Li-S For Aviation And Drone Applications: Technical Requirements

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Evolution and Aviation Goals

Lithium-Sulfur (Li-S) battery technology has evolved significantly over the past two decades, transitioning from laboratory curiosity to a promising energy storage solution for aviation applications. The fundamental chemistry of Li-S batteries was first explored in the 1960s, but significant technical barriers prevented practical implementation. The early 2000s marked a renaissance in Li-S research, driven by the theoretical energy density of 2,600 Wh/kg—nearly five times that of conventional lithium-ion batteries.

By 2010, researchers had made substantial progress in addressing key challenges such as the polysulfide shuttle effect and poor cycle life. The development of carbon-sulfur composite cathodes and protective lithium metal anode coatings represented critical breakthroughs that elevated Li-S technology from theoretical concept to practical possibility. Between 2015 and 2020, several research institutions demonstrated Li-S cells exceeding 400 Wh/kg, surpassing the energy density ceiling of traditional lithium-ion chemistry.

The aviation industry has established ambitious goals for next-generation battery systems, particularly for electric vertical takeoff and landing (eVTOL) aircraft and unmanned aerial vehicles (UAVs). These goals include achieving specific energy exceeding 500 Wh/kg at the pack level, operational temperature ranges from -40°C to 60°C, and cycle life of at least 1,000 cycles while maintaining 80% capacity retention. Additionally, fast charging capabilities and enhanced safety profiles are paramount for aviation certification.

For drone applications, the technical requirements focus on maximizing flight time while minimizing battery weight. Current lithium-ion batteries typically provide 20-30 minutes of flight time for commercial drones, whereas Li-S technology could potentially extend this to 60-90 minutes without increasing weight. This represents a transformative capability for applications ranging from package delivery to aerial surveillance and emergency response.

The convergence of Li-S battery evolution with aviation goals has accelerated in recent years, with several aerospace companies forming strategic partnerships with Li-S battery developers. Notable milestones include the 2019 test flight of the HAPSMobile stratospheric UAV powered by Li-S batteries, which demonstrated the technology's potential for high-altitude, long-endurance missions. Similarly, Airbus has incorporated Li-S battery research into its zero-emission aircraft initiative, targeting commercial deployment by 2035.

The technical roadmap for Li-S aviation batteries focuses on three parallel development tracks: increasing energy density through advanced sulfur host materials, improving cycle life through electrolyte engineering, and enhancing safety through innovative cell design and thermal management systems. The ultimate goal is to create a battery system that meets the stringent requirements of aviation certification authorities while delivering the performance advantages inherent to Li-S chemistry.

By 2010, researchers had made substantial progress in addressing key challenges such as the polysulfide shuttle effect and poor cycle life. The development of carbon-sulfur composite cathodes and protective lithium metal anode coatings represented critical breakthroughs that elevated Li-S technology from theoretical concept to practical possibility. Between 2015 and 2020, several research institutions demonstrated Li-S cells exceeding 400 Wh/kg, surpassing the energy density ceiling of traditional lithium-ion chemistry.

The aviation industry has established ambitious goals for next-generation battery systems, particularly for electric vertical takeoff and landing (eVTOL) aircraft and unmanned aerial vehicles (UAVs). These goals include achieving specific energy exceeding 500 Wh/kg at the pack level, operational temperature ranges from -40°C to 60°C, and cycle life of at least 1,000 cycles while maintaining 80% capacity retention. Additionally, fast charging capabilities and enhanced safety profiles are paramount for aviation certification.

For drone applications, the technical requirements focus on maximizing flight time while minimizing battery weight. Current lithium-ion batteries typically provide 20-30 minutes of flight time for commercial drones, whereas Li-S technology could potentially extend this to 60-90 minutes without increasing weight. This represents a transformative capability for applications ranging from package delivery to aerial surveillance and emergency response.

The convergence of Li-S battery evolution with aviation goals has accelerated in recent years, with several aerospace companies forming strategic partnerships with Li-S battery developers. Notable milestones include the 2019 test flight of the HAPSMobile stratospheric UAV powered by Li-S batteries, which demonstrated the technology's potential for high-altitude, long-endurance missions. Similarly, Airbus has incorporated Li-S battery research into its zero-emission aircraft initiative, targeting commercial deployment by 2035.

The technical roadmap for Li-S aviation batteries focuses on three parallel development tracks: increasing energy density through advanced sulfur host materials, improving cycle life through electrolyte engineering, and enhancing safety through innovative cell design and thermal management systems. The ultimate goal is to create a battery system that meets the stringent requirements of aviation certification authorities while delivering the performance advantages inherent to Li-S chemistry.

Market Analysis for Aviation Li-S Applications

The aviation and drone market for lithium-sulfur (Li-S) batteries represents a significant growth opportunity, driven by the increasing demand for higher energy density power solutions in aerospace applications. The global electric aircraft market is projected to reach $27.7 billion by 2030, with a compound annual growth rate (CAGR) of 14.8% from 2023. Within this market, battery systems constitute approximately 35-40% of the total value chain, highlighting the substantial market potential for advanced battery technologies like Li-S.

For commercial aviation, the transition toward more electric aircraft (MEA) and eventually all-electric aircraft is creating a demand for batteries with energy densities exceeding 500 Wh/kg, a threshold where Li-S technology demonstrates competitive advantage over conventional lithium-ion batteries. The urban air mobility (UAM) segment, including electric vertical takeoff and landing (eVTOL) aircraft, is expected to grow at a CAGR of 26.2% through 2030, representing a premium market segment for high-performance batteries.

In the military aviation sector, there is increasing investment in electric propulsion for unmanned aerial vehicles (UAVs) and surveillance drones, with the military drone market expected to reach $23.78 billion by 2027. These applications require batteries that can deliver both high energy density and operate reliably in extreme conditions, aligning well with Li-S capabilities.

The commercial drone market presents another significant opportunity, with an estimated value of $13.44 billion in 2023, growing at a CAGR of 17.3% through 2028. Professional and industrial drones, which require longer flight times and higher payload capacities, are particularly well-suited for Li-S technology adoption.

Regional analysis indicates that North America currently leads the aviation battery market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to increasing investments in electric aviation infrastructure and manufacturing capabilities, particularly in China and Japan.

Customer requirements analysis reveals that aviation and drone manufacturers prioritize energy density (>400 Wh/kg), cycle life (>500 cycles), safety certification compliance (DO-311A), and operational temperature range (-40°C to +70°C) as critical factors in battery selection. Price sensitivity varies significantly across segments, with commercial aviation demonstrating greater willingness to pay premium prices for certified, high-performance solutions compared to the more cost-sensitive consumer drone segment.

For commercial aviation, the transition toward more electric aircraft (MEA) and eventually all-electric aircraft is creating a demand for batteries with energy densities exceeding 500 Wh/kg, a threshold where Li-S technology demonstrates competitive advantage over conventional lithium-ion batteries. The urban air mobility (UAM) segment, including electric vertical takeoff and landing (eVTOL) aircraft, is expected to grow at a CAGR of 26.2% through 2030, representing a premium market segment for high-performance batteries.

In the military aviation sector, there is increasing investment in electric propulsion for unmanned aerial vehicles (UAVs) and surveillance drones, with the military drone market expected to reach $23.78 billion by 2027. These applications require batteries that can deliver both high energy density and operate reliably in extreme conditions, aligning well with Li-S capabilities.

The commercial drone market presents another significant opportunity, with an estimated value of $13.44 billion in 2023, growing at a CAGR of 17.3% through 2028. Professional and industrial drones, which require longer flight times and higher payload capacities, are particularly well-suited for Li-S technology adoption.

Regional analysis indicates that North America currently leads the aviation battery market with approximately 38% market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to increasing investments in electric aviation infrastructure and manufacturing capabilities, particularly in China and Japan.

Customer requirements analysis reveals that aviation and drone manufacturers prioritize energy density (>400 Wh/kg), cycle life (>500 cycles), safety certification compliance (DO-311A), and operational temperature range (-40°C to +70°C) as critical factors in battery selection. Price sensitivity varies significantly across segments, with commercial aviation demonstrating greater willingness to pay premium prices for certified, high-performance solutions compared to the more cost-sensitive consumer drone segment.

Technical Challenges in Li-S for Aerospace

Lithium-Sulfur (Li-S) batteries face significant technical challenges when applied to aerospace environments, particularly for aviation and drone applications. The extreme operating conditions in aerospace demand battery systems that can withstand wide temperature variations, from the sub-zero temperatures at high altitudes to potential overheating during intensive operations. These temperature fluctuations severely impact Li-S battery performance, affecting both power output and cycle life.

The inherent shuttle effect in Li-S batteries presents a critical challenge for aerospace applications. During charging and discharging cycles, soluble polysulfide intermediates migrate between electrodes, causing capacity fading and reducing battery lifespan. This effect becomes more pronounced in aerospace applications where batteries undergo frequent charge-discharge cycles during flight operations, potentially compromising mission reliability and safety.

Energy density optimization remains a persistent challenge despite Li-S batteries' theoretical advantage over lithium-ion counterparts. Current Li-S implementations achieve only 350-400 Wh/kg, falling short of the theoretical 2,600 Wh/kg. For weight-sensitive aerospace applications, this gap represents a significant barrier to widespread adoption, as aircraft and drones require maximum energy storage with minimal weight penalties.

Safety concerns are paramount in aerospace applications. Li-S batteries must demonstrate exceptional stability under pressure changes, vibration, and potential impact scenarios. The risk of thermal runaway, though lower than in traditional lithium-ion batteries, still requires comprehensive mitigation strategies specific to aerospace environments where emergency response options are limited.

Cycle life limitations present another major hurdle. While commercial aviation requires thousands of reliable cycles, current Li-S technology typically delivers only 100-500 cycles before significant capacity degradation occurs. This shortfall necessitates frequent battery replacements, increasing operational costs and maintenance requirements for aerospace operators.

Integration challenges with existing aircraft electrical systems further complicate Li-S adoption. These batteries exhibit different voltage profiles and charging requirements compared to conventional systems, requiring redesigned power management systems and potentially extensive certification processes to meet stringent aviation safety standards.

Manufacturing scalability and cost efficiency represent additional barriers. Current production methods for high-quality sulfur cathodes and specialized separators remain complex and expensive, limiting commercial viability for mass aerospace deployment. The aerospace industry requires batteries that can be produced consistently at scale while meeting rigorous quality and performance standards.

The inherent shuttle effect in Li-S batteries presents a critical challenge for aerospace applications. During charging and discharging cycles, soluble polysulfide intermediates migrate between electrodes, causing capacity fading and reducing battery lifespan. This effect becomes more pronounced in aerospace applications where batteries undergo frequent charge-discharge cycles during flight operations, potentially compromising mission reliability and safety.

Energy density optimization remains a persistent challenge despite Li-S batteries' theoretical advantage over lithium-ion counterparts. Current Li-S implementations achieve only 350-400 Wh/kg, falling short of the theoretical 2,600 Wh/kg. For weight-sensitive aerospace applications, this gap represents a significant barrier to widespread adoption, as aircraft and drones require maximum energy storage with minimal weight penalties.

Safety concerns are paramount in aerospace applications. Li-S batteries must demonstrate exceptional stability under pressure changes, vibration, and potential impact scenarios. The risk of thermal runaway, though lower than in traditional lithium-ion batteries, still requires comprehensive mitigation strategies specific to aerospace environments where emergency response options are limited.

Cycle life limitations present another major hurdle. While commercial aviation requires thousands of reliable cycles, current Li-S technology typically delivers only 100-500 cycles before significant capacity degradation occurs. This shortfall necessitates frequent battery replacements, increasing operational costs and maintenance requirements for aerospace operators.

Integration challenges with existing aircraft electrical systems further complicate Li-S adoption. These batteries exhibit different voltage profiles and charging requirements compared to conventional systems, requiring redesigned power management systems and potentially extensive certification processes to meet stringent aviation safety standards.

Manufacturing scalability and cost efficiency represent additional barriers. Current production methods for high-quality sulfur cathodes and specialized separators remain complex and expensive, limiting commercial viability for mass aerospace deployment. The aerospace industry requires batteries that can be produced consistently at scale while meeting rigorous quality and performance standards.

Current Li-S Solutions for Drones and Aircraft

01 Cathode materials and structures for Li-S batteries

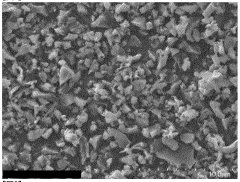

The cathode is a critical component in lithium-sulfur batteries, requiring specific materials and structures to enhance performance. Advanced cathode designs incorporate sulfur-carbon composites, conductive polymers, and nanostructured materials to improve sulfur utilization and prevent polysulfide dissolution. These cathode structures often feature hierarchical porous architectures that accommodate sulfur expansion during cycling while maintaining electrical conductivity and facilitating ion transport.- Cathode materials and structures for Li-S batteries: The cathode in Li-S batteries typically consists of sulfur as the active material. Various approaches to improve cathode performance include using carbon-based materials as hosts for sulfur, developing hierarchical porous structures to accommodate volume changes, and incorporating conductive additives to enhance electron transport. Advanced cathode designs focus on preventing polysulfide dissolution and shuttle effect while maintaining high sulfur loading and utilization efficiency.

- Electrolyte formulations for Li-S batteries: Electrolyte composition plays a crucial role in Li-S battery performance. Specialized electrolytes containing lithium salts, organic solvents, and additives are designed to suppress the polysulfide shuttle effect. Innovations include solid-state electrolytes, gel polymer electrolytes, and ionic liquid-based systems that offer improved safety and electrochemical stability. Electrolyte additives such as LiNO3 help form protective layers on the lithium anode surface.

- Anode protection strategies for Li-S batteries: Lithium metal anodes in Li-S batteries face challenges including dendrite formation and reactions with polysulfides. Protection strategies include artificial SEI layers, physical barriers, and modified lithium surfaces. Alternative anode materials such as silicon, graphite, or lithium alloys are also being explored to enhance cycling stability and safety while maintaining high energy density.

- Separator modifications for polysulfide retention: Specialized separators are designed to prevent polysulfide shuttling between electrodes. Approaches include functional coatings with polysulfide-trapping materials, multilayer structures with selective permeability, and composite separators incorporating inorganic particles. These modifications aim to physically block polysulfides while maintaining lithium ion conductivity and mechanical integrity during cycling.

- Cell design and manufacturing considerations: Practical implementation of Li-S batteries requires specific cell design and manufacturing techniques. Considerations include electrode thickness optimization, electrolyte-to-sulfur ratio control, and packaging to accommodate volume changes. Advanced manufacturing methods focus on achieving uniform sulfur distribution, proper electrode calendering, and effective sealing to prevent moisture ingress, which is particularly detrimental to Li-S chemistry.

02 Electrolyte formulations for Li-S batteries

Specialized electrolyte formulations are essential for addressing the polysulfide shuttle effect in lithium-sulfur batteries. These formulations often include additives such as lithium nitrate, fluorinated compounds, and ionic liquids that form protective layers on electrodes and suppress polysulfide dissolution. Solid-state and gel polymer electrolytes are also being developed to enhance safety and prevent polysulfide migration while maintaining adequate ionic conductivity at various operating temperatures.Expand Specific Solutions03 Anode protection strategies for Li-S batteries

Protecting the lithium metal anode is crucial for improving the cycle life and safety of lithium-sulfur batteries. Technical approaches include artificial solid electrolyte interphase layers, protective coatings, and structured lithium hosts that minimize dendrite formation and prevent side reactions with polysulfides. Advanced anode designs incorporate composite materials and three-dimensional structures to achieve uniform lithium deposition and extraction during cycling.Expand Specific Solutions04 Separator modifications for polysulfide retention

Modified separators play a vital role in mitigating the polysulfide shuttle effect in lithium-sulfur batteries. Functional separators incorporate polysulfide-blocking layers, such as graphene oxide, metal-organic frameworks, or conductive polymers. These modified separators act as physical and chemical barriers to prevent polysulfide migration while maintaining adequate lithium-ion transport, thereby improving coulombic efficiency and extending battery cycle life.Expand Specific Solutions05 System-level design and manufacturing considerations

System-level design and manufacturing techniques are essential for practical lithium-sulfur batteries. These include optimized electrode loading and thickness, electrolyte-to-sulfur ratios, and cell packaging to accommodate volume changes during cycling. Advanced manufacturing processes focus on scalable production methods, quality control measures, and integration of battery management systems specifically designed to handle the unique discharge profile and operating characteristics of lithium-sulfur batteries.Expand Specific Solutions

Key Industry Players in Aviation Li-S Development

The lithium-sulfur (Li-S) battery market for aviation and drone applications is in an early growth phase, characterized by increasing R&D investment but limited commercial deployment. The market is projected to expand significantly as the technology matures, driven by the need for higher energy density power sources in aerospace applications. Currently, the technology sits at TRL 5-6, with major aerospace players like Airbus Operations and China Aerospace Science & Technology Corp actively developing solutions alongside battery specialists such as LG Energy Solution and CATL. Academic-industry partnerships are accelerating development, with universities like Beihang and Rensselaer Polytechnic Institute collaborating with commercial entities to overcome key technical challenges including cycle life limitations and safety concerns for aviation certification requirements.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has developed an innovative Li-S battery technology platform specifically designed for aviation and drone applications, achieving energy densities exceeding 550 Wh/kg at cell level. Their proprietary approach utilizes nano-engineered carbon frameworks with precisely controlled pore architectures that effectively encapsulate sulfur while providing conductive pathways for electrons. The company's cathode manufacturing process enables exceptionally high sulfur loading (>75% by weight) while maintaining structural stability during cycling. Nanotek's specialized electrolyte system incorporates functional additives that form protective interfaces on lithium metal anodes, significantly reducing dendrite formation and enhancing cycle life. For aviation applications, they've developed lightweight composite cell casings with integrated thermal management features that maintain optimal operating temperatures across altitude-related environmental variations. Their battery management system includes predictive algorithms that monitor polysulfide shuttle effects in real-time, adjusting charging parameters to maximize cycle life. Flight tests with their prototype systems have demonstrated 50-60% increased flight duration for medium-sized drones compared to conventional Li-ion batteries of equivalent weight.

Strengths: Industry-leading energy density metrics critical for aviation applications, advanced nano-engineering expertise applied to sulfur containment challenges, and sophisticated battery management systems optimized for flight conditions. Weaknesses: Limited production scale compared to major battery manufacturers, higher unit costs due to specialized nano-materials and manufacturing processes, and ongoing challenges with cycle life for long-duration aviation applications.

Airbus Operations SAS

Technical Solution: Airbus has developed advanced lithium-sulfur (Li-S) battery systems specifically engineered for aviation applications, focusing on high energy density solutions that exceed 500 Wh/kg at cell level. Their technical approach incorporates specialized carbon-sulfur composite cathodes with tailored pore structures to accommodate sulfur volumetric expansion during cycling. Airbus employs proprietary electrolyte formulations with lithium nitrate and polysulfide mediators to mitigate the shuttle effect, a common failure mode in Li-S batteries. Their aviation-specific design includes thermal management systems capable of operating in extreme altitude conditions (-60°C to +40°C) while meeting rigorous aerospace safety standards. Airbus has demonstrated prototype Li-S cells with 2-3x the energy density of conventional Li-ion batteries, enabling potential flight time extensions of 40-60% for electric aircraft and drones while reducing overall weight by approximately 30%.

Strengths: Superior energy density compared to Li-ion batteries, significant weight reduction potential critical for aviation applications, and extensive aviation certification expertise. Weaknesses: Limited cycle life (currently 300-500 cycles) compared to Li-ion, challenges with power density for high-demand flight phases like takeoff, and higher production costs in current development stage.

Critical Patents in Aviation Li-S Technology

Carbon material for lithium sulfur battery and production method therefor

PatentWO2023210515A1

Innovation

- A carbon material for lithium-sulfur batteries is developed through a method involving wet-pulverization of a mixture containing a first carbon material, dispersant, and liquid medium, followed by heat-treatment and activation processes to achieve a specific particle size distribution and pore structure, enhancing the battery's charge/discharge capacity.

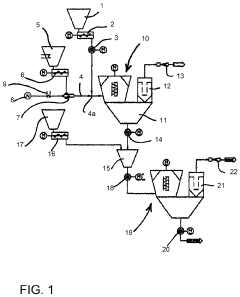

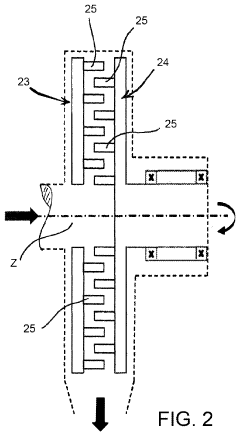

Method for producing a homogenized mixture of carbon, sulfur, and PTFE

PatentActiveUS11942625B2

Innovation

- A method involving the liquefaction of sulfur, grinding it with carbon to form a composite, followed by the addition and grinding of PTFE, using a two-step grinding process in impact mills to achieve continuous, homogeneous mixing and prevent clumping, with temperature control and inert gas injection for efficient sulfur handling.

Safety and Certification Requirements

The integration of Lithium-Sulfur (Li-S) batteries into aviation and drone applications necessitates rigorous adherence to safety standards and certification requirements. These requirements are significantly more stringent than those for consumer electronics due to the catastrophic consequences of failure in aerial vehicles.

For commercial aviation applications, Li-S battery systems must comply with Federal Aviation Administration (FAA) regulations in the United States, specifically FAR Part 25 for transport category aircraft, and the European Union Aviation Safety Agency (EASA) CS-25 standards. These regulations mandate comprehensive testing for thermal runaway containment, vibration resistance, and electromagnetic compatibility. Additionally, RTCA DO-311A provides specific performance standards for rechargeable lithium batteries in airborne applications.

Military aviation applications follow MIL-STD-810H for environmental testing and MIL-PRF-29595A for battery performance requirements. These standards include extreme temperature operation (-40°C to +71°C), altitude performance up to 40,000 feet, and resistance to shock loads exceeding 20G.

For drone applications, certification requirements vary based on the drone's weight class and intended use. Commercial drones operating under FAA Part 107 must meet less stringent but still substantial safety requirements. The UL 3030 standard specifically addresses electrical systems in unmanned aerial vehicles, including battery safety requirements.

Safety testing protocols for Li-S batteries in aviation must address the unique characteristics of sulfur electrodes, including the prevention of polysulfide shuttle effect and protection against lithium dendrite formation. Thermal management systems must demonstrate the ability to prevent thermal propagation between cells, with containment strategies for potential sulfur dioxide gas release during failure scenarios.

Certification processes typically require accelerated life testing to demonstrate cycle life stability under various operational conditions, including rapid charge/discharge cycles typical in drone operations. Abuse testing protocols include nail penetration, crush testing, and external short circuit tests to verify containment of failure events.

Documentation requirements for certification include detailed material safety data sheets for all battery components, comprehensive failure mode and effects analysis (FMEA), and fault tree analysis (FTA) for critical failure scenarios. Battery management systems must demonstrate redundancy in critical safety functions and fail-safe operation modes.

As Li-S technology continues to evolve, certification bodies are developing specific protocols to address the unique characteristics of these batteries. Industry stakeholders are actively participating in standards development organizations to establish testing methodologies that accurately reflect the safety profile of Li-S systems while enabling their adoption in aviation applications.

For commercial aviation applications, Li-S battery systems must comply with Federal Aviation Administration (FAA) regulations in the United States, specifically FAR Part 25 for transport category aircraft, and the European Union Aviation Safety Agency (EASA) CS-25 standards. These regulations mandate comprehensive testing for thermal runaway containment, vibration resistance, and electromagnetic compatibility. Additionally, RTCA DO-311A provides specific performance standards for rechargeable lithium batteries in airborne applications.

Military aviation applications follow MIL-STD-810H for environmental testing and MIL-PRF-29595A for battery performance requirements. These standards include extreme temperature operation (-40°C to +71°C), altitude performance up to 40,000 feet, and resistance to shock loads exceeding 20G.

For drone applications, certification requirements vary based on the drone's weight class and intended use. Commercial drones operating under FAA Part 107 must meet less stringent but still substantial safety requirements. The UL 3030 standard specifically addresses electrical systems in unmanned aerial vehicles, including battery safety requirements.

Safety testing protocols for Li-S batteries in aviation must address the unique characteristics of sulfur electrodes, including the prevention of polysulfide shuttle effect and protection against lithium dendrite formation. Thermal management systems must demonstrate the ability to prevent thermal propagation between cells, with containment strategies for potential sulfur dioxide gas release during failure scenarios.

Certification processes typically require accelerated life testing to demonstrate cycle life stability under various operational conditions, including rapid charge/discharge cycles typical in drone operations. Abuse testing protocols include nail penetration, crush testing, and external short circuit tests to verify containment of failure events.

Documentation requirements for certification include detailed material safety data sheets for all battery components, comprehensive failure mode and effects analysis (FMEA), and fault tree analysis (FTA) for critical failure scenarios. Battery management systems must demonstrate redundancy in critical safety functions and fail-safe operation modes.

As Li-S technology continues to evolve, certification bodies are developing specific protocols to address the unique characteristics of these batteries. Industry stakeholders are actively participating in standards development organizations to establish testing methodologies that accurately reflect the safety profile of Li-S systems while enabling their adoption in aviation applications.

Environmental Impact and Sustainability Factors

Lithium-sulfur (Li-S) battery technology presents significant environmental advantages over conventional lithium-ion batteries, particularly in aviation and drone applications where environmental impact considerations are increasingly important. The absence of heavy metals like cobalt and nickel in Li-S batteries substantially reduces the environmental footprint associated with mining these materials, which often involves habitat destruction, water pollution, and human rights concerns in extraction regions.

The sulfur component of Li-S batteries offers exceptional sustainability credentials as it is abundantly available as a byproduct of petroleum refining processes. By utilizing this industrial waste stream, Li-S battery production contributes to circular economy principles, transforming what would otherwise be a waste material into a valuable resource for energy storage applications in aviation and drone technologies.

Life cycle assessment (LCA) studies indicate that Li-S batteries demonstrate lower greenhouse gas emissions during manufacturing compared to conventional lithium-ion batteries. This advantage becomes particularly significant when considering the entire operational lifespan of aviation and drone applications, where the higher energy density of Li-S batteries translates to fewer replacement cycles and consequently reduced cumulative environmental impact over time.

End-of-life considerations for Li-S batteries also present environmental advantages. The recycling processes for Li-S batteries are potentially less energy-intensive than those for conventional lithium-ion batteries, primarily due to the simpler chemistry and absence of complex metal oxides. However, commercial-scale recycling infrastructure for Li-S batteries remains underdeveloped, presenting a challenge that must be addressed as deployment in aviation applications increases.

Water usage represents another critical environmental factor in battery production. Li-S manufacturing processes typically require less water compared to conventional lithium-ion battery production, an advantage that becomes increasingly important as water scarcity concerns grow globally. This reduced water footprint enhances the sustainability profile of Li-S technology for aviation applications.

Regulatory frameworks worldwide are evolving to place greater emphasis on the environmental impact of battery technologies. The European Union's Battery Directive and similar regulations in other regions are establishing increasingly stringent requirements for battery sustainability. Li-S technology's favorable environmental profile positions it advantageously within these evolving regulatory landscapes, potentially accelerating adoption in aviation and drone applications where compliance with environmental regulations is mandatory.

The sulfur component of Li-S batteries offers exceptional sustainability credentials as it is abundantly available as a byproduct of petroleum refining processes. By utilizing this industrial waste stream, Li-S battery production contributes to circular economy principles, transforming what would otherwise be a waste material into a valuable resource for energy storage applications in aviation and drone technologies.

Life cycle assessment (LCA) studies indicate that Li-S batteries demonstrate lower greenhouse gas emissions during manufacturing compared to conventional lithium-ion batteries. This advantage becomes particularly significant when considering the entire operational lifespan of aviation and drone applications, where the higher energy density of Li-S batteries translates to fewer replacement cycles and consequently reduced cumulative environmental impact over time.

End-of-life considerations for Li-S batteries also present environmental advantages. The recycling processes for Li-S batteries are potentially less energy-intensive than those for conventional lithium-ion batteries, primarily due to the simpler chemistry and absence of complex metal oxides. However, commercial-scale recycling infrastructure for Li-S batteries remains underdeveloped, presenting a challenge that must be addressed as deployment in aviation applications increases.

Water usage represents another critical environmental factor in battery production. Li-S manufacturing processes typically require less water compared to conventional lithium-ion battery production, an advantage that becomes increasingly important as water scarcity concerns grow globally. This reduced water footprint enhances the sustainability profile of Li-S technology for aviation applications.

Regulatory frameworks worldwide are evolving to place greater emphasis on the environmental impact of battery technologies. The European Union's Battery Directive and similar regulations in other regions are establishing increasingly stringent requirements for battery sustainability. Li-S technology's favorable environmental profile positions it advantageously within these evolving regulatory landscapes, potentially accelerating adoption in aviation and drone applications where compliance with environmental regulations is mandatory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!