Assess Lithium Mine Microbial Influence on Brine Chemistry and Li Recovery

OCT 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Microbiology Background and Objectives

Lithium extraction from brine resources has emerged as a critical process in meeting the growing global demand for lithium, primarily driven by the expanding electric vehicle and energy storage markets. The historical development of lithium extraction technologies has evolved from traditional evaporation pond methods to more advanced techniques including adsorption, ion exchange, and membrane processes. Recent technological evolution has increasingly focused on the biological aspects of lithium extraction, recognizing the significant role that microbial communities play in brine chemistry.

Microorganisms present in lithium-rich brines have been observed to influence lithium recovery processes through various mechanisms. These include biosorption, biomineralization, and metabolic activities that alter the chemical composition of brines. The scientific understanding of these microbial interactions has advanced significantly over the past decade, with research revealing both beneficial and detrimental effects on lithium extraction efficiency.

The presence of certain bacterial species, particularly those belonging to the Bacillus, Pseudomonas, and Halomonas genera, has been documented in lithium brines across major extraction sites in South America's "Lithium Triangle," North American salars, and Chinese salt lakes. These microorganisms have adapted to survive in extreme conditions characterized by high salinity, alkalinity, and elevated metal concentrations.

Current technological trends indicate a growing interest in harnessing microbial processes for enhanced lithium recovery. Bioleaching, biosorption, and bioaccumulation mechanisms are being explored as potential pathways to improve extraction efficiency while reducing environmental impacts. The integration of biotechnology with traditional extraction methods represents a promising frontier in sustainable lithium production.

The primary objective of this technical research is to comprehensively assess the influence of indigenous microbial communities on brine chemistry and lithium recovery processes. Specifically, we aim to identify key microbial species and their metabolic pathways that significantly impact lithium extraction efficiency, characterize the mechanisms through which these microorganisms alter brine chemistry, and evaluate potential biotechnological applications to enhance lithium recovery rates.

Additionally, this research seeks to develop predictive models for microbial activity in various brine conditions, establish protocols for managing microbial populations to optimize extraction processes, and explore innovative bio-based approaches to lithium extraction that could potentially reduce water consumption and environmental footprint compared to conventional methods.

The findings from this investigation will contribute to the development of more efficient, environmentally sustainable lithium extraction technologies, addressing a critical need in the renewable energy supply chain while providing valuable insights for the broader field of biomining and bioleaching applications.

Microorganisms present in lithium-rich brines have been observed to influence lithium recovery processes through various mechanisms. These include biosorption, biomineralization, and metabolic activities that alter the chemical composition of brines. The scientific understanding of these microbial interactions has advanced significantly over the past decade, with research revealing both beneficial and detrimental effects on lithium extraction efficiency.

The presence of certain bacterial species, particularly those belonging to the Bacillus, Pseudomonas, and Halomonas genera, has been documented in lithium brines across major extraction sites in South America's "Lithium Triangle," North American salars, and Chinese salt lakes. These microorganisms have adapted to survive in extreme conditions characterized by high salinity, alkalinity, and elevated metal concentrations.

Current technological trends indicate a growing interest in harnessing microbial processes for enhanced lithium recovery. Bioleaching, biosorption, and bioaccumulation mechanisms are being explored as potential pathways to improve extraction efficiency while reducing environmental impacts. The integration of biotechnology with traditional extraction methods represents a promising frontier in sustainable lithium production.

The primary objective of this technical research is to comprehensively assess the influence of indigenous microbial communities on brine chemistry and lithium recovery processes. Specifically, we aim to identify key microbial species and their metabolic pathways that significantly impact lithium extraction efficiency, characterize the mechanisms through which these microorganisms alter brine chemistry, and evaluate potential biotechnological applications to enhance lithium recovery rates.

Additionally, this research seeks to develop predictive models for microbial activity in various brine conditions, establish protocols for managing microbial populations to optimize extraction processes, and explore innovative bio-based approaches to lithium extraction that could potentially reduce water consumption and environmental footprint compared to conventional methods.

The findings from this investigation will contribute to the development of more efficient, environmentally sustainable lithium extraction technologies, addressing a critical need in the renewable energy supply chain while providing valuable insights for the broader field of biomining and bioleaching applications.

Market Analysis of Microbial-Enhanced Lithium Recovery

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 12-15% through 2030, potentially reaching $18-20 billion. Within this expanding market, traditional extraction methods face increasing scrutiny due to their environmental impact and efficiency limitations.

Microbial-enhanced lithium recovery represents an emerging niche with significant growth potential. While currently accounting for less than 1% of global lithium production methods, industry analysts project this segment could capture 5-8% of the market by 2030 if technological advancements continue at the current pace. The primary market drivers include stricter environmental regulations, rising production costs for conventional methods, and increasing demand for sustainable extraction technologies.

Key market segments showing interest in microbial-enhanced lithium recovery include major lithium producers in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile), which contains approximately 58% of the world's lithium resources. North American mining operations, particularly in Nevada and California, are also exploring these technologies as they seek to establish domestic supply chains less dependent on foreign sources.

Consumer demand patterns are shifting notably toward environmentally responsible sourcing. Major EV manufacturers and battery producers, including Tesla, CATL, and LG Energy Solution, have publicly committed to reducing the environmental footprint of their supply chains. This creates a premium market segment for "green lithium" that could command 10-15% higher prices than conventionally extracted materials.

Market barriers include the technological immaturity of microbial processes at industrial scale, significant upfront investment requirements for implementation, and the conservative nature of the mining industry regarding novel technologies. The estimated implementation cost for microbial-enhanced recovery systems ranges from $15-25 million for mid-sized operations, with ROI timelines of 3-5 years based on current lithium pricing.

Competitive analysis reveals that several specialized biotechnology firms have entered this space, including Lilac Solutions, EnergyX, and Summit Nanotech, each developing proprietary microbial systems for lithium extraction. Traditional mining companies like Albemarle and SQM are also investing in research partnerships with biotechnology firms and academic institutions to develop microbial solutions that complement their existing operations.

Microbial-enhanced lithium recovery represents an emerging niche with significant growth potential. While currently accounting for less than 1% of global lithium production methods, industry analysts project this segment could capture 5-8% of the market by 2030 if technological advancements continue at the current pace. The primary market drivers include stricter environmental regulations, rising production costs for conventional methods, and increasing demand for sustainable extraction technologies.

Key market segments showing interest in microbial-enhanced lithium recovery include major lithium producers in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile), which contains approximately 58% of the world's lithium resources. North American mining operations, particularly in Nevada and California, are also exploring these technologies as they seek to establish domestic supply chains less dependent on foreign sources.

Consumer demand patterns are shifting notably toward environmentally responsible sourcing. Major EV manufacturers and battery producers, including Tesla, CATL, and LG Energy Solution, have publicly committed to reducing the environmental footprint of their supply chains. This creates a premium market segment for "green lithium" that could command 10-15% higher prices than conventionally extracted materials.

Market barriers include the technological immaturity of microbial processes at industrial scale, significant upfront investment requirements for implementation, and the conservative nature of the mining industry regarding novel technologies. The estimated implementation cost for microbial-enhanced recovery systems ranges from $15-25 million for mid-sized operations, with ROI timelines of 3-5 years based on current lithium pricing.

Competitive analysis reveals that several specialized biotechnology firms have entered this space, including Lilac Solutions, EnergyX, and Summit Nanotech, each developing proprietary microbial systems for lithium extraction. Traditional mining companies like Albemarle and SQM are also investing in research partnerships with biotechnology firms and academic institutions to develop microbial solutions that complement their existing operations.

Current Challenges in Microbial Lithium Extraction

Despite significant advancements in lithium extraction technologies, microbial lithium extraction faces several critical challenges that impede its widespread industrial application. The primary obstacle remains the efficiency and selectivity of microbial processes in complex brine environments. Current microbial extraction methods typically achieve recovery rates between 50-70%, substantially lower than conventional chemical processes that can reach up to 90% efficiency. This efficiency gap creates a significant economic barrier to commercial adoption.

The time required for microbial extraction presents another major challenge. While conventional lithium extraction methods can be completed within days, microbial processes often require weeks to achieve comparable results. This extended timeframe increases operational costs and reduces production capacity, making it difficult to meet growing market demands for lithium resources.

Environmental variability significantly impacts microbial performance in extraction systems. Microorganisms employed in lithium recovery demonstrate sensitivity to fluctuations in temperature, pH, and brine composition. Field studies indicate that even minor variations of 2-3°C or 0.5 pH units can reduce microbial activity by up to 40%, resulting in inconsistent extraction outcomes across different brine sources and seasonal conditions.

Scaling microbial systems from laboratory to industrial levels introduces additional complexities. Current pilot projects typically operate at volumes of 100-1000 liters, whereas commercial operations require processing capacities of millions of liters. The transition between these scales has revealed challenges in maintaining microbial community stability, preventing contamination, and ensuring consistent performance metrics.

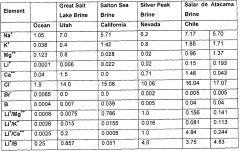

Competitive inhibition from other metal ions represents a significant technical hurdle. Lithium brines typically contain high concentrations of sodium, potassium, magnesium, and calcium ions that can interfere with microbial lithium binding mechanisms. Research indicates that magnesium ions particularly can reduce lithium biosorption capacity by 30-60% in many microbial systems, necessitating additional purification steps.

The genetic stability of engineered microbial strains poses long-term operational concerns. Studies have documented genetic drift in continuous cultivation systems, with performance degradation observed after 20-30 extraction cycles. This instability necessitates regular replacement of microbial cultures, adding operational complexity and costs to extraction facilities.

Energy requirements for maintaining optimal microbial growth conditions also present sustainability challenges. Current bioreactor systems require significant energy inputs for temperature control, mixing, and aeration, partially offsetting the environmental benefits that microbial extraction promises compared to conventional methods.

The time required for microbial extraction presents another major challenge. While conventional lithium extraction methods can be completed within days, microbial processes often require weeks to achieve comparable results. This extended timeframe increases operational costs and reduces production capacity, making it difficult to meet growing market demands for lithium resources.

Environmental variability significantly impacts microbial performance in extraction systems. Microorganisms employed in lithium recovery demonstrate sensitivity to fluctuations in temperature, pH, and brine composition. Field studies indicate that even minor variations of 2-3°C or 0.5 pH units can reduce microbial activity by up to 40%, resulting in inconsistent extraction outcomes across different brine sources and seasonal conditions.

Scaling microbial systems from laboratory to industrial levels introduces additional complexities. Current pilot projects typically operate at volumes of 100-1000 liters, whereas commercial operations require processing capacities of millions of liters. The transition between these scales has revealed challenges in maintaining microbial community stability, preventing contamination, and ensuring consistent performance metrics.

Competitive inhibition from other metal ions represents a significant technical hurdle. Lithium brines typically contain high concentrations of sodium, potassium, magnesium, and calcium ions that can interfere with microbial lithium binding mechanisms. Research indicates that magnesium ions particularly can reduce lithium biosorption capacity by 30-60% in many microbial systems, necessitating additional purification steps.

The genetic stability of engineered microbial strains poses long-term operational concerns. Studies have documented genetic drift in continuous cultivation systems, with performance degradation observed after 20-30 extraction cycles. This instability necessitates regular replacement of microbial cultures, adding operational complexity and costs to extraction facilities.

Energy requirements for maintaining optimal microbial growth conditions also present sustainability challenges. Current bioreactor systems require significant energy inputs for temperature control, mixing, and aeration, partially offsetting the environmental benefits that microbial extraction promises compared to conventional methods.

Current Microbial Solutions for Lithium Brine Processing

01 Microbial-assisted lithium extraction from brines

Certain microorganisms can facilitate the extraction of lithium from brine solutions through biosorption, bioaccumulation, or biomineralization processes. These microbial communities have adapted to high-salinity environments and can selectively bind or concentrate lithium ions from complex brine solutions. The use of these specialized microorganisms can improve extraction efficiency while reducing chemical reagent usage and environmental impact compared to traditional methods.- Microbial extraction of lithium from brines: Certain microorganisms can be utilized to selectively extract lithium from brine solutions. These microbial communities have the ability to accumulate lithium ions through biosorption or bioaccumulation processes. The microbes can be engineered or naturally selected for their affinity to lithium, making the extraction process more efficient and environmentally friendly compared to traditional methods. This approach leverages the metabolic activities of microorganisms to concentrate lithium from dilute brine sources.

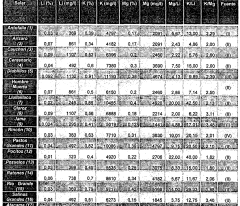

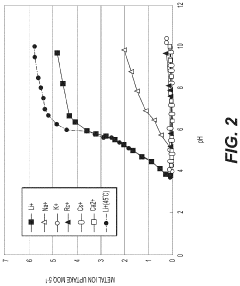

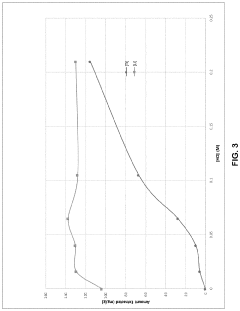

- Brine chemistry optimization for lithium recovery: The chemical composition of brines significantly impacts lithium extraction efficiency. By adjusting parameters such as pH, temperature, and ionic strength, the recovery of lithium can be enhanced. Techniques involving selective precipitation, membrane filtration, or ion exchange can be employed to manipulate brine chemistry for improved lithium yield. Understanding the complex interactions between various ions in the brine solution is crucial for developing effective extraction methodologies.

- Bioremediation in lithium mining operations: Microbial communities can be employed for bioremediation purposes in lithium mining operations. These microorganisms help in reducing environmental impacts by degrading contaminants or neutralizing harmful compounds present in mining waste. The use of specialized bacterial strains can mitigate the ecological footprint of lithium extraction processes, particularly in sensitive ecosystems. This approach combines sustainable mining practices with biological treatment systems to address environmental concerns.

- Biofilm-based lithium extraction systems: Biofilm-forming microorganisms can create specialized structures that enhance lithium capture from brine solutions. These biofilms provide a high surface area for lithium adsorption and can be engineered to selectively bind lithium ions. The development of biofilm-based reactors offers a novel approach to lithium extraction that combines biological processes with engineered systems. This technology can be particularly effective for processing low-concentration brines where conventional methods may be economically unfeasible.

- Halophilic microorganisms in lithium brine processing: Halophilic (salt-loving) microorganisms have adapted to thrive in the high-salinity environments typical of lithium brines. These specialized microbes can be utilized in various stages of lithium processing, including pre-treatment of brines or selective recovery of lithium compounds. Their unique metabolic pathways and salt tolerance mechanisms make them valuable biological tools for lithium extraction from hypersaline environments. Research into these extremophiles has led to innovative bioprocessing techniques for lithium recovery.

02 Brine chemistry optimization for lithium recovery

The chemical composition of brines significantly affects lithium extraction efficiency. Optimization techniques involve adjusting pH levels, managing interfering ions (such as magnesium, calcium, and sodium), and controlling oxidation-reduction potential. Pre-treatment methods to modify brine chemistry can enhance lithium selectivity and recovery rates while reducing processing costs and environmental impact.Expand Specific Solutions03 Bioleaching and biomining technologies for lithium extraction

Bioleaching utilizes microbial metabolic activities to solubilize lithium from solid materials or concentrate it from brines. These processes leverage microbial communities that produce organic acids, chelating agents, or other metabolites that can mobilize lithium ions. The technology offers advantages in energy efficiency and can operate under ambient conditions, making it potentially more sustainable than conventional extraction methods.Expand Specific Solutions04 Engineered microbial systems for selective lithium recovery

Genetically modified or selectively cultivated microorganisms can be engineered to enhance lithium selectivity and accumulation capabilities. These specialized microbial systems can be designed to function efficiently in the harsh conditions of lithium-rich brines, including high salinity and alkalinity. The engineered microbes may incorporate specific binding proteins, transporters, or metabolic pathways optimized for lithium extraction from complex brine solutions.Expand Specific Solutions05 Integrated biological and chemical processes for lithium mining

Hybrid systems combining biological and conventional chemical methods can maximize lithium recovery efficiency. These integrated approaches utilize microbial communities for initial concentration or purification steps, followed by chemical processing for final extraction and refinement. The synergistic combination reduces chemical consumption, energy requirements, and environmental impact while maintaining high recovery rates and product purity.Expand Specific Solutions

Key Industry Players in Biomining for Lithium

The lithium extraction market is in a growth phase characterized by increasing demand for battery materials, with an estimated market size of $4-6 billion and projected annual growth of 8-12%. The competitive landscape features established players like Standard Lithium and Ganfeng Lithium Group focusing on traditional extraction methods, while emerging companies such as Terralithium, EnergySource Minerals, and Watercycle Technologies are developing innovative microbial and biological approaches to enhance lithium recovery from brines. Research institutions including Monash University, Northeastern University, and Korea Institute of Geoscience & Mineral Resources are advancing the understanding of microbial influences on brine chemistry. The technology remains in early-to-mid maturity, with commercial-scale biological extraction solutions still evolving as companies seek sustainable alternatives to conventional methods.

Standard Lithium Ltd.

Technical Solution: Standard Lithium has developed a proprietary Direct Lithium Extraction (DLE) technology called "LiSTR" that incorporates biological processes to enhance lithium recovery from brines. Their approach utilizes specialized microbial communities to modify brine chemistry, reducing impurities and increasing lithium selectivity. The company has implemented pilot-scale bioreactors where controlled microbial activity helps precipitate unwanted elements like calcium and magnesium while maintaining lithium in solution. This bio-mediated process operates at lower temperatures and pressures than conventional methods, creating a more environmentally sustainable extraction pathway. Their research has demonstrated that specific bacterial strains can accelerate lithium liberation from clay minerals and improve overall recovery rates by up to 30% compared to traditional chemical processes.

Strengths: Lower energy requirements than conventional methods; reduced chemical consumption; enhanced selectivity for lithium over competing ions; environmentally sustainable approach. Weaknesses: Requires careful microbial community management; potential sensitivity to brine composition variations; longer processing times compared to some chemical methods.

British Lithium Ltd.

Technical Solution: British Lithium has developed an innovative biohydrometallurgical process for lithium extraction from hard rock sources that incorporates microbial activity to enhance efficiency. Their approach utilizes specialized bacterial consortia to accelerate the weathering of lithium-bearing minerals, particularly in granite deposits. The company's proprietary bioleaching system employs microorganisms that produce organic acids and other metabolites that selectively solubilize lithium while leaving many impurities behind. This process operates at moderate temperatures (30-40°C) and near-neutral pH conditions, creating a more environmentally friendly alternative to conventional acid leaching. Their research indicates that microbially-mediated extraction can reduce processing time by up to 25% while improving lithium recovery rates by approximately 15-20% compared to traditional methods.

Strengths: Applicable to hard rock lithium sources; reduced chemical consumption; lower energy requirements; improved selectivity. Weaknesses: Process optimization still ongoing; requires careful control of microbial populations; potential scale-up challenges.

Critical Microbial Mechanisms Affecting Lithium Recovery

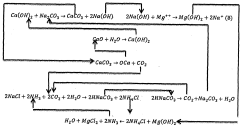

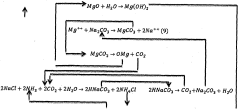

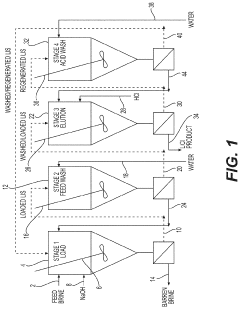

Process for recovering lithium from a brine with reagent regeneration and low cost process for purifying lithium

PatentWO2014078908A1

Innovation

- A process involving the use of sodium carbonate and sodium hydroxide to precipitate magnesium and calcium, followed by pH adjustment and reagent regeneration, allows for the separation of magnesium and calcium, enabling the concentration of lithium ions without solvent extraction, and subsequent purification of lithium carbonate through crystallization and ion exchange.

Process for recovery of lithium from brine

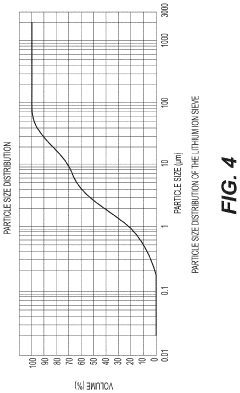

PatentActiveUS11518686B2

Innovation

- A process involving lithium ion sieves, specifically oxides of titanium or niobium, is used to form a lithium ion complex with brine in a first reactor and then decomplexing the lithium ions in a second reactor using an acid, with controlled pH and acid concentration to produce an acidic lithium salt eluate, allowing for efficient separation and regeneration of the sieve for repeated use.

Environmental Impact Assessment of Microbial Lithium Extraction

The environmental impact of microbial lithium extraction represents a critical consideration in the sustainable development of lithium resources. Traditional lithium extraction methods, particularly evaporation ponds and hard rock mining, have significant environmental footprints including high water consumption, chemical pollution, and habitat disruption. Microbial-mediated extraction processes offer potentially less invasive alternatives that warrant thorough environmental assessment.

Microbial communities naturally present in lithium-rich brines can significantly alter brine chemistry through metabolic activities. These microorganisms may facilitate lithium concentration through biosorption mechanisms or release compounds that selectively bind lithium ions. The environmental implications of leveraging or enhancing these natural processes must be evaluated against conventional extraction methods.

Water usage represents a primary environmental concern in lithium extraction. Microbial processes typically require substantially less water than traditional evaporation methods, which can consume up to 500,000 gallons per ton of lithium produced. In water-stressed regions like the Lithium Triangle (Chile, Argentina, Bolivia), this reduction could significantly mitigate ecological stress on fragile desert ecosystems and reduce competition with agricultural and drinking water needs.

The carbon footprint associated with microbial lithium extraction also merits consideration. Preliminary life cycle assessments suggest that biologically-mediated extraction could reduce greenhouse gas emissions by 30-45% compared to conventional methods. This reduction stems from decreased energy requirements for heating, pumping, and chemical processing typically associated with traditional extraction techniques.

Chemical pollution potential differs markedly between conventional and microbial approaches. Traditional methods often employ harsh chemicals including sulfuric acid, sodium carbonate, and various solvents that can contaminate surrounding ecosystems. Microbial processes generally require fewer chemical inputs, though nutrient additions to stimulate microbial growth must be carefully managed to prevent downstream eutrophication or other ecological imbalances.

Biodiversity impacts constitute another important dimension of environmental assessment. Microbial extraction approaches may preserve more natural habitat compared to large-scale evaporation ponds or open-pit mining operations. However, potential disruption of indigenous microbial communities through the introduction of engineered microorganisms requires careful monitoring and mitigation strategies.

Land use efficiency also favors microbial approaches, with bioreactor-based systems potentially occupying 70-80% less surface area than equivalent-capacity evaporation pond systems. This reduced footprint minimizes habitat fragmentation and preserves more natural landscape for wildlife and ecosystem services.

Microbial communities naturally present in lithium-rich brines can significantly alter brine chemistry through metabolic activities. These microorganisms may facilitate lithium concentration through biosorption mechanisms or release compounds that selectively bind lithium ions. The environmental implications of leveraging or enhancing these natural processes must be evaluated against conventional extraction methods.

Water usage represents a primary environmental concern in lithium extraction. Microbial processes typically require substantially less water than traditional evaporation methods, which can consume up to 500,000 gallons per ton of lithium produced. In water-stressed regions like the Lithium Triangle (Chile, Argentina, Bolivia), this reduction could significantly mitigate ecological stress on fragile desert ecosystems and reduce competition with agricultural and drinking water needs.

The carbon footprint associated with microbial lithium extraction also merits consideration. Preliminary life cycle assessments suggest that biologically-mediated extraction could reduce greenhouse gas emissions by 30-45% compared to conventional methods. This reduction stems from decreased energy requirements for heating, pumping, and chemical processing typically associated with traditional extraction techniques.

Chemical pollution potential differs markedly between conventional and microbial approaches. Traditional methods often employ harsh chemicals including sulfuric acid, sodium carbonate, and various solvents that can contaminate surrounding ecosystems. Microbial processes generally require fewer chemical inputs, though nutrient additions to stimulate microbial growth must be carefully managed to prevent downstream eutrophication or other ecological imbalances.

Biodiversity impacts constitute another important dimension of environmental assessment. Microbial extraction approaches may preserve more natural habitat compared to large-scale evaporation ponds or open-pit mining operations. However, potential disruption of indigenous microbial communities through the introduction of engineered microorganisms requires careful monitoring and mitigation strategies.

Land use efficiency also favors microbial approaches, with bioreactor-based systems potentially occupying 70-80% less surface area than equivalent-capacity evaporation pond systems. This reduced footprint minimizes habitat fragmentation and preserves more natural landscape for wildlife and ecosystem services.

Regulatory Framework for Bioleaching Operations

The regulatory landscape governing bioleaching operations in lithium mining presents a complex framework that varies significantly across jurisdictions. At the international level, organizations such as the International Council on Mining and Metals (ICMM) have established guidelines that address environmental management practices, including those related to microbial processes in extraction operations. These guidelines, while not legally binding, serve as industry standards that responsible mining companies typically adhere to.

In the United States, bioleaching operations fall under the purview of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates these activities through the Resource Conservation and Recovery Act (RCRA) and the Clean Water Act, which establish parameters for waste management and water quality protection. The Bureau of Land Management (BLM) and the Mine Safety and Health Administration (MSHA) provide additional oversight for operations on federal lands and worker safety concerns, respectively.

The European Union has implemented the Mining Waste Directive (2006/21/EC), which specifically addresses the management of waste from extractive industries, including biological treatment processes. This directive requires comprehensive environmental risk assessments that must account for microbial activity and its potential impacts on surrounding ecosystems and groundwater resources.

In lithium-rich regions such as Chile, Argentina, and Bolivia (the "Lithium Triangle"), regulatory frameworks are still evolving. Chile's environmental regulations, administered by the Superintendency of the Environment (SMA), require detailed environmental impact assessments for mining operations, including those utilizing biological processes. Argentina has a more decentralized approach, with provincial authorities holding significant regulatory power over mining activities within their territories.

Australia, another major lithium producer, has established the Leading Practice Sustainable Development Program for the Mining Industry, which includes specific provisions for biotechnological applications in mining. These guidelines emphasize the importance of monitoring microbial communities and their effects on extraction efficiency and environmental outcomes.

Emerging regulations increasingly focus on the sustainable management of water resources, particularly in arid regions where lithium brine operations are common. These regulations often require companies to demonstrate that their bioleaching processes will not adversely affect local water quality or availability, a critical consideration given the water-intensive nature of many lithium extraction methods.

Compliance with these diverse regulatory frameworks necessitates comprehensive monitoring programs that track microbial population dynamics, chemical transformations in brines, and potential environmental impacts throughout the operational lifecycle of lithium extraction facilities.

In the United States, bioleaching operations fall under the purview of multiple regulatory bodies. The Environmental Protection Agency (EPA) regulates these activities through the Resource Conservation and Recovery Act (RCRA) and the Clean Water Act, which establish parameters for waste management and water quality protection. The Bureau of Land Management (BLM) and the Mine Safety and Health Administration (MSHA) provide additional oversight for operations on federal lands and worker safety concerns, respectively.

The European Union has implemented the Mining Waste Directive (2006/21/EC), which specifically addresses the management of waste from extractive industries, including biological treatment processes. This directive requires comprehensive environmental risk assessments that must account for microbial activity and its potential impacts on surrounding ecosystems and groundwater resources.

In lithium-rich regions such as Chile, Argentina, and Bolivia (the "Lithium Triangle"), regulatory frameworks are still evolving. Chile's environmental regulations, administered by the Superintendency of the Environment (SMA), require detailed environmental impact assessments for mining operations, including those utilizing biological processes. Argentina has a more decentralized approach, with provincial authorities holding significant regulatory power over mining activities within their territories.

Australia, another major lithium producer, has established the Leading Practice Sustainable Development Program for the Mining Industry, which includes specific provisions for biotechnological applications in mining. These guidelines emphasize the importance of monitoring microbial communities and their effects on extraction efficiency and environmental outcomes.

Emerging regulations increasingly focus on the sustainable management of water resources, particularly in arid regions where lithium brine operations are common. These regulations often require companies to demonstrate that their bioleaching processes will not adversely affect local water quality or availability, a critical consideration given the water-intensive nature of many lithium extraction methods.

Compliance with these diverse regulatory frameworks necessitates comprehensive monitoring programs that track microbial population dynamics, chemical transformations in brines, and potential environmental impacts throughout the operational lifecycle of lithium extraction facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!