Electrode Architecture Optimization For High Areal Loading

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrode Architecture Background and Objectives

The evolution of battery technology has been a cornerstone of modern energy storage systems, with electrode architecture playing a pivotal role in determining battery performance. Over the past decades, the focus has shifted from merely increasing energy density to optimizing electrode structures for enhanced power capability, cycle life, and safety. The concept of high areal loading electrodes emerged as a critical pathway to achieve higher energy density batteries without compromising other performance metrics.

Historically, conventional electrode designs featured relatively thin structures with moderate material loading. However, as applications demanded more energy-dense solutions, particularly for electric vehicles and grid storage, the industry began exploring electrodes with higher active material content per unit area. This transition has not been without challenges, as increased material loading often leads to degraded ion transport, electronic conductivity issues, and mechanical instability.

The technical evolution trajectory shows a clear progression from simple slurry-cast electrodes to more sophisticated architectures incorporating 3D structures, gradient compositions, and engineered porosity. Recent advancements in nanomaterials and manufacturing techniques have further expanded the design possibilities, enabling unprecedented control over electrode microstructure and composition distribution.

The primary objective of electrode architecture optimization for high areal loading is to overcome the fundamental trade-off between energy density and power capability. Specifically, this involves developing electrode structures that can accommodate higher amounts of active materials while maintaining efficient ion transport pathways, robust electronic networks, and mechanical integrity during cycling. The target metrics typically include achieving areal capacities exceeding 4 mAh/cm² for lithium-ion batteries while preserving rate capability and cycle stability.

Secondary objectives include enhancing manufacturing scalability of these advanced architectures, reducing production costs, and ensuring compatibility with existing cell assembly processes. The optimization efforts also aim to address safety concerns associated with thicker electrodes, such as increased thermal gradients and potential for lithium plating during fast charging.

From a materials science perspective, the goals extend to understanding the complex interplay between electrode components (active materials, binders, conductive additives) at high loading conditions and developing predictive models to guide architecture design. This includes investigating novel binder systems, conductive networks, and porosity engineering approaches specifically tailored for high-loading scenarios.

The technological roadmap for electrode architecture optimization encompasses both incremental improvements to conventional manufacturing methods and disruptive approaches that fundamentally rethink electrode design principles, with the ultimate aim of pushing battery energy density boundaries while maintaining or improving other performance parameters.

Historically, conventional electrode designs featured relatively thin structures with moderate material loading. However, as applications demanded more energy-dense solutions, particularly for electric vehicles and grid storage, the industry began exploring electrodes with higher active material content per unit area. This transition has not been without challenges, as increased material loading often leads to degraded ion transport, electronic conductivity issues, and mechanical instability.

The technical evolution trajectory shows a clear progression from simple slurry-cast electrodes to more sophisticated architectures incorporating 3D structures, gradient compositions, and engineered porosity. Recent advancements in nanomaterials and manufacturing techniques have further expanded the design possibilities, enabling unprecedented control over electrode microstructure and composition distribution.

The primary objective of electrode architecture optimization for high areal loading is to overcome the fundamental trade-off between energy density and power capability. Specifically, this involves developing electrode structures that can accommodate higher amounts of active materials while maintaining efficient ion transport pathways, robust electronic networks, and mechanical integrity during cycling. The target metrics typically include achieving areal capacities exceeding 4 mAh/cm² for lithium-ion batteries while preserving rate capability and cycle stability.

Secondary objectives include enhancing manufacturing scalability of these advanced architectures, reducing production costs, and ensuring compatibility with existing cell assembly processes. The optimization efforts also aim to address safety concerns associated with thicker electrodes, such as increased thermal gradients and potential for lithium plating during fast charging.

From a materials science perspective, the goals extend to understanding the complex interplay between electrode components (active materials, binders, conductive additives) at high loading conditions and developing predictive models to guide architecture design. This includes investigating novel binder systems, conductive networks, and porosity engineering approaches specifically tailored for high-loading scenarios.

The technological roadmap for electrode architecture optimization encompasses both incremental improvements to conventional manufacturing methods and disruptive approaches that fundamentally rethink electrode design principles, with the ultimate aim of pushing battery energy density boundaries while maintaining or improving other performance parameters.

Market Demand Analysis for High-Loading Electrodes

The global energy storage market is witnessing unprecedented growth, with projections indicating a compound annual growth rate (CAGR) of 20-25% through 2030. This expansion is primarily driven by the accelerating transition to renewable energy sources and electric vehicles (EVs), both of which rely heavily on advanced battery technologies. Within this context, high-loading electrodes have emerged as a critical component for meeting escalating performance demands.

Consumer electronics manufacturers are increasingly seeking batteries with higher energy densities to support advanced features while maintaining or reducing device size. This market segment alone is expected to consume over 70 GWh of battery capacity annually by 2025, with particular emphasis on solutions that maximize energy storage within limited spatial constraints.

The EV sector represents the most significant demand driver for high-loading electrode technology. As automakers commit to electrification targets, the need for batteries that deliver extended range without proportional increases in weight or volume has become paramount. Industry analysts forecast that by 2030, EVs will require more than 2,000 GWh of battery capacity globally, creating substantial pressure for technological advancement in electrode architecture.

Grid-scale energy storage applications present another rapidly expanding market for high-loading electrodes. The intermittent nature of renewable energy generation necessitates efficient, high-capacity storage solutions. This sector is projected to grow at a CAGR exceeding 30% over the next decade, with particular demand for technologies that optimize cost-per-kWh metrics.

From a geographical perspective, Asia-Pacific currently dominates manufacturing capacity for advanced battery technologies, but North America and Europe are investing heavily to establish regional supply chains. This diversification is creating new market opportunities for innovative electrode technologies across multiple continents.

Cost considerations remain central to market adoption. While high-loading electrodes offer performance advantages, manufacturers must balance these benefits against potential increases in production complexity. Market research indicates that solutions achieving at least 30% improvement in energy density without exceeding a 15% cost premium will find the most favorable reception across industry segments.

Environmental and regulatory factors are increasingly influencing market dynamics. Regulations targeting carbon emissions and energy efficiency standards are indirectly boosting demand for higher-performance battery technologies. Additionally, growing consumer awareness regarding sustainability is creating market pull for solutions that maximize resource efficiency through higher loading capacities.

Consumer electronics manufacturers are increasingly seeking batteries with higher energy densities to support advanced features while maintaining or reducing device size. This market segment alone is expected to consume over 70 GWh of battery capacity annually by 2025, with particular emphasis on solutions that maximize energy storage within limited spatial constraints.

The EV sector represents the most significant demand driver for high-loading electrode technology. As automakers commit to electrification targets, the need for batteries that deliver extended range without proportional increases in weight or volume has become paramount. Industry analysts forecast that by 2030, EVs will require more than 2,000 GWh of battery capacity globally, creating substantial pressure for technological advancement in electrode architecture.

Grid-scale energy storage applications present another rapidly expanding market for high-loading electrodes. The intermittent nature of renewable energy generation necessitates efficient, high-capacity storage solutions. This sector is projected to grow at a CAGR exceeding 30% over the next decade, with particular demand for technologies that optimize cost-per-kWh metrics.

From a geographical perspective, Asia-Pacific currently dominates manufacturing capacity for advanced battery technologies, but North America and Europe are investing heavily to establish regional supply chains. This diversification is creating new market opportunities for innovative electrode technologies across multiple continents.

Cost considerations remain central to market adoption. While high-loading electrodes offer performance advantages, manufacturers must balance these benefits against potential increases in production complexity. Market research indicates that solutions achieving at least 30% improvement in energy density without exceeding a 15% cost premium will find the most favorable reception across industry segments.

Environmental and regulatory factors are increasingly influencing market dynamics. Regulations targeting carbon emissions and energy efficiency standards are indirectly boosting demand for higher-performance battery technologies. Additionally, growing consumer awareness regarding sustainability is creating market pull for solutions that maximize resource efficiency through higher loading capacities.

Current Challenges in High Areal Loading Technology

Despite significant advancements in battery technology, achieving high areal loading in electrodes remains one of the most challenging aspects of modern battery development. Current electrode architectures face substantial limitations when material loading exceeds 3-4 mg/cm², resulting in dramatic performance degradation. This phenomenon stems primarily from increased ionic and electronic transport resistance within thicker electrodes, creating significant bottlenecks in charge transfer processes.

The conventional slurry-casting method, while commercially viable, creates inherently tortuous pore networks that become increasingly problematic at higher loadings. As electrode thickness increases, electrolyte penetration becomes severely limited, resulting in underutilized active materials, particularly in the electrode regions furthest from the separator. Studies have shown that lithium-ion concentration gradients can vary by more than 40% across high-loading electrodes during cycling.

Mechanical integrity presents another critical challenge. High-loading electrodes experience substantial volume changes during cycling, leading to mechanical stress that can cause delamination from current collectors and internal cracking. These structural failures accelerate capacity fade and reduce cycle life, with some high-loading electrodes showing up to 30% capacity loss within just 100 cycles.

The binder systems traditionally employed (PVDF, CMC, SBR) become inadequate at higher loadings, unable to maintain cohesion between active particles while simultaneously preserving necessary porosity. This creates a fundamental design contradiction: increasing binder content improves mechanical stability but reduces electronic conductivity and blocks ion transport pathways.

Current collector limitations also emerge at high loadings. Standard aluminum and copper foils (15-20 μm) lack sufficient mechanical support and current distribution capabilities for electrodes exceeding 100 μm thickness. The resulting current density heterogeneity leads to localized heating and accelerated degradation at the electrode-collector interface.

Manufacturing challenges compound these issues, as conventional coating and drying processes developed for thin electrodes create significant defects in thicker films. Solvent removal becomes increasingly difficult, leading to trapped residual solvents, non-uniform density distribution, and surface cracking. Industry data indicates that manufacturing rejection rates increase exponentially when electrode loading exceeds 5 mg/cm².

Energy density improvements through high loading are further compromised by the need for additional conductive additives and stronger binders, which reduce the active material fraction. This creates a practical ceiling where theoretical energy density gains are offset by the increased inactive component requirements and performance losses.

The conventional slurry-casting method, while commercially viable, creates inherently tortuous pore networks that become increasingly problematic at higher loadings. As electrode thickness increases, electrolyte penetration becomes severely limited, resulting in underutilized active materials, particularly in the electrode regions furthest from the separator. Studies have shown that lithium-ion concentration gradients can vary by more than 40% across high-loading electrodes during cycling.

Mechanical integrity presents another critical challenge. High-loading electrodes experience substantial volume changes during cycling, leading to mechanical stress that can cause delamination from current collectors and internal cracking. These structural failures accelerate capacity fade and reduce cycle life, with some high-loading electrodes showing up to 30% capacity loss within just 100 cycles.

The binder systems traditionally employed (PVDF, CMC, SBR) become inadequate at higher loadings, unable to maintain cohesion between active particles while simultaneously preserving necessary porosity. This creates a fundamental design contradiction: increasing binder content improves mechanical stability but reduces electronic conductivity and blocks ion transport pathways.

Current collector limitations also emerge at high loadings. Standard aluminum and copper foils (15-20 μm) lack sufficient mechanical support and current distribution capabilities for electrodes exceeding 100 μm thickness. The resulting current density heterogeneity leads to localized heating and accelerated degradation at the electrode-collector interface.

Manufacturing challenges compound these issues, as conventional coating and drying processes developed for thin electrodes create significant defects in thicker films. Solvent removal becomes increasingly difficult, leading to trapped residual solvents, non-uniform density distribution, and surface cracking. Industry data indicates that manufacturing rejection rates increase exponentially when electrode loading exceeds 5 mg/cm².

Energy density improvements through high loading are further compromised by the need for additional conductive additives and stronger binders, which reduce the active material fraction. This creates a practical ceiling where theoretical energy density gains are offset by the increased inactive component requirements and performance losses.

Current Technical Solutions for Areal Loading Enhancement

01 High-density electrode architectures for improved areal loading

High-density electrode architectures can significantly increase the areal loading capacity of batteries and energy storage devices. These designs optimize the arrangement of active materials to maximize the surface area available for electrochemical reactions while maintaining structural integrity. Advanced manufacturing techniques enable the creation of three-dimensional electrode structures that can accommodate higher amounts of active material per unit area, leading to improved energy density and performance.- High-density electrode architectures for improved energy storage: High-density electrode architectures can be designed to increase the areal loading of active materials, resulting in improved energy storage capacity. These architectures often involve structured electrode designs that maximize the surface area available for electrochemical reactions while maintaining good mechanical stability and electrical conductivity. By optimizing the electrode architecture, the areal loading of active materials can be significantly increased, leading to higher energy density batteries and supercapacitors.

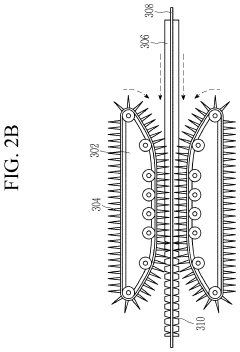

- Porous electrode structures for enhanced mass loading: Porous electrode structures can accommodate higher areal loading of active materials while facilitating efficient ion transport. These structures typically feature interconnected pores or channels that allow for better electrolyte penetration and ion diffusion throughout the electrode. The increased porosity enables higher mass loading without compromising electrochemical performance, as it maintains accessible pathways for ions even at high material densities. Various manufacturing techniques can be employed to create controlled porosity in electrode architectures.

- 3D electrode architectures for increased active material loading: Three-dimensional electrode architectures offer a solution for increasing the areal loading of active materials beyond the limitations of traditional planar electrodes. These 3D structures provide additional surface area for material deposition while maintaining short ion diffusion paths. Examples include arrays of pillars, honeycombs, or other complex geometries that extend into the third dimension. The increased surface area allows for higher mass loading without increasing the electrode thickness, which would otherwise lead to increased internal resistance.

- Composite electrode materials for high areal capacity: Composite electrode materials combine active materials with conductive additives and binders to achieve higher areal loading while maintaining good electronic and ionic conductivity. These composites are designed to optimize the balance between active material content (which determines capacity) and conductive network formation (which ensures efficient charge transport). Advanced composite formulations may incorporate nanomaterials, conductive polymers, or hierarchical structures to support higher mass loading without sacrificing rate capability or cycle life.

- Electrode architecture optimization for specific applications: Electrode architectures can be optimized for specific applications by tailoring the areal loading to meet particular performance requirements. For high-power applications, moderate areal loading with enhanced conductivity might be preferred, while high-energy applications may prioritize maximum areal loading. The optimization process considers factors such as electrode thickness, porosity, particle size distribution, and binder content. Advanced manufacturing techniques, including additive manufacturing and precision coating methods, enable fine control over electrode architecture parameters to achieve the desired areal loading for specific use cases.

02 Nanostructured electrode materials for enhanced areal capacity

Nanostructured materials offer significant advantages for electrode architecture by providing increased surface area and shortened ion diffusion paths. These materials can be engineered to form porous networks that allow for higher areal loading of active materials while maintaining efficient electron transport and ion accessibility. The use of nanomaterials in electrode design enables higher energy and power densities in batteries and supercapacitors.Expand Specific Solutions03 Composite electrode structures for optimized mass loading

Composite electrode structures combine different materials to achieve optimal areal loading while addressing challenges such as conductivity and mechanical stability. These structures typically incorporate conductive additives, binders, and active materials in carefully designed ratios. The synergistic effects between components allow for higher mass loading without sacrificing electrochemical performance, resulting in batteries with improved energy density and cycle life.Expand Specific Solutions04 Advanced current collector designs for high-loading electrodes

Innovative current collector designs play a crucial role in supporting high areal loading electrodes. These designs include three-dimensional structures, perforated foils, and foam-based collectors that provide improved mechanical support and electrical connectivity. By enhancing the interface between the current collector and active materials, these advanced designs enable higher mass loading while maintaining efficient electron transport throughout the electrode structure.Expand Specific Solutions05 Electrolyte optimization for high areal loading electrodes

Electrolyte formulations must be specifically optimized for electrodes with high areal loading to ensure efficient ion transport throughout the thicker electrode structures. This includes adjustments to electrolyte composition, concentration, and additives to improve wetting properties and ion conductivity. Advanced electrolyte systems can mitigate limitations associated with high mass loading electrodes, such as concentration polarization and restricted ion diffusion, thereby enabling the practical implementation of high-energy-density battery systems.Expand Specific Solutions

Key Industry Players in Advanced Electrode Development

The electrode architecture optimization for high areal loading is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-performance batteries in electric vehicles and energy storage systems. The global market size is projected to reach significant scale as major players intensify R&D efforts. Leading companies like Samsung SDI, LG Energy Solution, and Enovix are advancing the technology maturity through innovative approaches to electrode design. Research institutions including Georgia Tech and University of California are contributing fundamental breakthroughs, while specialized firms like Sila Nanotechnologies and Amprius Technologies are commercializing silicon-anode technologies that address loading challenges. The competitive landscape shows a mix of established battery manufacturers and emerging technology-focused startups driving innovation in this critical battery performance area.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced electrode architectures specifically designed for high areal loading applications in lithium-ion batteries. Their approach focuses on hierarchical porous structures that combine macro, meso, and micropores to facilitate efficient ion transport while maintaining high active material loading. The company employs gradient porosity designs where the electrode structure transitions from high porosity near the separator to higher density near the current collector, optimizing both energy density and power capability. Samsung SDI's proprietary binder systems and conductive additives enable mechanical stability at loadings exceeding 6 mAh/cm². Their manufacturing process incorporates precise control of slurry rheology and drying conditions to prevent cracking and delamination issues common in thick electrodes. Recent developments include 3D current collector designs with increased surface area to improve electronic conductivity throughout high-loading electrodes.

Strengths: Superior integration of electrode technology with cell manufacturing expertise; established scale-up capabilities for high-loading electrodes; strong IP portfolio in electrode architecture. Weaknesses: Higher manufacturing costs compared to conventional electrodes; potential challenges with cycle life at extreme fast charging conditions.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a multi-layer gradient electrode architecture optimized for high areal loading applications. Their technology employs a dual-porosity structure with controlled tortuosity to balance lithium-ion diffusion and electronic conductivity. The company's approach includes specialized calendering techniques that preserve critical pore networks while achieving densities up to 3.6 g/cm³ in cathodes. LG has developed proprietary composite binders that maintain cohesion in electrodes with loadings exceeding 5 mAh/cm². Their manufacturing process incorporates precision-controlled drying protocols that prevent crack formation in thick electrodes. Recent innovations include nano-engineered conductive networks that maintain electronic pathways throughout high-loading electrodes, reducing internal resistance. LG's electrode architecture also features tailored active material particle size distributions to optimize packing density while maintaining sufficient electrolyte accessibility.

Strengths: Excellent balance between energy density and power capability; proven manufacturing processes for consistent quality at scale; strong integration with cell design. Weaknesses: Higher raw material costs for specialized conductive additives; potential thermal management challenges at very high loadings.

Critical Patents in Electrode Architecture Optimization

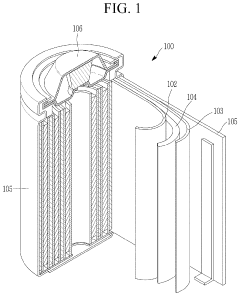

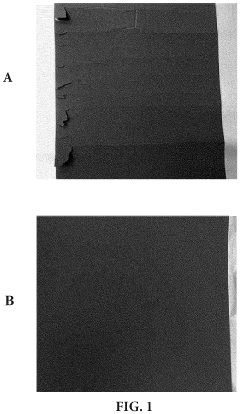

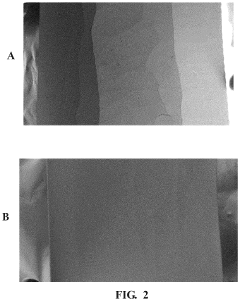

High loading electrodes having high areal capacity and energy storage devices including the same

PatentInactiveUS20210050599A1

Innovation

- A high areal capacity loading electrode with low porosity and a regular hexagonal pattern of holes, optimized in terms of size, depth, and spacing, is developed, using a metal current collector and active material layers like intercalated graphite or layered lithium nickel cobalt manganese oxide, to enhance charging rates and stability.

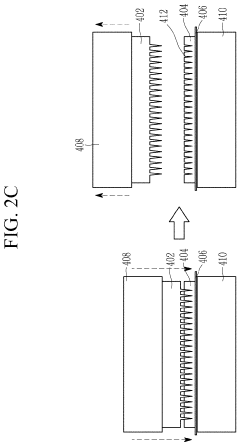

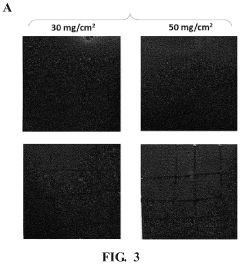

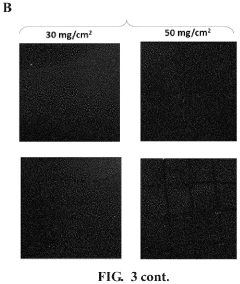

High loading electrodes

PatentPendingUS20240063369A1

Innovation

- The development of high loading electrodes with improved binder distribution uniformity, achieved through Variable Frequency Microwave (VFM) drying techniques, which allows for higher active material incorporation while maintaining excellent adhesion and mechanical characteristics, resulting in enhanced capacity retention and resistance to mechanical breakdown.

Materials Science Advancements for Electrode Performance

Recent advancements in materials science have significantly contributed to enhancing electrode performance for high areal loading applications. The evolution of electrode materials has moved from traditional carbon-based compounds to sophisticated nanostructured materials with tailored properties. These innovations address critical challenges in energy density, cycling stability, and rate capability that conventional electrodes face under high loading conditions.

Nanostructured materials, including carbon nanotubes, graphene, and metal-organic frameworks, have emerged as promising candidates for next-generation electrodes. Their unique properties—high surface area, excellent electrical conductivity, and mechanical stability—enable them to maintain performance even at increased mass loadings. For instance, 3D graphene networks have demonstrated the ability to sustain areal capacities exceeding 8 mAh/cm² while maintaining structural integrity.

Composite materials represent another breakthrough, combining the advantages of different material classes. Silicon-carbon composites, for example, leverage silicon's high theoretical capacity while carbon components provide structural support and conductivity pathways. These composites can achieve up to 10 times the capacity of traditional graphite electrodes while mitigating volume expansion issues that typically plague high-loading electrodes.

Conductive polymers and binders have undergone significant refinement to complement these advanced materials. Water-soluble binders like carboxymethyl cellulose and polyacrylic acid have replaced conventional PVDF binders, offering stronger adhesion and flexibility while reducing environmental impact. These binders maintain electrode integrity during the volume changes associated with high loading operations.

Surface modification techniques have also evolved to optimize electrode-electrolyte interfaces. Atomic layer deposition and molecular layer deposition enable precise control over surface properties, creating protective layers that prevent unwanted side reactions while maintaining ion transport pathways. These modifications have extended cycle life by up to 300% in high-loading conditions.

Hierarchical porosity design represents perhaps the most significant materials science advancement for electrode architecture. By creating multi-scale porous structures—combining macro, meso, and micropores—researchers have developed electrodes that simultaneously accommodate high material loading, facilitate electrolyte penetration, and provide short ion diffusion paths. This approach has successfully addressed the traditional trade-off between energy density and power capability in high-loading electrodes.

Nanostructured materials, including carbon nanotubes, graphene, and metal-organic frameworks, have emerged as promising candidates for next-generation electrodes. Their unique properties—high surface area, excellent electrical conductivity, and mechanical stability—enable them to maintain performance even at increased mass loadings. For instance, 3D graphene networks have demonstrated the ability to sustain areal capacities exceeding 8 mAh/cm² while maintaining structural integrity.

Composite materials represent another breakthrough, combining the advantages of different material classes. Silicon-carbon composites, for example, leverage silicon's high theoretical capacity while carbon components provide structural support and conductivity pathways. These composites can achieve up to 10 times the capacity of traditional graphite electrodes while mitigating volume expansion issues that typically plague high-loading electrodes.

Conductive polymers and binders have undergone significant refinement to complement these advanced materials. Water-soluble binders like carboxymethyl cellulose and polyacrylic acid have replaced conventional PVDF binders, offering stronger adhesion and flexibility while reducing environmental impact. These binders maintain electrode integrity during the volume changes associated with high loading operations.

Surface modification techniques have also evolved to optimize electrode-electrolyte interfaces. Atomic layer deposition and molecular layer deposition enable precise control over surface properties, creating protective layers that prevent unwanted side reactions while maintaining ion transport pathways. These modifications have extended cycle life by up to 300% in high-loading conditions.

Hierarchical porosity design represents perhaps the most significant materials science advancement for electrode architecture. By creating multi-scale porous structures—combining macro, meso, and micropores—researchers have developed electrodes that simultaneously accommodate high material loading, facilitate electrolyte penetration, and provide short ion diffusion paths. This approach has successfully addressed the traditional trade-off between energy density and power capability in high-loading electrodes.

Scalability and Manufacturing Considerations

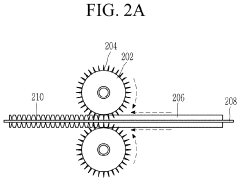

Scaling up electrode architectures with high areal loading from laboratory to industrial production presents significant challenges that must be addressed systematically. Current manufacturing processes for conventional electrodes typically involve slurry preparation, coating, drying, calendering, and slitting. However, these established methods require substantial modification to accommodate high loading electrodes, which demand precise control over porosity, thickness uniformity, and structural integrity.

The transition from lab-scale to mass production necessitates careful consideration of equipment capabilities. Industrial coating machines must be calibrated to handle thicker electrode slurries while maintaining coating uniformity across large surface areas. The viscosity management of high-solid-content slurries becomes particularly critical, as these formulations often exhibit non-Newtonian behavior that complicates the coating process. Advanced rheology modifiers and mixing protocols must be developed to ensure consistent slurry properties throughout production runs.

Drying processes represent another critical manufacturing bottleneck. High loading electrodes contain significantly more solvent that must be removed uniformly to prevent cracking and delamination. This necessitates longer drying times or innovative drying technologies such as microwave-assisted or vacuum drying systems. The energy consumption and carbon footprint of these extended drying processes must also be evaluated against sustainability goals.

Calendering high-loading electrodes requires precise pressure control to achieve target porosity without compromising structural integrity. Traditional calendering equipment may need redesign to apply more uniform pressure across thicker electrodes. Additionally, in-line quality control systems must be enhanced to detect internal defects that may not be visible on the electrode surface but could significantly impact performance.

Cost considerations cannot be overlooked in scaling up high-loading electrode production. While these electrodes potentially reduce cell-level costs through increased energy density, their manufacturing may require more expensive equipment, longer processing times, and specialized materials. A comprehensive techno-economic analysis must balance these factors against the performance benefits to determine optimal loading levels for different applications.

Quality control protocols must evolve to address the unique challenges of high-loading electrodes. Traditional metrics such as adhesion strength and electrical conductivity remain important but must be supplemented with advanced characterization techniques that can assess internal electrode structure, electrolyte wettability, and ion transport pathways. Non-destructive testing methods such as X-ray tomography may need to be integrated into production lines to ensure consistent quality.

The transition from lab-scale to mass production necessitates careful consideration of equipment capabilities. Industrial coating machines must be calibrated to handle thicker electrode slurries while maintaining coating uniformity across large surface areas. The viscosity management of high-solid-content slurries becomes particularly critical, as these formulations often exhibit non-Newtonian behavior that complicates the coating process. Advanced rheology modifiers and mixing protocols must be developed to ensure consistent slurry properties throughout production runs.

Drying processes represent another critical manufacturing bottleneck. High loading electrodes contain significantly more solvent that must be removed uniformly to prevent cracking and delamination. This necessitates longer drying times or innovative drying technologies such as microwave-assisted or vacuum drying systems. The energy consumption and carbon footprint of these extended drying processes must also be evaluated against sustainability goals.

Calendering high-loading electrodes requires precise pressure control to achieve target porosity without compromising structural integrity. Traditional calendering equipment may need redesign to apply more uniform pressure across thicker electrodes. Additionally, in-line quality control systems must be enhanced to detect internal defects that may not be visible on the electrode surface but could significantly impact performance.

Cost considerations cannot be overlooked in scaling up high-loading electrode production. While these electrodes potentially reduce cell-level costs through increased energy density, their manufacturing may require more expensive equipment, longer processing times, and specialized materials. A comprehensive techno-economic analysis must balance these factors against the performance benefits to determine optimal loading levels for different applications.

Quality control protocols must evolve to address the unique challenges of high-loading electrodes. Traditional metrics such as adhesion strength and electrical conductivity remain important but must be supplemented with advanced characterization techniques that can assess internal electrode structure, electrolyte wettability, and ion transport pathways. Non-destructive testing methods such as X-ray tomography may need to be integrated into production lines to ensure consistent quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!