Manufacturing Pathways For Lithium-Sulfur Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Development Background and Objectives

Lithium-sulfur (Li-S) batteries have emerged as a promising next-generation energy storage technology, attracting significant attention from both academia and industry over the past two decades. The fundamental appeal of Li-S batteries lies in their theoretical energy density of approximately 2600 Wh/kg, which substantially exceeds the 387 Wh/kg limit of conventional lithium-ion batteries. This remarkable potential stems from sulfur's high theoretical specific capacity of 1675 mAh/g and its natural abundance, making it an environmentally friendly and cost-effective cathode material.

The development of Li-S battery technology can be traced back to the 1960s when the first conceptual designs were proposed. However, meaningful progress was limited until the early 2000s when nanotechnology advancements enabled researchers to address some of the inherent challenges. The evolution of Li-S technology has been characterized by incremental improvements in addressing key technical barriers, particularly the polysulfide shuttle effect, volume expansion, and poor cycle life.

Recent technological breakthroughs have accelerated the development trajectory, with significant milestones achieved in electrolyte formulations, separator designs, and cathode architectures. The integration of carbon-based materials, particularly graphene and carbon nanotubes, has played a pivotal role in enhancing the conductivity and structural stability of sulfur cathodes. Additionally, novel approaches to encapsulate sulfur within porous structures have demonstrated promising results in mitigating polysulfide dissolution.

The primary objective of current Li-S battery development is to establish viable manufacturing pathways that can translate laboratory successes into commercially feasible products. This involves optimizing cell components and assembly processes to achieve consistent performance, long cycle life, and cost-effective production at scale. Specific technical goals include achieving energy densities exceeding 500 Wh/kg at the cell level, cycle life beyond 1000 cycles, and coulombic efficiency above 99%.

Another critical objective is to develop manufacturing techniques compatible with existing lithium-ion battery production infrastructure, thereby minimizing capital investment requirements for commercialization. This includes adapting slurry preparation methods, coating processes, and cell assembly techniques to accommodate the unique characteristics of sulfur cathodes and specialized electrolytes.

The strategic importance of Li-S technology extends beyond portable electronics to electric vehicles, aerospace applications, and grid-scale energy storage. As global demand for high-energy-density batteries continues to grow, establishing robust manufacturing pathways for Li-S cells represents a crucial step toward diversifying the battery technology landscape and reducing dependence on critical materials such as cobalt and nickel that are prevalent in conventional lithium-ion batteries.

The development of Li-S battery technology can be traced back to the 1960s when the first conceptual designs were proposed. However, meaningful progress was limited until the early 2000s when nanotechnology advancements enabled researchers to address some of the inherent challenges. The evolution of Li-S technology has been characterized by incremental improvements in addressing key technical barriers, particularly the polysulfide shuttle effect, volume expansion, and poor cycle life.

Recent technological breakthroughs have accelerated the development trajectory, with significant milestones achieved in electrolyte formulations, separator designs, and cathode architectures. The integration of carbon-based materials, particularly graphene and carbon nanotubes, has played a pivotal role in enhancing the conductivity and structural stability of sulfur cathodes. Additionally, novel approaches to encapsulate sulfur within porous structures have demonstrated promising results in mitigating polysulfide dissolution.

The primary objective of current Li-S battery development is to establish viable manufacturing pathways that can translate laboratory successes into commercially feasible products. This involves optimizing cell components and assembly processes to achieve consistent performance, long cycle life, and cost-effective production at scale. Specific technical goals include achieving energy densities exceeding 500 Wh/kg at the cell level, cycle life beyond 1000 cycles, and coulombic efficiency above 99%.

Another critical objective is to develop manufacturing techniques compatible with existing lithium-ion battery production infrastructure, thereby minimizing capital investment requirements for commercialization. This includes adapting slurry preparation methods, coating processes, and cell assembly techniques to accommodate the unique characteristics of sulfur cathodes and specialized electrolytes.

The strategic importance of Li-S technology extends beyond portable electronics to electric vehicles, aerospace applications, and grid-scale energy storage. As global demand for high-energy-density batteries continues to grow, establishing robust manufacturing pathways for Li-S cells represents a crucial step toward diversifying the battery technology landscape and reducing dependence on critical materials such as cobalt and nickel that are prevalent in conventional lithium-ion batteries.

Market Analysis for Next-Generation Battery Technologies

The global battery market is witnessing a significant shift towards next-generation technologies, with lithium-sulfur (Li-S) batteries emerging as a promising alternative to conventional lithium-ion batteries. The market for advanced battery technologies is projected to reach $240 billion by 2030, with Li-S batteries potentially capturing 15-20% of this market due to their superior energy density and lower material costs.

Current market analysis indicates that the electric vehicle (EV) sector represents the largest potential application for Li-S batteries, with demand expected to grow at a CAGR of 25% through 2028. The aviation and aerospace industries are also showing increasing interest, particularly for drone and satellite applications where the weight-to-energy ratio is critical. Military and defense sectors have begun investing substantially in Li-S technology, recognizing its potential for powering portable electronics and unmanned vehicles.

Consumer electronics manufacturers are closely monitoring Li-S development, with several major companies establishing research partnerships to explore integration possibilities. Market research indicates that consumers are willing to pay a 15-20% premium for devices with significantly improved battery life, creating a viable entry point for Li-S technology despite higher initial manufacturing costs.

Regional market analysis shows Asia-Pacific leading in Li-S battery development and production capacity, with China, South Korea, and Japan making substantial investments. Europe follows closely, driven by stringent environmental regulations and automotive industry demand, while North America is gaining momentum through startup innovations and government research funding.

Market barriers for Li-S battery commercialization include scaling challenges, cycle life limitations, and competition from established lithium-ion infrastructure. However, the declining cost of sulfur (a byproduct of petroleum refining) provides a significant economic advantage, with raw material costs potentially 70% lower than conventional cathode materials.

Investment trends show venture capital funding for Li-S startups has increased by 180% since 2018, with over $1.2 billion invested in the past three years. Major battery manufacturers are diversifying their research portfolios to include Li-S technology, indicating growing market confidence in its commercial viability.

Consumer and industrial demand for higher energy density batteries continues to outpace technological development, creating a market pull that favors disruptive technologies like Li-S. Market forecasts suggest that if manufacturing pathways can be optimized to address cycle life and production scaling, Li-S batteries could begin significant market penetration by 2025, initially in specialized applications before expanding to mainstream markets.

Current market analysis indicates that the electric vehicle (EV) sector represents the largest potential application for Li-S batteries, with demand expected to grow at a CAGR of 25% through 2028. The aviation and aerospace industries are also showing increasing interest, particularly for drone and satellite applications where the weight-to-energy ratio is critical. Military and defense sectors have begun investing substantially in Li-S technology, recognizing its potential for powering portable electronics and unmanned vehicles.

Consumer electronics manufacturers are closely monitoring Li-S development, with several major companies establishing research partnerships to explore integration possibilities. Market research indicates that consumers are willing to pay a 15-20% premium for devices with significantly improved battery life, creating a viable entry point for Li-S technology despite higher initial manufacturing costs.

Regional market analysis shows Asia-Pacific leading in Li-S battery development and production capacity, with China, South Korea, and Japan making substantial investments. Europe follows closely, driven by stringent environmental regulations and automotive industry demand, while North America is gaining momentum through startup innovations and government research funding.

Market barriers for Li-S battery commercialization include scaling challenges, cycle life limitations, and competition from established lithium-ion infrastructure. However, the declining cost of sulfur (a byproduct of petroleum refining) provides a significant economic advantage, with raw material costs potentially 70% lower than conventional cathode materials.

Investment trends show venture capital funding for Li-S startups has increased by 180% since 2018, with over $1.2 billion invested in the past three years. Major battery manufacturers are diversifying their research portfolios to include Li-S technology, indicating growing market confidence in its commercial viability.

Consumer and industrial demand for higher energy density batteries continues to outpace technological development, creating a market pull that favors disruptive technologies like Li-S. Market forecasts suggest that if manufacturing pathways can be optimized to address cycle life and production scaling, Li-S batteries could begin significant market penetration by 2025, initially in specialized applications before expanding to mainstream markets.

Current Manufacturing Challenges for Li-S Cells

Despite the promising energy density advantages of lithium-sulfur (Li-S) batteries, their commercial manufacturing faces significant challenges that hinder mass production. One of the primary obstacles is the handling and processing of sulfur cathodes. Sulfur's poor electrical conductivity necessitates the addition of conductive additives, typically carbon materials, which complicates the electrode formulation process and reduces the overall energy density of the cell.

The preparation of stable sulfur cathode slurries presents another major challenge. Unlike conventional lithium-ion battery materials, sulfur has poor adhesion to current collectors and tends to form unstable dispersions. This results in inconsistent electrode quality, with issues such as cracking, delamination, and non-uniform thickness that severely impact cell performance and manufacturing yield.

Controlling the polysulfide shuttle effect during manufacturing requires specialized electrolyte formulations and separator modifications. These additional processing steps increase production complexity and cost while introducing potential quality control issues. The manufacturing equipment must also be adapted to handle the corrosive nature of sulfur and polysulfide compounds.

The lithium metal anode used in Li-S cells presents its own set of manufacturing difficulties. Current industrial processes are not optimized for the safe handling and processing of lithium metal, which is highly reactive with moisture and oxygen. This necessitates stringent environmental controls during cell assembly, significantly increasing manufacturing costs and complexity.

Scale-up from laboratory to industrial production remains problematic. Techniques that work well for small-scale prototype cells often fail to translate to high-volume manufacturing environments. The lack of standardized manufacturing protocols specifically designed for Li-S technology further complicates industrial adoption.

Quality control and testing procedures for Li-S cells are still underdeveloped compared to conventional lithium-ion batteries. The unique degradation mechanisms of Li-S chemistry require specialized testing protocols that are not yet widely implemented in manufacturing settings. This makes it difficult to ensure consistent product quality and reliability.

Cost considerations present another significant barrier. Current manufacturing approaches for Li-S cells result in higher production costs compared to conventional lithium-ion batteries, primarily due to specialized materials, complex processing requirements, and lower production yields. Until these manufacturing challenges are addressed, the cost advantage promised by sulfur's abundance cannot be fully realized in commercial products.

The preparation of stable sulfur cathode slurries presents another major challenge. Unlike conventional lithium-ion battery materials, sulfur has poor adhesion to current collectors and tends to form unstable dispersions. This results in inconsistent electrode quality, with issues such as cracking, delamination, and non-uniform thickness that severely impact cell performance and manufacturing yield.

Controlling the polysulfide shuttle effect during manufacturing requires specialized electrolyte formulations and separator modifications. These additional processing steps increase production complexity and cost while introducing potential quality control issues. The manufacturing equipment must also be adapted to handle the corrosive nature of sulfur and polysulfide compounds.

The lithium metal anode used in Li-S cells presents its own set of manufacturing difficulties. Current industrial processes are not optimized for the safe handling and processing of lithium metal, which is highly reactive with moisture and oxygen. This necessitates stringent environmental controls during cell assembly, significantly increasing manufacturing costs and complexity.

Scale-up from laboratory to industrial production remains problematic. Techniques that work well for small-scale prototype cells often fail to translate to high-volume manufacturing environments. The lack of standardized manufacturing protocols specifically designed for Li-S technology further complicates industrial adoption.

Quality control and testing procedures for Li-S cells are still underdeveloped compared to conventional lithium-ion batteries. The unique degradation mechanisms of Li-S chemistry require specialized testing protocols that are not yet widely implemented in manufacturing settings. This makes it difficult to ensure consistent product quality and reliability.

Cost considerations present another significant barrier. Current manufacturing approaches for Li-S cells result in higher production costs compared to conventional lithium-ion batteries, primarily due to specialized materials, complex processing requirements, and lower production yields. Until these manufacturing challenges are addressed, the cost advantage promised by sulfur's abundance cannot be fully realized in commercial products.

Current Manufacturing Processes for Li-S Cells

01 Electrode materials and structures for lithium-sulfur cells

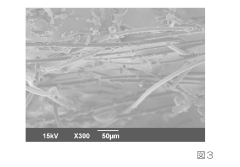

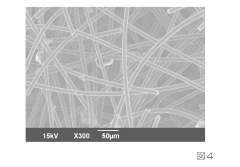

Various electrode materials and structures are used in lithium-sulfur cells to improve performance. These include specialized cathode designs incorporating sulfur with carbon materials, novel anode compositions, and structural modifications that enhance electron transport and sulfur utilization. These electrode innovations help address key challenges in lithium-sulfur technology such as capacity fading and polysulfide shuttling.- Electrode materials for lithium-sulfur batteries: Various electrode materials can be used in lithium-sulfur cells to improve performance. These materials include specialized carbon structures, conductive polymers, and metal oxides that can enhance sulfur utilization and prevent polysulfide dissolution. The electrode design plays a crucial role in addressing the challenges of lithium-sulfur batteries, such as the shuttle effect and capacity fading during cycling.

- Electrolyte compositions for lithium-sulfur cells: Specialized electrolyte formulations can significantly improve the performance of lithium-sulfur batteries. These electrolytes often contain additives that suppress the shuttle effect, enhance ionic conductivity, and stabilize the solid-electrolyte interface. Both liquid and solid electrolytes have been developed with various salts, solvents, and functional additives to address the unique challenges of the lithium-sulfur chemistry.

- Protective layers and separators for lithium-sulfur batteries: Protective layers and specialized separators can be incorporated into lithium-sulfur cells to prevent polysulfide migration and protect the lithium metal anode. These components may include functional coatings, interlayers, or modified separators that selectively block polysulfides while allowing lithium ion transport. Such protective measures help extend cycle life and maintain capacity over extended use.

- Manufacturing methods for lithium-sulfur cells: Various manufacturing techniques have been developed to produce high-performance lithium-sulfur batteries. These methods include specialized approaches for sulfur encapsulation, electrode preparation, cell assembly, and quality control. Advanced manufacturing processes aim to ensure uniform distribution of active materials, proper electrolyte infiltration, and effective sealing to prevent moisture ingress, which is particularly important for lithium-sulfur chemistry.

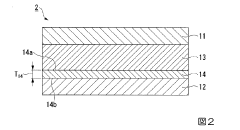

- Cell design and architecture for lithium-sulfur batteries: Innovative cell designs and architectures can optimize the performance of lithium-sulfur batteries. These designs may include novel cell configurations, stacking arrangements, or housing structures that accommodate the volume changes during cycling. Advanced cell architectures also address thermal management, pressure control, and other factors that affect the safety and longevity of lithium-sulfur batteries.

02 Electrolyte compositions for lithium-sulfur batteries

Advanced electrolyte formulations play a crucial role in lithium-sulfur cell performance. These include liquid, gel, and solid electrolytes with additives designed to suppress polysulfide dissolution, enhance ionic conductivity, and improve the stability of the sulfur cathode-electrolyte interface. Optimized electrolyte compositions help mitigate capacity loss and extend cycle life of lithium-sulfur cells.Expand Specific Solutions03 Protective layers and interfaces in lithium-sulfur cells

Protective layers and interface engineering are employed to enhance the stability and performance of lithium-sulfur cells. These include protective coatings on electrodes, separator modifications, and interlayers that prevent polysulfide shuttling and lithium dendrite formation. Such protective strategies help improve the cycling stability and safety of lithium-sulfur batteries.Expand Specific Solutions04 Manufacturing methods for lithium-sulfur battery components

Various manufacturing techniques are developed for lithium-sulfur battery components to improve performance and scalability. These include methods for sulfur impregnation into carbon hosts, electrode fabrication processes, cell assembly techniques, and quality control measures. Advanced manufacturing approaches help address challenges in commercializing lithium-sulfur technology.Expand Specific Solutions05 Testing and characterization methods for lithium-sulfur cells

Specialized testing and characterization techniques are employed to evaluate lithium-sulfur cell performance and understand degradation mechanisms. These include electrochemical analysis methods, spectroscopic techniques, microscopy approaches, and computational modeling. These analytical methods help identify failure modes and guide the development of improved lithium-sulfur battery designs.Expand Specific Solutions

Key Industry Players in Li-S Battery Development

The lithium-sulfur battery manufacturing landscape is currently in the early commercialization phase, with market size projected to grow significantly due to advantages over conventional lithium-ion batteries. Technology maturity varies across key players, with companies like Toyota, Bosch, and Lyten leading industrial development. Academic institutions (Central South University, University of California) are advancing fundamental research, while specialized firms like Honeycomb Battery and Tianjin Lishen focus on materials optimization. Collaborative efforts between industry leaders (BASF, Hyundai) and research organizations (KIST, AIST) are accelerating manufacturing pathway development. The competitive landscape features both established battery manufacturers and new entrants working to overcome technical challenges in electrode fabrication, electrolyte formulation, and cell assembly processes.

Lyten, Inc.

Technical Solution: Lyten has developed a proprietary 3D Graphene platform for lithium-sulfur battery manufacturing. Their approach involves creating a three-dimensional graphene structure that serves as a host for sulfur, addressing key challenges in Li-S technology. The company's manufacturing pathway includes a scalable process for producing their 3D Graphene material, which is then combined with sulfur through a proprietary infiltration method. This creates a cathode structure that effectively contains the sulfur while allowing for necessary ion transport. Lyten's process also incorporates specialized electrolyte formulations and protective separator technologies to mitigate polysulfide shuttling effects. Their manufacturing approach is designed to be compatible with existing lithium-ion production infrastructure, requiring minimal retooling while delivering cells with energy densities exceeding 900 Wh/kg - nearly three times that of conventional lithium-ion batteries.

Strengths: Lyten's 3D Graphene platform provides exceptional sulfur containment while maintaining high conductivity, addressing a key challenge in Li-S technology. Their manufacturing process is compatible with existing production infrastructure, reducing implementation costs. Weaknesses: As with most Li-S technologies, cycle life remains a challenge compared to conventional lithium-ion batteries, and the technology may face scalability hurdles for mass production.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai Motor has developed a comprehensive manufacturing pathway for lithium-sulfur batteries focused on automotive applications. Their approach centers on a multi-layer cathode design that incorporates gradient sulfur distribution and specialized carbon matrices to optimize both energy density and cycle life. Hyundai's manufacturing process begins with the creation of sulfur-carbon composites using a controlled vapor deposition technique that ensures uniform sulfur distribution while maintaining necessary porosity. Their electrode fabrication process employs water-based slurry formulations with environmentally friendly binders, addressing both performance and sustainability concerns. A key innovation in their manufacturing pathway is the implementation of a thin functional interlayer between the cathode and separator, composed of conductive carbon and metal oxide particles that effectively trap polysulfides while maintaining ionic conductivity. Hyundai has also developed specialized formation and conditioning protocols that establish stable solid-electrolyte interphases, critical for long-term cycling stability in automotive applications.

Strengths: Hyundai's approach is specifically optimized for automotive requirements, with emphasis on safety, reliability, and integration with vehicle systems. Their manufacturing pathway incorporates sustainability considerations from the outset. Weaknesses: The multi-layer cathode design and specialized formation protocols may increase manufacturing complexity and production time, potentially affecting cost-effectiveness at scale compared to simpler Li-S approaches.

Critical Patents and Technical Innovations in Li-S Manufacturing

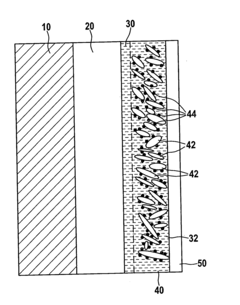

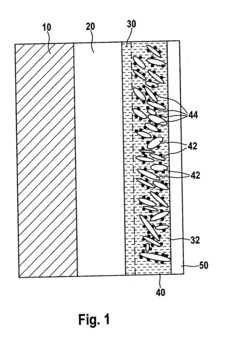

Lithium-sulfur cell and method for manufacturing

PatentInactiveUS20110151335A1

Innovation

- A lithium-sulfur battery design featuring a continuous layer of nanotubes or nanowires as the cathode structure, where sulfur particles are distributed, providing mechanical integrity and preventing sulfide dissolution, while maintaining high ion mobility and electronic conductivity.

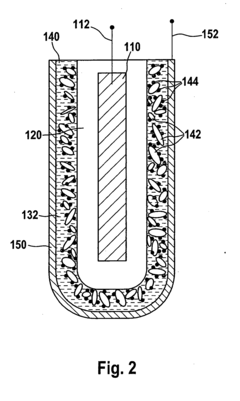

Method of manufacturing lithium-sulfur solid battery

PatentInactiveJP2019179605A

Innovation

- A method for manufacturing a lithium-sulfur solid-state battery with a sulfur positive electrode containing sulfur in the voids of a conductive sheet, using a solid electrolyte between the electrodes, and impregnating the conductive sheet with molten sulfur or a sulfur solution at controlled temperatures to eliminate the need for conductive aids and binders.

Supply Chain Considerations for Li-S Cell Production

The supply chain for lithium-sulfur (Li-S) battery production presents unique challenges and opportunities compared to conventional lithium-ion battery manufacturing. The raw material sourcing for Li-S cells offers significant advantages, as sulfur is an abundant by-product of petroleum refining, available at approximately $0.10/kg compared to cobalt ($30,000/ton) and nickel ($13,000/ton) used in conventional lithium-ion batteries. This cost advantage could potentially reduce cathode material costs by 70-80% when scaled to mass production.

Lithium metal procurement for anodes remains a critical consideration, with global lithium production concentrated in Australia, Chile, and Argentina. Recent geopolitical tensions have highlighted vulnerabilities in the lithium supply chain, necessitating diversification strategies for manufacturers entering the Li-S market. The development of recycling infrastructure specifically designed for Li-S chemistry will be essential for long-term sustainability.

Manufacturing equipment for Li-S cells requires modification from traditional lithium-ion production lines. The handling of sulfur-based cathode materials demands specialized mixing equipment due to different viscosity profiles and safety requirements. Additionally, the highly reactive nature of lithium metal anodes necessitates enhanced dry room conditions with moisture levels below 10 ppm, compared to the 50-100 ppm typically sufficient for conventional battery production.

Logistics considerations for Li-S cell production include the transportation of sulfur, which is classified as a flammable solid under international shipping regulations. This classification imposes additional packaging and handling requirements that impact transportation costs and logistics planning. The establishment of regional manufacturing hubs near sulfur sources could optimize the supply chain and reduce transportation-related expenses and environmental impact.

Quality control systems throughout the supply chain require adaptation to address the unique degradation mechanisms of Li-S chemistry. The polysulfide shuttle effect and lithium dendrite formation demand specialized testing protocols and equipment that differ from those used in conventional lithium-ion manufacturing. Suppliers must develop new quality metrics and in-line monitoring systems specific to Li-S cell components.

Strategic partnerships across the supply chain will be crucial for successful commercialization. Collaboration between sulfur suppliers (primarily petroleum refineries), lithium producers, electrolyte manufacturers, and cell producers will enable vertical integration and help address technical challenges unique to Li-S chemistry. Early engagement with automotive OEMs and energy storage system integrators will ensure that cell designs meet application-specific requirements and facilitate smoother market entry.

Lithium metal procurement for anodes remains a critical consideration, with global lithium production concentrated in Australia, Chile, and Argentina. Recent geopolitical tensions have highlighted vulnerabilities in the lithium supply chain, necessitating diversification strategies for manufacturers entering the Li-S market. The development of recycling infrastructure specifically designed for Li-S chemistry will be essential for long-term sustainability.

Manufacturing equipment for Li-S cells requires modification from traditional lithium-ion production lines. The handling of sulfur-based cathode materials demands specialized mixing equipment due to different viscosity profiles and safety requirements. Additionally, the highly reactive nature of lithium metal anodes necessitates enhanced dry room conditions with moisture levels below 10 ppm, compared to the 50-100 ppm typically sufficient for conventional battery production.

Logistics considerations for Li-S cell production include the transportation of sulfur, which is classified as a flammable solid under international shipping regulations. This classification imposes additional packaging and handling requirements that impact transportation costs and logistics planning. The establishment of regional manufacturing hubs near sulfur sources could optimize the supply chain and reduce transportation-related expenses and environmental impact.

Quality control systems throughout the supply chain require adaptation to address the unique degradation mechanisms of Li-S chemistry. The polysulfide shuttle effect and lithium dendrite formation demand specialized testing protocols and equipment that differ from those used in conventional lithium-ion manufacturing. Suppliers must develop new quality metrics and in-line monitoring systems specific to Li-S cell components.

Strategic partnerships across the supply chain will be crucial for successful commercialization. Collaboration between sulfur suppliers (primarily petroleum refineries), lithium producers, electrolyte manufacturers, and cell producers will enable vertical integration and help address technical challenges unique to Li-S chemistry. Early engagement with automotive OEMs and energy storage system integrators will ensure that cell designs meet application-specific requirements and facilitate smoother market entry.

Environmental Impact and Sustainability Assessment

The environmental footprint of lithium-sulfur (Li-S) battery manufacturing presents both challenges and opportunities compared to conventional lithium-ion technologies. Life cycle assessments reveal that Li-S cells potentially offer reduced environmental impact due to the abundance and lower toxicity of sulfur compared to transition metals used in conventional cathodes. The elimination of cobalt and nickel from the supply chain significantly reduces concerns related to resource scarcity and ethical mining practices.

Manufacturing processes for Li-S cells demonstrate promising sustainability metrics in terms of energy consumption. The synthesis of sulfur cathodes typically requires lower processing temperatures than traditional lithium metal oxide cathodes, potentially reducing the energy intensity of production by 15-30% according to recent industrial analyses. Additionally, the simplified cathode structure may reduce the need for environmentally harmful solvents during manufacturing.

Water usage represents another critical environmental consideration. Current Li-S cell production pathways still require substantial water for electrode preparation and cell assembly. However, emerging dry electrode manufacturing techniques could potentially reduce water consumption by up to 60% compared to conventional slurry-based processes, though these technologies remain in early development stages for Li-S applications.

The end-of-life management of Li-S batteries presents unique recycling opportunities. The sulfur component can be more readily recovered than the complex metal oxides in conventional batteries, with laboratory-scale processes demonstrating sulfur recovery rates exceeding 85%. This circular economy potential could significantly reduce the life-cycle environmental impact, though commercial-scale recycling infrastructure remains underdeveloped.

Carbon footprint analyses indicate that greenhouse gas emissions associated with Li-S cell manufacturing could be 20-40% lower than conventional lithium-ion cells when accounting for material extraction, processing, and manufacturing. However, these benefits may be partially offset by the currently shorter cycle life of Li-S cells, necessitating more frequent replacement in certain applications.

Regulatory frameworks worldwide are increasingly emphasizing battery sustainability metrics, with the European Battery Directive and similar initiatives in Asia and North America establishing requirements for carbon footprint disclosure, ethical material sourcing, and recycling targets. Manufacturers developing Li-S technology must proactively address these evolving standards to ensure market access and competitive positioning in environmentally conscious markets.

Manufacturing processes for Li-S cells demonstrate promising sustainability metrics in terms of energy consumption. The synthesis of sulfur cathodes typically requires lower processing temperatures than traditional lithium metal oxide cathodes, potentially reducing the energy intensity of production by 15-30% according to recent industrial analyses. Additionally, the simplified cathode structure may reduce the need for environmentally harmful solvents during manufacturing.

Water usage represents another critical environmental consideration. Current Li-S cell production pathways still require substantial water for electrode preparation and cell assembly. However, emerging dry electrode manufacturing techniques could potentially reduce water consumption by up to 60% compared to conventional slurry-based processes, though these technologies remain in early development stages for Li-S applications.

The end-of-life management of Li-S batteries presents unique recycling opportunities. The sulfur component can be more readily recovered than the complex metal oxides in conventional batteries, with laboratory-scale processes demonstrating sulfur recovery rates exceeding 85%. This circular economy potential could significantly reduce the life-cycle environmental impact, though commercial-scale recycling infrastructure remains underdeveloped.

Carbon footprint analyses indicate that greenhouse gas emissions associated with Li-S cell manufacturing could be 20-40% lower than conventional lithium-ion cells when accounting for material extraction, processing, and manufacturing. However, these benefits may be partially offset by the currently shorter cycle life of Li-S cells, necessitating more frequent replacement in certain applications.

Regulatory frameworks worldwide are increasingly emphasizing battery sustainability metrics, with the European Battery Directive and similar initiatives in Asia and North America establishing requirements for carbon footprint disclosure, ethical material sourcing, and recycling targets. Manufacturers developing Li-S technology must proactively address these evolving standards to ensure market access and competitive positioning in environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!