Scaling Li-S For Energy Storage Systems: Challenges And Solutions

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Li-S Battery Technology Evolution and Objectives

Lithium-sulfur (Li-S) batteries have emerged as a promising next-generation energy storage technology, offering theoretical energy densities up to five times higher than conventional lithium-ion batteries. The evolution of Li-S battery technology can be traced back to the 1960s when the first conceptual designs were proposed. However, significant research momentum only began building in the early 2000s as limitations of traditional lithium-ion chemistries became apparent and the demand for higher energy density solutions increased.

The technological trajectory of Li-S batteries has been marked by several breakthrough periods. The initial phase focused on fundamental understanding of the complex electrochemistry involving multiple polysulfide species. This was followed by innovations in cathode materials, particularly the development of carbon-sulfur composite structures to improve sulfur utilization and conductivity. The third wave of advancement centered on electrolyte formulations and additives to mitigate the notorious "shuttle effect" - a major degradation mechanism in Li-S systems.

Recent years have witnessed accelerated progress in addressing key challenges, with research expanding beyond materials to cell design, manufacturing processes, and system integration considerations. This evolution reflects the technology's transition from laboratory curiosity to commercial viability, with several startups and established companies now actively pursuing Li-S battery commercialization.

The primary objectives driving Li-S battery development include achieving energy densities exceeding 500 Wh/kg at the cell level, extending cycle life beyond 1,000 cycles, improving rate capability for fast-charging applications, and enhancing safety characteristics. These targets are aligned with the requirements of next-generation electric vehicles, aerospace applications, and grid-scale energy storage systems.

Another critical objective is cost reduction through the utilization of abundant and inexpensive sulfur, potentially enabling battery costs below $100/kWh - a threshold widely considered necessary for mass electric vehicle adoption. Environmental sustainability represents an additional goal, with Li-S technology offering advantages in terms of resource availability and reduced reliance on critical materials like cobalt and nickel.

The technology evolution pathway is increasingly focused on scalable manufacturing processes that can translate laboratory achievements into commercial products. This includes developing electrode fabrication techniques compatible with existing production infrastructure, designing electrolyte systems suitable for large-format cells, and creating battery management systems specifically optimized for the unique characteristics of Li-S chemistry.

The technological trajectory of Li-S batteries has been marked by several breakthrough periods. The initial phase focused on fundamental understanding of the complex electrochemistry involving multiple polysulfide species. This was followed by innovations in cathode materials, particularly the development of carbon-sulfur composite structures to improve sulfur utilization and conductivity. The third wave of advancement centered on electrolyte formulations and additives to mitigate the notorious "shuttle effect" - a major degradation mechanism in Li-S systems.

Recent years have witnessed accelerated progress in addressing key challenges, with research expanding beyond materials to cell design, manufacturing processes, and system integration considerations. This evolution reflects the technology's transition from laboratory curiosity to commercial viability, with several startups and established companies now actively pursuing Li-S battery commercialization.

The primary objectives driving Li-S battery development include achieving energy densities exceeding 500 Wh/kg at the cell level, extending cycle life beyond 1,000 cycles, improving rate capability for fast-charging applications, and enhancing safety characteristics. These targets are aligned with the requirements of next-generation electric vehicles, aerospace applications, and grid-scale energy storage systems.

Another critical objective is cost reduction through the utilization of abundant and inexpensive sulfur, potentially enabling battery costs below $100/kWh - a threshold widely considered necessary for mass electric vehicle adoption. Environmental sustainability represents an additional goal, with Li-S technology offering advantages in terms of resource availability and reduced reliance on critical materials like cobalt and nickel.

The technology evolution pathway is increasingly focused on scalable manufacturing processes that can translate laboratory achievements into commercial products. This includes developing electrode fabrication techniques compatible with existing production infrastructure, designing electrolyte systems suitable for large-format cells, and creating battery management systems specifically optimized for the unique characteristics of Li-S chemistry.

Market Analysis for Large-Scale Li-S Energy Storage

The global energy storage market is witnessing unprecedented growth, with projections indicating a compound annual growth rate (CAGR) of 20-25% through 2030. Within this expanding landscape, lithium-sulfur (Li-S) battery technology represents a promising segment poised for significant market penetration. Current market valuations for advanced battery technologies exceed $100 billion, with Li-S technology expected to capture an increasing share as technical challenges are overcome.

Market demand for large-scale energy storage solutions is being driven by several converging factors. The global transition to renewable energy sources necessitates efficient, high-capacity storage systems to address intermittency issues. Grid stabilization requirements are becoming more stringent as renewable penetration increases, creating opportunities for technologies that can provide long-duration storage capabilities. Additionally, the electrification of transportation and industrial sectors is accelerating demand for energy storage solutions with higher energy density and lower cost profiles.

Li-S technology offers compelling market advantages that position it favorably against competing technologies. With theoretical energy densities reaching 2,600 Wh/kg—approximately five times that of conventional lithium-ion batteries—Li-S systems present a step-change improvement for applications where weight and volume constraints are critical. The abundance and low cost of sulfur as a cathode material (approximately $150 per ton) provides a significant raw material cost advantage over cobalt and nickel-based alternatives.

Market segmentation analysis reveals several high-potential application areas for scaled Li-S technology. Utility-scale grid storage represents the largest potential market by volume, with particular opportunities in regions pursuing aggressive renewable energy targets. The electric aviation sector, though smaller in immediate volume, offers premium pricing potential due to the critical nature of weight reduction. Military and defense applications constitute another high-value niche market where performance advantages outweigh initial cost considerations.

Regional market analysis indicates varying adoption potentials. Asia-Pacific, particularly China, leads in manufacturing capacity development and deployment incentives. Europe demonstrates strong policy support through initiatives like the European Battery Alliance and stringent carbon reduction targets. North America shows increasing investment activity, particularly in grid-scale applications and defense-related energy storage.

Economic modeling suggests that Li-S technology could achieve cost parity with conventional lithium-ion batteries by 2027-2028, assuming current technical development trajectories continue. Total cost of ownership analyses indicate particular advantages in applications requiring frequent deep cycling or where weight premiums apply.

Market demand for large-scale energy storage solutions is being driven by several converging factors. The global transition to renewable energy sources necessitates efficient, high-capacity storage systems to address intermittency issues. Grid stabilization requirements are becoming more stringent as renewable penetration increases, creating opportunities for technologies that can provide long-duration storage capabilities. Additionally, the electrification of transportation and industrial sectors is accelerating demand for energy storage solutions with higher energy density and lower cost profiles.

Li-S technology offers compelling market advantages that position it favorably against competing technologies. With theoretical energy densities reaching 2,600 Wh/kg—approximately five times that of conventional lithium-ion batteries—Li-S systems present a step-change improvement for applications where weight and volume constraints are critical. The abundance and low cost of sulfur as a cathode material (approximately $150 per ton) provides a significant raw material cost advantage over cobalt and nickel-based alternatives.

Market segmentation analysis reveals several high-potential application areas for scaled Li-S technology. Utility-scale grid storage represents the largest potential market by volume, with particular opportunities in regions pursuing aggressive renewable energy targets. The electric aviation sector, though smaller in immediate volume, offers premium pricing potential due to the critical nature of weight reduction. Military and defense applications constitute another high-value niche market where performance advantages outweigh initial cost considerations.

Regional market analysis indicates varying adoption potentials. Asia-Pacific, particularly China, leads in manufacturing capacity development and deployment incentives. Europe demonstrates strong policy support through initiatives like the European Battery Alliance and stringent carbon reduction targets. North America shows increasing investment activity, particularly in grid-scale applications and defense-related energy storage.

Economic modeling suggests that Li-S technology could achieve cost parity with conventional lithium-ion batteries by 2027-2028, assuming current technical development trajectories continue. Total cost of ownership analyses indicate particular advantages in applications requiring frequent deep cycling or where weight premiums apply.

Technical Barriers and Global Development Status

Despite significant advancements in lithium-sulfur (Li-S) battery technology, several critical technical barriers continue to impede its widespread commercial adoption. The most persistent challenge remains the "polysulfide shuttle effect," where soluble lithium polysulfides dissolve in the electrolyte during cycling, causing active material loss, reduced coulombic efficiency, and accelerated capacity fading. This fundamental issue has proven difficult to overcome at scale despite numerous laboratory-level solutions.

Sulfur's inherently poor electrical conductivity (5×10^-30 S/cm) presents another significant barrier, necessitating conductive additives that reduce the overall energy density of the system. Additionally, the substantial volume expansion (approximately 80%) during lithiation creates mechanical stress that degrades electrode integrity over multiple cycles, particularly problematic when scaling to larger format cells.

The low areal sulfur loading in most research prototypes (typically 1-3 mg/cm²) remains insufficient for commercial viability, where 6-8 mg/cm² is considered the minimum threshold for competitive energy density. Achieving higher loadings introduces cascading challenges in electrolyte management, ion transport, and mechanical stability.

From a global development perspective, Li-S technology has progressed unevenly across different regions. European research institutions and companies, particularly in the UK and Germany, have established leadership positions in fundamental Li-S research, with OXIS Energy (until its closure in 2021) and Fraunhofer IWS demonstrating promising prototypes. In North America, companies like Sion Power and Lyten have secured significant venture funding and demonstrated cells with energy densities exceeding 400 Wh/kg.

Asian development has been concentrated in China and South Korea, where government-backed research initiatives have accelerated progress. The Chinese Academy of Sciences and various university partnerships have published breakthrough research on sulfur cathode architectures, while South Korean conglomerates have focused on electrolyte innovations.

Current technology readiness levels (TRL) vary significantly by application. For specialized aerospace and defense applications, Li-S batteries have reached TRL 6-7 with limited deployment in high-altitude platforms. However, for mainstream electric vehicles and grid storage applications, the technology remains at TRL 3-5, with significant scaling challenges unresolved.

Recent progress indicators suggest that commercial viability for niche applications may be achieved within 3-5 years, while mass-market applications likely require 7-10 years of additional development to overcome the fundamental technical barriers while maintaining cost competitiveness against rapidly improving lithium-ion technologies.

Sulfur's inherently poor electrical conductivity (5×10^-30 S/cm) presents another significant barrier, necessitating conductive additives that reduce the overall energy density of the system. Additionally, the substantial volume expansion (approximately 80%) during lithiation creates mechanical stress that degrades electrode integrity over multiple cycles, particularly problematic when scaling to larger format cells.

The low areal sulfur loading in most research prototypes (typically 1-3 mg/cm²) remains insufficient for commercial viability, where 6-8 mg/cm² is considered the minimum threshold for competitive energy density. Achieving higher loadings introduces cascading challenges in electrolyte management, ion transport, and mechanical stability.

From a global development perspective, Li-S technology has progressed unevenly across different regions. European research institutions and companies, particularly in the UK and Germany, have established leadership positions in fundamental Li-S research, with OXIS Energy (until its closure in 2021) and Fraunhofer IWS demonstrating promising prototypes. In North America, companies like Sion Power and Lyten have secured significant venture funding and demonstrated cells with energy densities exceeding 400 Wh/kg.

Asian development has been concentrated in China and South Korea, where government-backed research initiatives have accelerated progress. The Chinese Academy of Sciences and various university partnerships have published breakthrough research on sulfur cathode architectures, while South Korean conglomerates have focused on electrolyte innovations.

Current technology readiness levels (TRL) vary significantly by application. For specialized aerospace and defense applications, Li-S batteries have reached TRL 6-7 with limited deployment in high-altitude platforms. However, for mainstream electric vehicles and grid storage applications, the technology remains at TRL 3-5, with significant scaling challenges unresolved.

Recent progress indicators suggest that commercial viability for niche applications may be achieved within 3-5 years, while mass-market applications likely require 7-10 years of additional development to overcome the fundamental technical barriers while maintaining cost competitiveness against rapidly improving lithium-ion technologies.

Current Scaling Solutions for Li-S Systems

01 Electrode materials and structures for Li-S batteries

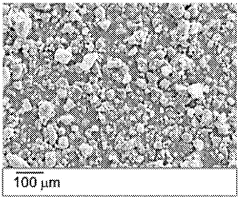

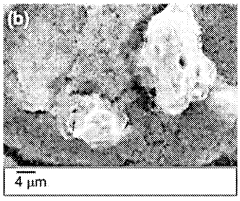

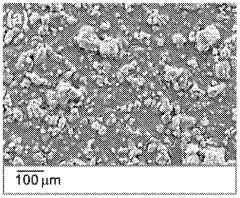

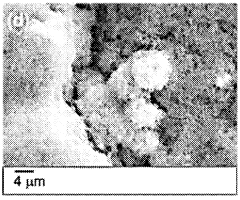

Advanced electrode materials and structures are critical for scaling Li-S batteries. These include novel carbon-based materials, conductive polymers, and metal oxides that can effectively host sulfur and mitigate polysulfide shuttling. Hierarchical porous structures and nanocomposites help improve sulfur utilization and cycling stability. These materials enable higher energy density and better performance at commercial scale.- Electrode materials for Li-S batteries: Various electrode materials can be used in lithium-sulfur batteries to improve performance and scalability. These materials include carbon-based structures, metal oxides, and composite materials that can enhance sulfur utilization and prevent polysulfide shuttling. The electrode design plays a crucial role in the battery's capacity, cycle life, and overall scalability for commercial applications.

- Electrolyte formulations for Li-S batteries: Specialized electrolyte formulations are essential for addressing the challenges in scaling lithium-sulfur batteries. These formulations can include additives that suppress polysulfide dissolution, enhance ionic conductivity, and improve the stability of the solid-electrolyte interphase. Optimized electrolytes contribute significantly to extending cycle life and enabling the commercial scaling of Li-S battery technology.

- Manufacturing processes for scaled production: Scaling lithium-sulfur batteries requires specialized manufacturing processes that can be implemented at industrial scale. These processes include methods for uniform sulfur loading, electrode coating techniques, cell assembly procedures, and quality control measures. Advanced manufacturing approaches help overcome challenges related to consistency, reproducibility, and cost-effectiveness in mass production of Li-S batteries.

- Sulfur loading and utilization optimization: Optimizing sulfur loading and utilization is critical for scaling lithium-sulfur batteries. This involves techniques to increase the sulfur content while maintaining good electronic conductivity, managing volume expansion during cycling, and ensuring efficient redox reactions. Higher sulfur loading directly impacts energy density, which is essential for commercial viability of Li-S batteries in various applications.

- Protective coatings and interlayers: Protective coatings and interlayers play a vital role in scaling lithium-sulfur batteries by addressing key degradation mechanisms. These include specialized barriers that prevent polysulfide migration, protect the lithium metal anode from dendrite formation, and enhance the structural stability of electrodes during cycling. Such protective strategies are essential for achieving the long-term stability required for commercial-scale Li-S battery applications.

02 Electrolyte innovations for Li-S battery scaling

Novel electrolyte formulations are essential for scaling Li-S batteries. These include functional additives, ionic liquids, and solid-state electrolytes that suppress polysulfide dissolution and enhance lithium ion transport. Modified electrolytes can improve the interfacial stability between electrodes and electrolyte, leading to extended cycle life and better performance at larger scales. These innovations address key challenges in commercializing Li-S technology.Expand Specific Solutions03 Manufacturing processes for scaled Li-S battery production

Scalable manufacturing processes are crucial for commercial Li-S battery production. These include optimized coating techniques, roll-to-roll processing, and assembly methods adapted for sulfur-based chemistries. Advanced quality control systems and automation help maintain consistency in large-scale production. These manufacturing innovations reduce costs and improve the feasibility of mass-producing Li-S batteries with consistent performance.Expand Specific Solutions04 Protective coatings and interlayers for Li-S battery components

Protective coatings and interlayers play a vital role in scaling Li-S batteries. These include functional separators, lithium metal protection layers, and sulfur encapsulation techniques that prevent polysulfide shuttling and lithium dendrite formation. These protective strategies enhance battery safety, extend cycle life, and improve performance consistency at larger scales, addressing key barriers to commercialization.Expand Specific Solutions05 System integration and battery management for scaled Li-S batteries

System integration and battery management solutions are essential for scaling Li-S technology. These include specialized battery management systems that account for the unique discharge profile of Li-S cells, thermal management strategies, and cell balancing techniques. Advanced monitoring systems help optimize performance and safety in larger battery packs. These innovations enable the practical implementation of Li-S batteries in various applications at commercial scale.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Lithium-Sulfur (Li-S) battery technology for energy storage systems is currently in the early commercialization phase, with a growing market projected to reach $1.4 billion by 2028. The competitive landscape features established players like Tesla and LG Energy Solution investing heavily in R&D, alongside specialized innovators such as BOS Balance of Storage Systems and Unicorn Energy. Academic institutions including Cornell University, University of Maryland, and Chinese research centers are advancing fundamental solutions to Li-S challenges. Technical maturity remains moderate, with companies addressing key issues of sulfur cathode stability, lithium dendrite formation, and electrolyte optimization. The industry is witnessing increased collaboration between commercial entities and research institutions to overcome cycle life and energy density limitations for grid-scale applications.

Hitachi Energy Ltd.

Technical Solution: Hitachi Energy has developed an innovative approach to Li-S battery technology for grid-scale energy storage systems. Their solution addresses the polysulfide shuttle effect through a multi-layered protection strategy combining physical confinement and chemical binding. Hitachi's proprietary cathode design incorporates nitrogen-doped mesoporous carbon structures that chemically bind with polysulfides while providing necessary electrical conductivity. Their system utilizes a gel polymer electrolyte that reduces polysulfide dissolution while maintaining high ionic conductivity. For large-scale implementation, Hitachi has engineered modular battery containers with advanced thermal management systems specifically designed for Li-S chemistry's unique heating profiles. Their battery management system incorporates machine learning algorithms that adapt to the complex electrochemical behavior of Li-S cells, optimizing performance across varying discharge rates and environmental conditions. Hitachi's manufacturing approach focuses on scalability through automated production lines adapted from their existing energy storage manufacturing facilities.

Strengths: Hitachi's extensive experience with grid integration provides practical solutions for deploying Li-S at utility scale. Their thermal management expertise addresses safety concerns critical for large-scale energy storage. Weaknesses: The technology currently shows performance degradation in high-temperature environments, and the manufacturing process requires specialized equipment that increases initial capital investment.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-faceted approach to scaling Li-S batteries for energy storage applications. Their technology centers on a proprietary sulfur-carbon composite cathode structure that utilizes microporous carbon to trap sulfur and limit polysulfide shuttling. LG has developed specialized functional electrolyte additives that form protective layers on both electrodes, significantly improving cycling stability. Their manufacturing process incorporates a solvent-free dry mixing technique that reduces environmental impact while enabling consistent large-scale production. LG's Li-S cells feature a dual-layer separator with selective polysulfide-blocking properties, addressing one of the key degradation mechanisms. The company has also created advanced battery management algorithms specifically calibrated for Li-S chemistry's unique discharge profile, enabling more accurate state-of-charge estimation and thermal management for large-scale energy storage systems.

Strengths: LG's established manufacturing infrastructure allows for rapid scaling of new battery technologies. Their expertise in electrolyte formulation has yielded significant improvements in Li-S cycle life. Weaknesses: Higher initial production costs compared to conventional lithium-ion batteries, and the technology still requires further optimization for long-duration energy storage applications exceeding 5,000 cycles.

Critical Patents and Research Breakthroughs

Lithium sulfur battery electrode process

PatentWO2023229728A2

Innovation

- A method involving dry mixing sulfur particles with a binder and a carbon source, followed by solvent addition to form a cathode slurry, resulting in a sulfur cathode with a porous shell structure that enhances electronic conductivity, accommodates volume expansion, and physically traps polysulfides, using a controlled binder-dissolution process to create a scalable and affordable electrode architecture.

Material Supply Chain Considerations

The lithium-sulfur (Li-S) battery supply chain presents unique challenges and opportunities compared to conventional lithium-ion batteries. Sulfur, the primary cathode material, offers significant advantages as an abundant, low-cost resource widely available as a byproduct of petroleum refining. This abundance contrasts sharply with the supply constraints facing critical materials in traditional lithium-ion batteries, such as cobalt and nickel, which face geopolitical risks and ethical sourcing concerns.

However, the Li-S battery supply chain faces several material-specific challenges. The production of high-purity lithium metal for anodes remains costly and energy-intensive, with limited global manufacturing capacity. Current lithium metal production methods require significant refinement to achieve the quality standards necessary for battery applications, creating a potential bottleneck as Li-S technology scales.

Electrolyte components for Li-S batteries, particularly lithium salts and specialized additives, represent another critical supply chain consideration. These materials often require sophisticated synthesis processes and high-purity precursors, potentially limiting manufacturing scalability. The development of alternative electrolyte formulations using more readily available materials could significantly improve supply chain resilience.

Carbon materials, essential for sulfur cathode composites, present fewer supply constraints but require specialized manufacturing processes to achieve the necessary structural properties. The production of advanced carbon architectures with optimized porosity and surface functionality demands precise control over synthesis conditions, potentially limiting manufacturing throughput and increasing costs.

Regional disparities in material availability and processing capabilities also impact the Li-S supply chain. China currently dominates much of the battery material processing industry, creating potential vulnerabilities for global supply security. Developing diversified supply sources and localized processing capabilities will be essential for building resilient Li-S battery manufacturing ecosystems.

Recycling infrastructure represents another critical consideration for sustainable Li-S deployment. Unlike conventional lithium-ion batteries, Li-S cells contain minimal amounts of high-value metals like cobalt, potentially reducing economic incentives for recycling. However, the development of efficient lithium and electrolyte recovery processes could improve the lifecycle sustainability of Li-S technology while reducing dependence on primary material sources.

Strategic partnerships between battery manufacturers, material suppliers, and end-users will be essential for addressing these supply chain challenges. Vertical integration strategies, long-term supply agreements, and collaborative research initiatives can help secure material supplies while driving continued innovation in material processing and manufacturing technologies.

However, the Li-S battery supply chain faces several material-specific challenges. The production of high-purity lithium metal for anodes remains costly and energy-intensive, with limited global manufacturing capacity. Current lithium metal production methods require significant refinement to achieve the quality standards necessary for battery applications, creating a potential bottleneck as Li-S technology scales.

Electrolyte components for Li-S batteries, particularly lithium salts and specialized additives, represent another critical supply chain consideration. These materials often require sophisticated synthesis processes and high-purity precursors, potentially limiting manufacturing scalability. The development of alternative electrolyte formulations using more readily available materials could significantly improve supply chain resilience.

Carbon materials, essential for sulfur cathode composites, present fewer supply constraints but require specialized manufacturing processes to achieve the necessary structural properties. The production of advanced carbon architectures with optimized porosity and surface functionality demands precise control over synthesis conditions, potentially limiting manufacturing throughput and increasing costs.

Regional disparities in material availability and processing capabilities also impact the Li-S supply chain. China currently dominates much of the battery material processing industry, creating potential vulnerabilities for global supply security. Developing diversified supply sources and localized processing capabilities will be essential for building resilient Li-S battery manufacturing ecosystems.

Recycling infrastructure represents another critical consideration for sustainable Li-S deployment. Unlike conventional lithium-ion batteries, Li-S cells contain minimal amounts of high-value metals like cobalt, potentially reducing economic incentives for recycling. However, the development of efficient lithium and electrolyte recovery processes could improve the lifecycle sustainability of Li-S technology while reducing dependence on primary material sources.

Strategic partnerships between battery manufacturers, material suppliers, and end-users will be essential for addressing these supply chain challenges. Vertical integration strategies, long-term supply agreements, and collaborative research initiatives can help secure material supplies while driving continued innovation in material processing and manufacturing technologies.

Safety and Environmental Impact Assessment

Lithium-sulfur (Li-S) batteries present unique safety challenges and environmental considerations that must be addressed before widespread commercial deployment. The inherent chemical properties of sulfur and lithium create specific safety concerns during operation. Elemental sulfur and lithium polysulfides formed during cycling can react with moisture to produce hydrogen sulfide gas, which is both toxic and flammable. Additionally, the formation of lithium dendrites during charging poses significant fire and explosion risks, particularly as systems scale to grid-level applications.

Thermal management represents another critical safety challenge for large-scale Li-S systems. The dissolution-precipitation processes during cycling generate considerable heat that must be efficiently dissipated to prevent thermal runaway. Current cooling technologies developed for lithium-ion batteries require substantial modification to address the unique thermal characteristics of Li-S chemistry, particularly at the energy storage system (ESS) scale.

From an environmental perspective, Li-S batteries offer several advantages over conventional lithium-ion technologies. Sulfur is abundant, non-toxic, and can be sourced from industrial waste streams, significantly reducing the environmental footprint compared to cobalt and nickel mining required for conventional cathodes. Life cycle assessments indicate that scaled Li-S production could reduce greenhouse gas emissions by 15-25% compared to lithium-ion manufacturing processes.

End-of-life management presents both challenges and opportunities. While the non-toxic nature of sulfur simplifies recycling processes, the complex morphological changes in electrodes during cycling create difficulties in material recovery. Current recycling technologies achieve approximately 60-70% material recovery rates, but research indicates potential for improvement to over 85% with specialized hydrometallurgical processes optimized for Li-S chemistry.

Regulatory frameworks for large-scale energy storage systems are still evolving to address Li-S specific safety protocols. The UN Transportation of Dangerous Goods regulations and IEC standards require updates to properly classify and manage Li-S batteries at scale. Industry stakeholders are collaborating with regulatory bodies to develop appropriate testing protocols that address the unique failure modes and thermal characteristics of Li-S systems.

Implementing robust battery management systems (BMS) with advanced algorithms specifically designed for Li-S chemistry represents a critical safety solution. These systems must accurately monitor state-of-charge and state-of-health parameters that differ significantly from conventional lithium-ion batteries, particularly addressing the "shuttle effect" that complicates voltage-based measurements in Li-S cells.

Thermal management represents another critical safety challenge for large-scale Li-S systems. The dissolution-precipitation processes during cycling generate considerable heat that must be efficiently dissipated to prevent thermal runaway. Current cooling technologies developed for lithium-ion batteries require substantial modification to address the unique thermal characteristics of Li-S chemistry, particularly at the energy storage system (ESS) scale.

From an environmental perspective, Li-S batteries offer several advantages over conventional lithium-ion technologies. Sulfur is abundant, non-toxic, and can be sourced from industrial waste streams, significantly reducing the environmental footprint compared to cobalt and nickel mining required for conventional cathodes. Life cycle assessments indicate that scaled Li-S production could reduce greenhouse gas emissions by 15-25% compared to lithium-ion manufacturing processes.

End-of-life management presents both challenges and opportunities. While the non-toxic nature of sulfur simplifies recycling processes, the complex morphological changes in electrodes during cycling create difficulties in material recovery. Current recycling technologies achieve approximately 60-70% material recovery rates, but research indicates potential for improvement to over 85% with specialized hydrometallurgical processes optimized for Li-S chemistry.

Regulatory frameworks for large-scale energy storage systems are still evolving to address Li-S specific safety protocols. The UN Transportation of Dangerous Goods regulations and IEC standards require updates to properly classify and manage Li-S batteries at scale. Industry stakeholders are collaborating with regulatory bodies to develop appropriate testing protocols that address the unique failure modes and thermal characteristics of Li-S systems.

Implementing robust battery management systems (BMS) with advanced algorithms specifically designed for Li-S chemistry represents a critical safety solution. These systems must accurately monitor state-of-charge and state-of-health parameters that differ significantly from conventional lithium-ion batteries, particularly addressing the "shuttle effect" that complicates voltage-based measurements in Li-S cells.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!