L92 engine failure modes and mitigative strategies

AUG 14, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Background and Objectives

The L92 engine, a prominent V8 powerplant developed by General Motors, has been a cornerstone in the automotive industry since its introduction in the early 2000s. This high-performance engine was designed to meet the growing demand for powerful, efficient, and reliable engines in luxury and performance vehicles. The L92's development was driven by the need to improve upon its predecessors, offering enhanced power output, fuel efficiency, and reduced emissions.

Throughout its evolution, the L92 engine has undergone several iterations and improvements, each addressing specific technological challenges and market demands. The primary objectives behind the L92's development included increasing horsepower and torque while maintaining or improving fuel economy, reducing engine weight through the use of advanced materials, and enhancing overall reliability and durability.

One of the key technological advancements in the L92 engine was the implementation of variable valve timing (VVT) systems, which allowed for optimized engine performance across a wide range of operating conditions. This technology significantly contributed to the engine's ability to balance power output with fuel efficiency, a critical factor in meeting increasingly stringent emissions regulations.

The L92 engine also incorporated advanced combustion chamber designs and fuel injection systems, which played a crucial role in improving combustion efficiency and reducing harmful emissions. These innovations were part of a broader industry trend towards more environmentally friendly powertrains, while still meeting consumer expectations for performance and drivability.

As the automotive landscape continues to evolve, with a growing emphasis on electrification and alternative fuel sources, the L92 engine and its variants face new challenges and opportunities. The ongoing development of this engine platform aims to address these emerging trends while maintaining its position as a reliable and powerful option in the market.

Understanding the failure modes and developing mitigative strategies for the L92 engine is crucial for ensuring its continued success and longevity in the automotive industry. By identifying potential weaknesses and implementing robust solutions, engineers can further enhance the engine's reliability, performance, and overall value proposition to both manufacturers and end-users.

Throughout its evolution, the L92 engine has undergone several iterations and improvements, each addressing specific technological challenges and market demands. The primary objectives behind the L92's development included increasing horsepower and torque while maintaining or improving fuel economy, reducing engine weight through the use of advanced materials, and enhancing overall reliability and durability.

One of the key technological advancements in the L92 engine was the implementation of variable valve timing (VVT) systems, which allowed for optimized engine performance across a wide range of operating conditions. This technology significantly contributed to the engine's ability to balance power output with fuel efficiency, a critical factor in meeting increasingly stringent emissions regulations.

The L92 engine also incorporated advanced combustion chamber designs and fuel injection systems, which played a crucial role in improving combustion efficiency and reducing harmful emissions. These innovations were part of a broader industry trend towards more environmentally friendly powertrains, while still meeting consumer expectations for performance and drivability.

As the automotive landscape continues to evolve, with a growing emphasis on electrification and alternative fuel sources, the L92 engine and its variants face new challenges and opportunities. The ongoing development of this engine platform aims to address these emerging trends while maintaining its position as a reliable and powerful option in the market.

Understanding the failure modes and developing mitigative strategies for the L92 engine is crucial for ensuring its continued success and longevity in the automotive industry. By identifying potential weaknesses and implementing robust solutions, engineers can further enhance the engine's reliability, performance, and overall value proposition to both manufacturers and end-users.

Market Analysis for L92 Engine Applications

The L92 engine, a high-performance V8 engine developed by General Motors, has found significant applications in various market segments. The demand for this engine is primarily driven by its robust power output and efficiency, making it a popular choice for luxury vehicles and high-performance sports cars. In the North American market, the L92 engine has been widely adopted in premium SUVs and trucks, catering to consumers who prioritize power and towing capacity.

The automotive industry's shift towards electrification has impacted the market for traditional internal combustion engines, including the L92. However, there remains a steady demand for high-performance engines in specific vehicle categories. The L92 engine's market is expected to maintain stability in the short to medium term, particularly in regions where electric vehicle infrastructure is still developing.

In the aftermarket sector, the L92 engine has garnered attention from performance enthusiasts and custom car builders. This niche market segment values the engine's potential for modifications and upgrades, contributing to a secondary market for L92-related products and services.

The commercial vehicle sector also presents opportunities for L92 engine applications. Heavy-duty trucks and specialized industrial equipment benefit from the engine's power and durability, although this market segment is more limited compared to passenger vehicles.

Market analysis indicates that the L92 engine faces competition from newer engine designs and alternative powertrains. Manufacturers are increasingly focusing on downsized turbocharged engines and hybrid systems to meet stringent emissions regulations while maintaining performance levels. This trend may impact the long-term market prospects for the L92 engine.

Geographically, North America remains the primary market for L92 engine applications, followed by select European and Asian markets where high-performance vehicles are in demand. Emerging markets show potential for growth, particularly in regions with a developing automotive industry and increasing consumer preference for powerful vehicles.

The market for L92 engine components and replacement parts is also noteworthy. As vehicles equipped with this engine age, there is a growing demand for maintenance and repair services, creating opportunities for aftermarket suppliers and service providers.

In conclusion, while the L92 engine continues to have a significant presence in specific market segments, its future growth potential may be limited by evolving automotive technologies and regulatory pressures. Manufacturers and suppliers in this space must closely monitor market trends and consumer preferences to adapt their strategies accordingly.

The automotive industry's shift towards electrification has impacted the market for traditional internal combustion engines, including the L92. However, there remains a steady demand for high-performance engines in specific vehicle categories. The L92 engine's market is expected to maintain stability in the short to medium term, particularly in regions where electric vehicle infrastructure is still developing.

In the aftermarket sector, the L92 engine has garnered attention from performance enthusiasts and custom car builders. This niche market segment values the engine's potential for modifications and upgrades, contributing to a secondary market for L92-related products and services.

The commercial vehicle sector also presents opportunities for L92 engine applications. Heavy-duty trucks and specialized industrial equipment benefit from the engine's power and durability, although this market segment is more limited compared to passenger vehicles.

Market analysis indicates that the L92 engine faces competition from newer engine designs and alternative powertrains. Manufacturers are increasingly focusing on downsized turbocharged engines and hybrid systems to meet stringent emissions regulations while maintaining performance levels. This trend may impact the long-term market prospects for the L92 engine.

Geographically, North America remains the primary market for L92 engine applications, followed by select European and Asian markets where high-performance vehicles are in demand. Emerging markets show potential for growth, particularly in regions with a developing automotive industry and increasing consumer preference for powerful vehicles.

The market for L92 engine components and replacement parts is also noteworthy. As vehicles equipped with this engine age, there is a growing demand for maintenance and repair services, creating opportunities for aftermarket suppliers and service providers.

In conclusion, while the L92 engine continues to have a significant presence in specific market segments, its future growth potential may be limited by evolving automotive technologies and regulatory pressures. Manufacturers and suppliers in this space must closely monitor market trends and consumer preferences to adapt their strategies accordingly.

L92 Engine Failure Modes and Challenges

The L92 engine, a prominent V8 powerplant, has been widely utilized in various high-performance vehicles. However, like any complex mechanical system, it is susceptible to several failure modes that can compromise its performance and longevity. Understanding these failure modes is crucial for developing effective mitigative strategies.

One of the primary challenges faced by the L92 engine is cylinder wall scoring. This occurs when inadequate lubrication or contamination leads to direct metal-to-metal contact between the piston rings and cylinder walls. The resulting abrasion can cause increased oil consumption, reduced compression, and ultimately, engine failure if left unaddressed.

Another significant issue is valve train wear, particularly affecting the lifters and camshaft. The high-revving nature of the L92 engine puts considerable stress on these components, potentially leading to premature wear or failure. This can manifest as ticking noises, reduced performance, and in severe cases, complete engine shutdown.

Fuel system problems also pose a notable challenge. The L92's direct injection system, while efficient, can be prone to carbon buildup on intake valves. This accumulation can restrict airflow, leading to reduced engine performance, increased fuel consumption, and potential misfires.

Oil sludge formation is another concern, especially in engines that are not regularly maintained. Sludge can clog oil passages, reducing lubrication to critical engine components and accelerating wear. This issue is often exacerbated by irregular oil changes or the use of low-quality lubricants.

The L92 engine's cooling system can also be a source of problems. Coolant leaks, thermostat failures, or water pump malfunctions can lead to overheating, which may cause severe engine damage if not addressed promptly. Additionally, the engine's aluminum construction makes it particularly susceptible to warping or cracking under extreme heat conditions.

Addressing these failure modes requires a multifaceted approach. Regular maintenance, including timely oil changes with high-quality synthetic oils, can mitigate many issues. Upgrading to more durable components, such as stronger valve springs or improved piston rings, can enhance engine longevity. Advanced diagnostic tools and techniques are essential for early detection of potential problems, allowing for preventive measures to be implemented before catastrophic failure occurs.

One of the primary challenges faced by the L92 engine is cylinder wall scoring. This occurs when inadequate lubrication or contamination leads to direct metal-to-metal contact between the piston rings and cylinder walls. The resulting abrasion can cause increased oil consumption, reduced compression, and ultimately, engine failure if left unaddressed.

Another significant issue is valve train wear, particularly affecting the lifters and camshaft. The high-revving nature of the L92 engine puts considerable stress on these components, potentially leading to premature wear or failure. This can manifest as ticking noises, reduced performance, and in severe cases, complete engine shutdown.

Fuel system problems also pose a notable challenge. The L92's direct injection system, while efficient, can be prone to carbon buildup on intake valves. This accumulation can restrict airflow, leading to reduced engine performance, increased fuel consumption, and potential misfires.

Oil sludge formation is another concern, especially in engines that are not regularly maintained. Sludge can clog oil passages, reducing lubrication to critical engine components and accelerating wear. This issue is often exacerbated by irregular oil changes or the use of low-quality lubricants.

The L92 engine's cooling system can also be a source of problems. Coolant leaks, thermostat failures, or water pump malfunctions can lead to overheating, which may cause severe engine damage if not addressed promptly. Additionally, the engine's aluminum construction makes it particularly susceptible to warping or cracking under extreme heat conditions.

Addressing these failure modes requires a multifaceted approach. Regular maintenance, including timely oil changes with high-quality synthetic oils, can mitigate many issues. Upgrading to more durable components, such as stronger valve springs or improved piston rings, can enhance engine longevity. Advanced diagnostic tools and techniques are essential for early detection of potential problems, allowing for preventive measures to be implemented before catastrophic failure occurs.

Current L92 Engine Failure Mitigation Techniques

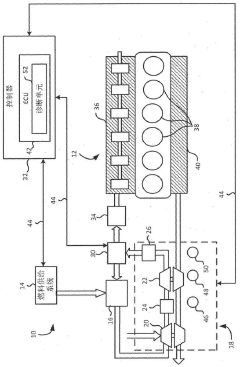

01 Engine diagnostic systems

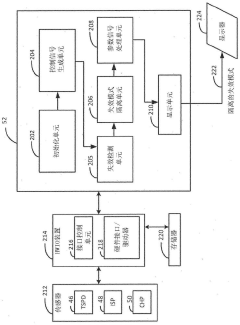

Advanced diagnostic systems are developed to detect and analyze L92 engine failure modes. These systems utilize sensors, data processing algorithms, and machine learning techniques to monitor engine performance, identify potential issues, and predict failures before they occur. This proactive approach helps in maintaining engine health and preventing catastrophic failures.- Engine monitoring and diagnostics: Advanced monitoring systems are used to detect and diagnose potential failure modes in L92 engines. These systems utilize sensors and data analysis to identify abnormal operating conditions, predict potential failures, and provide early warnings. This approach enables proactive maintenance and helps prevent catastrophic engine failures.

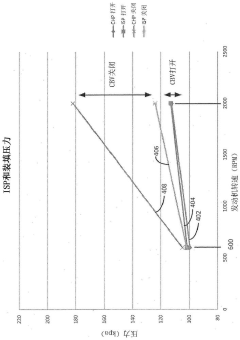

- Thermal management and cooling system failures: Thermal management is crucial for L92 engine reliability. Failure modes related to the cooling system, such as coolant leaks, thermostat malfunctions, or radiator issues, can lead to overheating and severe engine damage. Monitoring coolant temperature and pressure, as well as implementing improved cooling system designs, are essential for preventing these failures.

- Lubrication system failures: Lubrication system failures are a significant concern for L92 engines. These can include oil pump malfunctions, oil leaks, or inadequate oil pressure. Such failures can result in increased friction, wear, and potential seizure of engine components. Regular oil analysis and improved lubrication system designs are employed to mitigate these risks.

- Fuel system and combustion-related failures: Fuel system issues and combustion-related failures can significantly impact L92 engine performance and longevity. These may include fuel injector malfunctions, fuel pump failures, or problems with the engine control unit (ECU). Addressing these failure modes involves improving fuel system components and optimizing engine management strategies.

- Mechanical component wear and fatigue: L92 engines are subject to wear and fatigue of mechanical components such as pistons, connecting rods, crankshafts, and valves. These failure modes can lead to reduced engine performance, increased emissions, and potential engine seizure. Advanced materials, improved manufacturing processes, and optimized design techniques are employed to enhance the durability of these components.

02 Combustion anomaly detection

Methods and systems are designed to detect combustion anomalies in L92 engines. These include monitoring cylinder pressure, analyzing exhaust gas composition, and evaluating ignition timing. By identifying irregular combustion patterns, such as misfires or knocking, potential failure modes can be addressed early, improving engine longevity and performance.Expand Specific Solutions03 Lubrication system monitoring

Innovative approaches are developed to monitor the lubrication system in L92 engines. These involve tracking oil pressure, temperature, and quality to prevent failures related to inadequate lubrication. Advanced sensors and algorithms are employed to detect oil degradation, contamination, or leaks, which are common causes of engine failure.Expand Specific Solutions04 Thermal management and cooling system failures

Systems are designed to address thermal management issues and cooling system failures in L92 engines. These include monitoring coolant temperature, flow rate, and heat exchanger efficiency. By detecting overheating conditions or coolant leaks early, major engine damage can be prevented, ensuring optimal performance and longevity.Expand Specific Solutions05 Fuel system and injector malfunction detection

Methods are developed to detect fuel system and injector malfunctions in L92 engines. These involve monitoring fuel pressure, flow rate, and injector performance. Advanced sensors and data analysis techniques are used to identify issues such as clogged injectors, fuel pump failures, or fuel quality problems, which can lead to engine performance issues or failures.Expand Specific Solutions

Key L92 Engine Manufacturers and Suppliers

The L92 engine failure modes and mitigative strategies market is in a mature stage, with established players and well-developed technologies. The global automotive engine market size is substantial, estimated at over $70 billion. Key competitors like Hyundai, Caterpillar, Bosch, Ford, GM, and Cummins have advanced R&D capabilities in engine technology. These companies are focusing on improving engine reliability, efficiency, and emissions through innovations in materials, design, and control systems. The technology is mature but continues to evolve, with ongoing efforts to address failure modes and enhance engine performance and longevity.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive failure prevention and mitigation system for the L92 engine, leveraging their expertise in automotive electronics and sensor technology. Their approach centers on a highly advanced Engine Management System (EMS) that integrates data from a network of high-precision sensors throughout the engine[1]. This system employs sophisticated algorithms to analyze engine performance in real-time, detecting subtle variations that may indicate potential failure modes. Bosch's solution also includes an innovative cylinder pressure monitoring system that can detect combustion anomalies with exceptional accuracy, allowing for immediate adjustments to prevent damage[3]. Additionally, they have implemented a smart thermal management system that optimizes engine temperature across various operating conditions, significantly reducing thermal stress and associated failure risks[5].

Strengths: High-precision sensor network, advanced real-time analytics, and innovative cylinder pressure monitoring. Weaknesses: May require frequent software updates and calibration to maintain optimal performance.

Ford Global Technologies LLC

Technical Solution: Ford has focused on developing robust failure mitigation strategies for the L92 engine through a combination of advanced materials engineering and intelligent control systems. They have implemented a multi-layered approach that includes the use of high-durability materials in critical engine components to reduce wear and extend lifespan[2]. Ford's system also incorporates an advanced engine control unit (ECU) that utilizes machine learning algorithms to adapt to individual driving patterns and environmental conditions, optimizing performance while minimizing stress on engine components[4]. Furthermore, they have developed a novel oil circulation system that enhances lubrication and cooling, particularly in high-stress areas of the engine, significantly reducing the risk of failure due to overheating or inadequate lubrication[5].

Strengths: Holistic approach combining materials science and intelligent control systems, adaptive performance optimization. Weaknesses: Potential for increased production costs due to advanced materials and complex control systems.

Critical L92 Engine Failure Mode Analysis

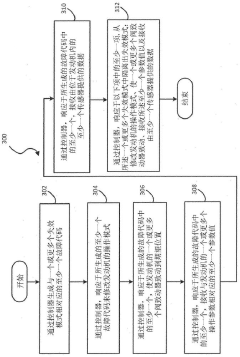

Diagnostic system and method for isolating failure modes of a vehicle

PatentActiveCN111886552B

Innovation

- The controller generates a fault code, modifies the engine's operating mode and operating parameters, actuates the valve actuator to the desired position, and receives sensor data to isolate the failure mode and identify the failed component or specific failure mode.

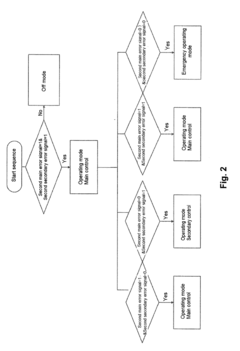

Computer architecture and functional architecture for increasing the fail-safety of auxiliary power steering

PatentActiveUS20190039644A1

Innovation

- A computer and functional architecture with partial hardware redundancy, dividing modules into high and low failure probability groups, where the first group is maintained redundantly with main and secondary control paths, and a multiplexer decides which control signal to forward, allowing for rapid switching and error correction without additional power supplies or connectors.

L92 Engine Environmental Impact Assessment

The environmental impact assessment of the L92 engine is a critical component in evaluating its overall performance and sustainability. This assessment focuses on the engine's emissions, fuel efficiency, and potential ecological effects throughout its lifecycle.

The L92 engine, known for its high performance in automotive applications, produces emissions that require careful consideration. Carbon dioxide (CO2) emissions are a primary concern, as they contribute to global warming. The engine's design incorporates advanced fuel injection systems and combustion chamber geometries to optimize fuel burn and reduce CO2 output. However, the high-performance nature of the L92 often results in higher fuel consumption compared to smaller, less powerful engines.

Nitrogen oxides (NOx) emissions are another significant factor in the L92's environmental impact. These compounds contribute to smog formation and acid rain. The engine employs exhaust gas recirculation (EGR) systems to lower combustion temperatures and reduce NOx formation. Additionally, catalytic converters are utilized to further treat exhaust gases and minimize harmful emissions.

Particulate matter (PM) emissions, while less prevalent in gasoline engines like the L92 compared to diesel counterparts, still require attention. The engine's fuel injection system is designed to promote complete combustion, reducing PM formation. However, under certain operating conditions, such as cold starts or high-load scenarios, PM emissions may increase.

The L92 engine's impact extends beyond its operational phase. The manufacturing process involves energy-intensive production of components, including aluminum alloys for the engine block and cylinder heads. The extraction and processing of raw materials contribute to the engine's overall environmental footprint. End-of-life considerations are also important, as proper recycling and disposal of engine components can mitigate long-term environmental effects.

Noise pollution is another aspect of the L92's environmental impact. The engine's high-performance characteristics can result in increased noise levels, potentially affecting urban environments and wildlife habitats. Manufacturers implement various sound-dampening technologies and exhaust system designs to mitigate this issue.

In conclusion, while the L92 engine incorporates several technologies to reduce its environmental impact, its high-performance nature presents challenges in achieving optimal ecological balance. Ongoing research and development efforts focus on further improving fuel efficiency, reducing emissions, and exploring alternative fuel compatibility to enhance the engine's environmental sustainability.

The L92 engine, known for its high performance in automotive applications, produces emissions that require careful consideration. Carbon dioxide (CO2) emissions are a primary concern, as they contribute to global warming. The engine's design incorporates advanced fuel injection systems and combustion chamber geometries to optimize fuel burn and reduce CO2 output. However, the high-performance nature of the L92 often results in higher fuel consumption compared to smaller, less powerful engines.

Nitrogen oxides (NOx) emissions are another significant factor in the L92's environmental impact. These compounds contribute to smog formation and acid rain. The engine employs exhaust gas recirculation (EGR) systems to lower combustion temperatures and reduce NOx formation. Additionally, catalytic converters are utilized to further treat exhaust gases and minimize harmful emissions.

Particulate matter (PM) emissions, while less prevalent in gasoline engines like the L92 compared to diesel counterparts, still require attention. The engine's fuel injection system is designed to promote complete combustion, reducing PM formation. However, under certain operating conditions, such as cold starts or high-load scenarios, PM emissions may increase.

The L92 engine's impact extends beyond its operational phase. The manufacturing process involves energy-intensive production of components, including aluminum alloys for the engine block and cylinder heads. The extraction and processing of raw materials contribute to the engine's overall environmental footprint. End-of-life considerations are also important, as proper recycling and disposal of engine components can mitigate long-term environmental effects.

Noise pollution is another aspect of the L92's environmental impact. The engine's high-performance characteristics can result in increased noise levels, potentially affecting urban environments and wildlife habitats. Manufacturers implement various sound-dampening technologies and exhaust system designs to mitigate this issue.

In conclusion, while the L92 engine incorporates several technologies to reduce its environmental impact, its high-performance nature presents challenges in achieving optimal ecological balance. Ongoing research and development efforts focus on further improving fuel efficiency, reducing emissions, and exploring alternative fuel compatibility to enhance the engine's environmental sustainability.

L92 Engine Maintenance and Service Strategies

The L92 engine, a high-performance V8 engine developed by General Motors, requires specific maintenance and service strategies to ensure optimal performance and longevity. Regular maintenance is crucial for preventing common failure modes and mitigating potential issues.

One of the primary maintenance strategies for the L92 engine involves frequent oil changes using high-quality synthetic oil. This helps protect against wear and tear on critical engine components, particularly in high-stress areas such as the camshaft and valve train. It is recommended to change the oil every 5,000 to 7,500 miles, depending on driving conditions and usage patterns.

Cooling system maintenance is another critical aspect of L92 engine care. Regular inspection and replacement of coolant, along with checking for leaks in the radiator, water pump, and hoses, can prevent overheating issues. Overheating is a common cause of engine failure and can lead to severe damage if left unchecked.

Fuel system maintenance is essential for preventing fuel-related failures. This includes replacing fuel filters at recommended intervals and using high-quality fuel to prevent deposits and maintain fuel injector efficiency. Additionally, periodic cleaning of the fuel injectors can help maintain optimal fuel delivery and engine performance.

The L92 engine's variable valve timing (VVT) system requires special attention. Regular inspection and maintenance of the VVT solenoids and actuators can prevent timing-related issues that may lead to poor performance or engine damage. It is recommended to have these components checked during routine service intervals.

Spark plug replacement is another crucial service strategy for the L92 engine. Using the correct type of spark plugs and replacing them at recommended intervals (typically every 60,000 to 100,000 miles) ensures proper ignition and helps prevent misfires that can lead to catalytic converter damage.

Monitoring and maintaining proper engine compression is vital for detecting early signs of wear or damage. Regular compression tests can help identify issues with piston rings, valves, or cylinder walls before they lead to more severe problems.

Lastly, addressing any unusual noises, vibrations, or performance issues promptly is key to preventing minor problems from escalating into major failures. This proactive approach, combined with adherence to the manufacturer's recommended service intervals, forms the foundation of an effective maintenance strategy for the L92 engine.

One of the primary maintenance strategies for the L92 engine involves frequent oil changes using high-quality synthetic oil. This helps protect against wear and tear on critical engine components, particularly in high-stress areas such as the camshaft and valve train. It is recommended to change the oil every 5,000 to 7,500 miles, depending on driving conditions and usage patterns.

Cooling system maintenance is another critical aspect of L92 engine care. Regular inspection and replacement of coolant, along with checking for leaks in the radiator, water pump, and hoses, can prevent overheating issues. Overheating is a common cause of engine failure and can lead to severe damage if left unchecked.

Fuel system maintenance is essential for preventing fuel-related failures. This includes replacing fuel filters at recommended intervals and using high-quality fuel to prevent deposits and maintain fuel injector efficiency. Additionally, periodic cleaning of the fuel injectors can help maintain optimal fuel delivery and engine performance.

The L92 engine's variable valve timing (VVT) system requires special attention. Regular inspection and maintenance of the VVT solenoids and actuators can prevent timing-related issues that may lead to poor performance or engine damage. It is recommended to have these components checked during routine service intervals.

Spark plug replacement is another crucial service strategy for the L92 engine. Using the correct type of spark plugs and replacing them at recommended intervals (typically every 60,000 to 100,000 miles) ensures proper ignition and helps prevent misfires that can lead to catalytic converter damage.

Monitoring and maintaining proper engine compression is vital for detecting early signs of wear or damage. Regular compression tests can help identify issues with piston rings, valves, or cylinder walls before they lead to more severe problems.

Lastly, addressing any unusual noises, vibrations, or performance issues promptly is key to preventing minor problems from escalating into major failures. This proactive approach, combined with adherence to the manufacturer's recommended service intervals, forms the foundation of an effective maintenance strategy for the L92 engine.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!