Application of Sulphanilic Acid in High-Strength Concrete Formulations

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Concrete: Background and Objectives

Sulphanilic acid, a synthetic organic compound with the chemical formula C6H7NO3S, has emerged as a promising additive in high-strength concrete formulations. This aromatic amine, derived from sulfanilic acid, has garnered significant attention in the construction industry due to its potential to enhance concrete properties and performance.

The development of high-strength concrete has been a continuous pursuit in civil engineering, driven by the increasing demand for taller structures, longer bridges, and more durable infrastructure. Traditional concrete formulations have limitations in terms of strength, durability, and resistance to environmental factors. As a result, researchers and industry professionals have been exploring innovative additives to overcome these challenges.

Sulphanilic acid's application in concrete technology represents a convergence of chemical engineering and materials science. Its unique molecular structure, featuring an amino group and a sulfonic acid group attached to a benzene ring, offers potential benefits in modifying concrete's microstructure and chemical properties.

The primary objective of incorporating sulphanilic acid into high-strength concrete formulations is to enhance the material's mechanical properties, particularly compressive strength and durability. Additionally, researchers aim to improve concrete's resistance to environmental degradation, such as chloride penetration and carbonation, which are critical factors in extending the lifespan of concrete structures.

Another key goal is to investigate the impact of sulphanilic acid on concrete's workability and setting time. These factors are crucial for practical applications in construction, as they affect the ease of placement and the overall efficiency of concrete operations. Researchers are also exploring the potential of sulphanilic acid to reduce the water-cement ratio without compromising workability, which could lead to denser and stronger concrete matrices.

Furthermore, the environmental implications of using sulphanilic acid in concrete are of significant interest. As the construction industry faces increasing pressure to reduce its carbon footprint, additives that can enhance concrete performance while potentially reducing cement content are highly sought after. The study of sulphanilic acid in this context aligns with broader sustainability goals in construction materials research.

The exploration of sulphanilic acid in high-strength concrete formulations is part of a larger trend in concrete technology towards "smart" or "reactive" additives. These additives are designed to interact with the concrete matrix at a molecular level, potentially offering benefits beyond traditional mineral admixtures. This research direction represents a shift towards more sophisticated, chemically engineered concrete solutions to meet the evolving demands of modern construction.

The development of high-strength concrete has been a continuous pursuit in civil engineering, driven by the increasing demand for taller structures, longer bridges, and more durable infrastructure. Traditional concrete formulations have limitations in terms of strength, durability, and resistance to environmental factors. As a result, researchers and industry professionals have been exploring innovative additives to overcome these challenges.

Sulphanilic acid's application in concrete technology represents a convergence of chemical engineering and materials science. Its unique molecular structure, featuring an amino group and a sulfonic acid group attached to a benzene ring, offers potential benefits in modifying concrete's microstructure and chemical properties.

The primary objective of incorporating sulphanilic acid into high-strength concrete formulations is to enhance the material's mechanical properties, particularly compressive strength and durability. Additionally, researchers aim to improve concrete's resistance to environmental degradation, such as chloride penetration and carbonation, which are critical factors in extending the lifespan of concrete structures.

Another key goal is to investigate the impact of sulphanilic acid on concrete's workability and setting time. These factors are crucial for practical applications in construction, as they affect the ease of placement and the overall efficiency of concrete operations. Researchers are also exploring the potential of sulphanilic acid to reduce the water-cement ratio without compromising workability, which could lead to denser and stronger concrete matrices.

Furthermore, the environmental implications of using sulphanilic acid in concrete are of significant interest. As the construction industry faces increasing pressure to reduce its carbon footprint, additives that can enhance concrete performance while potentially reducing cement content are highly sought after. The study of sulphanilic acid in this context aligns with broader sustainability goals in construction materials research.

The exploration of sulphanilic acid in high-strength concrete formulations is part of a larger trend in concrete technology towards "smart" or "reactive" additives. These additives are designed to interact with the concrete matrix at a molecular level, potentially offering benefits beyond traditional mineral admixtures. This research direction represents a shift towards more sophisticated, chemically engineered concrete solutions to meet the evolving demands of modern construction.

Market Analysis for High-Strength Concrete

The high-strength concrete market has been experiencing significant growth in recent years, driven by increasing demand for durable and high-performance construction materials. This market segment is expected to continue its upward trajectory due to rapid urbanization, infrastructure development, and the need for sustainable building solutions.

The global high-strength concrete market is primarily segmented into residential, commercial, and infrastructure sectors. Among these, the infrastructure sector holds the largest market share, followed by commercial and residential applications. The growing emphasis on constructing resilient and long-lasting structures, particularly in earthquake-prone regions and areas with extreme weather conditions, has been a key factor in driving market growth.

Geographically, Asia-Pacific dominates the high-strength concrete market, with China and India being the major contributors. The region's rapid economic growth, coupled with extensive infrastructure development projects, has fueled the demand for high-strength concrete. North America and Europe follow closely, with increasing adoption in high-rise buildings, bridges, and other critical infrastructure projects.

The market is characterized by intense competition among key players, including LafargeHolcim, CEMEX, Heidelberg Cement, and Sika AG. These companies are focusing on research and development to enhance the properties of high-strength concrete, including improved workability, durability, and environmental sustainability.

One of the emerging trends in the high-strength concrete market is the incorporation of advanced admixtures and supplementary cementitious materials to enhance performance characteristics. This is where the application of sulphanilic acid in high-strength concrete formulations becomes particularly relevant. The use of sulphanilic acid as an admixture has shown promising results in improving the mechanical properties and durability of high-strength concrete.

The demand for high-strength concrete with enhanced properties, such as increased compressive strength, reduced permeability, and improved resistance to chemical attacks, is driving innovation in concrete admixtures. This presents a significant opportunity for the application of sulphanilic acid in high-strength concrete formulations, as it has the potential to address these specific market needs.

Furthermore, the growing focus on sustainable construction practices and the need for reducing the carbon footprint of concrete production are influencing market dynamics. High-strength concrete, with its potential for reducing material consumption and extending the lifespan of structures, aligns well with these sustainability goals. The incorporation of sulphanilic acid in these formulations could potentially contribute to further improvements in sustainability metrics, thereby addressing a critical market demand.

The global high-strength concrete market is primarily segmented into residential, commercial, and infrastructure sectors. Among these, the infrastructure sector holds the largest market share, followed by commercial and residential applications. The growing emphasis on constructing resilient and long-lasting structures, particularly in earthquake-prone regions and areas with extreme weather conditions, has been a key factor in driving market growth.

Geographically, Asia-Pacific dominates the high-strength concrete market, with China and India being the major contributors. The region's rapid economic growth, coupled with extensive infrastructure development projects, has fueled the demand for high-strength concrete. North America and Europe follow closely, with increasing adoption in high-rise buildings, bridges, and other critical infrastructure projects.

The market is characterized by intense competition among key players, including LafargeHolcim, CEMEX, Heidelberg Cement, and Sika AG. These companies are focusing on research and development to enhance the properties of high-strength concrete, including improved workability, durability, and environmental sustainability.

One of the emerging trends in the high-strength concrete market is the incorporation of advanced admixtures and supplementary cementitious materials to enhance performance characteristics. This is where the application of sulphanilic acid in high-strength concrete formulations becomes particularly relevant. The use of sulphanilic acid as an admixture has shown promising results in improving the mechanical properties and durability of high-strength concrete.

The demand for high-strength concrete with enhanced properties, such as increased compressive strength, reduced permeability, and improved resistance to chemical attacks, is driving innovation in concrete admixtures. This presents a significant opportunity for the application of sulphanilic acid in high-strength concrete formulations, as it has the potential to address these specific market needs.

Furthermore, the growing focus on sustainable construction practices and the need for reducing the carbon footprint of concrete production are influencing market dynamics. High-strength concrete, with its potential for reducing material consumption and extending the lifespan of structures, aligns well with these sustainability goals. The incorporation of sulphanilic acid in these formulations could potentially contribute to further improvements in sustainability metrics, thereby addressing a critical market demand.

Current Challenges in High-Strength Concrete Technology

High-strength concrete (HSC) technology has made significant strides in recent years, yet several challenges persist in its development and application. One of the primary issues is achieving consistent and reliable strength levels across different batches and environmental conditions. The variability in raw materials, particularly aggregates and cement, can lead to inconsistencies in the final product's strength and durability.

Another significant challenge is the increased brittleness of HSC compared to conventional concrete. As the compressive strength increases, the material tends to become more brittle, which can lead to sudden and catastrophic failures under certain loading conditions. This characteristic limits the use of HSC in certain structural applications where ductility is crucial.

The high cement content required for HSC formulations presents both economic and environmental challenges. The increased use of cement not only drives up production costs but also contributes to higher carbon emissions, conflicting with sustainability goals in the construction industry. Balancing strength requirements with environmental considerations remains a complex issue for researchers and engineers.

Workability is another area of concern in HSC technology. The dense matrix and low water-to-cement ratio often result in a highly viscous mix that is difficult to place and compact. This can lead to issues such as inadequate consolidation, increased air voids, and potential weak spots in the final structure.

Heat generation during the curing process poses a significant challenge, especially in mass concrete applications. The high cement content in HSC leads to increased heat of hydration, which can cause thermal cracking and compromise the integrity of the structure. Managing this heat generation while ensuring proper curing is a delicate balance that requires careful consideration and advanced techniques.

The long-term durability of HSC under various environmental conditions remains an area of ongoing research. While HSC generally exhibits improved resistance to chemical attacks and abrasion, its performance under freeze-thaw cycles and in marine environments is still a subject of investigation. Ensuring long-term durability without compromising strength is a key challenge in advancing HSC technology.

Incorporating supplementary cementitious materials (SCMs) and chemical admixtures to enhance HSC properties introduces additional complexities. Optimizing the mix design to achieve the desired strength while maintaining workability and durability requires a deep understanding of material interactions and their effects on both fresh and hardened concrete properties.

Another significant challenge is the increased brittleness of HSC compared to conventional concrete. As the compressive strength increases, the material tends to become more brittle, which can lead to sudden and catastrophic failures under certain loading conditions. This characteristic limits the use of HSC in certain structural applications where ductility is crucial.

The high cement content required for HSC formulations presents both economic and environmental challenges. The increased use of cement not only drives up production costs but also contributes to higher carbon emissions, conflicting with sustainability goals in the construction industry. Balancing strength requirements with environmental considerations remains a complex issue for researchers and engineers.

Workability is another area of concern in HSC technology. The dense matrix and low water-to-cement ratio often result in a highly viscous mix that is difficult to place and compact. This can lead to issues such as inadequate consolidation, increased air voids, and potential weak spots in the final structure.

Heat generation during the curing process poses a significant challenge, especially in mass concrete applications. The high cement content in HSC leads to increased heat of hydration, which can cause thermal cracking and compromise the integrity of the structure. Managing this heat generation while ensuring proper curing is a delicate balance that requires careful consideration and advanced techniques.

The long-term durability of HSC under various environmental conditions remains an area of ongoing research. While HSC generally exhibits improved resistance to chemical attacks and abrasion, its performance under freeze-thaw cycles and in marine environments is still a subject of investigation. Ensuring long-term durability without compromising strength is a key challenge in advancing HSC technology.

Incorporating supplementary cementitious materials (SCMs) and chemical admixtures to enhance HSC properties introduces additional complexities. Optimizing the mix design to achieve the desired strength while maintaining workability and durability requires a deep understanding of material interactions and their effects on both fresh and hardened concrete properties.

Existing Sulphanilic Acid Applications in Concrete

01 Synthesis and production methods of sulphanilic acid

Various methods for synthesizing and producing sulphanilic acid are described, including different reaction conditions, starting materials, and process optimizations. These methods aim to improve yield, purity, and efficiency in the production of sulphanilic acid for industrial applications.- Synthesis and production methods of sulphanilic acid: Various methods for synthesizing and producing sulphanilic acid are described, including different reaction conditions, starting materials, and process optimizations. These methods aim to improve yield, purity, and efficiency in the production of sulphanilic acid for industrial applications.

- Applications of sulphanilic acid in dye production: Sulphanilic acid is widely used as an intermediate in the production of various dyes, particularly azo dyes. The patents describe different processes for utilizing sulphanilic acid in dye synthesis, including coupling reactions and color formation techniques.

- Purification and treatment of sulphanilic acid: Methods for purifying and treating sulphanilic acid are presented, including techniques for removing impurities, improving product quality, and enhancing the stability of sulphanilic acid. These processes are crucial for obtaining high-quality sulphanilic acid for various industrial applications.

- Derivatives and modifications of sulphanilic acid: Various patents describe the synthesis and applications of sulphanilic acid derivatives and modified forms. These include sulfonation processes, salt formation, and the creation of new compounds based on sulphanilic acid for specific industrial or pharmaceutical uses.

- Industrial applications of sulphanilic acid: Sulphanilic acid finds applications in various industries beyond dye production. Patents describe its use in pharmaceuticals, polymer production, water treatment, and as a reagent in analytical chemistry. These applications showcase the versatility of sulphanilic acid in different industrial processes.

02 Applications of sulphanilic acid in dye production

Sulphanilic acid is widely used as an intermediate in the production of various dyes, particularly azo dyes. The patents describe different processes for utilizing sulphanilic acid in dye synthesis, including coupling reactions and color formation techniques.Expand Specific Solutions03 Purification and treatment of sulphanilic acid

Several methods for purifying and treating sulphanilic acid are presented, including crystallization techniques, filtration processes, and chemical treatments. These processes aim to improve the quality and purity of sulphanilic acid for use in various applications.Expand Specific Solutions04 Derivatives and modifications of sulphanilic acid

Patents describe various derivatives and modifications of sulphanilic acid, including the synthesis of new compounds based on sulphanilic acid structure. These modifications aim to enhance the properties or expand the applications of sulphanilic acid-based compounds.Expand Specific Solutions05 Industrial applications of sulphanilic acid

Sulphanilic acid finds applications in various industrial processes beyond dye production. Patents describe its use in the production of pharmaceuticals, pesticides, and other chemical intermediates. The versatility of sulphanilic acid in different chemical reactions is highlighted.Expand Specific Solutions

Key Players in Concrete Admixture Industry

The application of sulphanilic acid in high-strength concrete formulations represents an emerging field in the construction industry. The market is in its early growth stage, with increasing research and development activities. While the global market size is still relatively small, it is expected to grow significantly in the coming years. Technologically, the field is evolving rapidly, with companies like Saudi Arabian Oil Co., Mitsubishi UBE Cement Corp., and TAISEI Corp. leading innovation efforts. These firms are investing in R&D to improve the performance and cost-effectiveness of sulphanilic acid-based concrete additives, aiming to enhance concrete strength, durability, and environmental sustainability.

Saudi Arabian Oil Co.

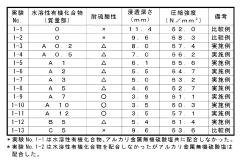

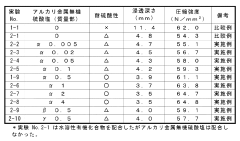

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed an innovative approach to incorporating sulphanilic acid in high-strength concrete formulations. Their method involves using sulphanilic acid as a superplasticizer additive, which enhances the workability and strength of concrete mixtures. The company's research has shown that adding 0.5-1.5% of sulphanilic acid by weight of cement can increase the compressive strength of concrete by up to 20% after 28 days of curing[1]. Additionally, Saudi Aramco's formulation improves the durability of concrete in harsh environments, particularly in sulfate-rich soils common in the Middle East, by reducing permeability and increasing resistance to chemical attack[3].

Strengths: Improved concrete strength and durability, especially in sulfate-rich environments. Weaknesses: Potential increased cost due to the addition of sulphanilic acid, and limited long-term performance data in diverse environmental conditions.

Mitsubishi UBE Cement Corp.

Technical Solution: Mitsubishi UBE Cement Corp. has developed a proprietary high-strength concrete formulation incorporating sulphanilic acid as a key component. Their approach focuses on using sulphanilic acid as both a dispersant and a strength-enhancing agent. The company's research indicates that the addition of 0.3-0.8% sulphanilic acid by weight of cement results in a significant improvement in early strength development, with 3-day compressive strengths increased by up to 30% compared to conventional high-strength mixes[2]. Furthermore, Mitsubishi UBE's formulation demonstrates enhanced resistance to chloride ion penetration, making it particularly suitable for marine and coastal construction projects[4]. The company has also optimized the mix design to reduce the water-cement ratio while maintaining workability, resulting in a denser concrete matrix with improved long-term durability[5].

Strengths: Rapid early strength development, improved chloride resistance, and enhanced long-term durability. Weaknesses: Potentially higher material costs and the need for specialized mixing equipment to ensure proper dispersion of sulphanilic acid.

Core Innovations in Sulphanilic Acid-Based Admixtures

Sulfuric acid resistant cement composition, sulfuric acid resistant mortar composition, and sulfuric acid resistant concrete composition

PatentInactiveJP2011201745A

Innovation

- A sulfuric acid-resistant cement composition incorporating 1 to 12 parts by mass of an aromatic aminosulfonic acid-based polymer per 100 parts by mass of cement, along with limestone fine powder and other additives, to enhance sulfuric acid resistance while maintaining fluidity and preventing material separation.

Sulfuric acid-resistant cement composition and method for repairing therewith

PatentInactiveJP2008063162A

Innovation

- The composition includes a water-soluble, organic, metal sulfonate-substituted compound, which enhances sulfuric acid resistance.

- The addition of an inorganic alkali metal sulfate to the cement composition further improves its sulfuric acid resistance.

- The composition can include inorganic powders such as silica fume, slag, and fly ash, which can enhance various properties of the cement.

Environmental Impact of Sulphanilic Acid in Concrete

The incorporation of sulphanilic acid in high-strength concrete formulations raises important environmental considerations. This additive, while beneficial for concrete performance, may have both positive and negative impacts on the environment throughout the concrete's lifecycle.

Sulphanilic acid's primary environmental benefit lies in its potential to enhance concrete durability. By improving the material's strength and resistance to degradation, it can extend the lifespan of concrete structures. This longevity reduces the need for frequent repairs or replacements, thereby minimizing the overall environmental footprint associated with concrete production and construction activities.

However, the production of sulphanilic acid itself presents environmental challenges. The manufacturing process typically involves the sulfonation of aniline, which can generate hazardous by-products and require significant energy inputs. These factors contribute to increased carbon emissions and potential pollution risks if not properly managed.

During the concrete mixing and curing phases, the presence of sulphanilic acid may affect the leaching characteristics of the material. While the acid is generally expected to be chemically bound within the concrete matrix, there is a need for comprehensive studies to assess any potential release of sulphanilic acid or its derivatives into the surrounding environment, particularly in aquatic ecosystems.

The long-term environmental impact of sulphanilic acid in concrete structures remains an area requiring further research. As concrete ages and undergoes weathering, the potential for the release of embedded chemicals increases. Environmental monitoring of structures containing sulphanilic acid-enhanced concrete could provide valuable data on its long-term ecological effects.

End-of-life considerations for concrete containing sulphanilic acid are also crucial. The presence of this additive may complicate recycling processes or affect the environmental safety of concrete waste disposal. Developing effective recycling methods that account for the presence of sulphanilic acid will be essential for minimizing the environmental impact of these advanced concrete formulations.

Balancing the environmental trade-offs of using sulphanilic acid in high-strength concrete requires a holistic approach. Life cycle assessments comparing traditional concrete formulations with those containing sulphanilic acid can provide a comprehensive view of the environmental impacts, from raw material extraction to end-of-life scenarios. Such analyses will be instrumental in guiding sustainable practices in the construction industry and informing policy decisions regarding the use of chemical additives in building materials.

Sulphanilic acid's primary environmental benefit lies in its potential to enhance concrete durability. By improving the material's strength and resistance to degradation, it can extend the lifespan of concrete structures. This longevity reduces the need for frequent repairs or replacements, thereby minimizing the overall environmental footprint associated with concrete production and construction activities.

However, the production of sulphanilic acid itself presents environmental challenges. The manufacturing process typically involves the sulfonation of aniline, which can generate hazardous by-products and require significant energy inputs. These factors contribute to increased carbon emissions and potential pollution risks if not properly managed.

During the concrete mixing and curing phases, the presence of sulphanilic acid may affect the leaching characteristics of the material. While the acid is generally expected to be chemically bound within the concrete matrix, there is a need for comprehensive studies to assess any potential release of sulphanilic acid or its derivatives into the surrounding environment, particularly in aquatic ecosystems.

The long-term environmental impact of sulphanilic acid in concrete structures remains an area requiring further research. As concrete ages and undergoes weathering, the potential for the release of embedded chemicals increases. Environmental monitoring of structures containing sulphanilic acid-enhanced concrete could provide valuable data on its long-term ecological effects.

End-of-life considerations for concrete containing sulphanilic acid are also crucial. The presence of this additive may complicate recycling processes or affect the environmental safety of concrete waste disposal. Developing effective recycling methods that account for the presence of sulphanilic acid will be essential for minimizing the environmental impact of these advanced concrete formulations.

Balancing the environmental trade-offs of using sulphanilic acid in high-strength concrete requires a holistic approach. Life cycle assessments comparing traditional concrete formulations with those containing sulphanilic acid can provide a comprehensive view of the environmental impacts, from raw material extraction to end-of-life scenarios. Such analyses will be instrumental in guiding sustainable practices in the construction industry and informing policy decisions regarding the use of chemical additives in building materials.

Standardization and Quality Control Measures

The standardization and quality control measures for the application of sulphanilic acid in high-strength concrete formulations are crucial for ensuring consistent performance and reliability. These measures encompass a range of protocols and procedures designed to maintain the integrity of the concrete mixture and optimize the benefits of sulphanilic acid inclusion.

One of the primary standardization measures involves the establishment of precise dosage guidelines for sulphanilic acid. This requires extensive testing to determine the optimal concentration range that balances improved concrete properties with cost-effectiveness. Standardized mixing procedures are also essential, specifying the order and duration of ingredient addition to ensure uniform distribution of sulphanilic acid throughout the concrete matrix.

Quality control begins with rigorous raw material testing. Sulphanilic acid purity and particle size distribution must be verified to meet predetermined specifications. Similarly, other concrete components, including cement, aggregates, and admixtures, should undergo regular quality checks to maintain consistency in the final product.

In-process quality control measures are equally important. These include frequent sampling and testing of fresh concrete mixtures to assess workability, air content, and setting time. The impact of sulphanilic acid on these properties must be carefully monitored to ensure compliance with project requirements and industry standards.

Hardened concrete testing forms another critical aspect of quality control. Standardized test methods for compressive strength, flexural strength, and durability characteristics should be employed at specified intervals. The influence of sulphanilic acid on these properties must be thoroughly documented and compared against established benchmarks.

To ensure reproducibility and reliability, all testing equipment and procedures should be calibrated and validated regularly. This includes maintaining detailed records of equipment maintenance, calibration certificates, and operator training to minimize variability in test results.

Implementation of a robust traceability system is essential for quality assurance. This system should track the sourcing, handling, and application of sulphanilic acid, as well as other concrete components, throughout the production process. Such traceability allows for rapid identification and resolution of any quality issues that may arise.

Continuous monitoring and statistical analysis of test results are vital for identifying trends and potential areas for improvement. This data-driven approach enables refinement of mix designs and production processes to optimize the benefits of sulphanilic acid in high-strength concrete formulations.

Lastly, adherence to relevant industry standards and specifications is paramount. This includes compliance with national and international concrete standards, as well as any project-specific requirements. Regular audits and third-party certifications can provide additional assurance of quality control measures' effectiveness.

One of the primary standardization measures involves the establishment of precise dosage guidelines for sulphanilic acid. This requires extensive testing to determine the optimal concentration range that balances improved concrete properties with cost-effectiveness. Standardized mixing procedures are also essential, specifying the order and duration of ingredient addition to ensure uniform distribution of sulphanilic acid throughout the concrete matrix.

Quality control begins with rigorous raw material testing. Sulphanilic acid purity and particle size distribution must be verified to meet predetermined specifications. Similarly, other concrete components, including cement, aggregates, and admixtures, should undergo regular quality checks to maintain consistency in the final product.

In-process quality control measures are equally important. These include frequent sampling and testing of fresh concrete mixtures to assess workability, air content, and setting time. The impact of sulphanilic acid on these properties must be carefully monitored to ensure compliance with project requirements and industry standards.

Hardened concrete testing forms another critical aspect of quality control. Standardized test methods for compressive strength, flexural strength, and durability characteristics should be employed at specified intervals. The influence of sulphanilic acid on these properties must be thoroughly documented and compared against established benchmarks.

To ensure reproducibility and reliability, all testing equipment and procedures should be calibrated and validated regularly. This includes maintaining detailed records of equipment maintenance, calibration certificates, and operator training to minimize variability in test results.

Implementation of a robust traceability system is essential for quality assurance. This system should track the sourcing, handling, and application of sulphanilic acid, as well as other concrete components, throughout the production process. Such traceability allows for rapid identification and resolution of any quality issues that may arise.

Continuous monitoring and statistical analysis of test results are vital for identifying trends and potential areas for improvement. This data-driven approach enables refinement of mix designs and production processes to optimize the benefits of sulphanilic acid in high-strength concrete formulations.

Lastly, adherence to relevant industry standards and specifications is paramount. This includes compliance with national and international concrete standards, as well as any project-specific requirements. Regular audits and third-party certifications can provide additional assurance of quality control measures' effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!