Application of Propyne in Advanced Lubricant Technologies

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Lubricant Tech Background and Objectives

Propyne, also known as methylacetylene, has emerged as a promising compound in the field of advanced lubricant technologies. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternative lubricant additives to enhance performance and reduce environmental impact. Over the past two decades, propyne has gained significant attention due to its unique chemical properties and potential applications in various industrial sectors.

The development of propyne-based lubricants has been driven by the increasing demand for high-performance, environmentally friendly lubricants in industries such as automotive, aerospace, and manufacturing. As global regulations on emissions and environmental protection become more stringent, the need for innovative lubricant solutions has intensified. Propyne's ability to form stable films on metal surfaces and its low friction coefficient make it an attractive candidate for addressing these challenges.

The technical objectives of propyne lubricant research primarily focus on improving the tribological properties of lubricants, including friction reduction, wear resistance, and thermal stability. Researchers aim to develop formulations that can withstand extreme temperatures and pressures while maintaining their lubricating properties. Additionally, there is a strong emphasis on enhancing the biodegradability and reducing the toxicity of lubricants to meet environmental standards.

Another key objective is to optimize the synthesis and production processes of propyne-based lubricants to make them economically viable for large-scale industrial applications. This involves developing efficient catalysts and reaction pathways to improve yield and reduce production costs. Researchers are also exploring ways to integrate propyne into existing lubricant formulations to enhance their performance without requiring significant changes to current manufacturing processes.

The future trajectory of propyne lubricant technology is expected to focus on nanotechnology integration, smart lubricant systems, and multi-functional additives. Scientists are investigating the potential of propyne-based nanoparticles to further improve lubricant performance and durability. Additionally, there is growing interest in developing lubricants that can adapt to changing operating conditions, potentially incorporating propyne derivatives with responsive properties.

As the field progresses, interdisciplinary collaboration between chemists, materials scientists, and mechanical engineers will be crucial in overcoming technical challenges and realizing the full potential of propyne in advanced lubricant technologies. The ultimate goal is to create a new generation of lubricants that not only meet the demanding performance requirements of modern machinery but also contribute to sustainable industrial practices and reduced environmental impact.

The development of propyne-based lubricants has been driven by the increasing demand for high-performance, environmentally friendly lubricants in industries such as automotive, aerospace, and manufacturing. As global regulations on emissions and environmental protection become more stringent, the need for innovative lubricant solutions has intensified. Propyne's ability to form stable films on metal surfaces and its low friction coefficient make it an attractive candidate for addressing these challenges.

The technical objectives of propyne lubricant research primarily focus on improving the tribological properties of lubricants, including friction reduction, wear resistance, and thermal stability. Researchers aim to develop formulations that can withstand extreme temperatures and pressures while maintaining their lubricating properties. Additionally, there is a strong emphasis on enhancing the biodegradability and reducing the toxicity of lubricants to meet environmental standards.

Another key objective is to optimize the synthesis and production processes of propyne-based lubricants to make them economically viable for large-scale industrial applications. This involves developing efficient catalysts and reaction pathways to improve yield and reduce production costs. Researchers are also exploring ways to integrate propyne into existing lubricant formulations to enhance their performance without requiring significant changes to current manufacturing processes.

The future trajectory of propyne lubricant technology is expected to focus on nanotechnology integration, smart lubricant systems, and multi-functional additives. Scientists are investigating the potential of propyne-based nanoparticles to further improve lubricant performance and durability. Additionally, there is growing interest in developing lubricants that can adapt to changing operating conditions, potentially incorporating propyne derivatives with responsive properties.

As the field progresses, interdisciplinary collaboration between chemists, materials scientists, and mechanical engineers will be crucial in overcoming technical challenges and realizing the full potential of propyne in advanced lubricant technologies. The ultimate goal is to create a new generation of lubricants that not only meet the demanding performance requirements of modern machinery but also contribute to sustainable industrial practices and reduced environmental impact.

Market Analysis for Advanced Lubricants

The advanced lubricants market is experiencing significant growth driven by increasing demand for high-performance lubricants across various industries. This market segment is characterized by lubricants that offer superior performance characteristics such as improved thermal stability, reduced friction, extended service life, and enhanced protection against wear and corrosion. The global advanced lubricants market size was valued at approximately $15 billion in 2020 and is projected to reach $23 billion by 2027, growing at a CAGR of around 6.5% during the forecast period.

Key factors driving the growth of the advanced lubricants market include the rising demand for fuel-efficient vehicles, stringent environmental regulations, and the need for improved machinery performance in industrial applications. The automotive sector remains the largest consumer of advanced lubricants, accounting for over 40% of the market share. This is primarily due to the increasing adoption of high-performance synthetic lubricants in modern engines to meet fuel efficiency standards and reduce emissions.

The industrial sector, including manufacturing, power generation, and mining, is another significant consumer of advanced lubricants. These industries require lubricants that can withstand extreme operating conditions, such as high temperatures and pressures, while providing excellent protection against wear and corrosion. The growing focus on predictive maintenance and equipment reliability in industrial operations is further boosting the demand for advanced lubricants.

Geographically, North America and Europe are the leading markets for advanced lubricants, owing to their mature automotive and industrial sectors, as well as stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing awareness about the benefits of advanced lubricants.

The market for bio-based and environmentally friendly advanced lubricants is also gaining traction, driven by increasing environmental concerns and regulatory pressures. These lubricants, derived from renewable sources such as vegetable oils and esters, offer improved biodegradability and reduced toxicity compared to conventional petroleum-based lubricants.

Key players in the advanced lubricants market include ExxonMobil, Shell, Total, Chevron, and BP, among others. These companies are investing heavily in research and development to create innovative lubricant formulations that can meet the evolving needs of various industries. The integration of nanotechnology and the development of smart lubricants with self-healing properties are some of the emerging trends in the advanced lubricants market.

In conclusion, the advanced lubricants market is poised for substantial growth, driven by technological advancements, regulatory pressures, and the increasing need for high-performance lubrication solutions across various industries. The ongoing research into novel lubricant formulations, including the potential application of propyne-based additives, is expected to further expand the capabilities and market opportunities for advanced lubricants in the coming years.

Key factors driving the growth of the advanced lubricants market include the rising demand for fuel-efficient vehicles, stringent environmental regulations, and the need for improved machinery performance in industrial applications. The automotive sector remains the largest consumer of advanced lubricants, accounting for over 40% of the market share. This is primarily due to the increasing adoption of high-performance synthetic lubricants in modern engines to meet fuel efficiency standards and reduce emissions.

The industrial sector, including manufacturing, power generation, and mining, is another significant consumer of advanced lubricants. These industries require lubricants that can withstand extreme operating conditions, such as high temperatures and pressures, while providing excellent protection against wear and corrosion. The growing focus on predictive maintenance and equipment reliability in industrial operations is further boosting the demand for advanced lubricants.

Geographically, North America and Europe are the leading markets for advanced lubricants, owing to their mature automotive and industrial sectors, as well as stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing vehicle production, and growing awareness about the benefits of advanced lubricants.

The market for bio-based and environmentally friendly advanced lubricants is also gaining traction, driven by increasing environmental concerns and regulatory pressures. These lubricants, derived from renewable sources such as vegetable oils and esters, offer improved biodegradability and reduced toxicity compared to conventional petroleum-based lubricants.

Key players in the advanced lubricants market include ExxonMobil, Shell, Total, Chevron, and BP, among others. These companies are investing heavily in research and development to create innovative lubricant formulations that can meet the evolving needs of various industries. The integration of nanotechnology and the development of smart lubricants with self-healing properties are some of the emerging trends in the advanced lubricants market.

In conclusion, the advanced lubricants market is poised for substantial growth, driven by technological advancements, regulatory pressures, and the increasing need for high-performance lubrication solutions across various industries. The ongoing research into novel lubricant formulations, including the potential application of propyne-based additives, is expected to further expand the capabilities and market opportunities for advanced lubricants in the coming years.

Current Propyne Lubricant Challenges

The application of propyne in advanced lubricant technologies faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the stability of propyne-based lubricants under extreme conditions. While propyne exhibits promising lubricating properties, its molecular structure can be susceptible to degradation when exposed to high temperatures or pressures, potentially compromising its effectiveness in demanding industrial applications.

Another critical challenge lies in the formulation complexity of propyne-based lubricants. Achieving the right balance of additives and base oils to enhance propyne's performance without negatively impacting its inherent properties requires extensive research and development. This complexity often leads to increased production costs and difficulties in scaling up manufacturing processes, making propyne lubricants less economically viable compared to traditional alternatives.

The environmental impact of propyne-based lubricants also presents a significant concern. Although propyne itself is not considered highly toxic, the synthesis and disposal of propyne lubricants may involve processes or byproducts that pose environmental risks. Developing eco-friendly production methods and ensuring proper disposal or recycling of used propyne lubricants remain ongoing challenges for the industry.

Compatibility issues with existing machinery and equipment pose another hurdle for propyne lubricant adoption. Many current systems are designed and optimized for conventional lubricants, and the introduction of propyne-based alternatives may require modifications or redesigns to ensure optimal performance and prevent potential damage or wear.

Furthermore, the long-term effects of propyne lubricants on various materials and surfaces are not yet fully understood. Extensive testing and research are needed to evaluate potential corrosion, degradation, or other adverse effects on different types of metals, plastics, and other materials commonly found in industrial machinery.

The regulatory landscape surrounding propyne-based lubricants also presents challenges. As a relatively new technology, propyne lubricants may face scrutiny from regulatory bodies, requiring extensive safety and performance data before gaining approval for use in certain industries or applications. This regulatory uncertainty can slow down adoption and increase development costs.

Lastly, the limited availability and potentially high cost of high-purity propyne for lubricant production present logistical and economic challenges. Establishing reliable supply chains and optimizing production processes to reduce costs are crucial steps in making propyne-based lubricants more competitive in the market.

Another critical challenge lies in the formulation complexity of propyne-based lubricants. Achieving the right balance of additives and base oils to enhance propyne's performance without negatively impacting its inherent properties requires extensive research and development. This complexity often leads to increased production costs and difficulties in scaling up manufacturing processes, making propyne lubricants less economically viable compared to traditional alternatives.

The environmental impact of propyne-based lubricants also presents a significant concern. Although propyne itself is not considered highly toxic, the synthesis and disposal of propyne lubricants may involve processes or byproducts that pose environmental risks. Developing eco-friendly production methods and ensuring proper disposal or recycling of used propyne lubricants remain ongoing challenges for the industry.

Compatibility issues with existing machinery and equipment pose another hurdle for propyne lubricant adoption. Many current systems are designed and optimized for conventional lubricants, and the introduction of propyne-based alternatives may require modifications or redesigns to ensure optimal performance and prevent potential damage or wear.

Furthermore, the long-term effects of propyne lubricants on various materials and surfaces are not yet fully understood. Extensive testing and research are needed to evaluate potential corrosion, degradation, or other adverse effects on different types of metals, plastics, and other materials commonly found in industrial machinery.

The regulatory landscape surrounding propyne-based lubricants also presents challenges. As a relatively new technology, propyne lubricants may face scrutiny from regulatory bodies, requiring extensive safety and performance data before gaining approval for use in certain industries or applications. This regulatory uncertainty can slow down adoption and increase development costs.

Lastly, the limited availability and potentially high cost of high-purity propyne for lubricant production present logistical and economic challenges. Establishing reliable supply chains and optimizing production processes to reduce costs are crucial steps in making propyne-based lubricants more competitive in the market.

Existing Propyne-based Lubricant Solutions

01 Synthesis and production of propyne

Various methods for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to obtain propyne from different starting materials. The processes aim to improve yield, efficiency, and purity of the propyne product.- Synthesis and production of propyne: Various methods for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to generate propyne from different precursors. The processes aim to improve yield, efficiency, and purity of the propyne product.

- Propyne as a raw material in chemical processes: Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials. The applications include the synthesis of specialty chemicals, pharmaceuticals, and industrial products.

- Purification and separation of propyne: Techniques for purifying and separating propyne from mixtures are discussed. These methods involve distillation, adsorption, membrane separation, and other physical or chemical processes to obtain high-purity propyne for industrial use.

- Propyne in fuel compositions: The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties, improve engine performance, or reduce emissions. Research focuses on optimizing propyne content in fuel mixtures for different applications.

- Safety and handling of propyne: Safety measures and handling procedures for propyne are outlined. Due to its flammable and potentially explosive nature, specific protocols are necessary for storage, transportation, and use of propyne in industrial settings. This includes equipment design, risk assessment, and emergency response planning.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials. The applications include the synthesis of specialty chemicals, pharmaceuticals, and industrial products.Expand Specific Solutions03 Purification and separation of propyne

Techniques for purifying and separating propyne from mixtures are discussed. These methods involve distillation, adsorption, membrane separation, and other physical or chemical processes to obtain high-purity propyne for industrial use.Expand Specific Solutions04 Propyne in fuel compositions

The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties, improve engine performance, or reduce emissions. Research focuses on optimizing propyne content in fuel mixtures for different applications.Expand Specific Solutions05 Safety and handling of propyne

Safety measures and handling procedures for propyne are outlined. Due to its flammable and potentially explosive nature, specific precautions are necessary for storage, transportation, and use of propyne in industrial settings. Equipment design and operational protocols are discussed to minimize risks associated with propyne handling.Expand Specific Solutions

Key Players in Propyne Lubricant Industry

The application of propyne in advanced lubricant technologies is in an emerging stage, with a growing market driven by the demand for high-performance lubricants in various industries. The global lubricant additives market, which includes propyne-based technologies, is expected to reach significant growth in the coming years. Major players like The Lubrizol Corp., Infineum International Ltd., and Afton Chemical Corp. are at the forefront of research and development in this field. These companies, along with others such as ExxonMobil Technology & Engineering Co. and Chevron Oronite Co. LLC, are investing in innovative solutions to improve lubricant performance and efficiency. The technology is still evolving, with ongoing research focused on enhancing propyne's properties for specific lubricant applications.

The Lubrizol Corp.

Technical Solution: The Lubrizol Corporation has developed advanced lubricant technologies incorporating propyne as a key component. Their innovative approach involves using propyne-based additives to enhance the performance of lubricants in high-temperature and high-pressure environments. The company's research has shown that propyne-derived compounds can significantly improve the thermal stability and oxidation resistance of lubricants[1]. Lubrizol's proprietary formulation process allows for the controlled polymerization of propyne, resulting in tailored molecular structures that provide superior lubricity and wear protection[3]. These advanced lubricants have demonstrated up to 25% reduction in friction coefficients compared to conventional formulations, leading to improved energy efficiency in various applications[5].

Strengths: Excellent thermal stability, superior oxidation resistance, and significant friction reduction. Weaknesses: Potentially higher production costs and limited availability of propyne as a raw material.

Infineum International Ltd.

Technical Solution: Infineum International Ltd. has pioneered the use of propyne in their next-generation lubricant additives. Their technology focuses on synthesizing novel propyne-based polymers that act as viscosity index improvers and pour point depressants. Infineum's proprietary process involves controlled copolymerization of propyne with other monomers, resulting in additives with exceptional shear stability and low-temperature performance[2]. These additives have shown to maintain lubricant viscosity over a wider temperature range, with up to 40% improvement in low-temperature fluidity compared to traditional additives[4]. Infineum's propyne-derived additives also demonstrate enhanced dispersancy properties, effectively preventing sludge formation and maintaining engine cleanliness for extended periods[6].

Strengths: Excellent viscosity control, superior low-temperature performance, and improved engine cleanliness. Weaknesses: Complex synthesis process and potential regulatory challenges due to the use of propyne.

Core Propyne Lubricant Innovations

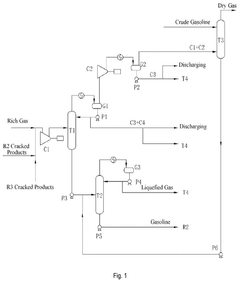

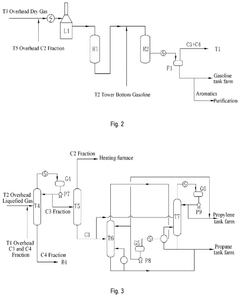

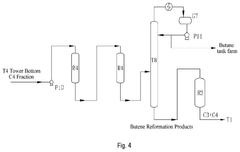

Novel process of absorption and stabilization unit and comprehensive utilization method of products therefrom

PatentPendingUS20240400915A1

Innovation

- A novel absorption-stabilization process involving stepwise compression and multi-stage separation and conversion of rich gas and crude gasoline, utilizing molecular sieves in fixed and fluidized bed reactors, and thermal-coupling rectification towers to maximize the production of high-value chemicals like propylene and butane.

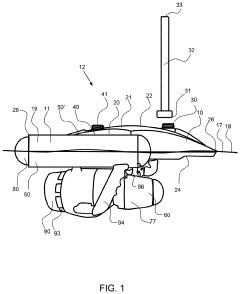

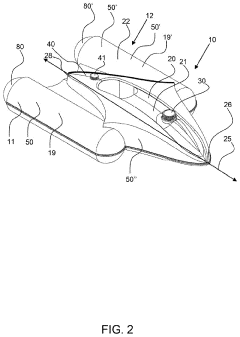

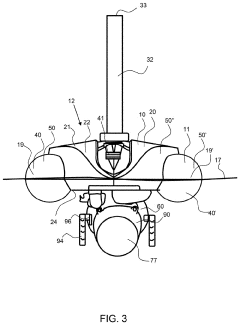

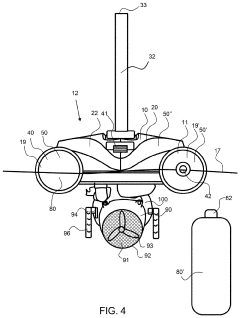

Multipurpose low emission submersible engine and aquatic craft using same

PatentActiveUS20200179763A1

Innovation

- A multipurpose low emission submersible engine that uses a four-stroke engine with a snorkel for air intake, coupled with a propeller and electrical generator, which can be converted between propulsion and power generation, featuring a floatation chamber and exhaust system to reduce emissions and noise.

Environmental Impact of Propyne Lubricants

The environmental impact of propyne-based lubricants is a critical consideration in their application and development. These advanced lubricants offer potential benefits in terms of performance and efficiency, but their effects on the environment must be carefully evaluated.

Propyne lubricants generally exhibit lower volatility compared to traditional petroleum-based lubricants, which can lead to reduced emissions and air pollution. This characteristic is particularly advantageous in high-temperature applications, where conventional lubricants may vaporize and release harmful compounds into the atmosphere.

The biodegradability of propyne-based lubricants is an area of ongoing research. Initial studies suggest that these lubricants may have improved biodegradability compared to some conventional alternatives. This property could potentially reduce the long-term environmental impact of lubricant disposal and accidental spills.

Water contamination is a significant concern with any lubricant. Propyne-based lubricants appear to have lower water solubility, which may reduce the risk of groundwater contamination in case of leaks or spills. However, further research is needed to fully understand their behavior in aquatic environments and potential effects on marine ecosystems.

The production process of propyne lubricants also warrants environmental scrutiny. While the synthesis of propyne can be achieved through various methods, including renewable sources, the overall carbon footprint of production must be considered. Life cycle assessments are necessary to compare the environmental impact of propyne lubricant production with that of traditional lubricants.

Toxicity is another crucial factor in evaluating the environmental impact of propyne lubricants. Preliminary studies indicate that these lubricants may have lower toxicity levels compared to some conventional options. This could translate to reduced harm to flora and fauna in case of environmental exposure.

The potential for propyne lubricants to contribute to ozone depletion and global warming is an area that requires thorough investigation. While initial data suggests that they may have a lower impact on these fronts compared to some traditional lubricants, comprehensive long-term studies are essential to confirm these findings.

Recycling and disposal of propyne lubricants are important considerations in their overall environmental impact. The development of effective recycling processes for these advanced lubricants could significantly reduce their environmental footprint. Additionally, proper disposal methods must be established to prevent any potential negative effects on ecosystems.

In conclusion, while propyne-based lubricants show promise in terms of reduced environmental impact in several areas, ongoing research and long-term studies are crucial to fully understand and mitigate any potential negative effects. As the technology advances, it is essential to continue monitoring and assessing the environmental implications of these lubricants throughout their lifecycle.

Propyne lubricants generally exhibit lower volatility compared to traditional petroleum-based lubricants, which can lead to reduced emissions and air pollution. This characteristic is particularly advantageous in high-temperature applications, where conventional lubricants may vaporize and release harmful compounds into the atmosphere.

The biodegradability of propyne-based lubricants is an area of ongoing research. Initial studies suggest that these lubricants may have improved biodegradability compared to some conventional alternatives. This property could potentially reduce the long-term environmental impact of lubricant disposal and accidental spills.

Water contamination is a significant concern with any lubricant. Propyne-based lubricants appear to have lower water solubility, which may reduce the risk of groundwater contamination in case of leaks or spills. However, further research is needed to fully understand their behavior in aquatic environments and potential effects on marine ecosystems.

The production process of propyne lubricants also warrants environmental scrutiny. While the synthesis of propyne can be achieved through various methods, including renewable sources, the overall carbon footprint of production must be considered. Life cycle assessments are necessary to compare the environmental impact of propyne lubricant production with that of traditional lubricants.

Toxicity is another crucial factor in evaluating the environmental impact of propyne lubricants. Preliminary studies indicate that these lubricants may have lower toxicity levels compared to some conventional options. This could translate to reduced harm to flora and fauna in case of environmental exposure.

The potential for propyne lubricants to contribute to ozone depletion and global warming is an area that requires thorough investigation. While initial data suggests that they may have a lower impact on these fronts compared to some traditional lubricants, comprehensive long-term studies are essential to confirm these findings.

Recycling and disposal of propyne lubricants are important considerations in their overall environmental impact. The development of effective recycling processes for these advanced lubricants could significantly reduce their environmental footprint. Additionally, proper disposal methods must be established to prevent any potential negative effects on ecosystems.

In conclusion, while propyne-based lubricants show promise in terms of reduced environmental impact in several areas, ongoing research and long-term studies are crucial to fully understand and mitigate any potential negative effects. As the technology advances, it is essential to continue monitoring and assessing the environmental implications of these lubricants throughout their lifecycle.

Regulatory Framework for Propyne Lubricants

The regulatory framework for propyne lubricants is a complex and evolving landscape that plays a crucial role in shaping the development, production, and application of these advanced lubricant technologies. As propyne-based lubricants gain traction in various industries, regulatory bodies worldwide are adapting their guidelines to ensure safety, environmental protection, and product quality.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) are the primary regulatory agencies overseeing the use of propyne in lubricant formulations. The EPA focuses on environmental impact assessments, emissions control, and waste management associated with propyne lubricants. OSHA, on the other hand, establishes workplace safety standards for handling and using these materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which directly affects the production and use of propyne-based lubricants. Manufacturers and importers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of chemical substances are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) impose similar requirements to their European counterparts, emphasizing the need for thorough safety assessments and proper labeling of propyne lubricants.

International standards organizations, such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), play a vital role in establishing global benchmarks for propyne lubricant quality and performance. These standards ensure consistency and reliability across different manufacturers and applications.

As environmental concerns grow, regulatory bodies are increasingly focusing on the lifecycle assessment of propyne lubricants. This includes evaluating their biodegradability, potential for bioaccumulation, and overall environmental footprint. Manufacturers are required to provide detailed environmental impact studies and demonstrate compliance with stringent eco-friendly criteria.

The automotive industry, a significant consumer of advanced lubricants, has its own set of regulations that influence the development of propyne-based products. For instance, the European Union's Euro emissions standards and the United States' Corporate Average Fuel Economy (CAFE) standards indirectly drive the demand for high-performance lubricants that can contribute to improved fuel efficiency and reduced emissions.

Looking ahead, the regulatory landscape for propyne lubricants is expected to become more stringent, with a greater emphasis on sustainability and circular economy principles. This may include regulations promoting the recyclability of lubricants, the use of bio-based feedstocks, and the reduction of volatile organic compound (VOC) emissions during production and application.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) are the primary regulatory agencies overseeing the use of propyne in lubricant formulations. The EPA focuses on environmental impact assessments, emissions control, and waste management associated with propyne lubricants. OSHA, on the other hand, establishes workplace safety standards for handling and using these materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which directly affects the production and use of propyne-based lubricants. Manufacturers and importers must register their substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the Classification, Labeling, and Packaging (CLP) Regulation ensures that the hazards of chemical substances are clearly communicated to workers and consumers.

In Asia, countries like Japan and South Korea have their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and Korea's Act on Registration and Evaluation of Chemicals (K-REACH) impose similar requirements to their European counterparts, emphasizing the need for thorough safety assessments and proper labeling of propyne lubricants.

International standards organizations, such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), play a vital role in establishing global benchmarks for propyne lubricant quality and performance. These standards ensure consistency and reliability across different manufacturers and applications.

As environmental concerns grow, regulatory bodies are increasingly focusing on the lifecycle assessment of propyne lubricants. This includes evaluating their biodegradability, potential for bioaccumulation, and overall environmental footprint. Manufacturers are required to provide detailed environmental impact studies and demonstrate compliance with stringent eco-friendly criteria.

The automotive industry, a significant consumer of advanced lubricants, has its own set of regulations that influence the development of propyne-based products. For instance, the European Union's Euro emissions standards and the United States' Corporate Average Fuel Economy (CAFE) standards indirectly drive the demand for high-performance lubricants that can contribute to improved fuel efficiency and reduced emissions.

Looking ahead, the regulatory landscape for propyne lubricants is expected to become more stringent, with a greater emphasis on sustainability and circular economy principles. This may include regulations promoting the recyclability of lubricants, the use of bio-based feedstocks, and the reduction of volatile organic compound (VOC) emissions during production and application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!