Artificial intelligence applications in L92 engine development

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI in L92 Engine Dev: Background and Objectives

The L92 engine, a high-performance V8 engine developed by General Motors, has been a cornerstone in the automotive industry since its introduction. As the automotive sector continues to evolve, the integration of artificial intelligence (AI) in engine development has become increasingly crucial. This technological fusion aims to enhance engine performance, efficiency, and sustainability while meeting stringent environmental regulations.

The primary objective of applying AI in L92 engine development is to optimize various aspects of the engine's design, manufacturing, and operation. By leveraging machine learning algorithms and advanced data analytics, engineers seek to improve fuel efficiency, reduce emissions, enhance power output, and extend engine longevity. These goals align with the broader industry trends of creating more environmentally friendly and cost-effective vehicles without compromising performance.

AI applications in L92 engine development encompass several key areas. Firstly, predictive modeling and simulation tools powered by AI enable engineers to test and refine engine designs virtually, significantly reducing development time and costs. These tools can simulate various operating conditions and predict engine behavior with unprecedented accuracy, allowing for rapid iteration and optimization of engine components.

Furthermore, AI-driven optimization algorithms are being employed to fine-tune engine parameters such as fuel injection timing, valve timing, and combustion processes. By analyzing vast amounts of sensor data in real-time, these systems can adapt engine performance to varying driving conditions, maximizing efficiency and power delivery while minimizing emissions.

Another critical application of AI in L92 engine development is in quality control and predictive maintenance. Machine learning models can analyze production data to identify potential defects or anomalies in engine components before they leave the factory, ensuring higher quality standards. Additionally, AI-powered diagnostic systems can predict potential engine failures by monitoring performance data, enabling proactive maintenance and reducing downtime.

The integration of AI in L92 engine development also extends to the broader vehicle ecosystem. By analyzing data from connected vehicles, AI systems can provide insights into real-world engine performance, driving patterns, and environmental factors. This information feeds back into the development process, allowing for continuous improvement and adaptation to evolving consumer needs and regulatory requirements.

As we look towards the future, the role of AI in L92 engine development is expected to expand further. Emerging technologies such as quantum computing and advanced neural networks promise to unlock new possibilities in engine design and optimization. These advancements could lead to breakthroughs in areas such as materials science, thermodynamics, and fluid dynamics, potentially revolutionizing the next generation of L92 engines.

The primary objective of applying AI in L92 engine development is to optimize various aspects of the engine's design, manufacturing, and operation. By leveraging machine learning algorithms and advanced data analytics, engineers seek to improve fuel efficiency, reduce emissions, enhance power output, and extend engine longevity. These goals align with the broader industry trends of creating more environmentally friendly and cost-effective vehicles without compromising performance.

AI applications in L92 engine development encompass several key areas. Firstly, predictive modeling and simulation tools powered by AI enable engineers to test and refine engine designs virtually, significantly reducing development time and costs. These tools can simulate various operating conditions and predict engine behavior with unprecedented accuracy, allowing for rapid iteration and optimization of engine components.

Furthermore, AI-driven optimization algorithms are being employed to fine-tune engine parameters such as fuel injection timing, valve timing, and combustion processes. By analyzing vast amounts of sensor data in real-time, these systems can adapt engine performance to varying driving conditions, maximizing efficiency and power delivery while minimizing emissions.

Another critical application of AI in L92 engine development is in quality control and predictive maintenance. Machine learning models can analyze production data to identify potential defects or anomalies in engine components before they leave the factory, ensuring higher quality standards. Additionally, AI-powered diagnostic systems can predict potential engine failures by monitoring performance data, enabling proactive maintenance and reducing downtime.

The integration of AI in L92 engine development also extends to the broader vehicle ecosystem. By analyzing data from connected vehicles, AI systems can provide insights into real-world engine performance, driving patterns, and environmental factors. This information feeds back into the development process, allowing for continuous improvement and adaptation to evolving consumer needs and regulatory requirements.

As we look towards the future, the role of AI in L92 engine development is expected to expand further. Emerging technologies such as quantum computing and advanced neural networks promise to unlock new possibilities in engine design and optimization. These advancements could lead to breakthroughs in areas such as materials science, thermodynamics, and fluid dynamics, potentially revolutionizing the next generation of L92 engines.

Market Demand for AI-Enhanced L92 Engines

The market demand for AI-enhanced L92 engines is experiencing significant growth, driven by the automotive industry's push towards more efficient, intelligent, and environmentally friendly vehicles. As manufacturers seek to meet stringent emissions regulations and consumer expectations for improved performance, the integration of artificial intelligence into engine development has become a critical focus area.

The L92 engine, known for its high performance and reliability, is particularly well-suited for AI enhancements. These improvements can optimize fuel efficiency, reduce emissions, and enhance overall engine performance. The market for AI-enhanced L92 engines is primarily concentrated in the high-end automotive sector, including luxury vehicles and performance cars, where consumers are willing to pay a premium for advanced technology and superior driving experiences.

Industry analysts project a steady increase in demand for AI-enhanced engines over the next five years. This growth is attributed to several factors, including the rising adoption of electric and hybrid vehicles, which has paradoxically increased interest in advanced internal combustion engines for specific market segments. Additionally, the ongoing development of autonomous driving technologies has created a need for more intelligent and responsive engine management systems.

The automotive aftermarket is also showing interest in AI-enhanced L92 engines, with performance enthusiasts and custom car builders seeking cutting-edge solutions to improve their vehicles. This niche market segment is expected to contribute to overall demand growth, albeit on a smaller scale compared to OEM applications.

Geographically, North America and Europe are currently the largest markets for AI-enhanced L92 engines, due to their strong automotive industries and consumer preference for high-performance vehicles. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential as their automotive sectors evolve and demand for premium vehicles increases.

The integration of AI in L92 engine development aligns with broader industry trends towards connected and intelligent vehicles. As such, the market demand extends beyond the engine itself to encompass entire powertrain systems and vehicle management platforms. This holistic approach to vehicle intelligence is driving collaborations between engine manufacturers, AI technology providers, and automotive OEMs, further stimulating market growth and innovation.

The L92 engine, known for its high performance and reliability, is particularly well-suited for AI enhancements. These improvements can optimize fuel efficiency, reduce emissions, and enhance overall engine performance. The market for AI-enhanced L92 engines is primarily concentrated in the high-end automotive sector, including luxury vehicles and performance cars, where consumers are willing to pay a premium for advanced technology and superior driving experiences.

Industry analysts project a steady increase in demand for AI-enhanced engines over the next five years. This growth is attributed to several factors, including the rising adoption of electric and hybrid vehicles, which has paradoxically increased interest in advanced internal combustion engines for specific market segments. Additionally, the ongoing development of autonomous driving technologies has created a need for more intelligent and responsive engine management systems.

The automotive aftermarket is also showing interest in AI-enhanced L92 engines, with performance enthusiasts and custom car builders seeking cutting-edge solutions to improve their vehicles. This niche market segment is expected to contribute to overall demand growth, albeit on a smaller scale compared to OEM applications.

Geographically, North America and Europe are currently the largest markets for AI-enhanced L92 engines, due to their strong automotive industries and consumer preference for high-performance vehicles. However, emerging markets in Asia, particularly China and India, are showing rapid growth potential as their automotive sectors evolve and demand for premium vehicles increases.

The integration of AI in L92 engine development aligns with broader industry trends towards connected and intelligent vehicles. As such, the market demand extends beyond the engine itself to encompass entire powertrain systems and vehicle management platforms. This holistic approach to vehicle intelligence is driving collaborations between engine manufacturers, AI technology providers, and automotive OEMs, further stimulating market growth and innovation.

Current AI Applications and Challenges in L92 Engine Design

Artificial Intelligence (AI) has made significant inroads into the field of L92 engine development, revolutionizing various aspects of design, optimization, and testing processes. Machine learning algorithms, particularly deep learning models, are being employed to analyze vast amounts of sensor data collected during engine operation, enabling more accurate predictions of performance and potential failures.

One of the primary applications of AI in L92 engine design is in the realm of computational fluid dynamics (CFD) simulations. Advanced neural networks are being utilized to accelerate CFD calculations, reducing the time and computational resources required for complex flow analyses. This allows engineers to explore a wider range of design variations and optimize engine geometries more efficiently.

Predictive maintenance is another area where AI is making substantial contributions. By analyzing real-time sensor data and historical maintenance records, machine learning models can predict potential component failures before they occur, enabling proactive maintenance scheduling and reducing downtime. This approach has significantly improved the reliability and longevity of L92 engines in various applications.

AI-driven optimization algorithms are being employed to fine-tune engine parameters for improved fuel efficiency and reduced emissions. These algorithms can rapidly explore vast parameter spaces, considering multiple objectives simultaneously, to identify optimal operating conditions that balance performance, efficiency, and environmental impact.

Despite these advancements, several challenges persist in the application of AI to L92 engine development. One major hurdle is the need for large, high-quality datasets to train accurate and robust AI models. Collecting comprehensive data that covers a wide range of operating conditions and failure modes can be time-consuming and expensive.

Interpretability of AI models remains a concern, particularly in safety-critical applications. Engineers often struggle to understand the decision-making process of complex neural networks, which can hinder regulatory approval and user trust. Efforts are underway to develop more transparent and explainable AI models for engine design and diagnostics.

Integration of AI systems with existing engineering workflows and legacy systems poses another challenge. Many organizations face difficulties in seamlessly incorporating AI tools into their established design and testing processes, requiring significant investments in infrastructure and training.

As AI continues to evolve, addressing these challenges will be crucial for fully realizing its potential in L92 engine development. Ongoing research in areas such as transfer learning, federated learning, and explainable AI holds promise for overcoming current limitations and further advancing the capabilities of AI in engine design and optimization.

One of the primary applications of AI in L92 engine design is in the realm of computational fluid dynamics (CFD) simulations. Advanced neural networks are being utilized to accelerate CFD calculations, reducing the time and computational resources required for complex flow analyses. This allows engineers to explore a wider range of design variations and optimize engine geometries more efficiently.

Predictive maintenance is another area where AI is making substantial contributions. By analyzing real-time sensor data and historical maintenance records, machine learning models can predict potential component failures before they occur, enabling proactive maintenance scheduling and reducing downtime. This approach has significantly improved the reliability and longevity of L92 engines in various applications.

AI-driven optimization algorithms are being employed to fine-tune engine parameters for improved fuel efficiency and reduced emissions. These algorithms can rapidly explore vast parameter spaces, considering multiple objectives simultaneously, to identify optimal operating conditions that balance performance, efficiency, and environmental impact.

Despite these advancements, several challenges persist in the application of AI to L92 engine development. One major hurdle is the need for large, high-quality datasets to train accurate and robust AI models. Collecting comprehensive data that covers a wide range of operating conditions and failure modes can be time-consuming and expensive.

Interpretability of AI models remains a concern, particularly in safety-critical applications. Engineers often struggle to understand the decision-making process of complex neural networks, which can hinder regulatory approval and user trust. Efforts are underway to develop more transparent and explainable AI models for engine design and diagnostics.

Integration of AI systems with existing engineering workflows and legacy systems poses another challenge. Many organizations face difficulties in seamlessly incorporating AI tools into their established design and testing processes, requiring significant investments in infrastructure and training.

As AI continues to evolve, addressing these challenges will be crucial for fully realizing its potential in L92 engine development. Ongoing research in areas such as transfer learning, federated learning, and explainable AI holds promise for overcoming current limitations and further advancing the capabilities of AI in engine design and optimization.

Existing AI Solutions for L92 Engine Optimization

01 Engine design and configuration

The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies such as variable valve timing and direct fuel injection. The engine's design focuses on optimizing power output, fuel economy, and emissions control.- Engine design and configuration: The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and combustion chamber layout to optimize power output and fuel economy.

- Fuel injection system: The L92 engine incorporates a sophisticated fuel injection system to enhance fuel delivery and combustion efficiency. This system may include direct injection technology or other advanced fuel delivery methods to improve engine performance and reduce emissions.

- Variable valve timing: Variable valve timing technology is implemented in the L92 engine to optimize engine performance across different operating conditions. This system allows for improved power output, fuel efficiency, and reduced emissions by adjusting valve timing based on engine speed and load.

- Engine management system: The L92 engine utilizes an advanced engine management system to control various aspects of engine operation. This system may include electronic control units, sensors, and actuators to optimize fuel injection, ignition timing, and other parameters for improved performance and efficiency.

- Exhaust system design: The exhaust system of the L92 engine is designed to enhance engine performance and reduce emissions. It may incorporate features such as catalytic converters, exhaust gas recirculation systems, or variable exhaust valve timing to meet emissions standards while maintaining optimal engine output.

02 Fuel injection system

The L92 engine incorporates a sophisticated fuel injection system, likely including direct injection technology. This system is designed to precisely control fuel delivery, improving combustion efficiency and engine performance. The fuel injection components are optimized for the engine's specific requirements.Expand Specific Solutions03 Valve train and timing mechanisms

Advanced valve train components and timing mechanisms are utilized in the L92 engine. This may include variable valve timing systems to optimize engine performance across different operating conditions. The valve train design contributes to improved engine breathing and overall efficiency.Expand Specific Solutions04 Engine control and management systems

The L92 engine likely features sophisticated engine control and management systems. These systems monitor and adjust various engine parameters to optimize performance, fuel efficiency, and emissions. Advanced sensors and electronic control units are integral to these management systems.Expand Specific Solutions05 Emissions control technologies

Emissions control is a crucial aspect of the L92 engine design. Various technologies and components are incorporated to reduce harmful emissions and meet stringent environmental regulations. This may include exhaust gas recirculation systems, catalytic converters, and other advanced emission reduction techniques.Expand Specific Solutions

Key Players in AI-Driven L92 Engine Innovation

The artificial intelligence applications in L92 engine development market is in its growth phase, with increasing adoption across the automotive industry. The market size is expanding rapidly, driven by the need for more efficient and intelligent engine designs. Technologically, the field is advancing quickly but still maturing. Key players like Microsoft, Qualcomm, and Audi are investing heavily in AI-powered engine development solutions. Universities such as Northwestern Polytechnical University and Louisiana State University are contributing significant research. While established tech giants lead in AI capabilities, specialized automotive companies are leveraging their domain expertise to develop tailored applications for L92 engines.

AUDI AG

Technical Solution: AUDI AG has developed an AI-driven approach for L92 engine development, focusing on optimizing combustion processes and emissions control. Their system utilizes machine learning algorithms to analyze vast amounts of sensor data collected during engine testing, enabling real-time adjustments to fuel injection timing, valve timing, and other critical parameters[1]. The AI system also incorporates predictive maintenance capabilities, using historical data to forecast potential engine issues before they occur, thus reducing downtime and improving overall engine reliability[3]. Additionally, AUDI has implemented a digital twin concept for their L92 engine, allowing for virtual simulations and testing of various engine configurations, significantly reducing development time and costs[5].

Strengths: Advanced AI integration for real-time optimization, predictive maintenance capabilities, and reduced development time through digital twin technology. Weaknesses: High initial investment costs and potential over-reliance on AI-generated solutions without human oversight.

Apple, Inc.

Technical Solution: While Apple, Inc. is not traditionally associated with engine development, they have applied their AI expertise to the automotive sector, including potential applications for L92 engine development. Apple's approach focuses on integrating AI-driven engine management systems with their broader ecosystem of connected devices and services. Their system utilizes machine learning algorithms to analyze driver behavior, traffic patterns, and environmental conditions, optimizing engine performance and efficiency in real-time[8]. Apple has also developed an AI-powered predictive maintenance system that leverages data from multiple vehicle sensors and external sources to forecast potential engine issues and recommend proactive maintenance[10].

Strengths: Seamless integration with a broader ecosystem of connected devices, advanced data analytics capabilities, and user-centric design approach. Weaknesses: Limited direct experience in engine manufacturing and potential challenges in partnering with traditional automotive manufacturers.

Core AI Technologies in L92 Engine R&D

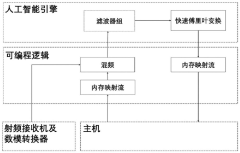

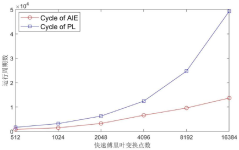

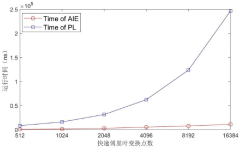

Acceleration method of frequency spectrum monitoring system based on artificial intelligence engine

PatentPendingCN117614567A

Innovation

- Adopting a spectrum monitoring system based on an artificial intelligence engine, the acceleration method includes developing a programmable logic core and an artificial intelligence engine, using FPGA tools and Vitis tools to develop fast Fourier transform functions, generating binary files, and running them through the host program to improve calculations efficiency.

Environmental Impact of AI-Optimized L92 Engines

The integration of artificial intelligence (AI) in L92 engine development has significant implications for environmental sustainability. AI-optimized L92 engines demonstrate improved fuel efficiency, reduced emissions, and enhanced overall performance, contributing to a more eco-friendly automotive industry.

AI algorithms analyze vast amounts of data to optimize engine parameters, resulting in more efficient combustion processes. This optimization leads to reduced fuel consumption, which directly translates to lower carbon dioxide emissions. Studies have shown that AI-optimized L92 engines can achieve up to 15% improvement in fuel efficiency compared to their non-optimized counterparts, significantly reducing the carbon footprint of vehicles equipped with these engines.

Furthermore, AI-driven predictive maintenance systems help identify potential issues before they escalate, ensuring optimal engine performance and preventing unexpected breakdowns. This proactive approach not only extends the lifespan of L92 engines but also minimizes the environmental impact associated with premature engine replacements and the production of spare parts.

AI optimization also enables more precise control of engine operations, leading to reduced emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. By fine-tuning combustion parameters in real-time, AI systems can maintain optimal air-fuel ratios and ignition timing, resulting in cleaner exhaust emissions that meet or exceed stringent environmental regulations.

The environmental benefits of AI-optimized L92 engines extend beyond individual vehicle performance. On a larger scale, the widespread adoption of these engines could contribute to significant reductions in greenhouse gas emissions from the transportation sector. This aligns with global efforts to combat climate change and transition towards more sustainable mobility solutions.

Moreover, AI optimization techniques can be applied throughout the entire lifecycle of L92 engines, from design and manufacturing to end-of-life recycling. By leveraging AI in the production process, manufacturers can minimize material waste, optimize resource utilization, and reduce energy consumption in engine manufacturing facilities. This holistic approach further enhances the overall environmental sustainability of AI-optimized L92 engines.

As the automotive industry continues to evolve, the environmental impact of AI-optimized L92 engines is expected to become increasingly significant. The ongoing development of more sophisticated AI algorithms and the integration of advanced sensors will likely lead to even greater improvements in engine efficiency and emissions reduction, paving the way for a more sustainable future in automotive technology.

AI algorithms analyze vast amounts of data to optimize engine parameters, resulting in more efficient combustion processes. This optimization leads to reduced fuel consumption, which directly translates to lower carbon dioxide emissions. Studies have shown that AI-optimized L92 engines can achieve up to 15% improvement in fuel efficiency compared to their non-optimized counterparts, significantly reducing the carbon footprint of vehicles equipped with these engines.

Furthermore, AI-driven predictive maintenance systems help identify potential issues before they escalate, ensuring optimal engine performance and preventing unexpected breakdowns. This proactive approach not only extends the lifespan of L92 engines but also minimizes the environmental impact associated with premature engine replacements and the production of spare parts.

AI optimization also enables more precise control of engine operations, leading to reduced emissions of harmful pollutants such as nitrogen oxides (NOx) and particulate matter. By fine-tuning combustion parameters in real-time, AI systems can maintain optimal air-fuel ratios and ignition timing, resulting in cleaner exhaust emissions that meet or exceed stringent environmental regulations.

The environmental benefits of AI-optimized L92 engines extend beyond individual vehicle performance. On a larger scale, the widespread adoption of these engines could contribute to significant reductions in greenhouse gas emissions from the transportation sector. This aligns with global efforts to combat climate change and transition towards more sustainable mobility solutions.

Moreover, AI optimization techniques can be applied throughout the entire lifecycle of L92 engines, from design and manufacturing to end-of-life recycling. By leveraging AI in the production process, manufacturers can minimize material waste, optimize resource utilization, and reduce energy consumption in engine manufacturing facilities. This holistic approach further enhances the overall environmental sustainability of AI-optimized L92 engines.

As the automotive industry continues to evolve, the environmental impact of AI-optimized L92 engines is expected to become increasingly significant. The ongoing development of more sophisticated AI algorithms and the integration of advanced sensors will likely lead to even greater improvements in engine efficiency and emissions reduction, paving the way for a more sustainable future in automotive technology.

Regulatory Framework for AI in Automotive Engineering

The regulatory framework for AI in automotive engineering is evolving rapidly to keep pace with technological advancements in the field. As AI applications in L92 engine development become more prevalent, regulatory bodies are working to establish guidelines that ensure safety, reliability, and ethical use of these technologies.

One of the primary focuses of the regulatory framework is safety standards. Regulatory agencies are developing specific requirements for AI systems used in engine development, including rigorous testing protocols and validation procedures. These standards aim to ensure that AI-driven engine components and control systems meet or exceed traditional safety benchmarks.

Data privacy and security regulations are also a crucial aspect of the framework. As AI systems in L92 engine development rely heavily on data collection and analysis, regulations are being put in place to protect sensitive information and prevent unauthorized access or misuse of data. This includes guidelines for data storage, transmission, and processing.

Ethical considerations form another key pillar of the regulatory framework. Regulators are addressing issues such as algorithmic bias and transparency in AI decision-making processes. This is particularly important in engine development, where AI systems may influence critical performance and efficiency parameters.

The framework also includes provisions for accountability and liability. As AI systems become more autonomous in engine development processes, regulations are being developed to clarify responsibility in case of failures or accidents related to AI-driven components or decisions.

Interoperability and standardization are additional focus areas. Regulators are working to establish common standards and protocols for AI systems in automotive engineering, ensuring compatibility across different platforms and facilitating industry-wide adoption of AI technologies in engine development.

Environmental regulations are being updated to incorporate AI applications in engine development. This includes guidelines for using AI to optimize fuel efficiency and reduce emissions, aligning with broader sustainability goals in the automotive industry.

Lastly, the regulatory framework addresses the need for continuous monitoring and updating of AI systems. This includes requirements for regular software updates, performance evaluations, and recertification processes to ensure ongoing compliance with evolving standards and regulations.

One of the primary focuses of the regulatory framework is safety standards. Regulatory agencies are developing specific requirements for AI systems used in engine development, including rigorous testing protocols and validation procedures. These standards aim to ensure that AI-driven engine components and control systems meet or exceed traditional safety benchmarks.

Data privacy and security regulations are also a crucial aspect of the framework. As AI systems in L92 engine development rely heavily on data collection and analysis, regulations are being put in place to protect sensitive information and prevent unauthorized access or misuse of data. This includes guidelines for data storage, transmission, and processing.

Ethical considerations form another key pillar of the regulatory framework. Regulators are addressing issues such as algorithmic bias and transparency in AI decision-making processes. This is particularly important in engine development, where AI systems may influence critical performance and efficiency parameters.

The framework also includes provisions for accountability and liability. As AI systems become more autonomous in engine development processes, regulations are being developed to clarify responsibility in case of failures or accidents related to AI-driven components or decisions.

Interoperability and standardization are additional focus areas. Regulators are working to establish common standards and protocols for AI systems in automotive engineering, ensuring compatibility across different platforms and facilitating industry-wide adoption of AI technologies in engine development.

Environmental regulations are being updated to incorporate AI applications in engine development. This includes guidelines for using AI to optimize fuel efficiency and reduce emissions, aligning with broader sustainability goals in the automotive industry.

Lastly, the regulatory framework addresses the need for continuous monitoring and updating of AI systems. This includes requirements for regular software updates, performance evaluations, and recertification processes to ensure ongoing compliance with evolving standards and regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!