Silicon Micropillars in Adhesion Studies

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Micropillar Background and Objectives

Silicon micropillars have emerged as a significant area of research in adhesion studies, representing a convergence of materials science, nanotechnology, and biomimetics. These microscopic structures, typically fabricated from silicon, mimic the adhesive properties found in nature, such as the remarkable ability of geckos to adhere to various surfaces. The development of silicon micropillars stems from the broader field of biomimetic adhesives, which has seen substantial growth over the past two decades.

The primary objective of research on silicon micropillars in adhesion studies is to create synthetic adhesive systems that can match or surpass the performance of their biological counterparts. These systems aim to achieve strong adhesion, easy detachment, and reusability across a wide range of surfaces and environmental conditions. Silicon, with its well-established fabrication techniques and favorable mechanical properties, has become the material of choice for many researchers in this field.

The evolution of silicon micropillar technology can be traced back to early attempts at replicating the hierarchical structures found on gecko feet. Initial studies focused on understanding the fundamental principles of van der Waals forces and contact mechanics at the microscale. As fabrication techniques improved, researchers began to explore more complex geometries and arrangements of micropillars, leading to significant advancements in adhesive performance.

Current research objectives in this field encompass several key areas. One primary goal is to optimize the geometry and arrangement of silicon micropillars to maximize adhesion strength while maintaining easy detachment. This involves investigating various pillar shapes, sizes, and spatial distributions. Another important objective is to enhance the durability and longevity of these adhesive structures, addressing challenges such as wear, contamination, and environmental degradation.

Researchers are also exploring the integration of silicon micropillars with other materials and technologies to create multifunctional adhesive systems. This includes the development of smart adhesives that can respond to external stimuli, such as temperature, humidity, or electrical signals. Additionally, there is growing interest in scaling up the production of silicon micropillar adhesives for practical applications, which requires advancements in fabrication techniques and process optimization.

The potential applications of silicon micropillar adhesives span a wide range of industries, from robotics and manufacturing to medical devices and consumer products. As such, a key objective of ongoing research is to tailor these adhesive systems for specific use cases, considering factors such as surface properties, environmental conditions, and performance requirements.

In conclusion, the background and objectives of silicon micropillar research in adhesion studies reflect a dynamic and rapidly evolving field. By combining insights from nature with advanced fabrication techniques and materials science, researchers aim to develop next-generation adhesive technologies that could revolutionize numerous industries and applications.

The primary objective of research on silicon micropillars in adhesion studies is to create synthetic adhesive systems that can match or surpass the performance of their biological counterparts. These systems aim to achieve strong adhesion, easy detachment, and reusability across a wide range of surfaces and environmental conditions. Silicon, with its well-established fabrication techniques and favorable mechanical properties, has become the material of choice for many researchers in this field.

The evolution of silicon micropillar technology can be traced back to early attempts at replicating the hierarchical structures found on gecko feet. Initial studies focused on understanding the fundamental principles of van der Waals forces and contact mechanics at the microscale. As fabrication techniques improved, researchers began to explore more complex geometries and arrangements of micropillars, leading to significant advancements in adhesive performance.

Current research objectives in this field encompass several key areas. One primary goal is to optimize the geometry and arrangement of silicon micropillars to maximize adhesion strength while maintaining easy detachment. This involves investigating various pillar shapes, sizes, and spatial distributions. Another important objective is to enhance the durability and longevity of these adhesive structures, addressing challenges such as wear, contamination, and environmental degradation.

Researchers are also exploring the integration of silicon micropillars with other materials and technologies to create multifunctional adhesive systems. This includes the development of smart adhesives that can respond to external stimuli, such as temperature, humidity, or electrical signals. Additionally, there is growing interest in scaling up the production of silicon micropillar adhesives for practical applications, which requires advancements in fabrication techniques and process optimization.

The potential applications of silicon micropillar adhesives span a wide range of industries, from robotics and manufacturing to medical devices and consumer products. As such, a key objective of ongoing research is to tailor these adhesive systems for specific use cases, considering factors such as surface properties, environmental conditions, and performance requirements.

In conclusion, the background and objectives of silicon micropillar research in adhesion studies reflect a dynamic and rapidly evolving field. By combining insights from nature with advanced fabrication techniques and materials science, researchers aim to develop next-generation adhesive technologies that could revolutionize numerous industries and applications.

Market Applications of Adhesion Technologies

Adhesion technologies have found widespread applications across various industries, driving innovation and enhancing product performance. In the automotive sector, advanced adhesives are revolutionizing vehicle assembly processes, enabling lightweight construction and improving fuel efficiency. These technologies are crucial for bonding dissimilar materials, such as metals and composites, in modern car designs. The aerospace industry also heavily relies on adhesion technologies for structural bonding in aircraft and spacecraft, where high-performance adhesives offer weight reduction and improved fatigue resistance compared to traditional fastening methods.

In the electronics industry, adhesives play a vital role in the miniaturization of devices and the assembly of delicate components. From smartphones to wearable technology, adhesives enable the creation of sleek, water-resistant designs while providing necessary thermal management. The medical field has seen significant advancements in adhesion technologies, with applications ranging from wound care products to implantable medical devices. Biocompatible adhesives are used in surgical procedures, drug delivery systems, and tissue engineering, contributing to improved patient outcomes and less invasive treatments.

The construction industry utilizes adhesion technologies for various applications, including structural glazing, flooring installation, and composite panel bonding. These technologies offer advantages such as improved energy efficiency, enhanced aesthetics, and increased durability of buildings. In the renewable energy sector, adhesives are essential for the manufacturing of solar panels and wind turbine blades, contributing to the growth of sustainable energy solutions.

Consumer goods and packaging industries benefit from adhesion technologies in creating innovative product designs and improving packaging performance. From resealable food packaging to tamper-evident seals, adhesives enhance product functionality and consumer convenience. The textile industry employs adhesion technologies in the production of technical textiles, sportswear, and protective clothing, enabling the development of waterproof, breathable, and high-performance fabrics.

The growing focus on sustainability has led to the development of bio-based and environmentally friendly adhesives, expanding the market for green adhesion technologies across various sectors. As industries continue to seek innovative solutions for product development and manufacturing processes, the demand for advanced adhesion technologies is expected to grow. The ongoing research in areas such as silicon micropillars for adhesion studies holds promise for further advancements in this field, potentially leading to new applications and improved performance in existing markets.

In the electronics industry, adhesives play a vital role in the miniaturization of devices and the assembly of delicate components. From smartphones to wearable technology, adhesives enable the creation of sleek, water-resistant designs while providing necessary thermal management. The medical field has seen significant advancements in adhesion technologies, with applications ranging from wound care products to implantable medical devices. Biocompatible adhesives are used in surgical procedures, drug delivery systems, and tissue engineering, contributing to improved patient outcomes and less invasive treatments.

The construction industry utilizes adhesion technologies for various applications, including structural glazing, flooring installation, and composite panel bonding. These technologies offer advantages such as improved energy efficiency, enhanced aesthetics, and increased durability of buildings. In the renewable energy sector, adhesives are essential for the manufacturing of solar panels and wind turbine blades, contributing to the growth of sustainable energy solutions.

Consumer goods and packaging industries benefit from adhesion technologies in creating innovative product designs and improving packaging performance. From resealable food packaging to tamper-evident seals, adhesives enhance product functionality and consumer convenience. The textile industry employs adhesion technologies in the production of technical textiles, sportswear, and protective clothing, enabling the development of waterproof, breathable, and high-performance fabrics.

The growing focus on sustainability has led to the development of bio-based and environmentally friendly adhesives, expanding the market for green adhesion technologies across various sectors. As industries continue to seek innovative solutions for product development and manufacturing processes, the demand for advanced adhesion technologies is expected to grow. The ongoing research in areas such as silicon micropillars for adhesion studies holds promise for further advancements in this field, potentially leading to new applications and improved performance in existing markets.

Current Challenges in Silicon Micropillar Fabrication

The fabrication of silicon micropillars for adhesion studies faces several significant challenges that researchers and engineers are actively working to overcome. One of the primary difficulties lies in achieving precise control over the dimensions and geometry of the micropillars. The aspect ratio, spacing, and uniformity of the pillars are crucial factors that directly influence their adhesive properties, yet maintaining consistency across large arrays remains a formidable task.

Another major challenge is the selection of appropriate fabrication techniques that can produce high-quality micropillars while being scalable and cost-effective. Traditional lithography methods, while capable of high resolution, often struggle with creating high aspect ratio structures efficiently. Alternative techniques such as deep reactive ion etching (DRIE) offer improved aspect ratios but can introduce unwanted surface roughness or scalloping effects that may interfere with adhesion studies.

The material properties of silicon itself present additional hurdles. While silicon is widely used due to its well-understood properties and compatibility with existing semiconductor fabrication processes, it is inherently brittle. This brittleness can lead to pillar breakage during fabrication or testing, especially for high aspect ratio structures or when subjected to lateral forces. Researchers are exploring ways to modify the mechanical properties of silicon or incorporate other materials to enhance the durability of the micropillars without compromising their adhesive characteristics.

Surface functionalization of silicon micropillars is another area of ongoing research and development. Creating specific surface chemistries or topographies on the pillars is essential for tailoring their adhesive properties. However, achieving uniform and stable surface modifications across an array of micropillars, particularly at the nanoscale, remains challenging. Techniques for precise and reproducible surface treatments that can withstand various environmental conditions are still being refined.

The integration of silicon micropillars with sensing or actuation mechanisms for dynamic adhesion studies poses additional fabrication challenges. Incorporating elements such as piezoelectric materials or flexible substrates while maintaining the integrity and functionality of the micropillar array requires sophisticated design and manufacturing approaches that are still evolving.

Lastly, the characterization and testing of silicon micropillars present their own set of challenges. Developing standardized methods for measuring adhesion strength, durability, and performance under various conditions is crucial for comparing different designs and materials. However, the microscale nature of these structures demands highly sensitive and specialized equipment, as well as careful experimental protocols to ensure accurate and reproducible results.

Another major challenge is the selection of appropriate fabrication techniques that can produce high-quality micropillars while being scalable and cost-effective. Traditional lithography methods, while capable of high resolution, often struggle with creating high aspect ratio structures efficiently. Alternative techniques such as deep reactive ion etching (DRIE) offer improved aspect ratios but can introduce unwanted surface roughness or scalloping effects that may interfere with adhesion studies.

The material properties of silicon itself present additional hurdles. While silicon is widely used due to its well-understood properties and compatibility with existing semiconductor fabrication processes, it is inherently brittle. This brittleness can lead to pillar breakage during fabrication or testing, especially for high aspect ratio structures or when subjected to lateral forces. Researchers are exploring ways to modify the mechanical properties of silicon or incorporate other materials to enhance the durability of the micropillars without compromising their adhesive characteristics.

Surface functionalization of silicon micropillars is another area of ongoing research and development. Creating specific surface chemistries or topographies on the pillars is essential for tailoring their adhesive properties. However, achieving uniform and stable surface modifications across an array of micropillars, particularly at the nanoscale, remains challenging. Techniques for precise and reproducible surface treatments that can withstand various environmental conditions are still being refined.

The integration of silicon micropillars with sensing or actuation mechanisms for dynamic adhesion studies poses additional fabrication challenges. Incorporating elements such as piezoelectric materials or flexible substrates while maintaining the integrity and functionality of the micropillar array requires sophisticated design and manufacturing approaches that are still evolving.

Lastly, the characterization and testing of silicon micropillars present their own set of challenges. Developing standardized methods for measuring adhesion strength, durability, and performance under various conditions is crucial for comparing different designs and materials. However, the microscale nature of these structures demands highly sensitive and specialized equipment, as well as careful experimental protocols to ensure accurate and reproducible results.

Existing Silicon Micropillar Fabrication Techniques

01 Fabrication of silicon micropillars

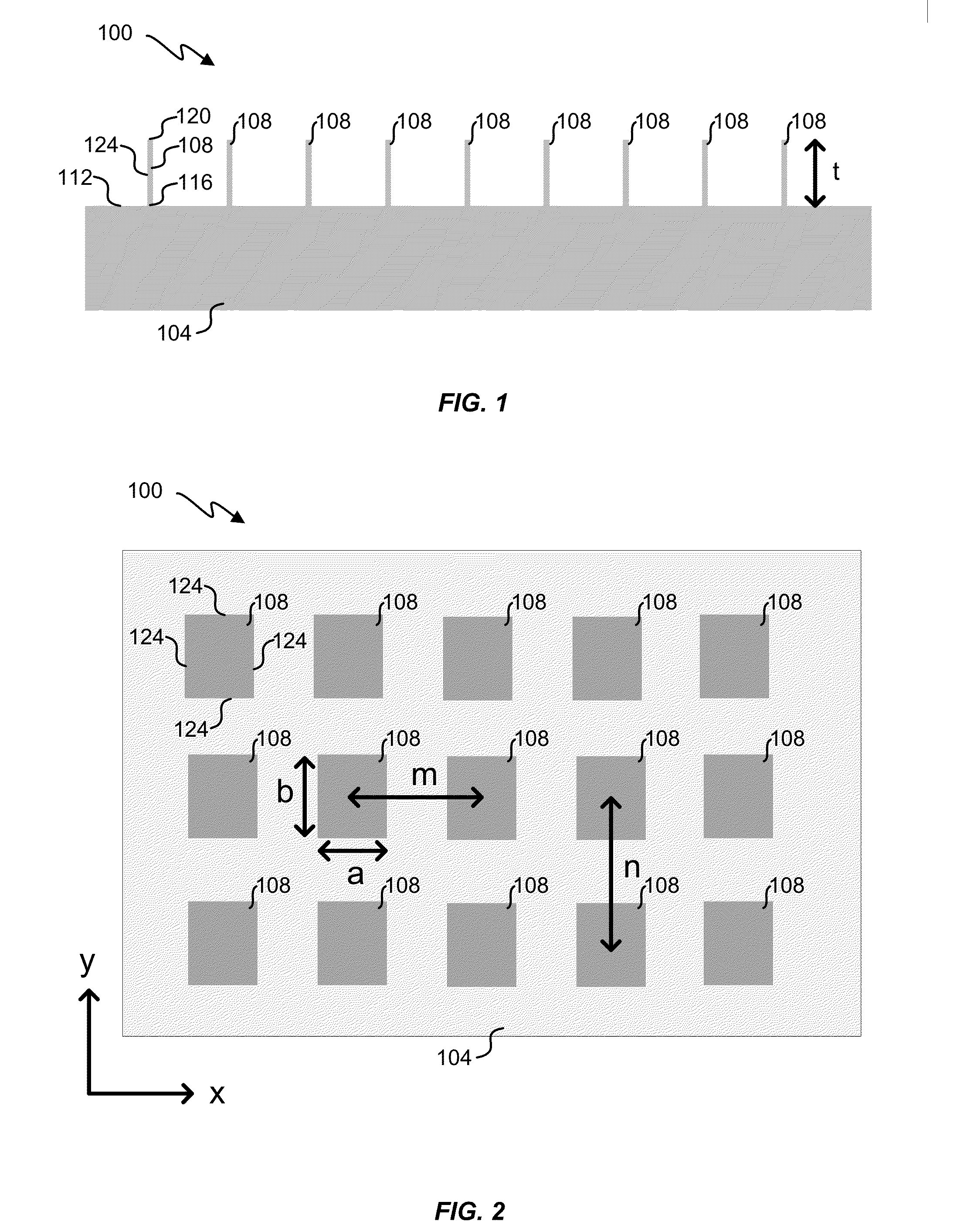

Silicon micropillars can be fabricated using various techniques such as etching, lithography, and deposition processes. These methods allow for precise control over the size, shape, and spacing of the micropillars, which are crucial factors in determining their adhesive properties. The fabrication process often involves creating a pattern on the silicon surface and then selectively removing material to form the pillars.- Fabrication of silicon micropillars: Silicon micropillars can be fabricated using various techniques such as etching, lithography, and deposition processes. These methods allow for precise control over the size, shape, and spacing of the micropillars, which are crucial factors in determining their adhesive properties. The fabrication process often involves creating a pattern on the silicon surface and then selectively removing material to form the pillars.

- Surface modification of silicon micropillars: The adhesion properties of silicon micropillars can be enhanced through surface modification techniques. These may include chemical treatments, plasma processing, or the application of coatings to alter the surface energy or create specific functional groups. Such modifications can improve the wettability, increase the contact area, or introduce chemical bonding sites to enhance adhesion strength.

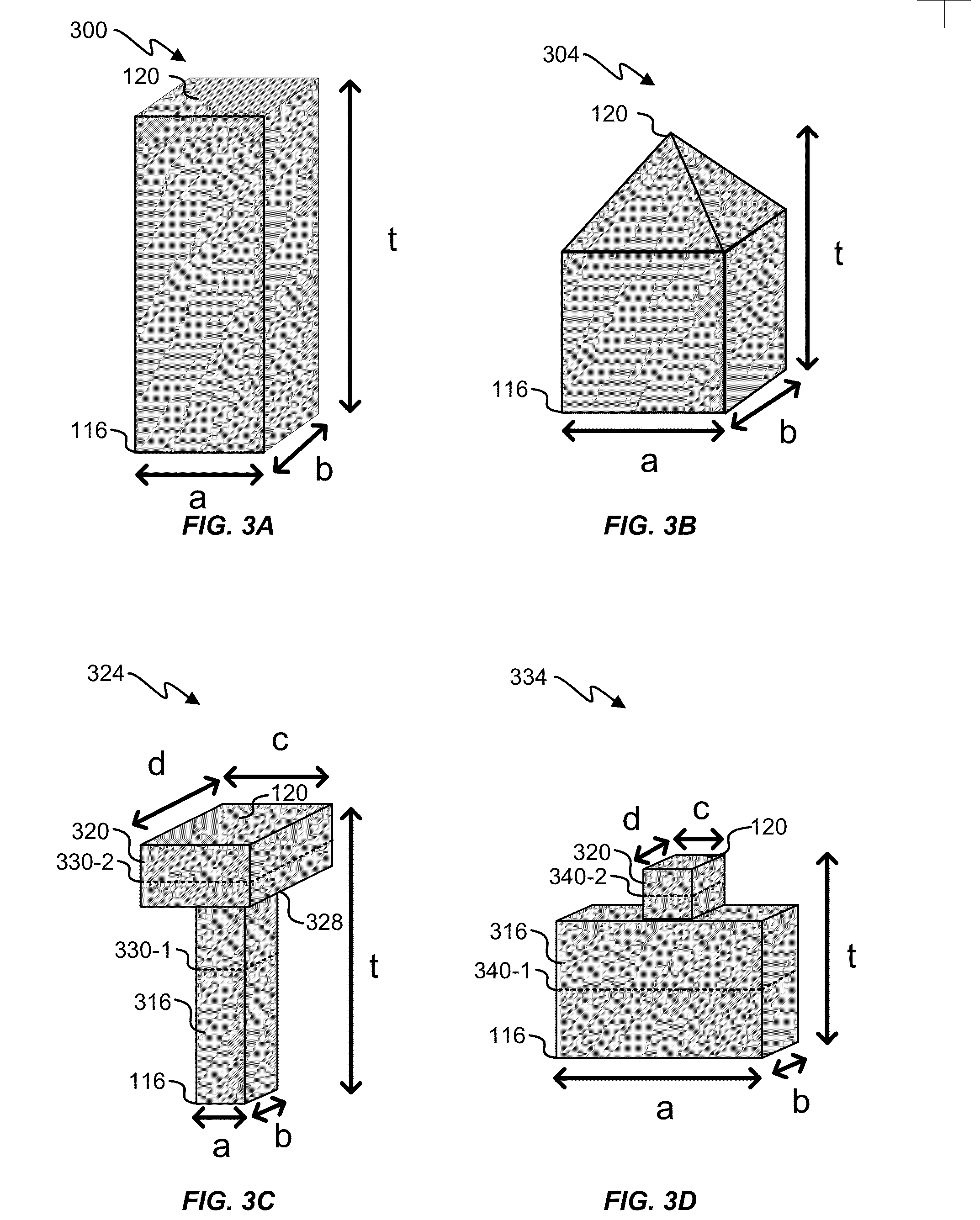

- Structural design for improved adhesion: The geometry and arrangement of silicon micropillars play a crucial role in their adhesive performance. Factors such as pillar height, diameter, spacing, and tip shape can be optimized to maximize adhesion strength and durability. Hierarchical structures or patterns may also be incorporated to mimic natural adhesive systems like gecko feet, enhancing the overall adhesive properties.

- Integration with flexible substrates: Silicon micropillars can be integrated with flexible substrates to create adaptable adhesive surfaces. This combination allows for conformability to various surface topographies, enhancing the contact area and adhesion strength. The integration process may involve transfer printing techniques or direct growth methods on flexible materials.

- Characterization and testing of adhesion properties: Various methods are employed to characterize and test the adhesion properties of silicon micropillars. These may include atomic force microscopy, shear strength tests, and pull-off force measurements. Advanced imaging techniques can be used to observe the contact mechanics and deformation behavior of the micropillars during adhesion and detachment processes, providing insights for further optimization.

02 Surface modification of silicon micropillars

The adhesion properties of silicon micropillars can be enhanced through surface modification techniques. These may include chemical treatments, plasma processing, or the deposition of thin films on the pillar surfaces. Such modifications can alter the surface energy, wettability, and chemical reactivity of the micropillars, thereby improving their adhesive performance.Expand Specific Solutions03 Structural design for improved adhesion

The structural design of silicon micropillars plays a crucial role in their adhesive properties. Factors such as pillar height, diameter, aspect ratio, and tip geometry can be optimized to enhance adhesion. Hierarchical structures, inspired by natural adhesive systems like gecko feet, can also be incorporated to improve adhesion across multiple length scales.Expand Specific Solutions04 Integration with flexible substrates

Silicon micropillars can be integrated with flexible substrates to create adhesive systems that can conform to various surface topographies. This integration often involves transfer printing techniques or direct growth methods on flexible materials. The resulting flexible adhesive systems can find applications in wearable electronics, medical devices, and soft robotics.Expand Specific Solutions05 Characterization and testing of adhesion

Various methods are employed to characterize and test the adhesion properties of silicon micropillars. These may include atomic force microscopy, shear strength tests, and pull-off force measurements. Advanced imaging techniques can also be used to visualize the contact mechanics and deformation behavior of the micropillars during adhesion and detachment processes.Expand Specific Solutions

Key Players in Silicon Micropillar Development

The research on silicon micropillars in adhesion studies is in an emerging phase, with growing market potential due to its applications in various industries. The technology's maturity is still developing, as evidenced by ongoing research at academic institutions like Carnegie Mellon University, Tsinghua University, and Cornell University. Companies such as Dow Silicones Corp., Shin-Etsu Chemical Co., Ltd., and Momentive Performance Materials, Inc. are likely at the forefront of commercializing this technology. The competitive landscape is diverse, with both established chemical companies and innovative startups vying for market share in this promising field of nanotechnology and materials science.

Carnegie Mellon University

Technical Solution: Carnegie Mellon University has made significant contributions to silicon micropillar research for adhesion studies. Their approach involves creating hierarchical structures combining micropillars with nanoscale features. They have developed a method to fabricate silicon micropillars with diameters ranging from 500 nm to 5 μm and heights up to 20 μm [2]. The team has investigated the effects of pillar aspect ratio, tip shape, and surface roughness on adhesion performance. They have also explored the use of plasma treatments to modify the surface chemistry of the micropillars, enhancing their adhesive properties [4]. Carnegie Mellon researchers have demonstrated the potential of these structures for applications in micromanipulation and transfer printing of electronic devices.

Strengths: Ability to create hierarchical micro/nanostructures. Expertise in surface modification techniques. Weaknesses: Challenges in scaling up production for large-area applications.

Wuhan University

Technical Solution: Wuhan University has made significant contributions to the field of silicon micropillars for adhesion studies, focusing on the development of high-performance dry adhesives. Their approach involves creating hierarchical structures that combine silicon micropillars with nanoscale features to maximize adhesion strength. The team has developed a multi-step fabrication process that includes deep reactive ion etching (DRIE) to create micropillars with diameters of 2-10 μm and heights up to 50 μm, followed by a secondary etching step to introduce nanoscale roughness on the pillar surfaces [9]. Wuhan University researchers have investigated the effects of pillar geometry, spacing, and surface chemistry on adhesion performance. They have demonstrated adhesion strengths comparable to gecko foot-hairs and explored applications in climbing robots and temporary bonding for electronic assembly [10].

Strengths: Ability to create hierarchical micro/nanostructures with high adhesion strength. Expertise in optimizing pillar geometry and surface properties. Weaknesses: Challenges in maintaining consistent performance over multiple attachment-detachment cycles.

Innovative Micropillar Designs for Enhanced Adhesion

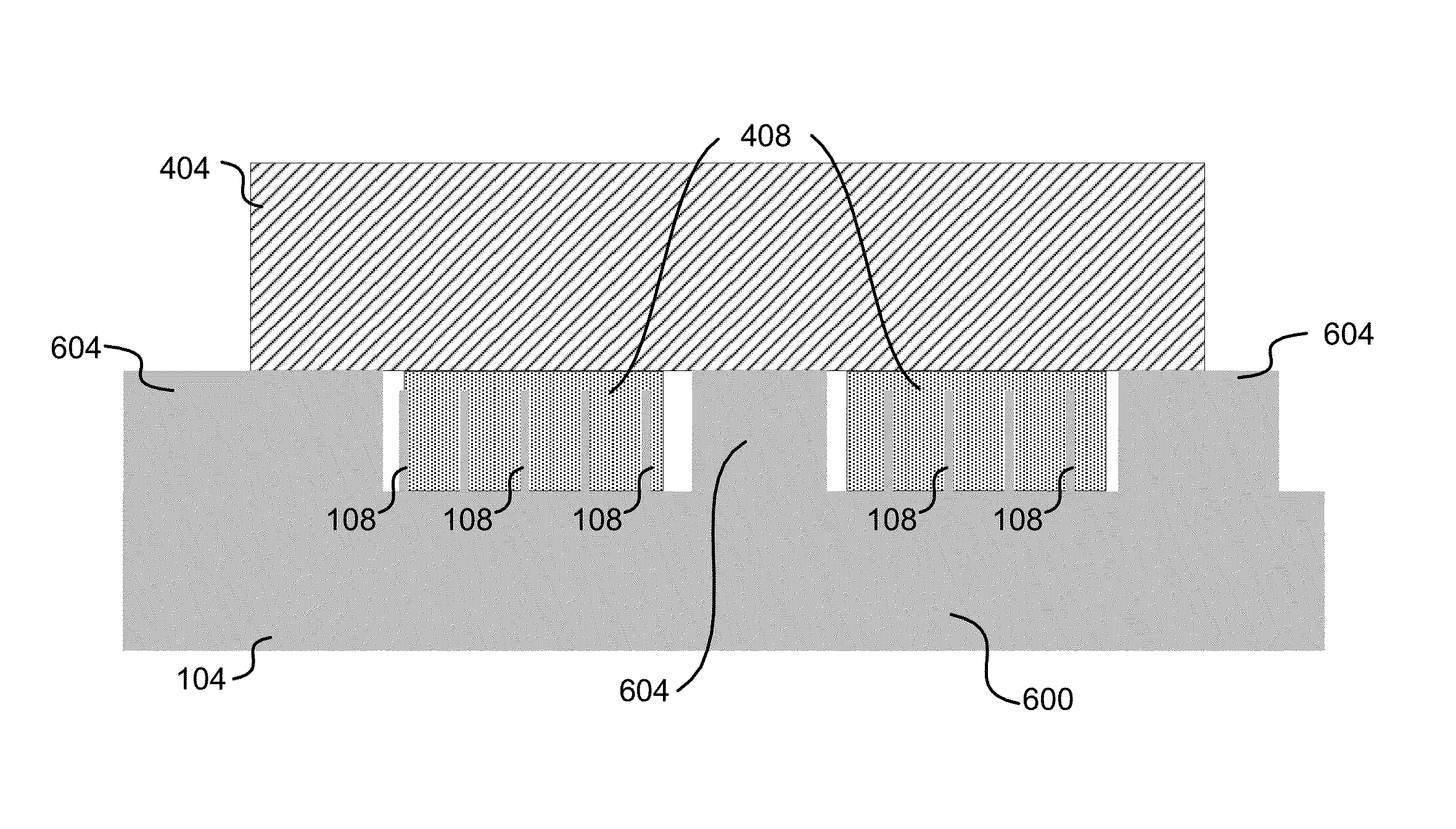

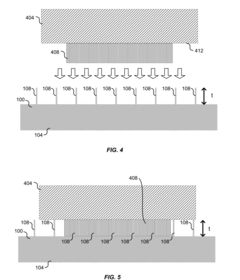

Micro-pillar assisted semiconductor bonding

PatentActiveUS20150364441A1

Innovation

- The use of micro pillars on the silicon substrate to penetrate and break indium oxide, reducing the initial surface contact area and heat transfer, allowing for easier melting of indium and improved bonding by modulating heat and pressure transfer.

A process for surface modification of materials

PatentWO2016142131A1

Innovation

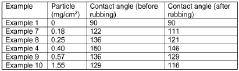

- A process involving embossing the surface with micropillars and applying a specific adhesive layer followed by deposition of hydrophobic particles, which are selected for strong adherence and optimal size distribution, to create a stable superhydrophobic surface that retains hydrophobic properties even under mild abrasion.

Environmental Impact of Silicon Micropillar Production

The production of silicon micropillars for adhesion studies has significant environmental implications that warrant careful consideration. The manufacturing process typically involves energy-intensive techniques such as photolithography, etching, and chemical vapor deposition. These methods consume substantial amounts of electricity, contributing to greenhouse gas emissions if the energy source is not renewable.

Furthermore, the fabrication of silicon micropillars requires the use of various chemicals, including photoresists, etchants, and cleaning agents. Many of these substances are potentially hazardous and can pose risks to both human health and the environment if not properly managed. Proper disposal and treatment of chemical waste from the production process are crucial to prevent soil and water contamination.

Water usage is another environmental concern in silicon micropillar production. The manufacturing process often requires large volumes of ultra-pure water for cleaning and rinsing steps. This high water demand can strain local water resources, particularly in water-scarce regions.

The extraction and processing of raw materials for silicon micropillar production also have environmental impacts. Silicon is typically derived from quartz, which is mined through open-pit or underground methods. These mining activities can lead to habitat destruction, soil erosion, and potential water pollution if not properly managed.

On a positive note, the small scale of silicon micropillars means that material usage is relatively low compared to larger silicon-based devices. Additionally, advancements in manufacturing techniques, such as nanoimprint lithography, offer the potential for more environmentally friendly production methods with reduced energy consumption and chemical usage.

Recycling and proper disposal of silicon micropillar devices at the end of their lifecycle are important considerations. While silicon itself is not toxic, the presence of other materials used in the fabrication process may complicate recycling efforts. Developing effective recycling strategies for these microstructures could help mitigate their long-term environmental impact.

As research in this field progresses, there is a growing emphasis on developing more sustainable production methods for silicon micropillars. This includes exploring alternative materials, optimizing manufacturing processes to reduce resource consumption, and implementing closed-loop systems to minimize waste and maximize resource efficiency.

Furthermore, the fabrication of silicon micropillars requires the use of various chemicals, including photoresists, etchants, and cleaning agents. Many of these substances are potentially hazardous and can pose risks to both human health and the environment if not properly managed. Proper disposal and treatment of chemical waste from the production process are crucial to prevent soil and water contamination.

Water usage is another environmental concern in silicon micropillar production. The manufacturing process often requires large volumes of ultra-pure water for cleaning and rinsing steps. This high water demand can strain local water resources, particularly in water-scarce regions.

The extraction and processing of raw materials for silicon micropillar production also have environmental impacts. Silicon is typically derived from quartz, which is mined through open-pit or underground methods. These mining activities can lead to habitat destruction, soil erosion, and potential water pollution if not properly managed.

On a positive note, the small scale of silicon micropillars means that material usage is relatively low compared to larger silicon-based devices. Additionally, advancements in manufacturing techniques, such as nanoimprint lithography, offer the potential for more environmentally friendly production methods with reduced energy consumption and chemical usage.

Recycling and proper disposal of silicon micropillar devices at the end of their lifecycle are important considerations. While silicon itself is not toxic, the presence of other materials used in the fabrication process may complicate recycling efforts. Developing effective recycling strategies for these microstructures could help mitigate their long-term environmental impact.

As research in this field progresses, there is a growing emphasis on developing more sustainable production methods for silicon micropillars. This includes exploring alternative materials, optimizing manufacturing processes to reduce resource consumption, and implementing closed-loop systems to minimize waste and maximize resource efficiency.

Scalability of Silicon Micropillar Technologies

The scalability of silicon micropillar technologies is a critical factor in their potential for widespread adoption and commercial viability. As research on silicon micropillars in adhesion studies continues to advance, the ability to scale up production becomes increasingly important. Current fabrication methods, such as photolithography and etching techniques, have demonstrated the capability to produce silicon micropillars on a laboratory scale. However, transitioning from small-scale production to large-scale manufacturing presents several challenges.

One of the primary obstacles in scaling silicon micropillar technologies is maintaining consistent quality and uniformity across larger surface areas. As the production area increases, ensuring precise control over pillar dimensions, spacing, and surface properties becomes more complex. Variations in these parameters can significantly impact the adhesive properties of the micropillars, potentially compromising their effectiveness in real-world applications.

Another consideration is the cost-effectiveness of large-scale production. While silicon is a relatively abundant material, the intricate fabrication processes required for micropillar creation can be resource-intensive. Developing more efficient manufacturing techniques that reduce material waste and energy consumption is crucial for improving scalability. Additionally, optimizing process parameters to increase throughput without sacrificing quality is essential for making silicon micropillar technologies economically viable on an industrial scale.

The integration of silicon micropillars into existing manufacturing processes and products presents another scalability challenge. Adapting current production lines to incorporate micropillar fabrication or developing new specialized equipment for large-scale production requires significant investment and engineering expertise. Furthermore, ensuring compatibility with a wide range of substrate materials and geometries is necessary for broad applicability across different industries.

Despite these challenges, recent advancements in nanofabrication techniques show promise for improving the scalability of silicon micropillar technologies. Innovations in high-throughput lithography methods, such as nanoimprint lithography and roll-to-roll processing, offer potential solutions for increasing production rates while maintaining precision. Additionally, the development of self-assembly techniques and template-based approaches may provide more cost-effective alternatives for large-scale micropillar fabrication.

As research progresses, addressing these scalability issues will be crucial for realizing the full potential of silicon micropillars in adhesion applications. Collaborative efforts between academic researchers and industry partners will be essential in overcoming technical hurdles and developing commercially viable production methods. With continued innovation and investment, silicon micropillar technologies have the potential to revolutionize adhesive solutions across various sectors, from consumer electronics to biomedical devices.

One of the primary obstacles in scaling silicon micropillar technologies is maintaining consistent quality and uniformity across larger surface areas. As the production area increases, ensuring precise control over pillar dimensions, spacing, and surface properties becomes more complex. Variations in these parameters can significantly impact the adhesive properties of the micropillars, potentially compromising their effectiveness in real-world applications.

Another consideration is the cost-effectiveness of large-scale production. While silicon is a relatively abundant material, the intricate fabrication processes required for micropillar creation can be resource-intensive. Developing more efficient manufacturing techniques that reduce material waste and energy consumption is crucial for improving scalability. Additionally, optimizing process parameters to increase throughput without sacrificing quality is essential for making silicon micropillar technologies economically viable on an industrial scale.

The integration of silicon micropillars into existing manufacturing processes and products presents another scalability challenge. Adapting current production lines to incorporate micropillar fabrication or developing new specialized equipment for large-scale production requires significant investment and engineering expertise. Furthermore, ensuring compatibility with a wide range of substrate materials and geometries is necessary for broad applicability across different industries.

Despite these challenges, recent advancements in nanofabrication techniques show promise for improving the scalability of silicon micropillar technologies. Innovations in high-throughput lithography methods, such as nanoimprint lithography and roll-to-roll processing, offer potential solutions for increasing production rates while maintaining precision. Additionally, the development of self-assembly techniques and template-based approaches may provide more cost-effective alternatives for large-scale micropillar fabrication.

As research progresses, addressing these scalability issues will be crucial for realizing the full potential of silicon micropillars in adhesion applications. Collaborative efforts between academic researchers and industry partners will be essential in overcoming technical hurdles and developing commercially viable production methods. With continued innovation and investment, silicon micropillar technologies have the potential to revolutionize adhesive solutions across various sectors, from consumer electronics to biomedical devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!