Applications of Silicon Micropillars in Green Technology

JUL 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Micropillars: Background and Objectives

Silicon micropillars have emerged as a promising technology in the field of green energy and environmental sustainability. These nanoscale structures, typically made from silicon, have garnered significant attention due to their unique properties and potential applications in various green technologies. The development of silicon micropillars can be traced back to the early 2000s when researchers began exploring ways to enhance the efficiency of solar cells and other energy-related devices.

The evolution of silicon micropillar technology has been driven by the growing need for more efficient and sustainable energy solutions. As global concerns about climate change and environmental degradation have intensified, researchers have sought innovative ways to harness renewable energy sources and reduce carbon emissions. Silicon micropillars have shown great promise in addressing these challenges, offering improved performance in solar cells, water purification systems, and energy storage devices.

The primary objective of silicon micropillar research in green technology is to leverage the unique properties of these structures to enhance the efficiency and effectiveness of various environmental applications. By manipulating the size, shape, and arrangement of silicon micropillars, scientists aim to optimize their performance in areas such as light absorption, surface area enhancement, and electron transport.

One of the key goals in this field is to improve the efficiency of solar cells. Silicon micropillars can significantly increase the light-trapping capabilities of photovoltaic devices, allowing for greater energy conversion and reduced material usage. This has the potential to make solar energy more cost-effective and widely accessible, contributing to the global transition towards renewable energy sources.

Another important objective is the development of advanced water purification technologies. Silicon micropillars can be engineered to create highly efficient filtration membranes capable of removing contaminants at the molecular level. This could lead to more effective and energy-efficient water treatment processes, addressing the growing global challenge of water scarcity and pollution.

Furthermore, researchers are exploring the use of silicon micropillars in energy storage applications, such as lithium-ion batteries and supercapacitors. The high surface area and unique electrical properties of these structures could potentially enhance the performance and longevity of energy storage devices, supporting the integration of renewable energy sources into the power grid.

As the field of green technology continues to evolve, silicon micropillars are expected to play an increasingly important role in addressing environmental challenges. The ongoing research and development in this area aim to push the boundaries of what is possible in sustainable technology, paving the way for more efficient, cost-effective, and environmentally friendly solutions across various sectors.

The evolution of silicon micropillar technology has been driven by the growing need for more efficient and sustainable energy solutions. As global concerns about climate change and environmental degradation have intensified, researchers have sought innovative ways to harness renewable energy sources and reduce carbon emissions. Silicon micropillars have shown great promise in addressing these challenges, offering improved performance in solar cells, water purification systems, and energy storage devices.

The primary objective of silicon micropillar research in green technology is to leverage the unique properties of these structures to enhance the efficiency and effectiveness of various environmental applications. By manipulating the size, shape, and arrangement of silicon micropillars, scientists aim to optimize their performance in areas such as light absorption, surface area enhancement, and electron transport.

One of the key goals in this field is to improve the efficiency of solar cells. Silicon micropillars can significantly increase the light-trapping capabilities of photovoltaic devices, allowing for greater energy conversion and reduced material usage. This has the potential to make solar energy more cost-effective and widely accessible, contributing to the global transition towards renewable energy sources.

Another important objective is the development of advanced water purification technologies. Silicon micropillars can be engineered to create highly efficient filtration membranes capable of removing contaminants at the molecular level. This could lead to more effective and energy-efficient water treatment processes, addressing the growing global challenge of water scarcity and pollution.

Furthermore, researchers are exploring the use of silicon micropillars in energy storage applications, such as lithium-ion batteries and supercapacitors. The high surface area and unique electrical properties of these structures could potentially enhance the performance and longevity of energy storage devices, supporting the integration of renewable energy sources into the power grid.

As the field of green technology continues to evolve, silicon micropillars are expected to play an increasingly important role in addressing environmental challenges. The ongoing research and development in this area aim to push the boundaries of what is possible in sustainable technology, paving the way for more efficient, cost-effective, and environmentally friendly solutions across various sectors.

Green Tech Market Demand Analysis

The green technology market has experienced significant growth in recent years, driven by increasing environmental concerns and the urgent need for sustainable solutions. Within this context, silicon micropillars have emerged as a promising technology with diverse applications in green tech sectors. The demand for silicon micropillar-based solutions is primarily fueled by their potential to enhance energy efficiency, reduce resource consumption, and minimize environmental impact across various industries.

In the renewable energy sector, silicon micropillars have garnered substantial interest for their ability to improve solar cell efficiency. The unique structure of these micropillars allows for better light trapping and absorption, potentially leading to higher conversion rates in photovoltaic systems. This application aligns with the growing demand for more efficient and cost-effective solar energy solutions, as the global solar market continues to expand rapidly.

Water purification and treatment represent another significant area of market demand for silicon micropillar technology. The high surface area and customizable properties of micropillars make them excellent candidates for advanced filtration systems. As water scarcity becomes an increasingly pressing issue worldwide, the demand for innovative and energy-efficient water treatment solutions is expected to rise, creating a favorable market environment for silicon micropillar applications.

In the field of energy storage, silicon micropillars show promise for enhancing the performance of batteries and supercapacitors. The unique structure of micropillars can potentially increase the energy density and charging speed of these devices, addressing key challenges in the electric vehicle and renewable energy storage markets. As these sectors continue to grow, the demand for advanced energy storage solutions incorporating silicon micropillar technology is likely to increase.

The green building industry also presents opportunities for silicon micropillar applications, particularly in the development of smart windows and energy-efficient coatings. These technologies can significantly reduce energy consumption in buildings by regulating heat and light transmission. With the global push towards sustainable construction and energy-efficient buildings, the market for such advanced materials is expected to expand.

Furthermore, the automotive industry's shift towards more environmentally friendly vehicles creates potential demand for silicon micropillar-based technologies in areas such as lightweight materials, improved catalytic converters, and enhanced sensors for emission control systems. As regulations on vehicle emissions become stricter worldwide, the need for innovative green technologies in this sector is likely to grow.

While the market potential for silicon micropillar applications in green technology is substantial, it is important to note that many of these applications are still in the research and development phase. The transition from laboratory success to commercial viability will be crucial in determining the actual market demand and adoption rates. Factors such as production scalability, cost-effectiveness, and compatibility with existing manufacturing processes will play significant roles in shaping the market landscape for silicon micropillar technologies in the coming years.

In the renewable energy sector, silicon micropillars have garnered substantial interest for their ability to improve solar cell efficiency. The unique structure of these micropillars allows for better light trapping and absorption, potentially leading to higher conversion rates in photovoltaic systems. This application aligns with the growing demand for more efficient and cost-effective solar energy solutions, as the global solar market continues to expand rapidly.

Water purification and treatment represent another significant area of market demand for silicon micropillar technology. The high surface area and customizable properties of micropillars make them excellent candidates for advanced filtration systems. As water scarcity becomes an increasingly pressing issue worldwide, the demand for innovative and energy-efficient water treatment solutions is expected to rise, creating a favorable market environment for silicon micropillar applications.

In the field of energy storage, silicon micropillars show promise for enhancing the performance of batteries and supercapacitors. The unique structure of micropillars can potentially increase the energy density and charging speed of these devices, addressing key challenges in the electric vehicle and renewable energy storage markets. As these sectors continue to grow, the demand for advanced energy storage solutions incorporating silicon micropillar technology is likely to increase.

The green building industry also presents opportunities for silicon micropillar applications, particularly in the development of smart windows and energy-efficient coatings. These technologies can significantly reduce energy consumption in buildings by regulating heat and light transmission. With the global push towards sustainable construction and energy-efficient buildings, the market for such advanced materials is expected to expand.

Furthermore, the automotive industry's shift towards more environmentally friendly vehicles creates potential demand for silicon micropillar-based technologies in areas such as lightweight materials, improved catalytic converters, and enhanced sensors for emission control systems. As regulations on vehicle emissions become stricter worldwide, the need for innovative green technologies in this sector is likely to grow.

While the market potential for silicon micropillar applications in green technology is substantial, it is important to note that many of these applications are still in the research and development phase. The transition from laboratory success to commercial viability will be crucial in determining the actual market demand and adoption rates. Factors such as production scalability, cost-effectiveness, and compatibility with existing manufacturing processes will play significant roles in shaping the market landscape for silicon micropillar technologies in the coming years.

Current State and Challenges in Silicon Micropillar Technology

Silicon micropillar technology has made significant strides in recent years, particularly in its applications for green technology. The current state of this field is characterized by rapid advancements in fabrication techniques, material science, and integration methods. Researchers have successfully developed silicon micropillars with various dimensions, ranging from nanometers to micrometers, and have demonstrated their potential in diverse green technology applications.

One of the primary areas of progress is in photovoltaics, where silicon micropillars have shown promise in enhancing solar cell efficiency. By increasing light absorption and reducing reflection, these structures have the potential to significantly improve the performance of solar panels. Additionally, silicon micropillars have been explored for their use in water purification systems, leveraging their high surface area to volume ratio for efficient filtration and contaminant removal.

Despite these advancements, several challenges remain in the widespread adoption and commercialization of silicon micropillar technology. One of the most significant hurdles is the scalability of production processes. While laboratory-scale fabrication has been successful, translating these methods to large-scale, cost-effective manufacturing remains a considerable challenge. The precision required in creating uniform and consistent micropillar arrays across large surface areas poses significant technical difficulties.

Another challenge lies in the long-term stability and durability of silicon micropillar structures. Exposure to environmental factors such as temperature fluctuations, humidity, and mechanical stress can potentially degrade the performance and structural integrity of these micropillars over time. Developing robust protective coatings or encapsulation methods to ensure the longevity of silicon micropillar-based devices is an ongoing area of research.

The integration of silicon micropillars into existing green technology systems also presents challenges. Compatibility issues with current manufacturing processes and the need for redesigning certain components to accommodate micropillar structures can be significant barriers to adoption. Furthermore, optimizing the performance of micropillar-based devices in real-world conditions, where factors such as dust accumulation and varying light conditions come into play, requires extensive testing and refinement.

From a materials perspective, while silicon remains the primary focus, there is ongoing research into alternative or complementary materials that could enhance the properties of micropillars. This includes exploring hybrid structures or doping techniques to improve electrical and optical characteristics. However, balancing enhanced performance with cost-effectiveness and environmental sustainability remains a complex challenge.

Lastly, the regulatory landscape surrounding the use of silicon micropillars in green technology applications is still evolving. Ensuring compliance with safety standards and environmental regulations, particularly for applications in water treatment or energy production, requires ongoing dialogue between researchers, industry stakeholders, and regulatory bodies.

One of the primary areas of progress is in photovoltaics, where silicon micropillars have shown promise in enhancing solar cell efficiency. By increasing light absorption and reducing reflection, these structures have the potential to significantly improve the performance of solar panels. Additionally, silicon micropillars have been explored for their use in water purification systems, leveraging their high surface area to volume ratio for efficient filtration and contaminant removal.

Despite these advancements, several challenges remain in the widespread adoption and commercialization of silicon micropillar technology. One of the most significant hurdles is the scalability of production processes. While laboratory-scale fabrication has been successful, translating these methods to large-scale, cost-effective manufacturing remains a considerable challenge. The precision required in creating uniform and consistent micropillar arrays across large surface areas poses significant technical difficulties.

Another challenge lies in the long-term stability and durability of silicon micropillar structures. Exposure to environmental factors such as temperature fluctuations, humidity, and mechanical stress can potentially degrade the performance and structural integrity of these micropillars over time. Developing robust protective coatings or encapsulation methods to ensure the longevity of silicon micropillar-based devices is an ongoing area of research.

The integration of silicon micropillars into existing green technology systems also presents challenges. Compatibility issues with current manufacturing processes and the need for redesigning certain components to accommodate micropillar structures can be significant barriers to adoption. Furthermore, optimizing the performance of micropillar-based devices in real-world conditions, where factors such as dust accumulation and varying light conditions come into play, requires extensive testing and refinement.

From a materials perspective, while silicon remains the primary focus, there is ongoing research into alternative or complementary materials that could enhance the properties of micropillars. This includes exploring hybrid structures or doping techniques to improve electrical and optical characteristics. However, balancing enhanced performance with cost-effectiveness and environmental sustainability remains a complex challenge.

Lastly, the regulatory landscape surrounding the use of silicon micropillars in green technology applications is still evolving. Ensuring compliance with safety standards and environmental regulations, particularly for applications in water treatment or energy production, requires ongoing dialogue between researchers, industry stakeholders, and regulatory bodies.

Existing Green Tech Solutions Using Silicon Micropillars

01 Fabrication methods for silicon micropillars

Various techniques are employed to create silicon micropillars, including etching processes, lithography, and deposition methods. These fabrication methods allow for precise control over the size, shape, and arrangement of the micropillars, which is crucial for their performance in different applications.- Fabrication methods for silicon micropillars: Various techniques are employed to create silicon micropillars, including etching processes, lithography, and deposition methods. These fabrication methods allow for precise control over the size, shape, and spacing of the micropillars, which is crucial for their performance in different applications.

- Applications in solar cells and photovoltaics: Silicon micropillars are utilized in solar cell and photovoltaic technologies to enhance light absorption and improve overall efficiency. The unique structure of micropillars allows for better light trapping and increased surface area, leading to improved energy conversion in solar devices.

- Use in microfluidic and lab-on-a-chip devices: Silicon micropillars play a significant role in microfluidic systems and lab-on-a-chip devices. They can be used for fluid manipulation, particle separation, and as structural elements in miniaturized analytical systems, enhancing the performance of these devices in various scientific and medical applications.

- Integration with MEMS and sensor technologies: Silicon micropillars are integrated into Micro-Electro-Mechanical Systems (MEMS) and various sensor technologies. Their unique properties allow for the development of highly sensitive and miniaturized sensors for applications in environmental monitoring, biomedical devices, and industrial process control.

- Surface modification and functionalization: The surface of silicon micropillars can be modified and functionalized to enhance their properties for specific applications. This includes coating with various materials, chemical treatments, and the addition of functional groups to tailor the micropillars for use in areas such as biosensing, catalysis, and advanced materials.

02 Applications in solar cells and photovoltaics

Silicon micropillars are utilized in solar cell and photovoltaic technologies to enhance light absorption and improve overall efficiency. The unique structure of micropillars allows for better light trapping and increased surface area, leading to improved energy conversion in solar devices.Expand Specific Solutions03 Use in microfluidic and lab-on-a-chip devices

Silicon micropillars play a significant role in microfluidic and lab-on-a-chip devices. They can be used for fluid manipulation, particle separation, and as structural elements in miniaturized analytical systems, enabling more efficient and precise biomedical and chemical analyses.Expand Specific Solutions04 Integration with MEMS and sensor technologies

Silicon micropillars are integrated into Micro-Electro-Mechanical Systems (MEMS) and various sensor technologies. Their unique properties allow for enhanced sensitivity and functionality in applications such as pressure sensors, accelerometers, and other miniaturized sensing devices.Expand Specific Solutions05 Surface modification and functionalization

The surface of silicon micropillars can be modified and functionalized to tailor their properties for specific applications. This includes coating with various materials, chemical treatments, and the addition of functional groups to enhance their performance in areas such as catalysis, sensing, and biomedical applications.Expand Specific Solutions

Key Players in Silicon Micropillar Industry

The field of silicon micropillars in green technology is in an early growth stage, with increasing market potential as sustainability efforts gain momentum. The market size is expanding, driven by applications in energy efficiency and environmental remediation. Technologically, it's progressing from experimental to early commercial stages. Key players like The Regents of the University of California, California Institute of Technology, and Evonik Operations GmbH are advancing research and development. Academic institutions, including Zhejiang University and Colorado State University, are contributing significantly to fundamental research. Industrial players such as Industrial Technology Research Institute and SiOnyx LLC are working on practical applications, indicating a gradual shift towards commercialization in this promising green technology sector.

The Regents of the University of California

Technical Solution: The University of California has developed innovative silicon micropillar arrays for enhanced solar cell efficiency. Their technology utilizes vertically aligned silicon micropillars with diameters ranging from 1-10 μm and heights of 10-100 μm[1]. These structures significantly increase light absorption and reduce reflection, leading to improved photovoltaic performance. The micropillars are fabricated using a combination of lithography and etching techniques, allowing for precise control over pillar dimensions and spacing[2]. Additionally, the university has explored the use of these micropillars in water splitting applications for hydrogen production, demonstrating a 2-3 fold increase in catalytic activity compared to planar silicon surfaces[3].

Strengths: Highly efficient light absorption, versatile applications in solar cells and water splitting. Weaknesses: Complex fabrication process, potential for increased surface recombination.

California Institute of Technology

Technical Solution: Caltech has pioneered the development of silicon micropillar arrays for photoelectrochemical (PEC) water splitting. Their approach involves creating highly ordered, vertically aligned silicon micropillars with diameters of 2-3 μm and heights up to 30 μm[4]. These structures are then coated with catalysts such as platinum or nickel to enhance water splitting efficiency. The micropillars significantly increase the surface area for catalytic reactions while maintaining good charge transport properties. Caltech researchers have reported a 5-fold increase in photocurrent density compared to planar silicon electrodes[5]. Furthermore, they have explored the integration of these micropillar arrays with protective coatings to enhance stability in harsh electrochemical environments[6].

Strengths: High surface area for catalysis, improved charge separation and transport. Weaknesses: Potential for increased fabrication costs, challenges in scaling up production.

Core Innovations in Silicon Micropillar Fabrication

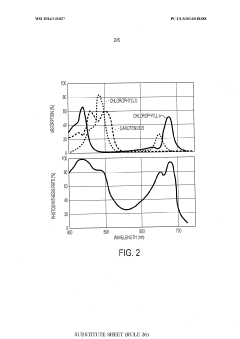

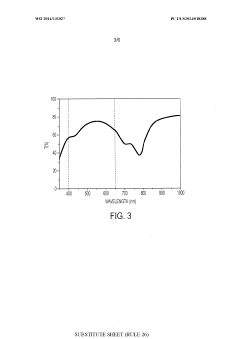

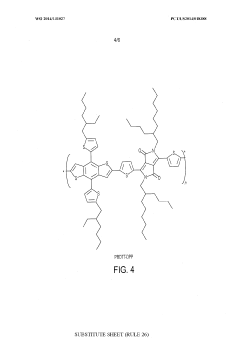

Transparent organic solar cells for agronomic applications

PatentWO2014131027A1

Innovation

- The development of visibly transparent organic photovoltaic (OPV) cells with high transparency in the visible range (400-700 nm) and power conversion efficiency, utilizing copolymers and transparent electrodes like silver nanowires or conductive oxides, which absorb near-infrared and ultraviolet light to generate electricity without reducing visible light transmission, combined with semi-transparent or down-conversion materials to optimize energy harvesting and plant growth conditions.

green compacts based on silicon

PatentInactiveJP2011527278A

Innovation

- A sol-gel method is employed to agglomerate silicon particles into 'green compacts' by preparing a silane solution, hydrolyzing it with suitable conditions, mixing with silicon powder, and solidifying it in a mold to form a matrix that can be used as a smelter for producing silicon ingots.

Environmental Impact Assessment

The environmental impact assessment of silicon micropillars in green technology applications reveals both positive and negative aspects. On the positive side, these structures contribute significantly to enhancing the efficiency of solar cells, potentially reducing the overall carbon footprint of energy production. By improving light absorption and electron collection, silicon micropillars enable the development of more compact and efficient photovoltaic systems, which could lead to a decrease in the amount of raw materials required for solar panel production.

Furthermore, silicon micropillars have shown promise in water purification applications. Their high surface area-to-volume ratio and customizable surface properties make them effective in removing contaminants from water, potentially reducing the need for chemical treatments and energy-intensive purification processes. This could result in more sustainable water management practices and decreased environmental pollution from conventional water treatment methods.

However, the production of silicon micropillars does raise some environmental concerns. The manufacturing process often involves energy-intensive steps and the use of potentially hazardous chemicals. The etching and deposition techniques used to create these structures may generate waste products that require careful disposal to prevent environmental contamination. Additionally, the long-term durability and end-of-life management of devices incorporating silicon micropillars need to be considered to ensure they do not contribute to electronic waste issues.

In terms of resource consumption, while silicon is abundant, the high-purity silicon required for these applications may lead to increased mining and refining activities. This could potentially impact local ecosystems and contribute to habitat destruction if not managed responsibly. However, the improved efficiency of devices using silicon micropillars may offset these impacts by reducing the overall material requirements in the long term.

The potential for silicon micropillars to enhance the performance of various green technologies also extends to areas such as catalysis for CO2 reduction and hydrogen production. These applications could contribute to the development of more sustainable industrial processes and alternative energy sources, potentially mitigating greenhouse gas emissions and reducing reliance on fossil fuels.

Overall, the environmental impact of silicon micropillars in green technology applications appears to be mixed, with significant potential benefits in energy efficiency and resource conservation, balanced against manufacturing-related concerns and resource extraction impacts. As the technology matures, ongoing research and development efforts should focus on optimizing production processes to minimize negative environmental effects while maximizing the positive contributions to sustainability and green technology advancements.

Furthermore, silicon micropillars have shown promise in water purification applications. Their high surface area-to-volume ratio and customizable surface properties make them effective in removing contaminants from water, potentially reducing the need for chemical treatments and energy-intensive purification processes. This could result in more sustainable water management practices and decreased environmental pollution from conventional water treatment methods.

However, the production of silicon micropillars does raise some environmental concerns. The manufacturing process often involves energy-intensive steps and the use of potentially hazardous chemicals. The etching and deposition techniques used to create these structures may generate waste products that require careful disposal to prevent environmental contamination. Additionally, the long-term durability and end-of-life management of devices incorporating silicon micropillars need to be considered to ensure they do not contribute to electronic waste issues.

In terms of resource consumption, while silicon is abundant, the high-purity silicon required for these applications may lead to increased mining and refining activities. This could potentially impact local ecosystems and contribute to habitat destruction if not managed responsibly. However, the improved efficiency of devices using silicon micropillars may offset these impacts by reducing the overall material requirements in the long term.

The potential for silicon micropillars to enhance the performance of various green technologies also extends to areas such as catalysis for CO2 reduction and hydrogen production. These applications could contribute to the development of more sustainable industrial processes and alternative energy sources, potentially mitigating greenhouse gas emissions and reducing reliance on fossil fuels.

Overall, the environmental impact of silicon micropillars in green technology applications appears to be mixed, with significant potential benefits in energy efficiency and resource conservation, balanced against manufacturing-related concerns and resource extraction impacts. As the technology matures, ongoing research and development efforts should focus on optimizing production processes to minimize negative environmental effects while maximizing the positive contributions to sustainability and green technology advancements.

Scalability and Cost Analysis

The scalability and cost analysis of silicon micropillars in green technology applications is a critical factor in determining their widespread adoption and commercial viability. As the demand for sustainable solutions grows, the ability to scale up production while maintaining cost-effectiveness becomes paramount.

Currently, the fabrication of silicon micropillars relies on advanced manufacturing techniques such as photolithography and etching processes. While these methods offer high precision and control over the micropillar structures, they can be expensive and time-consuming when considering large-scale production. The cost of specialized equipment and clean room facilities adds significantly to the overall expenses.

However, recent advancements in nanoimprint lithography and roll-to-roll manufacturing techniques show promise for improving scalability. These methods have the potential to increase production throughput while reducing costs. For instance, roll-to-roll manufacturing could enable continuous production of silicon micropillar arrays on flexible substrates, opening up new possibilities for large-area applications in solar cells and water purification systems.

The raw material costs for silicon micropillars are relatively low, as silicon is abundant and widely available. However, the processing and purification steps required to achieve the necessary quality for green technology applications can add to the overall expenses. Efforts to optimize these processes and reduce material waste are ongoing, with potential for significant cost reductions in the future.

Energy consumption during production is another important consideration. While the initial energy investment for manufacturing silicon micropillars may be high, their long-term benefits in energy-efficient applications often outweigh these costs. Researchers are exploring ways to minimize energy usage during fabrication, such as using low-temperature processes and renewable energy sources for production facilities.

As production scales up, economies of scale are expected to play a significant role in reducing costs. Increased automation and improved process efficiencies can lead to lower per-unit costs, making silicon micropillar-based technologies more competitive in the market. Additionally, the development of standardized production methods and equipment could further drive down costs across the industry.

The potential for recycling and reusing silicon micropillars at the end of their lifecycle is an important factor in long-term cost analysis. Developing efficient recycling processes could not only reduce environmental impact but also lower raw material costs for future production cycles.

In conclusion, while current production methods for silicon micropillars face scalability and cost challenges, ongoing research and technological advancements show promising pathways for overcoming these obstacles. As the technology matures and production processes are optimized, silicon micropillars are likely to become increasingly cost-effective and scalable for various green technology applications.

Currently, the fabrication of silicon micropillars relies on advanced manufacturing techniques such as photolithography and etching processes. While these methods offer high precision and control over the micropillar structures, they can be expensive and time-consuming when considering large-scale production. The cost of specialized equipment and clean room facilities adds significantly to the overall expenses.

However, recent advancements in nanoimprint lithography and roll-to-roll manufacturing techniques show promise for improving scalability. These methods have the potential to increase production throughput while reducing costs. For instance, roll-to-roll manufacturing could enable continuous production of silicon micropillar arrays on flexible substrates, opening up new possibilities for large-area applications in solar cells and water purification systems.

The raw material costs for silicon micropillars are relatively low, as silicon is abundant and widely available. However, the processing and purification steps required to achieve the necessary quality for green technology applications can add to the overall expenses. Efforts to optimize these processes and reduce material waste are ongoing, with potential for significant cost reductions in the future.

Energy consumption during production is another important consideration. While the initial energy investment for manufacturing silicon micropillars may be high, their long-term benefits in energy-efficient applications often outweigh these costs. Researchers are exploring ways to minimize energy usage during fabrication, such as using low-temperature processes and renewable energy sources for production facilities.

As production scales up, economies of scale are expected to play a significant role in reducing costs. Increased automation and improved process efficiencies can lead to lower per-unit costs, making silicon micropillar-based technologies more competitive in the market. Additionally, the development of standardized production methods and equipment could further drive down costs across the industry.

The potential for recycling and reusing silicon micropillars at the end of their lifecycle is an important factor in long-term cost analysis. Developing efficient recycling processes could not only reduce environmental impact but also lower raw material costs for future production cycles.

In conclusion, while current production methods for silicon micropillars face scalability and cost challenges, ongoing research and technological advancements show promising pathways for overcoming these obstacles. As the technology matures and production processes are optimized, silicon micropillars are likely to become increasingly cost-effective and scalable for various green technology applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!