Hybridization potential of L92 engine with electric motors

AUG 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Hybridization Background and Objectives

The L92 engine, a powerful V8 powerplant developed by General Motors, has been a cornerstone of high-performance vehicles for over a decade. As the automotive industry shifts towards electrification, there is growing interest in exploring the hybridization potential of this robust engine. The evolution of hybrid technology has opened new avenues for combining traditional internal combustion engines with electric motors, offering a balance between performance and efficiency.

The primary objective of hybridizing the L92 engine is to leverage its proven reliability and power output while addressing the increasing demand for improved fuel economy and reduced emissions. This hybridization effort aims to create a powertrain that can deliver the exhilarating performance expected from a V8 engine while also providing the benefits of electric propulsion, such as instant torque and improved efficiency in urban driving conditions.

Historically, the L92 engine has been known for its high output and durability, making it a popular choice for performance-oriented vehicles. However, as environmental regulations become more stringent and consumer preferences shift towards more sustainable options, the need for adaptation becomes evident. The hybridization of the L92 engine represents a technological bridge between traditional high-performance engines and the future of electrified powertrains.

The technical evolution in this field has seen significant advancements in battery technology, power electronics, and electric motor design. These developments have made it increasingly feasible to integrate electric propulsion systems with conventional engines without compromising performance. The goal is to create a symbiotic relationship between the L92 engine and electric motors, where each component complements the other's strengths.

In pursuing this hybridization, several key technical objectives have been identified. These include optimizing the integration of electric motors with the L92 engine, developing sophisticated control systems for seamless power delivery, and designing an efficient energy recovery system to maximize the benefits of regenerative braking. Additionally, there is a focus on minimizing the weight impact of the added hybrid components to maintain the vehicle's dynamic performance characteristics.

The market trends driving this technological pursuit include increasing consumer demand for vehicles that offer both high performance and improved fuel efficiency. There is also a growing regulatory pressure to reduce fleet-wide emissions, making hybrid powertrains an attractive solution for manufacturers looking to balance performance offerings with environmental compliance.

As we delve deeper into the hybridization potential of the L92 engine, it becomes clear that this endeavor is not just about improving a single powertrain but about paving the way for a new generation of high-performance hybrid vehicles. The success of this project could set a precedent for the hybridization of other performance engines, potentially reshaping the landscape of the automotive industry.

The primary objective of hybridizing the L92 engine is to leverage its proven reliability and power output while addressing the increasing demand for improved fuel economy and reduced emissions. This hybridization effort aims to create a powertrain that can deliver the exhilarating performance expected from a V8 engine while also providing the benefits of electric propulsion, such as instant torque and improved efficiency in urban driving conditions.

Historically, the L92 engine has been known for its high output and durability, making it a popular choice for performance-oriented vehicles. However, as environmental regulations become more stringent and consumer preferences shift towards more sustainable options, the need for adaptation becomes evident. The hybridization of the L92 engine represents a technological bridge between traditional high-performance engines and the future of electrified powertrains.

The technical evolution in this field has seen significant advancements in battery technology, power electronics, and electric motor design. These developments have made it increasingly feasible to integrate electric propulsion systems with conventional engines without compromising performance. The goal is to create a symbiotic relationship between the L92 engine and electric motors, where each component complements the other's strengths.

In pursuing this hybridization, several key technical objectives have been identified. These include optimizing the integration of electric motors with the L92 engine, developing sophisticated control systems for seamless power delivery, and designing an efficient energy recovery system to maximize the benefits of regenerative braking. Additionally, there is a focus on minimizing the weight impact of the added hybrid components to maintain the vehicle's dynamic performance characteristics.

The market trends driving this technological pursuit include increasing consumer demand for vehicles that offer both high performance and improved fuel efficiency. There is also a growing regulatory pressure to reduce fleet-wide emissions, making hybrid powertrains an attractive solution for manufacturers looking to balance performance offerings with environmental compliance.

As we delve deeper into the hybridization potential of the L92 engine, it becomes clear that this endeavor is not just about improving a single powertrain but about paving the way for a new generation of high-performance hybrid vehicles. The success of this project could set a precedent for the hybridization of other performance engines, potentially reshaping the landscape of the automotive industry.

Market Analysis for Hybrid L92 Powertrains

The market for hybrid powertrains incorporating the L92 engine and electric motors shows significant growth potential across various automotive segments. As consumers increasingly prioritize fuel efficiency and environmental sustainability, hybrid vehicles have gained traction in both personal and commercial transportation sectors. The L92 engine, known for its robust performance and reliability, presents an attractive base for hybridization, potentially offering a balance between power and efficiency that appeals to a wide range of customers.

In the passenger vehicle market, hybrid L92 powertrains could target the luxury SUV and high-performance sedan segments. These vehicles typically require substantial power output while facing increasing pressure to meet stringent emissions regulations. The combination of the L92's V8 capabilities with electric motor assistance could provide the necessary performance while significantly improving fuel economy and reducing emissions.

The commercial vehicle sector also presents substantial opportunities for hybrid L92 powertrains. Light-duty trucks and vans used for urban deliveries and service operations could benefit from the improved fuel efficiency and reduced emissions of a hybrid system, particularly in stop-and-go traffic conditions. Additionally, the marine industry, where the L92 engine has found applications, could see increased demand for hybrid solutions to meet environmental regulations in coastal and inland waterways.

Market analysis indicates that the global hybrid vehicle market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is driven by factors such as government incentives, stricter emissions standards, and increasing consumer awareness of environmental issues. The hybridization of the L92 engine could capture a significant portion of this market, particularly in regions with a strong preference for larger displacement engines but facing pressure to reduce carbon footprints.

The North American market, where V8 engines have traditionally been popular, represents a key target for hybrid L92 powertrains. As fuel economy standards tighten, hybridization offers a path to maintain the power characteristics consumers desire while meeting regulatory requirements. Europe and China, with their aggressive electrification targets, also present opportunities for advanced hybrid systems that can serve as a bridge technology in the transition to fully electric vehicles.

Competitive analysis reveals that several major automotive manufacturers are investing in hybrid technologies for their larger engines. However, the specific combination of the L92 engine with electric motors could offer a unique value proposition, leveraging the engine's established reputation and performance characteristics. This hybrid solution could potentially outperform competitors in terms of power density and overall system efficiency, providing a compelling option for both OEMs and aftermarket applications.

In the passenger vehicle market, hybrid L92 powertrains could target the luxury SUV and high-performance sedan segments. These vehicles typically require substantial power output while facing increasing pressure to meet stringent emissions regulations. The combination of the L92's V8 capabilities with electric motor assistance could provide the necessary performance while significantly improving fuel economy and reducing emissions.

The commercial vehicle sector also presents substantial opportunities for hybrid L92 powertrains. Light-duty trucks and vans used for urban deliveries and service operations could benefit from the improved fuel efficiency and reduced emissions of a hybrid system, particularly in stop-and-go traffic conditions. Additionally, the marine industry, where the L92 engine has found applications, could see increased demand for hybrid solutions to meet environmental regulations in coastal and inland waterways.

Market analysis indicates that the global hybrid vehicle market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is driven by factors such as government incentives, stricter emissions standards, and increasing consumer awareness of environmental issues. The hybridization of the L92 engine could capture a significant portion of this market, particularly in regions with a strong preference for larger displacement engines but facing pressure to reduce carbon footprints.

The North American market, where V8 engines have traditionally been popular, represents a key target for hybrid L92 powertrains. As fuel economy standards tighten, hybridization offers a path to maintain the power characteristics consumers desire while meeting regulatory requirements. Europe and China, with their aggressive electrification targets, also present opportunities for advanced hybrid systems that can serve as a bridge technology in the transition to fully electric vehicles.

Competitive analysis reveals that several major automotive manufacturers are investing in hybrid technologies for their larger engines. However, the specific combination of the L92 engine with electric motors could offer a unique value proposition, leveraging the engine's established reputation and performance characteristics. This hybrid solution could potentially outperform competitors in terms of power density and overall system efficiency, providing a compelling option for both OEMs and aftermarket applications.

Current Challenges in L92 Hybrid Integration

The integration of electric motors with the L92 engine presents several significant challenges that need to be addressed for successful hybridization. One of the primary obstacles is the space constraint within the existing vehicle architecture. The L92 engine, being a large displacement V8, occupies substantial space in the engine bay, leaving limited room for the addition of electric motors and associated components.

Power management and distribution pose another critical challenge. Balancing the power output between the combustion engine and electric motors requires sophisticated control systems. The development of an efficient power management strategy that optimizes fuel economy while maintaining performance is a complex task, necessitating advanced algorithms and real-time decision-making capabilities.

Thermal management is a crucial aspect that demands careful consideration. The integration of electric motors introduces additional heat sources, potentially affecting the overall thermal balance of the powertrain. Designing an effective cooling system that can handle the combined heat output of the L92 engine and electric motors without compromising performance or efficiency is a significant engineering challenge.

Weight distribution and vehicle dynamics present further complications. The addition of electric motors and battery packs can significantly alter the weight distribution of the vehicle, potentially impacting handling characteristics and ride quality. Engineers must carefully consider the placement of these components to maintain optimal weight balance and preserve the vehicle's driving dynamics.

Battery integration and packaging pose substantial challenges. Finding suitable locations for battery packs that do not compromise passenger or cargo space while ensuring proper protection and cooling is a complex task. Additionally, the added weight of the battery system must be carefully managed to minimize its impact on overall vehicle performance and efficiency.

Durability and reliability concerns arise from the integration of two distinct powertrain systems. Ensuring that the hybrid system can withstand the rigors of various driving conditions and maintain long-term reliability requires extensive testing and validation. This includes addressing potential issues related to vibration, thermal cycling, and electromagnetic interference between the combustion engine and electric components.

Cost considerations present a significant hurdle in the hybridization process. The addition of electric motors, batteries, and associated control systems substantially increases the overall cost of the powertrain. Balancing the additional expenses with the potential benefits in terms of fuel efficiency and performance is crucial for market viability.

Lastly, meeting emissions regulations while maintaining the performance characteristics of the L92 engine is a complex challenge. The hybridization process must not only improve fuel efficiency but also ensure compliance with increasingly stringent emissions standards, potentially requiring advanced exhaust after-treatment systems and precise control of the combustion process.

Power management and distribution pose another critical challenge. Balancing the power output between the combustion engine and electric motors requires sophisticated control systems. The development of an efficient power management strategy that optimizes fuel economy while maintaining performance is a complex task, necessitating advanced algorithms and real-time decision-making capabilities.

Thermal management is a crucial aspect that demands careful consideration. The integration of electric motors introduces additional heat sources, potentially affecting the overall thermal balance of the powertrain. Designing an effective cooling system that can handle the combined heat output of the L92 engine and electric motors without compromising performance or efficiency is a significant engineering challenge.

Weight distribution and vehicle dynamics present further complications. The addition of electric motors and battery packs can significantly alter the weight distribution of the vehicle, potentially impacting handling characteristics and ride quality. Engineers must carefully consider the placement of these components to maintain optimal weight balance and preserve the vehicle's driving dynamics.

Battery integration and packaging pose substantial challenges. Finding suitable locations for battery packs that do not compromise passenger or cargo space while ensuring proper protection and cooling is a complex task. Additionally, the added weight of the battery system must be carefully managed to minimize its impact on overall vehicle performance and efficiency.

Durability and reliability concerns arise from the integration of two distinct powertrain systems. Ensuring that the hybrid system can withstand the rigors of various driving conditions and maintain long-term reliability requires extensive testing and validation. This includes addressing potential issues related to vibration, thermal cycling, and electromagnetic interference between the combustion engine and electric components.

Cost considerations present a significant hurdle in the hybridization process. The addition of electric motors, batteries, and associated control systems substantially increases the overall cost of the powertrain. Balancing the additional expenses with the potential benefits in terms of fuel efficiency and performance is crucial for market viability.

Lastly, meeting emissions regulations while maintaining the performance characteristics of the L92 engine is a complex challenge. The hybridization process must not only improve fuel efficiency but also ensure compliance with increasingly stringent emissions standards, potentially requiring advanced exhaust after-treatment systems and precise control of the combustion process.

Existing L92 Hybridization Solutions

01 Engine design and configuration

The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and overall engine architecture to optimize power output and fuel economy.- Engine design and configuration: The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies such as variable valve timing and direct fuel injection. The engine's design focuses on optimizing power output, fuel economy, and emissions control.

- Fuel injection system: The L92 engine incorporates a sophisticated fuel injection system, likely featuring direct injection technology. This system is designed to improve fuel atomization, combustion efficiency, and overall engine performance. It may include high-pressure fuel pumps and precision injectors for optimal fuel delivery.

- Valve train and timing mechanisms: Advanced valve train components and timing mechanisms are utilized in the L92 engine to enhance performance and efficiency. This may include variable valve timing systems, roller rocker arms, and hydraulic lifters. These components work together to optimize engine breathing and combustion across various operating conditions.

- Engine control and management systems: The L92 engine likely employs sophisticated electronic control and management systems to optimize performance, fuel efficiency, and emissions. These systems may include advanced engine control units (ECUs), sensors, and actuators to monitor and adjust various engine parameters in real-time.

- Emissions control technologies: To meet stringent emissions regulations, the L92 engine incorporates various emissions control technologies. These may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced air intake designs. The engine's overall design and control strategies are likely optimized to minimize harmful emissions while maintaining performance.

02 Fuel injection system

The L92 engine incorporates a sophisticated fuel injection system to enhance combustion efficiency and power delivery. This system may include direct injection technology or other advanced fuel delivery methods to improve engine performance and reduce emissions.Expand Specific Solutions03 Variable valve timing

Variable valve timing technology is implemented in the L92 engine to optimize engine performance across different operating conditions. This system allows for improved power output, fuel efficiency, and reduced emissions by adjusting valve timing based on engine speed and load.Expand Specific Solutions04 Engine management and control systems

Advanced engine management and control systems are utilized in the L92 engine to optimize performance, fuel efficiency, and emissions. These systems may include electronic control units, sensors, and actuators to monitor and adjust various engine parameters in real-time.Expand Specific Solutions05 Exhaust and emissions control

The L92 engine incorporates exhaust and emissions control technologies to meet stringent environmental regulations. This may include catalytic converters, exhaust gas recirculation systems, and other emission reduction technologies to minimize harmful pollutants.Expand Specific Solutions

Key Players in L92 Hybrid Development

The hybridization of L92 engines with electric motors is in a transitional phase, reflecting the automotive industry's shift towards electrification. The market for hybrid powertrains is expanding rapidly, driven by stringent emissions regulations and consumer demand for fuel-efficient vehicles. While the technology is maturing, there's still room for innovation and optimization. Key players like Toyota, Ford, and Volkswagen are leading the development, with Toyota's extensive hybrid experience giving them an edge. Other major automakers such as Honda, Hyundai, and BMW are also investing heavily in this technology, indicating a competitive and dynamic market landscape. The integration of electric motors with traditional combustion engines presents both challenges and opportunities for manufacturers to differentiate their offerings and improve overall vehicle performance.

Toyota Motor Corp.

Technical Solution: Toyota has developed a hybrid system that combines the L92 engine with electric motors, focusing on optimizing fuel efficiency and performance. The system utilizes a power split device to distribute power between the engine, electric motor, and generator. Toyota's hybrid technology incorporates a high-voltage battery pack and sophisticated power control unit to manage energy flow. The L92 engine is modified to operate on the Atkinson cycle for improved efficiency, while the electric motors provide instant torque for acceleration and low-speed driving. Toyota's system also features regenerative braking to recover energy during deceleration[1][3]. The company has continuously improved its hybrid technology, achieving up to 40% thermal efficiency in some models[5].

Strengths: Proven reliability, high fuel efficiency, and seamless power delivery. Weaknesses: Higher initial cost compared to conventional powertrains and complexity of the system.

Ford Global Technologies LLC

Technical Solution: Ford's hybridization approach for the L92 engine focuses on a modular hybrid system that can be adapted to various vehicle platforms. The system integrates an electric motor between the engine and transmission, allowing for electric-only operation at low speeds and power boost during acceleration. Ford's technology includes a lithium-ion battery pack and an advanced thermal management system to optimize battery performance and longevity. The L92 engine is modified with variable valve timing and direct injection to improve efficiency when working in conjunction with the electric motor. Ford's hybrid system also incorporates a brake energy recuperation system and an intelligent power management unit that optimizes the use of electric and combustion power based on driving conditions and battery state of charge[2][4].

Strengths: Versatility across different vehicle types, good balance of performance and efficiency. Weaknesses: Less fuel efficiency in highway driving compared to some competitors.

Core Innovations in L92 Hybrid Technology

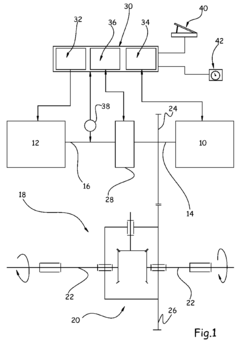

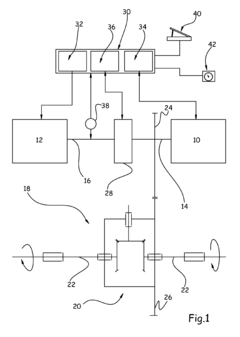

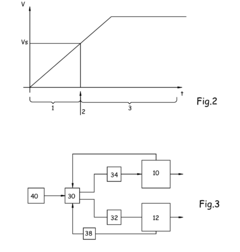

Basically electric hybrid drivetrain for a vehicle

PatentInactiveEP2266855A1

Innovation

- A hybrid engine design featuring an electric motor and a thermal engine connected via a kinematic chain with clutch and disengagement means that automatically uncouples the thermal engine below a threshold speed and couples it above that speed, eliminating the need for a gearbox and simplifying control, while ensuring efficient operation of both motors.

Environmental Impact Assessment

The hybridization of the L92 engine with electric motors presents significant potential for reducing environmental impact across multiple fronts. This integration of conventional internal combustion technology with electric propulsion systems offers a pathway to improved fuel efficiency and reduced emissions, aligning with increasingly stringent environmental regulations and sustainability goals.

One of the primary environmental benefits of this hybridization is the reduction in greenhouse gas emissions. By incorporating electric motors, the hybrid system can optimize engine operation, allowing the L92 engine to run at its most efficient points while using electric power to supplement performance. This results in lower fuel consumption and, consequently, decreased carbon dioxide emissions. Studies have shown that hybrid powertrains can reduce CO2 emissions by 20-30% compared to conventional engines, depending on the specific hybrid configuration and driving conditions.

The hybrid system also addresses other pollutants associated with internal combustion engines. Nitrogen oxides (NOx) and particulate matter emissions can be significantly reduced through the strategic use of electric power, particularly during low-speed operation and idling. This is especially beneficial in urban environments where air quality is a major concern.

Furthermore, the hybridization of the L92 engine can contribute to noise pollution reduction. Electric motors operate more quietly than internal combustion engines, particularly at low speeds. This can lead to decreased noise levels in urban areas and improved quality of life for residents.

The environmental impact of battery production and disposal must also be considered. While the production of batteries for hybrid systems does have an environmental footprint, advancements in battery technology and recycling processes are continually improving their lifecycle impact. The overall environmental benefit of hybrid systems typically outweighs the initial production impact over the vehicle's lifetime.

Energy efficiency improvements resulting from hybridization extend beyond direct emissions reductions. The ability to capture and reuse energy through regenerative braking systems further enhances the overall efficiency of vehicles equipped with this technology. This not only reduces fuel consumption but also decreases the wear on traditional braking systems, potentially reducing the environmental impact associated with brake pad production and disposal.

In conclusion, the hybridization of the L92 engine with electric motors offers substantial potential for reducing environmental impact. Through decreased emissions, improved fuel efficiency, and reduced noise pollution, this technology aligns with global efforts to mitigate the environmental consequences of transportation. As hybrid systems continue to evolve, their positive environmental impact is likely to increase, making them a crucial component in the transition towards more sustainable mobility solutions.

One of the primary environmental benefits of this hybridization is the reduction in greenhouse gas emissions. By incorporating electric motors, the hybrid system can optimize engine operation, allowing the L92 engine to run at its most efficient points while using electric power to supplement performance. This results in lower fuel consumption and, consequently, decreased carbon dioxide emissions. Studies have shown that hybrid powertrains can reduce CO2 emissions by 20-30% compared to conventional engines, depending on the specific hybrid configuration and driving conditions.

The hybrid system also addresses other pollutants associated with internal combustion engines. Nitrogen oxides (NOx) and particulate matter emissions can be significantly reduced through the strategic use of electric power, particularly during low-speed operation and idling. This is especially beneficial in urban environments where air quality is a major concern.

Furthermore, the hybridization of the L92 engine can contribute to noise pollution reduction. Electric motors operate more quietly than internal combustion engines, particularly at low speeds. This can lead to decreased noise levels in urban areas and improved quality of life for residents.

The environmental impact of battery production and disposal must also be considered. While the production of batteries for hybrid systems does have an environmental footprint, advancements in battery technology and recycling processes are continually improving their lifecycle impact. The overall environmental benefit of hybrid systems typically outweighs the initial production impact over the vehicle's lifetime.

Energy efficiency improvements resulting from hybridization extend beyond direct emissions reductions. The ability to capture and reuse energy through regenerative braking systems further enhances the overall efficiency of vehicles equipped with this technology. This not only reduces fuel consumption but also decreases the wear on traditional braking systems, potentially reducing the environmental impact associated with brake pad production and disposal.

In conclusion, the hybridization of the L92 engine with electric motors offers substantial potential for reducing environmental impact. Through decreased emissions, improved fuel efficiency, and reduced noise pollution, this technology aligns with global efforts to mitigate the environmental consequences of transportation. As hybrid systems continue to evolve, their positive environmental impact is likely to increase, making them a crucial component in the transition towards more sustainable mobility solutions.

Cost-Benefit Analysis of L92 Hybridization

The cost-benefit analysis of hybridizing the L92 engine with electric motors reveals a complex interplay of financial, environmental, and performance factors. Initial investment costs for hybridization are substantial, primarily due to the integration of electric motors, battery systems, and advanced control electronics. These upfront expenses can significantly impact the overall vehicle cost, potentially affecting market competitiveness in the short term.

However, the long-term benefits of hybridization are compelling. Fuel efficiency improvements ranging from 20% to 40% can be expected, depending on the specific hybrid configuration and driving conditions. This translates to substantial fuel cost savings over the vehicle's lifetime, particularly in regions with high fuel prices. Additionally, reduced fuel consumption leads to lower carbon emissions, enhancing the vehicle's environmental profile and potentially qualifying for government incentives or tax breaks in many jurisdictions.

Performance benefits of hybridization include improved low-end torque and acceleration, as electric motors can provide instant torque to supplement the L92 engine's power output. This can result in a more responsive driving experience, especially in urban environments. The hybrid system also enables features like regenerative braking, further improving overall energy efficiency.

Maintenance costs present a mixed picture. While the electric components may require less frequent maintenance than traditional mechanical systems, the increased complexity of the hybrid powertrain could lead to higher specialized service costs. Battery replacement, though typically infrequent, represents a significant future expense that must be factored into long-term ownership costs.

From a manufacturing perspective, hybridization may initially increase production complexity and costs. However, as production scales up and technologies mature, these costs are expected to decrease. The potential for shared platforms and components across multiple hybrid models could further improve cost-effectiveness in the long run.

Market positioning and brand image benefits should also be considered. Offering hybrid variants of vehicles equipped with the L92 engine can enhance a brand's eco-friendly credentials and appeal to environmentally conscious consumers. This could lead to increased market share and brand loyalty, particularly as emission regulations become more stringent globally.

In conclusion, while the initial costs of hybridizing the L92 engine are significant, the long-term benefits in fuel efficiency, performance, and environmental impact present a compelling case for investment. The exact cost-benefit ratio will depend on factors such as production volume, target market characteristics, and regulatory environments. A phased approach to hybridization, starting with mild hybrid systems and progressing to full hybrids, could help balance costs and benefits while allowing for technological refinement and market adaptation.

However, the long-term benefits of hybridization are compelling. Fuel efficiency improvements ranging from 20% to 40% can be expected, depending on the specific hybrid configuration and driving conditions. This translates to substantial fuel cost savings over the vehicle's lifetime, particularly in regions with high fuel prices. Additionally, reduced fuel consumption leads to lower carbon emissions, enhancing the vehicle's environmental profile and potentially qualifying for government incentives or tax breaks in many jurisdictions.

Performance benefits of hybridization include improved low-end torque and acceleration, as electric motors can provide instant torque to supplement the L92 engine's power output. This can result in a more responsive driving experience, especially in urban environments. The hybrid system also enables features like regenerative braking, further improving overall energy efficiency.

Maintenance costs present a mixed picture. While the electric components may require less frequent maintenance than traditional mechanical systems, the increased complexity of the hybrid powertrain could lead to higher specialized service costs. Battery replacement, though typically infrequent, represents a significant future expense that must be factored into long-term ownership costs.

From a manufacturing perspective, hybridization may initially increase production complexity and costs. However, as production scales up and technologies mature, these costs are expected to decrease. The potential for shared platforms and components across multiple hybrid models could further improve cost-effectiveness in the long run.

Market positioning and brand image benefits should also be considered. Offering hybrid variants of vehicles equipped with the L92 engine can enhance a brand's eco-friendly credentials and appeal to environmentally conscious consumers. This could lead to increased market share and brand loyalty, particularly as emission regulations become more stringent globally.

In conclusion, while the initial costs of hybridizing the L92 engine are significant, the long-term benefits in fuel efficiency, performance, and environmental impact present a compelling case for investment. The exact cost-benefit ratio will depend on factors such as production volume, target market characteristics, and regulatory environments. A phased approach to hybridization, starting with mild hybrid systems and progressing to full hybrids, could help balance costs and benefits while allowing for technological refinement and market adaptation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!