Evaluating Thermal Conductivity in Silicon Micropillars

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Micropillar Thermal Conductivity Background

Silicon micropillars have emerged as a significant area of interest in the field of thermal management and nanostructured materials. The study of thermal conductivity in these structures dates back to the early 2000s when researchers began exploring the potential of nanostructured silicon for thermoelectric applications. The fundamental goal of this research is to understand and manipulate the thermal properties of silicon at the nanoscale, particularly in pillar structures, to achieve enhanced thermal management in various applications.

The evolution of silicon micropillar research has been driven by the increasing demand for efficient heat dissipation in microelectronics and the pursuit of improved thermoelectric materials. As electronic devices continue to shrink and become more powerful, the need for effective thermal management solutions has become critical. Silicon, being the backbone of the semiconductor industry, naturally became a focus for such investigations.

Initially, researchers observed that the thermal conductivity of silicon nanostructures, including micropillars, was significantly reduced compared to bulk silicon. This reduction was attributed to increased phonon scattering at the boundaries and surfaces of the nanostructures. This discovery opened up new possibilities for tailoring the thermal properties of silicon for specific applications.

Over the years, various techniques have been developed to fabricate and characterize silicon micropillars. These include top-down approaches like electron beam lithography and reactive ion etching, as well as bottom-up methods such as vapor-liquid-solid growth. The advancement in fabrication techniques has allowed for greater control over the dimensions, spacing, and surface properties of the micropillars, enabling more precise studies of their thermal behavior.

Concurrently, measurement techniques for evaluating thermal conductivity at the nanoscale have also evolved. Methods such as the 3ω technique, time-domain thermoreflectance, and scanning thermal microscopy have been adapted and refined to accurately measure the thermal properties of individual micropillars and arrays.

The research in this field has expanded to include the investigation of various factors affecting thermal conductivity in silicon micropillars. These factors include pillar dimensions (diameter and height), surface roughness, doping levels, and the presence of defects or impurities. Additionally, the impact of external factors such as temperature and pressure on the thermal behavior of these structures has been studied extensively.

Recent years have seen a shift towards more complex structures and hybrid materials. Researchers have begun exploring the thermal properties of silicon micropillars combined with other materials, such as metal coatings or embedded nanoparticles, to further manipulate their thermal characteristics. This trend reflects the growing understanding of the interplay between material composition, structure, and thermal behavior at the nanoscale.

The evolution of silicon micropillar research has been driven by the increasing demand for efficient heat dissipation in microelectronics and the pursuit of improved thermoelectric materials. As electronic devices continue to shrink and become more powerful, the need for effective thermal management solutions has become critical. Silicon, being the backbone of the semiconductor industry, naturally became a focus for such investigations.

Initially, researchers observed that the thermal conductivity of silicon nanostructures, including micropillars, was significantly reduced compared to bulk silicon. This reduction was attributed to increased phonon scattering at the boundaries and surfaces of the nanostructures. This discovery opened up new possibilities for tailoring the thermal properties of silicon for specific applications.

Over the years, various techniques have been developed to fabricate and characterize silicon micropillars. These include top-down approaches like electron beam lithography and reactive ion etching, as well as bottom-up methods such as vapor-liquid-solid growth. The advancement in fabrication techniques has allowed for greater control over the dimensions, spacing, and surface properties of the micropillars, enabling more precise studies of their thermal behavior.

Concurrently, measurement techniques for evaluating thermal conductivity at the nanoscale have also evolved. Methods such as the 3ω technique, time-domain thermoreflectance, and scanning thermal microscopy have been adapted and refined to accurately measure the thermal properties of individual micropillars and arrays.

The research in this field has expanded to include the investigation of various factors affecting thermal conductivity in silicon micropillars. These factors include pillar dimensions (diameter and height), surface roughness, doping levels, and the presence of defects or impurities. Additionally, the impact of external factors such as temperature and pressure on the thermal behavior of these structures has been studied extensively.

Recent years have seen a shift towards more complex structures and hybrid materials. Researchers have begun exploring the thermal properties of silicon micropillars combined with other materials, such as metal coatings or embedded nanoparticles, to further manipulate their thermal characteristics. This trend reflects the growing understanding of the interplay between material composition, structure, and thermal behavior at the nanoscale.

Market Demand Analysis

The market demand for evaluating thermal conductivity in silicon micropillars has been steadily growing, driven by the increasing need for efficient heat management in microelectronics and nanodevices. As electronic components continue to shrink in size while simultaneously increasing in performance, the ability to accurately measure and control thermal properties at the microscale becomes crucial.

The semiconductor industry, particularly in the development of advanced integrated circuits and microprocessors, represents a significant portion of the market demand for this technology. With the ongoing trend towards miniaturization and higher processing speeds, thermal management has become a critical factor in ensuring device reliability and performance. Silicon micropillars, with their unique thermal properties, offer potential solutions for heat dissipation in these applications.

Another key market segment driving demand is the emerging field of thermoelectric devices. These devices, which convert temperature differences into electrical energy or vice versa, rely heavily on materials with specific thermal conductivity properties. Silicon micropillars, when properly engineered, can exhibit tailored thermal conductivity, making them attractive candidates for next-generation thermoelectric applications.

The renewable energy sector, particularly in solar cell technology, also contributes to the market demand. As solar cells become more efficient and compact, understanding and controlling thermal conductivity at the microscale becomes essential for optimizing energy conversion and preventing performance degradation due to heat buildup.

In the automotive industry, the shift towards electric vehicles has intensified the need for advanced thermal management solutions. Evaluating thermal conductivity in silicon micropillars could lead to innovations in battery cooling systems and power electronics, addressing critical challenges in EV performance and safety.

The medical device industry represents another growing market for this technology. As medical devices become smaller and more sophisticated, precise control of thermal properties becomes crucial for applications such as implantable sensors and drug delivery systems.

Market analysts project that the global market for thermal management solutions in microelectronics, which includes technologies for evaluating thermal conductivity in microstructures like silicon micropillars, will experience significant growth in the coming years. This growth is expected to be driven by the increasing adoption of 5G technology, the Internet of Things (IoT), and artificial intelligence applications, all of which require advanced thermal management strategies.

While quantitative market size estimates vary, industry experts agree that the demand for technologies enabling precise evaluation and control of thermal conductivity at the microscale will continue to expand. This growth is expected to be particularly strong in regions with established semiconductor industries and research hubs, such as North America, East Asia, and Western Europe.

The semiconductor industry, particularly in the development of advanced integrated circuits and microprocessors, represents a significant portion of the market demand for this technology. With the ongoing trend towards miniaturization and higher processing speeds, thermal management has become a critical factor in ensuring device reliability and performance. Silicon micropillars, with their unique thermal properties, offer potential solutions for heat dissipation in these applications.

Another key market segment driving demand is the emerging field of thermoelectric devices. These devices, which convert temperature differences into electrical energy or vice versa, rely heavily on materials with specific thermal conductivity properties. Silicon micropillars, when properly engineered, can exhibit tailored thermal conductivity, making them attractive candidates for next-generation thermoelectric applications.

The renewable energy sector, particularly in solar cell technology, also contributes to the market demand. As solar cells become more efficient and compact, understanding and controlling thermal conductivity at the microscale becomes essential for optimizing energy conversion and preventing performance degradation due to heat buildup.

In the automotive industry, the shift towards electric vehicles has intensified the need for advanced thermal management solutions. Evaluating thermal conductivity in silicon micropillars could lead to innovations in battery cooling systems and power electronics, addressing critical challenges in EV performance and safety.

The medical device industry represents another growing market for this technology. As medical devices become smaller and more sophisticated, precise control of thermal properties becomes crucial for applications such as implantable sensors and drug delivery systems.

Market analysts project that the global market for thermal management solutions in microelectronics, which includes technologies for evaluating thermal conductivity in microstructures like silicon micropillars, will experience significant growth in the coming years. This growth is expected to be driven by the increasing adoption of 5G technology, the Internet of Things (IoT), and artificial intelligence applications, all of which require advanced thermal management strategies.

While quantitative market size estimates vary, industry experts agree that the demand for technologies enabling precise evaluation and control of thermal conductivity at the microscale will continue to expand. This growth is expected to be particularly strong in regions with established semiconductor industries and research hubs, such as North America, East Asia, and Western Europe.

Current Challenges in Thermal Conductivity Measurement

The evaluation of thermal conductivity in silicon micropillars presents several significant challenges that researchers and engineers must overcome. One of the primary difficulties lies in the accurate measurement of temperature gradients across these microscale structures. Traditional methods, such as the 3ω technique or time-domain thermoreflectance, often struggle to provide precise readings at such small scales, leading to potential inaccuracies in thermal conductivity calculations.

Another major challenge is the impact of surface scattering on phonon transport in silicon micropillars. As the dimensions of these structures approach the mean free path of phonons, boundary scattering becomes increasingly dominant, significantly altering the thermal conductivity compared to bulk silicon. This size-dependent effect complicates the interpretation of measurement results and necessitates the development of more sophisticated models to account for these nanoscale phenomena.

The presence of defects and impurities in silicon micropillars further compounds the difficulty of thermal conductivity measurements. These structural irregularities can act as scattering centers for phonons, modifying the heat transport properties of the material. Accurately characterizing and quantifying the impact of these defects on thermal conductivity remains a significant challenge, requiring advanced characterization techniques and theoretical models.

Heat dissipation to the surrounding environment poses another obstacle in thermal conductivity measurements of silicon micropillars. The high surface-to-volume ratio of these structures makes them particularly susceptible to heat loss through convection and radiation. Isolating the intrinsic thermal conductivity of the micropillars from these external influences demands careful experimental design and sophisticated data analysis methods.

Furthermore, the anisotropic nature of silicon's crystal structure introduces directional dependence in thermal conductivity measurements. This anisotropy becomes more pronounced in micropillars, where the confined geometry can lead to preferential phonon transport along specific crystallographic directions. Accurately accounting for this directional variation in thermal conductivity measurements adds another layer of complexity to the experimental and analytical processes.

Lastly, the integration of measurement apparatus with silicon micropillars without altering their thermal properties presents a significant engineering challenge. The introduction of probes or sensors for temperature measurement can potentially disrupt the heat flow and introduce artifacts in the data. Developing non-invasive measurement techniques that maintain the integrity of the micropillar structure while providing accurate thermal data remains an ongoing area of research and development in the field.

Another major challenge is the impact of surface scattering on phonon transport in silicon micropillars. As the dimensions of these structures approach the mean free path of phonons, boundary scattering becomes increasingly dominant, significantly altering the thermal conductivity compared to bulk silicon. This size-dependent effect complicates the interpretation of measurement results and necessitates the development of more sophisticated models to account for these nanoscale phenomena.

The presence of defects and impurities in silicon micropillars further compounds the difficulty of thermal conductivity measurements. These structural irregularities can act as scattering centers for phonons, modifying the heat transport properties of the material. Accurately characterizing and quantifying the impact of these defects on thermal conductivity remains a significant challenge, requiring advanced characterization techniques and theoretical models.

Heat dissipation to the surrounding environment poses another obstacle in thermal conductivity measurements of silicon micropillars. The high surface-to-volume ratio of these structures makes them particularly susceptible to heat loss through convection and radiation. Isolating the intrinsic thermal conductivity of the micropillars from these external influences demands careful experimental design and sophisticated data analysis methods.

Furthermore, the anisotropic nature of silicon's crystal structure introduces directional dependence in thermal conductivity measurements. This anisotropy becomes more pronounced in micropillars, where the confined geometry can lead to preferential phonon transport along specific crystallographic directions. Accurately accounting for this directional variation in thermal conductivity measurements adds another layer of complexity to the experimental and analytical processes.

Lastly, the integration of measurement apparatus with silicon micropillars without altering their thermal properties presents a significant engineering challenge. The introduction of probes or sensors for temperature measurement can potentially disrupt the heat flow and introduce artifacts in the data. Developing non-invasive measurement techniques that maintain the integrity of the micropillar structure while providing accurate thermal data remains an ongoing area of research and development in the field.

Existing Thermal Conductivity Measurement Techniques

01 Silicon micropillar structure for thermal management

Silicon micropillars are used to enhance thermal conductivity in semiconductor devices. These structures provide increased surface area for heat dissipation, improving overall thermal management. The design and arrangement of micropillars can be optimized to maximize heat transfer efficiency in various electronic applications.- Silicon micropillar structure for thermal management: Silicon micropillars are used to enhance thermal conductivity in semiconductor devices. These structures provide increased surface area for heat dissipation, improving overall thermal management. The design and arrangement of micropillars can be optimized to maximize heat transfer efficiency in various electronic applications.

- Fabrication methods for silicon micropillars: Various techniques are employed to fabricate silicon micropillars, including etching processes, lithography, and selective growth methods. These fabrication techniques allow for precise control over the dimensions, spacing, and density of micropillars, which directly influence their thermal conductivity properties.

- Integration of silicon micropillars in electronic devices: Silicon micropillars are integrated into electronic devices such as integrated circuits, power semiconductors, and thermal management systems. The incorporation of these structures helps in efficient heat dissipation, reducing thermal resistance and improving device performance and reliability.

- Thermal conductivity enhancement mechanisms: The thermal conductivity of silicon micropillars is enhanced through various mechanisms, including phonon transport optimization, surface area maximization, and the creation of preferential heat flow paths. These mechanisms contribute to improved heat dissipation and thermal management in microelectronic devices.

- Advanced materials and coatings for silicon micropillars: Research focuses on developing advanced materials and coatings for silicon micropillars to further enhance their thermal conductivity. This includes the use of composite materials, nanostructured coatings, and novel surface treatments to optimize heat transfer properties and improve overall thermal performance.

02 Fabrication methods for silicon micropillars

Various techniques are employed to fabricate silicon micropillars, including etching processes, lithography, and selective growth methods. These fabrication techniques allow for precise control over the dimensions, spacing, and density of micropillars, which directly influence their thermal conductivity properties.Expand Specific Solutions03 Integration of silicon micropillars in electronic devices

Silicon micropillars are integrated into electronic devices such as integrated circuits, power semiconductors, and thermal management systems. The integration process involves considerations of device architecture, material compatibility, and manufacturing constraints to effectively utilize the thermal conductivity benefits of micropillars.Expand Specific Solutions04 Thermal conductivity enhancement mechanisms

The thermal conductivity of silicon micropillars is enhanced through various mechanisms, including phonon transport optimization, surface area maximization, and the creation of preferential heat flow paths. Understanding these mechanisms allows for the design of more efficient thermal management solutions in semiconductor devices.Expand Specific Solutions05 Advanced materials and coatings for silicon micropillars

Research explores the use of advanced materials and coatings to further enhance the thermal conductivity of silicon micropillars. This includes the application of high thermal conductivity materials, nanostructured coatings, and composite structures to improve heat dissipation capabilities.Expand Specific Solutions

Key Players in Silicon Micropillar Research

The thermal conductivity evaluation in silicon micropillars is an emerging field within semiconductor technology, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for efficient heat management in miniaturized electronic devices. The technology's maturity is still evolving, with key players like Shin-Etsu Chemical, Robert Bosch, and California Institute of Technology leading research efforts. Companies such as Dow Silicones and Nitto Denko are also contributing to advancements in this area. The competitive landscape is characterized by a mix of established semiconductor manufacturers and research institutions, with potential for significant breakthroughs in thermal management for next-generation microelectronics.

California Institute of Technology

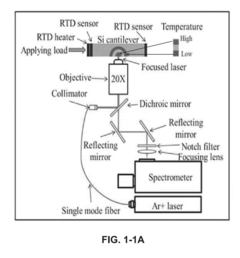

Technical Solution: California Institute of Technology has developed a novel approach for evaluating thermal conductivity in silicon micropillars. Their method utilizes a combination of Raman spectroscopy and finite element modeling to accurately measure and predict thermal properties at the microscale. The technique involves fabricating arrays of silicon micropillars with varying dimensions and geometries, then using laser-based Raman thermometry to measure temperature distributions along the pillars[1]. This data is then fed into sophisticated finite element models to extract thermal conductivity values. The institute has also explored the effects of surface roughness and pillar diameter on thermal transport, finding that conductivity decreases significantly as pillar dimensions approach the phonon mean free path[2][3].

Strengths: High precision measurements at microscale, ability to account for size effects and surface properties. Weaknesses: Complex experimental setup, requires specialized equipment and expertise.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has developed an innovative approach to evaluate thermal conductivity in silicon micropillars using a modified 3ω method. Their technique involves fabricating silicon micropillar arrays with integrated metal heater lines directly on the pillars. By applying an AC current to these heater lines and measuring the resulting temperature oscillations, they can extract the thermal conductivity with high accuracy. The method accounts for size effects and can measure conductivity in pillars with diameters as small as 50 nm[4]. Additionally, they have developed a comprehensive theoretical model that considers phonon boundary scattering and confinement effects, allowing for precise interpretation of experimental results[5].

Strengths: Ability to measure extremely small structures, direct integration of measurement apparatus. Weaknesses: Fabrication complexity, potential for measurement artifacts due to heater integration.

Core Innovations in Micropillar Thermal Analysis

In-situ Combined Sensing of Uniaxial Nanomechanical and Micromechanical Stress with Simultaneous Measurement of Surface Temperature Profiles by Raman Shift in Nanoscale and Microscale Structures

PatentActiveUS20160018334A1

Innovation

- The use of Raman spectroscopy to measure thermal and mechanical properties simultaneously by separating the Raman shift signals induced by stress and temperature, allowing for the analysis of thermal conductivity and mechanical stress in silicon microstructures under applied stress and temperature conditions.

Methods and devices for controlling thermal conductivity and thermoelectric power of semiconductor nanowires

PatentWO2009014985A2

Innovation

- Semiconductor nanowires are used to control thermal conductivity and thermoelectric power independently of electrical conductivity by adjusting their dimensions and doping levels, exploiting phonon drag effects to enhance thermopower and reduce thermal conductivity, thereby achieving ZT values greater than 1.

Impact on Semiconductor Device Performance

The thermal conductivity of silicon micropillars plays a crucial role in semiconductor device performance, particularly in the context of miniaturization and increased power density. As devices continue to shrink in size and increase in complexity, efficient heat dissipation becomes paramount to maintain optimal performance and reliability.

Silicon micropillars, with their unique structural properties, offer potential advantages in thermal management. Their high surface-to-volume ratio allows for enhanced heat transfer compared to bulk silicon. This characteristic is particularly beneficial in applications such as microprocessors, where localized heating can lead to performance degradation and reduced lifespan.

The impact of thermal conductivity in silicon micropillars extends to various aspects of semiconductor device performance. Improved thermal conductivity can lead to more uniform temperature distribution across the device, reducing the occurrence of hot spots that can cause thermal runaway and device failure. This, in turn, enables higher operating frequencies and increased power handling capabilities, directly translating to enhanced device performance.

Moreover, efficient heat dissipation through silicon micropillars can contribute to improved electromigration resistance. Electromigration, a common failure mechanism in integrated circuits, is exacerbated by high temperatures. By effectively managing heat, silicon micropillars can potentially extend the lifetime and reliability of semiconductor devices.

The thermal properties of silicon micropillars also influence the design and integration of cooling solutions in semiconductor packages. Enhanced thermal conductivity at the microscale level can lead to more efficient and compact cooling systems, potentially reducing the overall size and cost of semiconductor devices while maintaining or improving performance.

In the context of emerging technologies such as 3D integrated circuits and advanced packaging techniques, the thermal conductivity of silicon micropillars becomes even more critical. These technologies often involve stacking multiple layers of active components, intensifying the challenges of heat dissipation. Silicon micropillars with optimized thermal properties can serve as effective thermal vias, facilitating heat transfer between layers and maintaining acceptable operating temperatures throughout the device.

Furthermore, the impact of thermal conductivity in silicon micropillars extends to the realm of energy efficiency. Improved thermal management can lead to reduced power consumption in semiconductor devices, as less energy is wasted as heat. This has far-reaching implications for battery life in mobile devices and energy consumption in data centers, aligning with global efforts towards sustainable computing.

Silicon micropillars, with their unique structural properties, offer potential advantages in thermal management. Their high surface-to-volume ratio allows for enhanced heat transfer compared to bulk silicon. This characteristic is particularly beneficial in applications such as microprocessors, where localized heating can lead to performance degradation and reduced lifespan.

The impact of thermal conductivity in silicon micropillars extends to various aspects of semiconductor device performance. Improved thermal conductivity can lead to more uniform temperature distribution across the device, reducing the occurrence of hot spots that can cause thermal runaway and device failure. This, in turn, enables higher operating frequencies and increased power handling capabilities, directly translating to enhanced device performance.

Moreover, efficient heat dissipation through silicon micropillars can contribute to improved electromigration resistance. Electromigration, a common failure mechanism in integrated circuits, is exacerbated by high temperatures. By effectively managing heat, silicon micropillars can potentially extend the lifetime and reliability of semiconductor devices.

The thermal properties of silicon micropillars also influence the design and integration of cooling solutions in semiconductor packages. Enhanced thermal conductivity at the microscale level can lead to more efficient and compact cooling systems, potentially reducing the overall size and cost of semiconductor devices while maintaining or improving performance.

In the context of emerging technologies such as 3D integrated circuits and advanced packaging techniques, the thermal conductivity of silicon micropillars becomes even more critical. These technologies often involve stacking multiple layers of active components, intensifying the challenges of heat dissipation. Silicon micropillars with optimized thermal properties can serve as effective thermal vias, facilitating heat transfer between layers and maintaining acceptable operating temperatures throughout the device.

Furthermore, the impact of thermal conductivity in silicon micropillars extends to the realm of energy efficiency. Improved thermal management can lead to reduced power consumption in semiconductor devices, as less energy is wasted as heat. This has far-reaching implications for battery life in mobile devices and energy consumption in data centers, aligning with global efforts towards sustainable computing.

Environmental Considerations in Micropillar Fabrication

The environmental impact of silicon micropillar fabrication is a critical consideration in the development and implementation of this technology. The production process involves several steps that can have significant environmental implications, necessitating careful management and mitigation strategies.

One of the primary environmental concerns is the use of hazardous chemicals in the fabrication process. Etching and cleaning steps often require strong acids, bases, and solvents, which can pose risks to both human health and the environment if not properly handled and disposed of. Proper waste management systems and treatment facilities are essential to minimize the release of these chemicals into the ecosystem.

Energy consumption is another major environmental factor in micropillar fabrication. The process typically involves high-temperature operations and precision equipment, both of which demand substantial energy inputs. This energy demand contributes to the overall carbon footprint of the technology, highlighting the need for energy-efficient manufacturing processes and the use of renewable energy sources where possible.

Water usage is also a significant consideration, particularly in areas where water resources are scarce. The fabrication process often requires large volumes of ultra-pure water for cleaning and processing steps. Implementing water recycling systems and optimizing water use efficiency can help reduce the environmental impact and conserve this valuable resource.

The production of silicon micropillars may also generate particulate matter and gaseous emissions. These emissions can contribute to air pollution if not properly controlled. Advanced filtration systems and scrubbers are necessary to capture and treat these emissions before they are released into the atmosphere.

Material efficiency is another crucial aspect of environmental consideration. Optimizing the fabrication process to minimize material waste and maximize the yield of usable micropillars can significantly reduce the overall environmental footprint. Additionally, exploring the potential for recycling and reusing materials within the production cycle can further enhance sustainability.

As the demand for silicon micropillars grows, scaling up production while maintaining environmental standards becomes increasingly challenging. Developing cleaner, more efficient fabrication techniques is essential for the long-term sustainability of this technology. This may include exploring alternative materials or processes that offer similar thermal conductivity properties with reduced environmental impact.

Lastly, the end-of-life considerations for products incorporating silicon micropillars must be addressed. Designing for recyclability and implementing effective recycling programs can help minimize the environmental impact of these components once they reach the end of their useful life.

One of the primary environmental concerns is the use of hazardous chemicals in the fabrication process. Etching and cleaning steps often require strong acids, bases, and solvents, which can pose risks to both human health and the environment if not properly handled and disposed of. Proper waste management systems and treatment facilities are essential to minimize the release of these chemicals into the ecosystem.

Energy consumption is another major environmental factor in micropillar fabrication. The process typically involves high-temperature operations and precision equipment, both of which demand substantial energy inputs. This energy demand contributes to the overall carbon footprint of the technology, highlighting the need for energy-efficient manufacturing processes and the use of renewable energy sources where possible.

Water usage is also a significant consideration, particularly in areas where water resources are scarce. The fabrication process often requires large volumes of ultra-pure water for cleaning and processing steps. Implementing water recycling systems and optimizing water use efficiency can help reduce the environmental impact and conserve this valuable resource.

The production of silicon micropillars may also generate particulate matter and gaseous emissions. These emissions can contribute to air pollution if not properly controlled. Advanced filtration systems and scrubbers are necessary to capture and treat these emissions before they are released into the atmosphere.

Material efficiency is another crucial aspect of environmental consideration. Optimizing the fabrication process to minimize material waste and maximize the yield of usable micropillars can significantly reduce the overall environmental footprint. Additionally, exploring the potential for recycling and reusing materials within the production cycle can further enhance sustainability.

As the demand for silicon micropillars grows, scaling up production while maintaining environmental standards becomes increasingly challenging. Developing cleaner, more efficient fabrication techniques is essential for the long-term sustainability of this technology. This may include exploring alternative materials or processes that offer similar thermal conductivity properties with reduced environmental impact.

Lastly, the end-of-life considerations for products incorporating silicon micropillars must be addressed. Designing for recyclability and implementing effective recycling programs can help minimize the environmental impact of these components once they reach the end of their useful life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!