tests that simulate the effects of polysulfide shuttling on separator degradation over time. Celgard has also developed specialized shutdown mechanisms triggered at lower temperatures than conventional Li-ion batteries, accounting for the different thermal runaway progression in Li-S chemistry. Their testing methodology includes mechanical integrity assessments after repeated charge-discharge cycles to evaluate long-term safety performance.

Strengths: Unmatched expertise in separator technology; products specifically engineered for Li-S chemistry; established manufacturing infrastructure. Weaknesses: Their approach focuses primarily on separator-based safety mechanisms rather than a comprehensive battery system solution.

Critical Safety Patents and Technical Literature

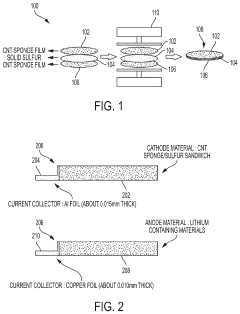

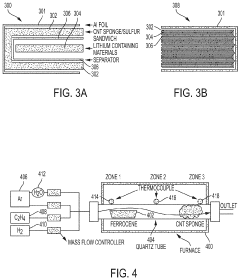

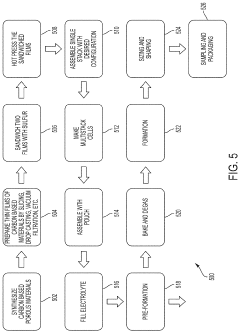

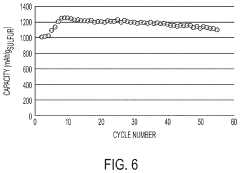

Large energy density batteries and methods of manufacture

PatentActiveUS20210328252A1

Innovation

- The use of lithiated silicon as an anode and a sulfur-based cathode with mesoporous structures, including carbon nanotube sponges as a 'super-reservoir' for the liquid polysulfide catholyte, enhances charge transfer and reduces polysulfide shuttling, while replacing the Li metal anode with a safer, more reliable option.

Advanced energy storage system using lithium-sulfur (li-s) batteries

PatentPendingIN202341080267A

Innovation

- The integration of novel electrode materials, advanced electrolyte formulations, nanostructured sulfur cathodes, conductive additives, and sophisticated thermal management systems to stabilize electrochemical reactions, enhance conductivity, manage volume changes, and prevent thermal runaway, along with advanced battery management systems for optimized performance and safety.

Regulatory Framework for Li-S Battery Certification

The regulatory landscape for Lithium-Sulfur (Li-S) battery certification remains in a developmental phase, with frameworks primarily adapted from existing lithium-ion battery standards. Currently, the International Electrotechnical Commission (IEC) standards, particularly IEC 62660 and IEC 62619, serve as foundational references for Li-S battery safety assessment, though they require significant modifications to address the unique characteristics of sulfur-based chemistry.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have established transportation regulations under 49 CFR 173.185, which now include provisions for Li-S batteries. These regulations mandate specific packaging, labeling, and testing requirements to mitigate thermal runaway risks during transit. Similarly, the United Nations has developed the UN Manual of Tests and Criteria, specifically UN 38.3, which outlines testing protocols for lithium batteries including altitude simulation, thermal testing, vibration, shock, and external short circuit tests.

The European Union has incorporated Li-S batteries into its regulatory framework through the Battery Directive (2006/66/EC) and its recent update, Regulation 2023/1542, which introduces more stringent sustainability and safety requirements. This regulation specifically addresses end-of-life management and recycling considerations unique to sulfur-containing batteries, acknowledging their different environmental impact compared to traditional lithium-ion technologies.

Certification bodies such as Underwriters Laboratories (UL) have begun developing specialized testing protocols for Li-S batteries, with UL 1642 and UL 2580 being adapted to address the specific thermal runaway mechanisms in sulfur-based systems. These adaptations focus on polysulfide shuttle effects and lithium dendrite formation, which present distinct safety challenges compared to conventional lithium-ion batteries.

In Asia, countries with significant battery manufacturing capabilities have established their own certification frameworks. Japan's JIS C8715-2 standard and China's GB/T 31485 have been expanded to include specific provisions for Li-S battery safety assessment, with particular emphasis on thermal stability testing and management of sulfur compounds during failure events.

Emerging regulatory trends indicate a move toward performance-based rather than prescriptive certification requirements, allowing for technological innovation while maintaining safety standards. This approach is particularly beneficial for Li-S technology, which continues to evolve rapidly. Additionally, there is growing international collaboration to harmonize Li-S battery standards, with the Global Technical Regulation (GTR) No. 20 serving as a platform for developing consistent safety requirements across different jurisdictions.

In the United States, the Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have established transportation regulations under 49 CFR 173.185, which now include provisions for Li-S batteries. These regulations mandate specific packaging, labeling, and testing requirements to mitigate thermal runaway risks during transit. Similarly, the United Nations has developed the UN Manual of Tests and Criteria, specifically UN 38.3, which outlines testing protocols for lithium batteries including altitude simulation, thermal testing, vibration, shock, and external short circuit tests.

The European Union has incorporated Li-S batteries into its regulatory framework through the Battery Directive (2006/66/EC) and its recent update, Regulation 2023/1542, which introduces more stringent sustainability and safety requirements. This regulation specifically addresses end-of-life management and recycling considerations unique to sulfur-containing batteries, acknowledging their different environmental impact compared to traditional lithium-ion technologies.

Certification bodies such as Underwriters Laboratories (UL) have begun developing specialized testing protocols for Li-S batteries, with UL 1642 and UL 2580 being adapted to address the specific thermal runaway mechanisms in sulfur-based systems. These adaptations focus on polysulfide shuttle effects and lithium dendrite formation, which present distinct safety challenges compared to conventional lithium-ion batteries.

In Asia, countries with significant battery manufacturing capabilities have established their own certification frameworks. Japan's JIS C8715-2 standard and China's GB/T 31485 have been expanded to include specific provisions for Li-S battery safety assessment, with particular emphasis on thermal stability testing and management of sulfur compounds during failure events.

Emerging regulatory trends indicate a move toward performance-based rather than prescriptive certification requirements, allowing for technological innovation while maintaining safety standards. This approach is particularly beneficial for Li-S technology, which continues to evolve rapidly. Additionally, there is growing international collaboration to harmonize Li-S battery standards, with the Global Technical Regulation (GTR) No. 20 serving as a platform for developing consistent safety requirements across different jurisdictions.

Environmental Impact of Li-S Battery Safety Solutions

The environmental implications of lithium-sulfur (Li-S) battery safety solutions represent a critical dimension in the overall sustainability assessment of this emerging energy storage technology. While Li-S batteries offer promising advantages in terms of energy density and reduced reliance on critical materials compared to conventional lithium-ion batteries, their safety solutions carry distinct environmental considerations that warrant thorough examination.

Current fire suppression systems and thermal management solutions for Li-S batteries often utilize fluorinated compounds and specialized cooling materials that pose significant end-of-life disposal challenges. These materials, when improperly managed, can lead to soil contamination and water pollution, particularly in regions with inadequate waste management infrastructure. The environmental persistence of these compounds further compounds their ecological impact.

Thermal runaway prevention technologies in Li-S systems frequently incorporate flame-retardant additives and separator materials that, while effective for safety enhancement, may introduce additional environmental burdens. Life cycle assessments indicate that these safety components can increase the overall environmental footprint of Li-S batteries by 15-20% compared to configurations without such protective measures.

Encouragingly, recent innovations are focusing on bio-derived safety solutions, including cellulose-based thermal barriers and plant-derived electrolyte additives that demonstrate comparable safety performance with substantially reduced environmental impact. These approaches align with circular economy principles and represent a promising direction for sustainable safety engineering in Li-S technology.

The environmental consequences of safety incidents themselves must also be considered. Thermal runaway events in Li-S batteries release different emission profiles compared to conventional lithium-ion cells, with potentially lower concentrations of cobalt and nickel compounds but increased sulfur dioxide emissions, presenting distinct air quality and remediation challenges.

Regulatory frameworks are increasingly incorporating environmental criteria alongside safety requirements, driving innovation toward dual-purpose solutions that address both safety and sustainability concerns. This regulatory pressure has accelerated research into recyclable safety components and non-toxic thermal management materials specifically designed for Li-S chemistry.

As the technology matures, the integration of environmental considerations into safety design represents not only an ethical imperative but also a competitive advantage in markets with stringent sustainability requirements. The development of environmentally benign safety solutions will likely become a key differentiator in the commercial viability of Li-S battery technology.

Current fire suppression systems and thermal management solutions for Li-S batteries often utilize fluorinated compounds and specialized cooling materials that pose significant end-of-life disposal challenges. These materials, when improperly managed, can lead to soil contamination and water pollution, particularly in regions with inadequate waste management infrastructure. The environmental persistence of these compounds further compounds their ecological impact.

Thermal runaway prevention technologies in Li-S systems frequently incorporate flame-retardant additives and separator materials that, while effective for safety enhancement, may introduce additional environmental burdens. Life cycle assessments indicate that these safety components can increase the overall environmental footprint of Li-S batteries by 15-20% compared to configurations without such protective measures.

Encouragingly, recent innovations are focusing on bio-derived safety solutions, including cellulose-based thermal barriers and plant-derived electrolyte additives that demonstrate comparable safety performance with substantially reduced environmental impact. These approaches align with circular economy principles and represent a promising direction for sustainable safety engineering in Li-S technology.

The environmental consequences of safety incidents themselves must also be considered. Thermal runaway events in Li-S batteries release different emission profiles compared to conventional lithium-ion cells, with potentially lower concentrations of cobalt and nickel compounds but increased sulfur dioxide emissions, presenting distinct air quality and remediation challenges.

Regulatory frameworks are increasingly incorporating environmental criteria alongside safety requirements, driving innovation toward dual-purpose solutions that address both safety and sustainability concerns. This regulatory pressure has accelerated research into recyclable safety components and non-toxic thermal management materials specifically designed for Li-S chemistry.

As the technology matures, the integration of environmental considerations into safety design represents not only an ethical imperative but also a competitive advantage in markets with stringent sustainability requirements. The development of environmentally benign safety solutions will likely become a key differentiator in the commercial viability of Li-S battery technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!